In medical device prototype development, have you ever faced these dilemmas:

You spent three months developing a minimally invasive surgical instrument prototype that could not be used in animal testing because materials were not up to the ISO 10993 biocompatibility standard, or you encountered assembly problems during functional verification that needed scrapping and starting all over again?

As a rapid prototyping team that specializes in medical device prototype development, I know all too well how these issues can stall a project for months. Therefore, I've compiled this guide to help you avoid compliance pitfalls, choose the right processes, and control costs, allowing your medical device prototype development to move much more smoothly.

Core Answer Summary

| Comparison Dimensions | 3D Printed Prototypes | CNC Machining Prototypes |

| Core benefits | Fast iteration, unrivaled geometric freedom. | Realistic material properties, ultra-high precision, and surface finish. |

| Suitable Application Phases | Proof of concept, early morphology fitting. | Functional testing, preclinical trials, and submission of registration. |

| Applicable materials | Photosensitive resin, engineering plastics. | Medical stainless steel, titanium alloy, PEEK. |

| Precision and Surface Finish | Potential layering, requiring post-processing. | Mirror-level surface finish, precise tolerances. |

| Cost-Effectiveness | Low unit cost for complex structures. | High cost-effectiveness for small batches and high-requirement parts. |

| Compliance Support | ★★★☆☆ - Depends on material certification. | ★★★★★ - Easier material and process traceability. |

Why Trust This Guide? JS Precision's Focus on Medical Device Prototype Compliance Experience

Before answering the question, "Why Trust This Guide?", I would like to share real-world experience from JS Precision. During the past 15 years, we have focused on rapid prototyping of medical devices, serving 500+ medical clients.

From small, startup blood glucose monitor prototypes to large, cardiac stent delivery systems for multinationals, we have even completed the internally complex machining in titanium alloy for minimally invasive surgical instruments, thus allowing our customers to reach from design to validation in only 45 days.

Our team is familiar with every detail of the FDA prototype guidelines, and our Medical Device Prototype Approval Rate far exceeds the industry average.For example, last year, a neurointerventional device development client had problems during its application because its prototype did not meet the traceability requirement laid down by the FDA.

After taking over, we reworked the prototype and successfully met the standards of precision, besides completing all documentation, including material batches and processing parameters, to help pass the review.

It's not a compilation of theories, rather, it distills 15 years of hands-on experience into this guidebook. Every suggestion will help you solve practical problems, like how to control cost in the prototype stage or how to choose the right process that complies with ISO 13485 Medical Devices standards. You can safely trust it.

Want to mitigate compliance risks in medical device prototype development in advance? Contact JS Precision, and harnessing 15 years of compliance experience, we will give you a free on-site assessment of traceability and documentation completeness for your prototype, which will reduce your time in later stages regarding material certification and processing records and speed up the FDA application process.

What Truly Defines a Successful Medical Device Prototype?

The foregoing chapter illustrated the credibility of the guideposts. This chapter explains that a successful Medical Device Prototype is an integration of function, form, and compliance. The core points are as follows:

Multidimensionality of Standards for a Successful Prototype

- Functionality: The prototype simulates the performance of the final product. Examples include: opening and closing force of surgical instruments, which would be the same as the mass-produced version.

- Representativeness: Uses target or similar materials (avoiding the substitution of key materials like titanium alloys with plastic).

- Testability: Adapts to validation processes, such as implantable prototypes having reserved sensor interfaces.

- Compliance Foresight: Advance documentation for material certification, reducing the time to take regulatory approval.

Prototype Goals at Different Stages

- Proof-of-concept: Use 3D printing to create rough models, proving the feasibility of the design.

- Functional Prototype Stage: Ensure accuracy using CNC machining and complete core performance testing.

- Clinical Trial Stage: Comply with ISO 13485 Medical Devices standards, bridging the gap to mass production.

JS Precision defines the prototype goals in accordance with stages of the client's project. For instance, in an insulin pen prototype, we would iterate appearance using 3D printing and ensure accuracy with CNC machining in stages.

3D Printing vs. CNC Machining: Which Path is Right for Your Medical Device Prototype Development?

