CNC milling services play an important role as a bridge between design and the part itself in the world of precision manufacturing.

In premium sectors including aerospace, medical, and consumer durables, the quality of manufacturing of precision components is directly linked to competitiveness. Knowing the technology of milling precision parts through CNC helps immensely in achieving success.

The paper will discuss the difficulties of CNC milling aluminum, the capabilities of complex geometry handling in precision CNC milling, and reasons for the preference of large global companies for China CNC milling service providers such as JS Precision.

Whether you are looking for specific custom CNC milling services or a long-term cooperative CNC milling company, this guide will help you make informed decisions.

Core Answer Summary

| Core Questions/Key Points | Technical Points/Key Answers | Business Value/Value Brought to You |

| What is CNC Milling? | This refers to a subtractive manufacturing process whereby computer-controlled multi-bladed cutting tools are used to cut blanks. The basic workflow involves: CAD→CAM→G-code→machine tool processing. | The effort to clearly establish applicable conditions provides a basis for making a choice. |

| What are the major benefits of CNC Milling? | With an accuracy of ±0.005mm, flexible materials, high repeatability, and the capacity to machine complex shapes, it offers high automation productivity. | It resolves problems related to the production of high-demand components and guarantees implementation of design. |

| Difficulties and methods in aluminum alloy milling? | To reduce sticking of tools and thermal deformation, it uses optimized solutions for coated tools, high-pressure cooling, and parameters. | It concentrates on overcoming the risks involved in machining, providing solutions for surface finish and accuracy. |

| How to choose a high-quality service provider? | Assessment in terms of five-axis facilities, ISO rating, industry expertise, and material & process knowledge is important. | Look for a competent and reliable service provider to ensure timely and quality completion of deliveries. |

| How to get an accurate price quote? | Supply STEP models/PDF drawings, quantity, and delivery dates to coordinate with the DFM communication. Shorten the price quotation process. | Design optimization to minimize costs. |

Key Takeaways

- Degrees of freedom geometric:

Advances in precision CNC milling, particularly five-axis technology, have made it possible to efficiently perform complex operations such as 3D surfaces, deep cavities, and thin walls, which would otherwise not have been possible through other processes.

- An expertise in aluminum processing is necessary:

Highly skilled CNC milling company can overcome the sticking, deformation, or smoothness issues of aluminum alloys by proper tool path optimization.

- Overall advantages of Chinese manufacturing:

Selecting China CNC milling service such as JS Precision allows one to reap huge supply chain efficiency and cost savings advantages while being guaranteed world class quality.

- It starts with successful communication:

being able to provide design documents in STEP+PDF format, as well as proper technical requirements, is the key to receiving precise and efficient quotes and collaborations for custom CNC milling services.

Why Trust This Guide? JS Precision CNC Milling Services

While selecting CNC milling services, you require professional, reliable, and practical referencing information. JS Precision, a CNC milling company with 15 years of experience, not only has global-level technological capabilities but also experience in terms of practical achieved outcomes.

Our core competitiveness stems from three aspects:

- Technology Strengths: The firm has more than 50 imported 5-axis/3-axis CNC milling machines, of which high-end machines like the DMG MORI DMU 50 can provide stable CNC milling accuracy of to within +\- 0.005 mm.

- Guaranteed Quality System: ISO 9001:2015 certified quality management system. All components are subjected to inspection in all dimensions using CMMs, etc., meeting the aerospace standard of AS9100.

- Deep Industry Expertise: Serving clients from over 30 countries worldwide by providing custom CNC milling services for a variety of sectors including aerospace, medical devices, and drone production with a total cumulative delivery of over 1 million parts.

ISO 13485:2016 Medical Device – Quality Management System, published by the International Organization for Standardization, is an important guideline for our services for clients from the medical industry.Our data is genuine and traceable.As an example, the implant parts processed for a medical company showed a 100% success rate, with a reduced number of delivery cycles of 20% compared to the industry average.

If you are looking for a reliable partner for machining complex parts, contact JS Precision's engineering team immediately. Tell us your part requirements, and you'll receive a free professional DFM analysis report and preliminary machining plan, saving your project time and effort.

