CNC machining prototyping is a core technology in modern product development, determining success or failure. When a CNC prototype for automotive cylinder head, employing complex internal cooling channels, suffers from insufficient cooling efficiency due to machining errors, the entire project can face months of delays and massive rework.

The key to CNC machining prototyping is not just "making a prototype," but also producing a tangible proof that closely resembles the finished product in terms of precision, material qualities, and functionality.

This guide will show you how to work with the best CNC prototype manufacturers to manage every step of the process, from cost control to parameter optimization, so your ideas can effectively and error-free go from blueprint to reality.

Key Summary Answers

| Core Issues | JS Precision Solution Route | Key Benefits to the Project |

| Achieve high-quality prototypes within tight deadlines | Master the parameter optimization logic and rapid response process of rapid prototyping CNC machining. | Significantly shorten the development cycle, achieving rapid iterative verification measured in "days". |

| Decision making in the face of complex design and diverse materials | We provide CNC machining services ranging from materials science to multi-axis machining, handling complex custom machined parts. | We ensure perfect realization of designs, delivering functional prototypes suitable for rigorous testing on the first attempt. |

| Control budgets and understanding value composition | Clear cost breakdown and value-based evaluation of rapid prototyping CNC machining. | Achieving optimal cost-effectiveness, every investment directly contributes to reducing mass production risks and improving product performance. |

| Choose reliable manufacturing partners | Defining the technical, quality, and service standards a professional CNC prototype manufacturer should possess. | Building long-term trusting partnerships, transforming prototype manufacturing from a project risk point into a core competency. |

CNC Machining Prototyping: How JS Precision Achieves High Precision And Cost Control

JS Precision has been deeply involved in the field of CNC machining prototyping for over 12 years. Our quality management system strictly follows the requirements of the International Organization for Standardization (ISO) ISO 9001:2015, which provides a framework for our process stability and continuous improvement.

We have completed over 8000 precision prototype projects for 5000+ clients worldwide, serving multiple high demand industries such as aerospace, automotive, medical devices, and consumer electronics.

Our core competencies include attaining the ultimate in both high precision and cost control:

Equipped with more than 20 five-axis CNC machining centers and coordinate measuring machines, we can regularly achieve machining accuracy of ±0.005mm. We have successfully completed prototype CNC machining of 0.1mm inner diameter features on micro-medical devices.

At the same time, we established a standardized process optimization system, achieving a reduced average cost per prototype by 15%-20% by using such strategies as the aggregation of orders and reusing tooling.

This guide is the culmination of our numerous successful cases. Every technique has been validated in actual projects, so you can be sure to refer to it with confidence.

As seasoned practitioners in the field of rapid prototyping, we firmly believe that professional CNC machining prototyping covers more than just technical output, it extends deeper into providing solutions to help clients mitigate risks and improve efficiency.

Would you like to enjoy the dual advantages of ±0.005mm high precision and 15%-20% cost reduction at the same time? Please submit your prototype requirements and drawings to JS Precision. For free, we will provide a CNC machining prototyping solution tailored to your needs with proven techniques to help mitigate risks and speed project implementation.

CNC Machining Prototyping: A Necessity In Product Development?

While the rapid prototyping methods are diverse, CNC machining prototyping has unique advantages and has become an indispensable core component in product development:

- Functional Testing: The use of real engineering materials allows for the accurate simulation of the final product's mechanical properties, wear resistance, and other indicators, offering unparalleled reliability of test data.

- Verification of Assembly: High dimensional accuracy and controllable assembly clearances enable the detection of component fit issues very early, thus preventing failures in assembly during mass production.

- Market Samples: High-quality prototypes visually demonstrate the product's appearance and functionality, facilitating financing and customer communication.

- Small Lot Trial Production: This enables production in small lots, thereby helping companies test the market for feedback and fine-tune their production without making substantial investments.

More importantly, in prototype cnc machining, the same real engineering materials are used as in mass production, and the test data directly guide mass production decisions, hence, it is the most efficient investment for reducing mass production risks.

More Than The Basics: What Should Be Included In Core Values For Professional CNC Machining Services?

High-quality CNC machining services are far more than just "processing supplied materials", they represent value creation across the entire chain from design to delivery. As a professional solution provider, the core value of JS Precision is reflected in five aspects:

- DFM (Design Feasibility Assessment): It rapidly analyzes CAD drawings, finds machining difficulties and cost risks, and gives optimization suggestions.