Once the success criteria of a prototype have been defined, the appropriate machining technology must be selected. There is no "best" between 3D Printing and CNC Machining, but only "most suitable." The core comparison is as follows:

| Comparison Dimensions | 3D Printing | CNC Machining |

| Speed | Fast: Simple structures 1-3 days. | Medium: Complex structures 3-7 days. |

| Cost | Low (small batch of simple parts). | Medium-high (high precision complex parts). |

| Materials | Resin, some metal powder. | All metal, medical plastics, PEEK, etc. |

| Accuracy | ±0.1mm (suitable for proof of concept). | ± 0.005mm (suitable for functional/clinical). |

| Scalability | Small batch iteration (5-10 pieces). | Connecting to mass production (no need to change process). |

Technology Selection Logic:

- Proof of concept stage: Focus on rapid iteration of appearance/structure using 3D Printing.

- Functional testing/clinical stage: Give priority to CNC Machining for accuracy in its mechanical performance.

- Complex requirements: Hybrid use required, between 3D printing for screening design and CNC for functional prototyping.

JS Precision provides hybrid manufacturing strategies, such as medical device prototype development. Not sure which technology is suitable? Send in your part drawings, and we'll provide free process design comparisons to reduce development costs.

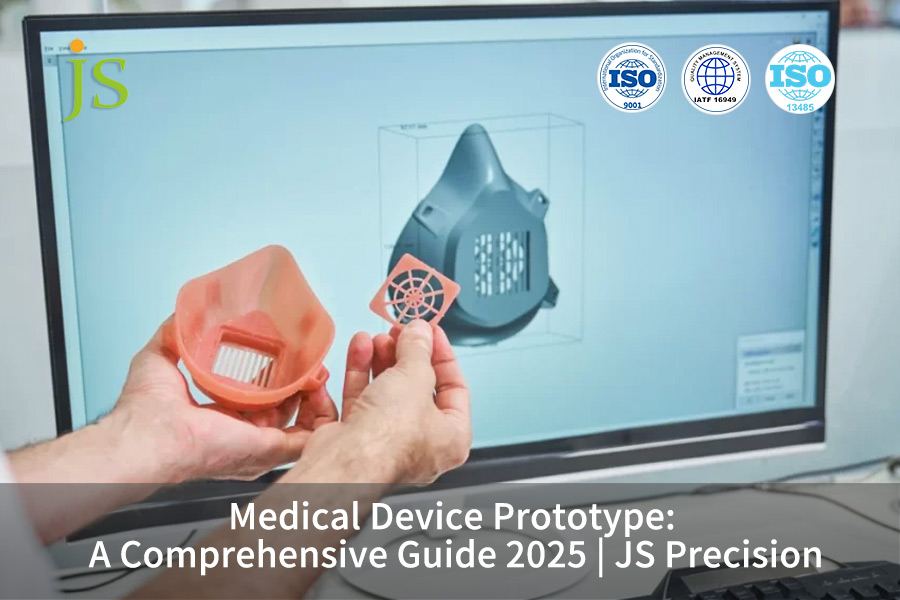

Figure 1: 3D Printing Medical Devices. 3D printing is suitable for a wide range of medical device prototypes, from initial concept models to functional prototypes for testing.

Why DFM Should Be Integrated Early into Medical Device Prototype Development?

Immediately following the selection of manufacturing technology, an important next step that can't be overlooked is DFM, or Design for Manufacturability. Many wait until the mass production stage to take DFM into consideration, but integrating DFM into your prototype stage can save you immense time and costs.

Core Reason for Integrating DFM at the Prototype Stage

If the prototype design is not suitable for manufacturing, disruptive modifications may need to be made during mass production.

For instance, one customer produced a prototype for an infusion set using three pieces. Once mass production started, they found that there was low efficiency in assembling it and the costs were high, thus, they redesigned into a single, integrated part. This added two months to the project's timeline and another $20,000 in cost. Early integration of DFM can avoid such problems.

Three Core Practices of DFM in the Prototype Phase

- Material Transition Planning: Mechanical differences between prototype and mass production materials should be tested to prevent performance failures, such as the transition from ABS to PEEK.

- Simplified Assembly Design: Check snap-fits and screw posts in the prototype to reduce parts count, such as surgical forceps from 4 to 2 pieces.

- Reasonable Tolerance Design: Set ±0.1mm for non-critical surfaces to avoid unnecessary high precision, and control the cost of medical device prototyping.

What Are the Key Factors Driving the Cost of Medical Device Prototyping?

Good DFM can control costs, but you also need to understand which factors directly affect the cost of medical device prototyping. Only by understanding the cost structure can we budget reasonably and avoid overspending. The core driving factors are as follows:

Material cost and availability:

Some medical-grade special materials are very expensive, such as PEEK and titanium alloy. (One kilogram of PEEK costs several hundred US dollars.) Some special materials need to be imported, besides, long delivery cycles increase waiting costs.