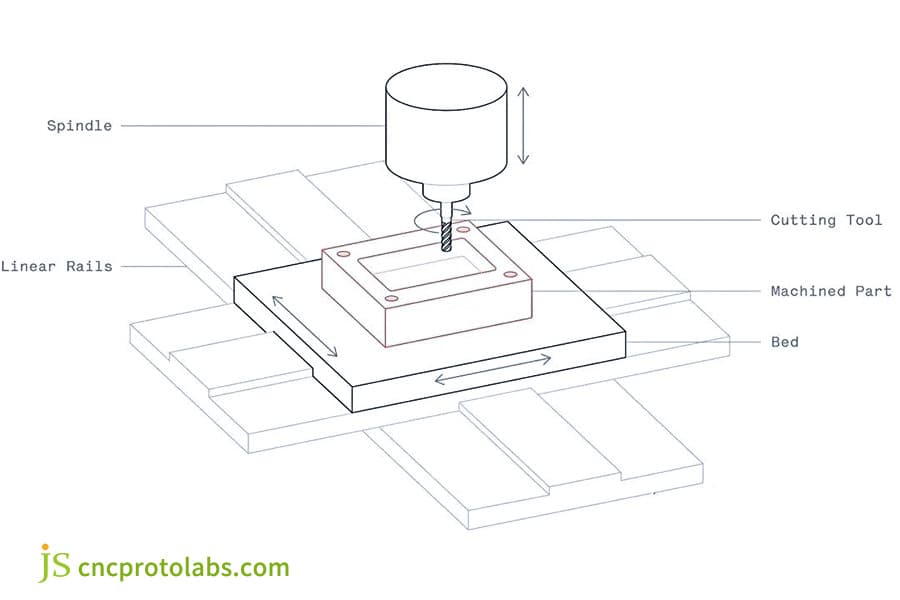

What Is CNC Milling And How Does It Work?

Understanding "what is CNC milling" is the foundation for selection. It can be defined as a subtractive process of precision manufacturing that is computer numerically controlled. Essentially, it entails the use of a rotation tool to remove excess material in order to create the desired component.

Core Definition and Principles

It uses a programmed axis to control the cutting tool. It provides a high degree of accuracy that far surpasses manual machining. It is capable of dealing with complex part geometries.

From Digital Model to Solid Part

The entire process affects the parts. The main steps involved are:

- CAD Design: The design should be made on 3D utilizing tools like SolidWorks.

- CAM Programming: The model needs to be imported into a CAM program in order to produce G-code and set cutting parameters and paths.

- Machine Tool Debugging: Clamp the work piece and machine tool, and then verify the zero point of the machining.

- Machining Execution: The machining is accomplished by the automatic cutting machine. Real-time machining status is monitored.

- Quality Inspection: The machining of parts is inspected by CMM and surface roughness tester.

CNC Milling Core Component Parameter Table

| Component Type | Core Equipment/Tool | Key Parameters | Applicable Scenarios | Accuracy Level |

| Machine Tool | Three-axis CNC Milling Machine | Spindle speed 8000rpm, travel 1000×800×600mm | Simple flat surfaces, hole-type parts | ±0.01mm |

| Machine Tool | Five-axis CNC Milling Machine | Spindle speed 24000rpm, travel 800×600×500mm | Complex curved surfaces, multi-angle parts | ±0.005mm |

| Cutting Tool | Carbide End Mill | Diameter 0.5-20mm, 2-4 flutes | Roughing/Finishing of metals | Ra<1.6μm |

| Cutting Tool | Diamond-coated Tool | Cutting speed 300-500m/min, HV10000+ | Aluminum alloys and other viscous materials | Ra<0.8μm |

Want to learn more about the applicable scenarios for different types of CNC milling equipment? Download JS Precision's exclusive "CNC Milling Equipment Selection Guide" now! Fill in your industry and part requirements to receive it for free and get the optimal machining solution.

What Are The Key Advantages Of CNC Milling Services For Complex Parts?

The CNC milling services, owing to its capabilities in terms of accuracy, flexibility, and efficiency, remains a preferred service to produce complex parts, matching the requirements of high-end products.

Precision and Consistency

- Precision to an achievement tolerance of ±0.005mm, with some to ±0.002mm, meeting aerospace and medical standards.