- Material/Process Consultation: Recommend appropriate material and process based on product application, and perform a trade-off analysis among performance, cost, and delivery time for the prototype.

- Multi-Axis Precision Machining: Flexibly utilize three to five-axis equipment with the use of the optimal solution for part complexity, balancing precision and efficiency.

- Full Range of Secondary Processing: Advanced anodizing, sandblasting, and heat treatment options to achieve functional and aesthetic requirements.

- Rigorous FAI Report: Full-process quality control, providing detailed dimension inspection reports to ensure design specifications are complied with.

These values bring our CNC machining services far beyond simple execution to real partnership with the clients.

Need professional CNC machining services to drive your project forward? Contact JS Precision now, and let them know about your part requirements and project timeline. We'll create a customized end-to-end solution for you, providing extensive support-from DFM analysis through final delivery.

Figure 1:Surface treatment and post-treatment are key steps in the production of CNC machining prototypes.

Speed And Precision: How To Optimize The Parameters Of Rapid Prototyping CNC Machining?

The essence of rapid prototyping CNC machining is "speed," but precision must never be sacrificed in trying to achieve speed. The key to this balance does not rest with the maximum horsepower of the equipment but with the right combination of parameters.

Golden Ratio of Feed Rate and Spindle Speed

Different materials require a certain match of spindle speed and cutting feed.

- Aluminium Alloy: High spindle speed, medium feed rate: a balance between efficiency without sticking.

- Stainless Steels: Low to medium spindle speed and lower feed rate to minimize tool wear and overheating.

Intelligent Strategy for Cutting Depth and Stepover

Roughing and finishing have different goals, requiring different strategies:

- Roughing: Large depth of cut + large stepover, fast material removal

- Finishing: shallow depth of cut + small stepover for surface finish.

A stepped approach will probably reduce machining time by more than 30% without losing any quality.

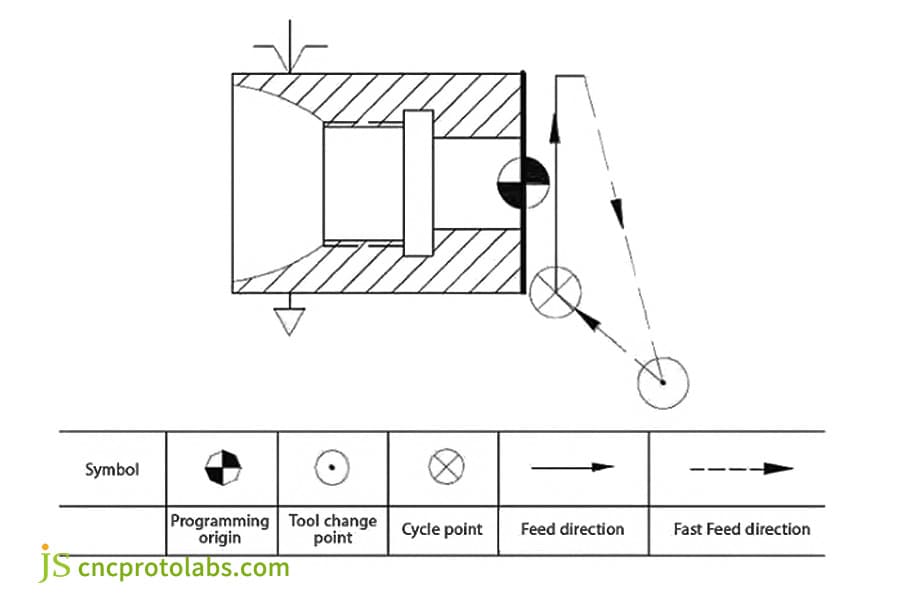

Toolpath and machining sequence optimization

The following are the often-overlooked "hidden" speed-up points in rapid prototyping CNC machining:

- Plan the shortest travel path to reduce ineffective movement of the machine tool.

- Machining sequence optimization: This can be done starting with datum surfaces before complex feature and roughing before finishing to avoid repetitive positioning error.

Want to quickly optimize your rapid prototyping CNC machining parameters? Upload your part drawing and note "parameter optimization." JS Precision engineers will provide you with free, targeted parameter adjustment suggestions to help you improve machining speed while maintaining accuracy.