Geometric complexity:

For example, if the prototype contains complex internal cavities (2mm diameter channels) or tiny features (0.5mm thin walls), processing will take significantly more time and cost accordingly: while the processing of a simple flat plate prototype would cost $200, processing of a prototype of a surgical instrument with complex internal cavities may exceed $1000.

Precision and surface finish requirements:

An increase in the level of precision represents an exponential increase in cost. For example, increasing the precision from ±0.1mm to ±0.01mm doubles the cost of processing. Similarly, a high surface finish entails additional polishing at a few hundred US dollars per square meter.

Post-processing and cleaning requirements:

Medical prototypes require aseptic cleaning ($50-100/time) and deburring. Manual deburring of complex parts costs $200. More than $1000 USD, including surface anodizing, will be paid extra.

Compliance documentation:

Providing material certifications, processing records, and other documentation requires engineer time; a complete ISO 13485 compliance document costs 1000-2000 USD.

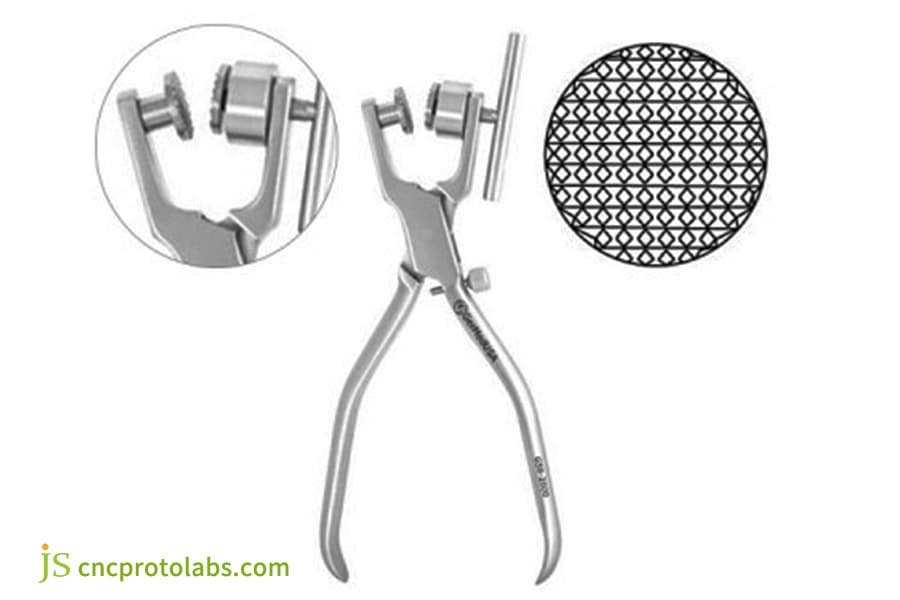

Figure 2: Some medical device applications require surface finishes (especially high-polish and mirror finishes) for sanitation and cleanliness purposes.

What Are The Special Material Demands For Prototyping Medical Devices?

Once the cost factors are understood, let's focus on the material factor. The demands for materials in the prototyping medical devices are much higher compared to ordinary products. We can't just look at the mechanical properties, we have to consider four special requirements:

- Biocompatibility: According to ISO 10993 standards in order to avoid allergy or inflammation due to prototype implantation (the employment of titanium alloy is because of the zero rejection rate.

- Sterilability: Resistant to gamma rays, EO, and steam sterilization (metals have better compatibility than resins).

- Mechanical Properties: Long-term fatigue strength emphasized. Examples include PEEK for reusable devices.

- Chemical Stability: The material does not react with the medications or blood, for example, the materials of an infusion set do not dissolve in medications.

JS Precision has complete inventory and certification management for medical-grade materials. On a regular basis, our warehouse will stock various materials, including titanium alloys, PEEK, and medical-grade ABS. Each batch of material is fully documented with certification to assure that the prototype materials will meet regulatory requirements at the outset.

Not sure which material meets the requirements for prototyping medical devices? Contact JS Precision, we offer a range of ISO 10993 certified medical materials and batch certificates to ensure compliance right from the beginning.

Figure 3: Biocompatible screws. Biocompatibility is a necessary condition for any device that comes into contact with the human body.

Critical Factors When Selecting Medical Device Prototyping Companies

After selecting materials and processes, the following 7 points should be considered when selecting medical device prototyping companies:

- ISO 13485 Certification: Basic standard in the medical industry, which JS Precision has been granted and is subject to regular audits.