- The program control allows for consistency in the batches, ensuring a pass rate over 99.5%, thus eliminating human factors.

Superior Material and Design Flexibility

The CNC milling services are compatible with a wide range of materials, including metal materials such as aluminum alloys, stainless steel, and titanium alloys, and engineering plastics such as PEEK and nylon, and can mill complex shapes such as deep cavities, thin walls, and undercuts.

Highly Efficient Automated Production

After proper programming and debugging in CAM, CNC milling machines are able to run 24/7 without human intervention and are capable of producing in smaller to medium scale sizes of 10 to 1,000 units.

JS Precision, which complies with the criteria of ISO 286-1:2010, fulfills the IT5 tolerance requirements, ensuring the quality of the premium parts.

Can Precision CNC Milling Handle Truly Complex Geometries?

Handling complex geometric components is a challenge for precision machining. For this reason, precision CNC milling multi-axis technology has proved to be a reliable solution.

The Unleashing of Multi-Axis Technology

| Axis Types | Machining Characteristics | Applicable Parts | Advantages | Limitations |

| Three-Axis Milling | X/Y/Z three-axis motion | Flat and simple hole series parts | Low cost, simple programming | Unable to process complex surfaces and reverse buckles. |

| 3+2 Axis Milling | Three straight and two rotary positioning | Multi sided and simple curved surface parts | Balancing cost and flexibility | Multiple positioning is required, resulting in slightly lower efficiency. |

| Five-Axis Linkage Milling | Five axis continuous motion | Impeller, complex curved parts | One clamping full processing | High equipment cost and high programming requirements. |

Five-axis linkage precision CNC milling is the basic technology used to deal with complex surfaces. It has the ability to mill complex curved surfaces that cannot be machined by general three-axis machine tools in one cut by virtue of the flexible relative motion between the cutter and the object, such as drone bodies and aircraft engine impellers.

Solutions for Complex Features

- Deep Cavity Machining: Long-neck end mills + 70 bar high-pressure cooling system to ensure effective chip evacuation and minimize wear on tools and parts.

- Micro-feature Machining: Use of micro-diameter tools and low-speed feeds preserves feature integrity.

- Thin-walled machining: High-speed, lightweight machining is achieved by dynamic milling technology to control the cutting deformation.

- Complex undercut machining: Multi-angle five-axis cutting prevents errors from second clamping.

Blending Tech Skills with Programming

To machine complex geometrical components, skill sets that are a mix of advanced CAM software capabilities and that of an engineer are required. At JS Precision, the engineers utilize software like Mastercam and HyperMill for optimized tool path planning to eliminate possible collisions while machining.

What Are The Specific Challenges In CNC Milling Aluminum And How To Overcome Them?

CNC milling aluminum alloys has broad applications, this is because they are lightweight, strong, and of lower cost, but they tend to be problematic to mill.

Tool Sticking and Built-up Edge

Aluminum alloy has high viscosity and is prone to forming chip deposits on cutting tools, accelerating tool wear and reducing surface quality.

Remedies:

- Tool Selection: Diamond/TiAlN-coated tools to inhibit material adhesion.

- Parameter Optimization: Cutting Speed 200-500 m/min, Reduced Feed rate to minimize Contact Time.

- Cutting Fluid: Aluminum alloy cutting fluid with high lubrication and chip evacuation capabilities.

Thermal Deformation Control

Aluminum alloy has fast thermal conductivity, and high-speed cutting heat can easily cause deformation of parts, especially for thin-walled parts.

Solutions:

- Cooling Strategy: 50-100 bar High Pressure Cooling to accurately cool cutting temperatures.

- Process Optimization: Machining in steps, enabling avoidance of the effects of roughing stresses.

- Fixture Design: Flexible fixtures to minimize deformations due to clamping or compression.

Achieving a Mirror Finish

The finished parts must have a mirror finish of Ra < 0.8μm, thus requiring synchronized machining and processing: the use of high-speed, short-step finishing techniques to reduce scratches, the use of sharp cutting tools to provide smooth cutting action, or even vibratory polishing or anodizing for parts of high requirements.