Figure 2: CNC cutting tool path diagram.

How To Calculate And Optimize The Cost Of Rapid Prototyping CNC Machining?

Their pricing structure for rapid prototyping CNC machining is pretty transparent, set upon four cornerstones:

| Cost Composition | Explanation | Proportion Range |

| Material Costs | Raw material procurement costs, as per the type of material used, specifications, and rate of wastage. | 20%-30% |

| Programming and Equipment Time | Costs of programming time and machine tool processing time, related to part complexity and machining accuracy. | 40%-50% |

| Tool Wear | Costs during machining by tool wear and replacement. | 10%-15% |

| Post-treatment Costs | Costs of post-processing steps like anodizing, heat treatment, among others. | 10%-20% |

Three aspects from which it is possible to view cost optimization:

1. Design Optimization: Avoid difficult-to-machine features and standardize internal corner radius dimensions.

2. Process Optimization: Improve parameters to enhance efficiency, enabling the replacement of multi-process three-axis machining with five-axis machining.

3. Lot Sizing: Combine smaller quantity part orders to minimize the one-off cost associated with programming and clamping.

JS Precision insists on cost transparency in the quotation of each component. Cost optimization with quality assurance is possible by professional optimization solutions.

How To Choose The Best Material For Your Prototype CNC Machining?

The choice of material for prototype CNC machining directly affects testing results, machining difficulty, and cost. The key is to make decisions based on the prototype's purpose, mechanical performance requirements, and machining feasibility, rather than blindly pursuing high-end materials. Common materials are compared below:

| Material Category | Representative Material | Processing Difficulty | Cost | Core Performance | Applicable Scenarios |

| Aluminum Alloy | 6061, 7075 | Low - Medium | Medium | Lightweight, easy to process, corrosion resistant. | Appearance verification, structural testing, general prototypes. |

| Stainless Steel | 304, 316 | Medium - High | Medium - High | High strength, corrosion resistance, good toughness. | High strength, corrosion resistance, good toughness. |

| Engineering Plastics | POM, PEEK | Low-Medium | Medium-High | Insulation, chemical resistance, light weight. | Prototypes with special functions, Insulators. |

Lightweight & easy to process: How to choose the appropriate family of aluminum alloys

- 5 Series (5052): Good plasticity, strong corrosion resistance, suitable for bending and second process.

- 6 Series (6061): "Universal prototype material", easy to process, reasonable cost, suitable for most scenarios.

- 7 Series (7075): Strength close to steel, difficult to process and high cost, only suitable for extreme strength requirements.

When Strength and Corrosion Resistance are Primary Considerations: Stainless Steel vs. Specialty Alloys

- 304 Stainless Steel: Economical, when basic corrosion-resistant structural prototypes will suffice.

- 316 Stainless Steel: Stronger resistance to corrosion, medical and marine environment-related prototype jobs.

- Specialty Alloys include Titanium Alloys, etc. These are high-strength/lightweight/biocompatible materials for aerospace applications and up-market medical applications.

The Wisdom of Non-Metallic Prototypes: High-Performance Engineering Plastics

- POM: It has high hardness and good abrasion resistance, so it's suitable for manufacturing gears, bushings, and other transmission parts.

- PEEK: Resists high temperatures and chemical corrosion, first choice for medical and aerospace specialty prototypes.

- ULTEM (Polyetherimide): Excellent insulation, high strength, suitable to be used for insulating components in electronic devices.