- Knowledge of FDA Regulations: Understand what needs to be on prototype documentation so that additional documentation is not required later.

- Level of Medical Device Prototype Engineering Services: DFM advice and design optimization ability.

- Equipment Diversity: 5-axis CNC machining and metal 3D printers are available for the processing of complicated structures.

- Material Library and Certifications: Inventory of commonly used medical materials, providing biocompatibility reports and other documentation.

- Quality Inspection Process: Accuracy testing by a coordinate measuring machine and sterility testing to assure quality in prototypes.

- Intellectual Property Protection: Strict confidentiality agreements are in place; JS has no known cases of intellectual property leaks.

Currently screening medical device prototyping companies? Ask for a copy of JS Precision's ISO 13485 certification documents and quality inspection process manual. We will give you a clear view of our compliance capabilities and engineering strength, helping you make the right choice.

Does Your Prototype Need to Comply with ISO 13485 Medical Devices Standards?

Many clients ask me, "Does the prototype stage need to comply with the ISO 13485 Medical Devices standard?" My answer is: absolutely. Because ISO 13485 is not just "a certificate", but directly influences every stage of prototype production. The core requirements are as follows:

- Traceability: Material batches and processing parameters, like titanium alloy suppliers and speeds of CNC machines, are registered for filing purposes.

- Process Validation: fixing the parameters in 3D printing like temperature and layer thickness to avoid potential fluctuations in quality.

- Document Control: Record all design changes and test results; nothing is changed without documentation.

At JS Precision, from the moment you place your order, your prototype is already operating within a controlled, ISO 13485 compliant system. For instance, if you are prototyping a surgical instrument, we will be able to provide you with a full complement of documentation, including material certifications, processing records, and inspection reports.

These will give you a solid foundation for FDA filings, as these documents can be used directly.

Many clients in the past who made their own prototypes did not record this information and found themselves three months behind when the FDA asked for such a recording during the application process. And the prototype we made, with complete documentation, passed the review in one go.

Proactive Risk Management in Medical Device Prototype Engineering Services

After meeting the ISO 13485 Medical Devices standard, risk management becomes effective. Risks are ubiquitous in medical device prototype engineering services, such as those related to design flaws, manufacturing contamination, and user misuse. Only through identifying and controlling risks in advance can failures in prototypes be avoided.

Risk Management Process Based on ISO 14971

We follow the process of "Identifying Risks → Assessing Risk Levels → Developing Control Measures," focusing on high-risk issues.

For example, during the design phase, we list the risk items that may appear, such as "insufficient prototype strength" and "excessive dimensional deviation," assess the probability of their occurrence and the impact, and focus on solving the problems with high probability and high impact first.

Three Practical Steps for Risk Control at the Prototype Stage

- Design FMEA: Analyze possible defects, such as optimizing the diameter tolerance of tubing in infusion set prototypes.

- Manufacturing FMEA: Clean machine tools regularly to prevent contamination. Check dimensions every 2 hours.

- User FMEA: Simulate misuse - for instance, mishandling surgical forceps - and optimize handle design to improve safety.

Case Study: JS Precision Helps Minimally Invasive Surgical Instruments Achieve 75% Time Savings

Now that many theories and methods have been discussed, I will go on to use a real case to demonstrate how JS Precision helps clients solve practical problems.

Client Needs

The client is a startup dealing in minimally invasive surgical instruments. They were to develop a prototype of a handheld instrument made of titanium alloy. There were two critical needs for this instrument:

- Lightweight: ≤50g, lightweight for surgeons to operate easily and continuously.

- High strength: Tensile strength ≥800MPa to avoid breaking during surgical procedures.

An internal channel with a diameter of only 2mm, requiring a smooth, burr-free surface; otherwise it would affect the delivery function of the instrument. The client was developing this prototype for animal testing and subsequent FDA 510(k) filing.

Previously, the client contacted other suppliers, but they were unable to fabricate the complex internal channels. This caused a one-month delay and a waste of money at $5,000. They then approached JS Precision, to which we provided a three-step solution.

JS Precision's threefold solution

1. Initial Prototyping:

Rapid creation of a representative model of a complex internal cavity concept using metal 3D printing (titanium alloy powder), which was completed in 3 days, during verification on the shape and assembly, it was found that the thin wall of 1mm was liable to generate deformation and, thus, the thickness was changed to 1.2mm.