Optimization Table for Milling Aluminum Alloys

| Aluminum Alloy Grade | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tool Type | Surface Roughness (Ra/μm) |

| 6061-T6 | 300-400 | 0.15-0.25 | 1-3 | TiAlN Coated End Mill | 0.8-1.6 |

| 7075-T6 | 250-350 | 0.12-0.20 | 0.8-2.5 | Diamond Coated End Mill | 0.6-1.2 |

| 5052-H32 | 350-450 | 0.18-0.30 | 1.2-3.5 | Carbide End Mill | 1.0-1.8 |

| 2024-T3 | 280-380 | 0.14-0.22 | 1.0-2.8 | TiCN Coated End Mill | 0.7-1.4 |

| 6063-T5 | 320-420 | 0.16-0.28 | 1.1-3.2 | Ordinary coated end mill | 0.9-1.7 |

If you are encountering process challenges in CNC milling aluminum, feel free to send your part drawings and technical requirements to JS Precision. Our process engineers will provide you with free parameter optimization solutions to help you improve machining quality and reduce production costs.

Case Study: JS Precision Five Axis Milling Helps Drone Components Reduce Weight By 40% And Costs By 25%

The machining of complex components can often involve a number of daunting tasks, however, JS Precision's precision CNC milling technology always has an optimal answer to these tasks. The following is a successful case study of exactly how we solved a number of fuselage frame machining tasks for a European drone production company.

Client Challenges

The original design consisted of six pieces of 6061 aluminum alloy, as follows, and had four fundamental problems:

- Excess weight, which totals 320 grams, affecting the endurance of flights.

- Lack of structural strength, which causes stress concentration at joint areas, thereby causing fatigue damage.

- Large assembly errors, exceeding cumulative tolerances of ±0.1 mm, impacting flight stability.

- Regions having deep holes, thin sections, and curved surfaces, thus being very hard to machine.

JS Precision Solution

Once the requirements were received, JS Precision engineering experts began a Design-Focused Analysis (DFM) to arrive at a customized combined design and machining solution:

1. Material Optimization: Change 6061 aluminum alloy to 7075-T6 aluminum alloy with higher strength (tensile strength ≥ 540MPa) and lighter weight, reducing part weight while improving strength.

2. Structural Integration: The six spliced sections were reconfigured into one integrated section, reducing the potential for structural integrity problems at the joints where the sections were spliced together.

3. Machining Strategy:

- Employing five-axis precision CNC milling, an especially designed long neck carbide end mill (50 mm long) along with high-pressure cooling of 70bar was used for deep corner clearance in the single-pass process, thereby avoiding secondary clamping.

- When machining the 0.8mm thin-walled area, a dynamic milling process was adopted. The cutting speed and feed rate adopted during machining were 320m/min and 0.12mm per revolution respectively. This helped to control the cutting forces and avoid deformations.

- Our company uses five-axis continuous machining technology to obtain precise multi-angle composite surfaces through machining all the parts in one step, with dimensions within a tolerance range of ±0.02mm.

Results:

- Weight Optimization: The weight of the integrated component itself is only 192 grams, a 40% reduction from the original design, thus extending the drone’s flying time by 15%.

- Performance Enhancement: The one-piece molding structure overcomes the stress concentration problem in spliced regions, thus improving the fatigue strength of the components by 30%, which results in a doubled service life.

- Cost Reduction: With optimized machining, the time for individual part machining is reduced from 4 hours to 2.8 hours. With material cost optimization, production costs are reduced by 25%, and the individual unit cost is reduced by $120.

- Delivery Guarantee: The delivery time cycle of the first batch of 50 pieces is always within 3 weeks, 10 days shorter than the customer's original supplier, and is able to meet the urgent mass production request of the customer.

If you also have needs for weight reduction, cost reduction, or precision improvement for complex parts, contact JS Precision immediately. Describe your project requirements in detail, and we will customize a unique machining solution to help your product stand out in the market.

Why Choose a China CNC Milling Service Provider Like JS Precision?

With all-rounded advantages, JS Precision has been a worldwide preferred vendor for China CNC milling service. As the benchmark enterprise, JS Precision provides customers with triple guarantees concerning technology, pricing, and logistics, and it has long-term cooperation with multi-national corporations.