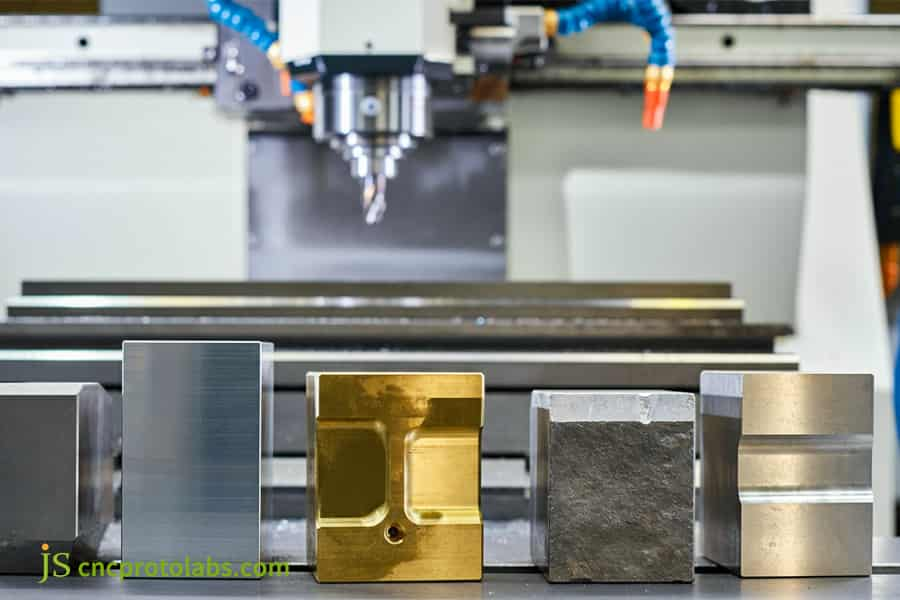

Figure 3:The advantage of CNC machining is that it can process a variety of materials, including metals such as aluminum, titanium, stainless steel, as well as engineering plastics such as PEEK, ABS, PMMA, etc.

What Are The Machining Strategies For Complex Custom Machined Parts?

Custom machined parts often present design challenges such as deep cavities, thin walls, small internal diameters, and complex curved surfaces. JS Precision's efficient machining strategies focus on the flexible use of advanced equipment and process techniques.

Five-Axis Machining: One Clamp, Infinite Possibilities

Five-axis simultaneous machining is a core technology for complex custom machined parts. It allows for multi-angle machining, completing all features in a single clamping, avoiding clamping errors, resolving three-axis interference, and easily machining impellers, complex molds, and other parts.

The multi axis machining accuracy and equipment performance evaluation of complex parts can refer to the specifications for performance evaluation of CNC machine tools in the American Society of Mechanical Engineers (ASME) ASME B5.57 standard.

Thin-walled deep cavity: process secret to avoid vibration and deformation

Some of the solutions to the challenge of wall thickness < 1mm and depth >5 times the diameter include:

- Tool Selection: Use slender/vibration-resistant tools for fewer vibrations

- Helical / Layered Cutting Path: To even out the cutting force.

- Holding Method: Vacuum suction, soft jaw clamps to increase clamping area.

- Cooling Strategy: A high-pressure cooling system for efficient and effective heat removal to avoid deformation.

JS Precision has completed aluminum alloy deep cavity parts with a wall thickness of 0.8mm and a depth of 30mm, with deformation controlled within ± 0.01mm.

Need the machining of custom machined parts with complex structures? Upload your part drawings, and JS Precision engineers will design a customized machining strategy for you free of charge, specifying equipment selection, process steps, and precision assurance solutions to ensure the accurate machining of complex parts.

CNC Prototype For Automotive Application Case: How To Achieve Performance Breakthroughs From Design To Validation?

The automotive industry requires extremely high precision, reliability, and extreme performance, hence, CNC prototypes for automotive become an important testing ground for technological capabilities.

Demonstrated below are two case studies of how JS Precision can help clients make a breakthrough with their professional CNC machining prototyping service in the two core areas of lightweighting and thermal management.