2. Create Functional Prototypes:

Change to the use of 5-axis CNC machining, with one-off milling of the main body from TC4 titanium alloy bar stock, high-speed milling technology guarantees the surface roughness Ra in internal channels is ≤0.8μm, with DFM applied to optimize the structure of the handle, while keeping the weight under 48g.

3. Compliance Support:

Compile complete material certifications to ASTM F136 standards and machining records, including machining parameters and dimensional inspection reports for each step, in compliance with ISO 13485 to directly support an FDA application.

Final Results

The original prototype development cycle of 6 months was shortened to 1.5 months, saving 75% of the time. The first functional prototype successfully passed animal testing, without additional iteration costs and directly advanced the process for the FDA application.

Do you want your medical device prototype development to achieve both time and cost savings? Contact JS Precision to learn how we can combine 3D printing with CNC technology to tailor-make an efficient development solution that will keep the cost of medical device prototyping in check.

Figure 4: Bone Mill Hand Held With Titanium Alloy

Ready to Start Your Project? How to Partner with JS Precision

Having grasped the main aspects of prototype development, if you are ready to initiate a project, then your partnership with JS Precision is just four simple and straightforward steps:

1. Consultation and Requirements Analysis: Inform our team about the functional requirements, compliance standards of the prototype (FDA prototype guidelines), and the phase of the project. Consequently, our team will iron out the core requirements.

2. Design and Process Review: Our engineers will provide DFM recommendations for your design, determine the appropriate processing technology-3D Printing or CNC Machining, or hybrid processes-and output a preliminary design.

3. Manufacturing and Quality Inspection: The prototype shall be manufactured in conformance with the ISO 13485 standard. Full-dimensional inspections (coordinate measuring machine) and performance tests (such as sterility testing) shall be performed to ensure the quality of the prototype.

4. Delivery and Support: We will deliver the prototype and complete compliance documentation (material certifications, processing records, inspection reports), and provide subsequent support like design optimization and iterative processing.

We recommend involving the JS Precision engineering team as early as possible to get DFM recommendations and cost optimization solutions earlier to avoid design modifications later. Our one-stop medical device prototype engineering services will lead you through a smooth transition from prototype to mass production.

FAQs

Q1: Must the prototype medical devices and final products use the same materials?

Not necessarily, but JS Precision suggests the use of materials with similar performances or those that are already certified, to ensure valid test results and an easy transition from prototype to mass production without problems associated with material replacement.

Q2: Must I consider FDA requirements even at the prototype stage?

Absolutely. Early incorporation of FDA prototype guidelines, such as human factors engineering and testing standards, can prevent major design changes later, which is a key step toward accelerating product launch.

Q3: Does JS Precision offer anything other than prototypes?

Yes, our whole range of services extends from prototype development to small-batch pilot production, including DFM optimization, compliance documentation, and the integration of mass production processes that guarantee a seamless transition from concept into the market.

Q4: Can 3D-printed prototypes be used for clinical registration applications?

Yes, but three conditions need to be met: material biocompatibility certification, process validation, and complete documentation. Documentation of JS Precision's CNC-machined prototypes usually has an edge over others.

Q5: What is a typical prototype development cycle for a medical device?

These will vary from a few weeks to several months, based on the prototype's complexity, selection of technology, and number of iterations. JS Precision uses concurrent engineering and an efficient supply chain to minimize the time spent during development.

Q6: What are the key considerations for the prototypes of implantable devices?

The three essentials are biocompatibility, long-term mechanical properties, including fatigue strength, and sterilizability. JS Precision helps you select the right materials and processes to ensure these three requirements are met.

Q7: Does the cost estimate include all post-processing and inspection?

Pricing at JS Precision is always transparent. All costs, such as cleaning, deburring, full-size inspection, and aseptic processing, are clearly listed with no hidden fees whatsoever.

Q8: What is the most overlooked key point when selecting the supplier for the prototype of the medical device?

It is the quality system and documentation capabilities of the supplier. While it is important to make aesthetically pleasing parts, complete compliance documentation in support of registration is much more important for application processing later on.

Summary

A successful Medical Device Prototype is not a question of luck; it's about balancing functionality, compliance, and cost, and selecting the right technology, materials, and partners.

With over 15 years of practical experience, JS Precision knows that planning for compliance in advance, conducting proper DFM (Design for Manufacturing), and controlling risks can spare a prototype development from most pitfalls.

Take action and put your ideas onto the shortcut to success now!

Just send us your CAD files along with initial requirements, and you will get a professional solution within 24 hours that also includes preliminary DFM suggestions, process road map, and a transparent quote.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com