Cost Efficiency and Scalability:

With the precision manufacturing industry cluster in China, JS Precision enjoys cost scalability through economies of scale. The cost of custom CNC milling services provided by JS Precision is 30%-40% less compared with Europe or America, transparent price without any extra charge to the penny.

Integrated Supply Chain:

Material supply, processing, and post-production processing are all combined into one-stop service. Tie-ups with world-class suppliers reduce material supply cycles. There are several processes in post-production processing, therefore, it takes 20% less time than the average of the same industry, and the quality completely can be controlled.

International Standard Quality Commitment:

Certified by ISO 9001, AS9100, and ISO 13485, with more than 10 precision test equipment, JS Precision can make comprehensive quality tests for parts. It guarantees the parts qualified rate for every test is over 99.8%.

How To Get a Fast And Accurate Quote For Your Custom CNC Milling Project?

Accurate and speedy quoting is the key to starting a project. The correct level of information reduces cycle time and eliminates errors.

Prepare Your Query Package

The correct quote requires the necessary information in this format: STEP model 3D, PDF with material tolerances, quantity for purchase and date for delivery. Any particular requirement can be added.

Understanding Professional Quotations

JS Precision quotations are all-inclusive of all expenses in clear detail-material costtion which also considers 5%-10% wastage, Processing Fee, Post Processing Fee, Testing Fee, and Taxes & Freight Charges.

Collaborate in Optimization with the Engineers

DFM communication can reduce costs and increase efficiency. We will suggest three aspects: relaxing non critical tolerances, simplifying complex structures, and recommending cost-effective alternative materials.

Want a quick and correct quote for our custom CNC milling services? You can upload your part designs to our JS Precision interface today to have our quote calculation done in 24 hours with optimized suggestions in place so that you can begin with your project quickly and easily.

FAQs

Q1: What level of precision can CNC milling achieve?

Usually ±0.025mm. JS Precision uses precision CNC milling machinery with a higher level of precision, as well as precision machinery for testing, so that the precision of ±0.005mm is achieved, which is required for such advanced work.

Q2: What is the typical delivery time for machining aluminum alloy parts?

For simple aluminum alloy parts, the production takes 5-7 working days. For complex aluminum alloy parts, including 5-axis machining, the production time would be 2-4 weeks, depending on the CNC milling services schedule.

Q3: What materials does JS Precision support?

JS Precision provides processing services for various materials like different grades of aluminum alloys, stainless steel, titanium alloys, brass, carbon steel, and engineering plastics like PEEK, nylon, and PTFE.

Q4: Do you have a minimum order quantity (MOQ) requirement?

For custom CNC milling services, JS Precision can perform prototype machining and production machining with large MOQs. For manufacturing, there are no mandatory large MOQ requirements, and this meets different orders from their clients.

Q5: How do you handle surface oxidation or scratches on aluminum?

This inhibits oxidation and scratching by optimizing routes, using specialized fixturing, and a controlled machining environment. Follow-up processes, such as sand blasting and anodizing, can then provide a successful protective finish.

Q6: Can you mill hard metals-hardened steel?

Yes, they have machine tools and specialized tools suitable for machining hard materials and are capable of hard milling at a high speed. This machine is able to work with hard steel with a hardness level of HRC 50 or harder and can maintain a stable level of precision.

Q7: How do you ensure consistent quality in mass production?

JS Precision ensures consistent part quality in mass production via a three-tiered inspection system: First Article Inspection (FAI), in-process sampling, and final coordinate measuring machine (CMM) inspection.

Q8: What if the design changes during the project?

We will advise this immediately to JS Precision's project engineer in charge. We will have an immediate evaluation of the impacts on processing cost and time as well as delivery time due to the design change, and along with this, an updated solution and quotation will be given out for your confirmation.

Summary

CNC milling services, with its advantages of precision, flexibility, and efficiency, has become the cornerstone of high-end manufacturing.

Choosing the right partner who combines technology, quality, and cost advantages is the key to unlocking value. JS Precision specializes in CNC milling aluminum technology, solving complex machining problems for global customers.

Whether for single prototypes or volume production, JS Precision utilizes our overall advantages to bring you competitive prices for high-quality custom CNC milling services.

Take immediate action today and send us your part design documents to let our expert team protect your project and enable innovation in product manufacturing through our precision production approach.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com