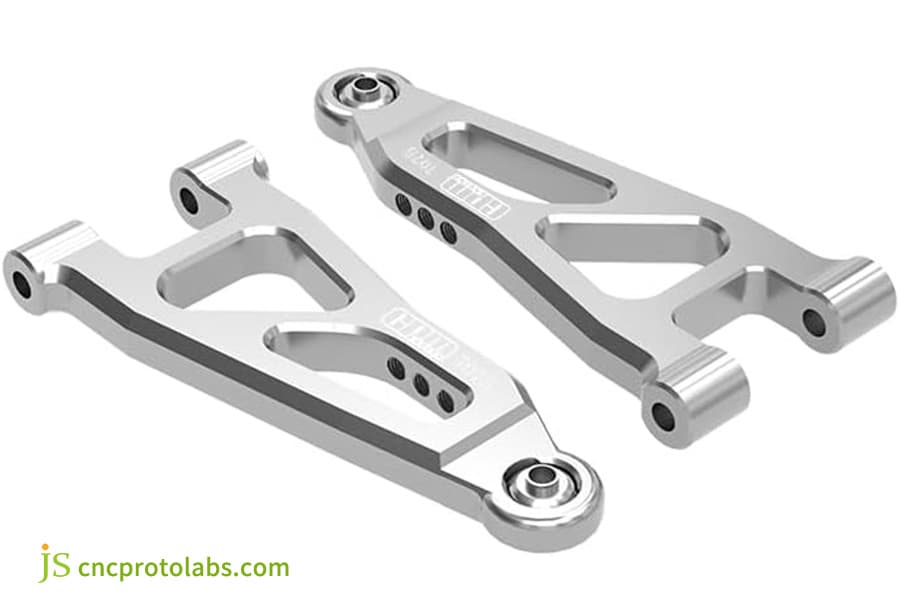

Case Study 1: 40% Weight Reduction - 7-Day Prototype Challenge for an FSAE Racing Car's Ultra-light Suspension Control Arm

Challenge:

A university racing team designed a topology-optimized suspension control arm, seeking to reduce the weight from 3.2 kg to below 2 kg using 7075 aluminum alloy without losing any strength. It has complex internal hollowing and features a thin wall at 1.2mm, so advanced prototype CNC machining is required, and it has to be delivered within 7 days.

JS Precision Solution:

- We conducted a Design Factor Analysis (DFM) and presented three suggestions for design optimization, including standardizing the inner corner radius and optimizing the opening of the hollow structure. The solution ensured part strength while improving tool life and machining efficiency.

- To that end, we applied a five-axis CNC machining center to perform all the precision machining tasks of the complex curved surface and hollow features in one setup, which avoided the accumulation of errors from multiple setups.

- To address the machining characteristics of 7075 aluminum alloy and its thin-wall and easily deformed nature, we adopted a dynamic milling strategy to minimize cutting forces and applied a high-pressure cooling system to effectively avoid overheating and deforming of the material.

Results:

The weight of the final part was 1.8 kg, more than a 40% reduction in weight. It passed all tests on the first attempt and functioned consistently during the 24-hour endurance race, which contributed to the team's excellent performance. This case demonstrates that professional CNC machining prototyping can achieve extremely lightweight design.

Figure 4:7075 Alloy Front Lower Suspension Arms

Case Study 2: 40% Improvement in Cooling Efficiency – Zero-Leakage Prototype Verification of an Integrated Electric Vehicle Liquid Cooling Plate

Challenge:

Continuing the pursuit of ultimate performance from the previous case, an electric vehicle company needed to manufacture a prototype battery liquid cooling plate with complex internal flow channels and zero leakage. Material requirements were C1100 pure copper.

Traditional welding yields for copper parts are low due to issues such as crack porosity. With copper having high viscosity, rapid prototyping CNC machining easily leads to tool sticking and serious processing difficulties.

JS Precision Solution:

To address this challenge, we innovatively proposed a composite process combining additive and subtractive manufacturing.

- First, by using metal 3D printing (SLM) technology to create a copper alloy substrate with complex conformal flow channels, we solved the problem of traditional machining incapable of achieving complex internal flow channels.

- Subsequently, five-axis precision CNC machining was employed for high-precision milling and polishing of key parts such as the sealing surface and interface threads to make sure that the flatness error of the sealing surface is controlled within 0.003mm to achieve zero-leakage sealing requirements.

- This combined process can perfectly balance the manufacturing requirements of complex internal flow channels and ultra-high precision assembly interface machining requirements.

Results:

Cooling efficiency enhanced by 40%, zero leakage in 5-Bar pressure testing, and passing 2000-hour bench durability testing. As a professional CNC prototype manufacturer, we solved the manufacturing challenges of complex custom machined parts using a composite process.

Submit your automotive parts drawings and performance requirements immediately, and JS Precision engineers will customize a CNC prototype for automotive exclusive solution for you free of charge.

What Are The Qualifications Of a Good CNC Prototype Manufacturer?

The selection of the correct CNC prototype manufacturer is vital towards the success of any CNC machining prototyping project. Excellent suppliers need to possess strong capabilities along multiple dimensions. The evaluation checklist therefore goes on to become as follows:

Technical Competencies

- Equipment Improvement: Does the manufacturer have 5-axis machining centre, high speed milling equipment and precision measuring instruments? Can the quantity meet delivery deadlines?

- Multi-material experience: Does the manufacturer process different materials like aluminum alloys, stainless steel, engineering plastics, etc. apart from handling various machining difficulties?

- Complex Part Capabilities: Has the manufacturing company been involved with successful cases regarding custom machined parts that require deep cavities and thin walls?

Quality System Dimension

- Capabilities of Measurement: Does the manufacturer have a coordinate measuring machine? Does the manufacturer provide detailed inspection reports?

- Quality Inspection Process: Build a full-process quality inspection system, is it ISO 9001 accredited?

- Precision Guarantee: Is the manufacturer capable of making a clear undertaking and delivering actual outcomes concerning machining precision?

Service Communication Dimension

- DFM Pro-activeness: Does the manufacturer actively suggest how to optimize the design?

- Project transparency: Can progress be synchronized in a timely manner and problems be responded to quickly.

- Response Speed: Whether the manufacturer can respond to quotations and inquiries within 24 hours, whether the manufacturer can provide expedited service.

Intellectual Property Protection Dimension

- Is it with a complete confidentiality system? Whether the manufacturer can sign the confidentiality agreement in order to protect design drawing and technical information.

Above all, JS Precision strictly complies with the aforementioned standards and commits to becoming the most dependable CNC prototype manufacturing service provider for customers.

FAQs

Q1: What is the main difference between CNC machined prototypes and 3D printed prototypes?

CNC machining prototypes use real engineering materials, offering higher structural strength, precision, and surface quality, making them more suitable for functional and durability testing and direct use as final parts, 3D printing is better suited for rapid prototyping and complex structure demonstrations.

Q2: Normally, after sending in the drawings, how long does it take for a prototype to be returned?

Simple parts can be delivered the next day, moderately complex parts usually take 3-5 days, custom machined parts with complex structures or parts requiring special post-processing generally take 5-7 days. JS Precision offers expedited services to shorten the lead time.

Q3: What is the smallest part or feature that can be machined?

Utilizing micro-milling technology, JS Precision can machine features down to 0.1mm in detail, suitable for prototype CNC machining projects with extremely precise dimensional requirements, such as precision medical devices and microelectronic components.

Q4: How do I get a quotation? What is the major determinant of the price?

You can get an instant quote online based on your 3D file, or contact customer service for a detailed quote based on your requirements. Key influencing factors include material costs, processing time (design complexity), post-processing requirements, and order quantity. All costs are transparent and there are no hidden fees.

Q5: Will the cost of machining a single prototype be very high?

The unit price of a single prototype is relatively high because it includes one-time costs such as programming and fixtures. However, this is the lowest-cost way to verify the design and avoid mass production errors. The unit price will decrease significantly when processing in small batches.

Q6: Will you check my design files before machining?

Yes. JS Precision provides a free Design Manufacturability (DFM) analysis, pointing out problems that may lead to high costs, long lead times, or inability to machine, and providing specific optimization suggestions to help customers reduce risks.

Q7: My design has high tolerance requirements. Can you ensure this?

We can consistently achieve a standard tolerance of ±0.025mm, and ±0.005mm for special requirements. Whether a specific tolerance can be achieved depends on the part features and materials. We will confirm the key tolerance zone with you before providing a quote.

Q8: What surface treatment options are available after machining?

We offer a variety of post-processing services including anodizing (multiple colors), sandblasting, passivation, nickel plating, heat treatment, silkscreen printing, and laser engraving to meet the functional requirements (such as corrosion resistance) and aesthetic needs of parts.

Summary

In summary, CNC machining prototyping is not simply "making a prototype," but rather the core engine for reducing risk and improving efficiency in the product development process.

As an experienced CNC prototype manufacturer, JS Precision is committed to applying professional CNC machining services to accurately transfer your innovative designs into physical reality.

Whether you are exploring in the early stages of product development or facing complex custom machined parts machining challenges, you can trust our expertise. Choosing JS Precision means choosing not only a machining service, but also a reliable partner for product success.

Now, let your design bridge between the virtual and reality.

Visit the JS Precision website now, upload your 3D files using our intelligent quotation system, and receive a clear quote and professional DFM feedback within 60 seconds. Let us accelerate your product success together with precise and reliable CNC machining prototypes.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com