Imagine a scene: You're a procurement manager for a machinery manufacturing company and need to order a specially commissioned run of sheet metal welding parts for a new project. You make some phone calls to various factories, but some give you unfirm prices, some quote too high, and some cannot give you a accurate quote because they lack sufficient design data.

Or perhaps you're an entrepreneur startup designer who would like to create a metal welding prototype for your latest invention but have no clue how to get a clear, affordable metal welding price quote.

If you have experienced such difficulties in the past, then this guide is for you. It will explain step by step how to get true metal welding project quotes on the Internet, so that you can avoid quote pitfalls, save time and money, and go about your metal welding project with ease.

Core Answer Summary

| Key Points | JS Solution | Key Value |

| Key Things for Precise Quoting | Design Review + Process Matching + Material and Complexity Consideration. | Transparency without concealed charges saves 15%+. |

| Key to Welding Cost Control | Simplify Joints / Standardize Materials / Select Suitable Welding Methods. | Small-batch costs can save 10%-20%, and large-batch costs can save 30%+. |

| Quotation Detail Optimization | Establishing weld specifications / post-processing requirements / manufacturing quantity and delivery timeline. | Avoiding quotation deviation and improving project progress efficiency. |

| Special Metal Welding Capabilities | Covering Inconel, magnesium alloys, etc., with exclusive process support. | Meet the requirements of high corrosion resistance and high precision scenarios. |

Why Is JS's Online Metal Welding Quote So Accurate?

It is not simple to get accurate quotes in the metal welding industry, it requires deep industry experience and professional technical support.

JS possesses over 15 years of industrial experience in custom sheet metal welding manufacturing and has completed over 30,000 metal welding projects for over 5,000 customers worldwide in diverse industries, including automotive, aviation, medical devices, and environmental protection equipment.

For example, in the automotive industry, we completed a complex chassis part welding job for one of the world's leading automakers that included welding various metal materials and tight precision dimensional requirements. The finished product was fully meets to the client's quality requirements.

In the medical device industry, we've produced stainless steel enclosures for different medical device companies with strict compliance to medical industry welding standards in order to ensure product reliability and safety.

This metal welding quote guide is a collective experience of ours based on years of hands-on experience in online sheet metal welding services.

We understand the nature and requirements of different industries as well as different types of metal welding works and the factors influencing the accuracy of quotes. Therefore, you can have full confidence in the information as well as methods presented in this guide.

Once you choose JS's online sheet metal welding services, you can be assured of receiving accurate quotes. You can rely on our extensive body of experience in custom sheet metal welding manufacturing to give you an accurate quote for your metal welding project.

Design Determines Cost: Essential Welding Design Techniques

Upon receiving a metal welding quote, project cost is directly determined by weldment design. A good design ensures weld quality and brings sheet metal welding prices down efficiently. Some important weldment design techniques follow:

Tip 1: Simplify Joint Design

Multifunction joints increase welding time and complexity, so the employment of simpler joints such as butt joints and fillet joints is ideal. For example, simplifying a multifunctional complex joint to a single butt joint can reduce welding time by 30%, significantly reducing the cost.

Tip 2: Offer Adequate Clearance

An appropriate clearance assures penetration weld. Excessive clearance has a greater consumable cost, and too little clearance results in rework because of inadequate penetration. For the thickness of the material and process, a clearance between 0.5-2mm is ideal.

Tip 3: Consider Symmetrical Structures

Symmetrical patterns guarantee equal heating distribution in welding to reduce distortion, without the need for additional correction processes. For example, a symmetrical stainless steel box structure reduces welding distortion by over 25%.

Tip 4: Standardize Material Thickness

Non-standard material is difficult to obtain, expensive, and requires specialized equipment. In custom sheet metal welding manufacturing, JS standardizes material thickness in order to reduce costs.

Tip 5: Clarify Welding Standards

Different applications require different levels of welding, and too high a level is costly. For example, standard mechanical brackets can be manufactured in accordance with normal industrial specifications, reducing costs by 20% compared to aerospace standards.

When it comes to custom sheet metal welding manufacturing, JS can simplify weldment designs using its immense experience and apply these designing techniques to reduce the sheet metal welding price. It will make your welding processes cost-effective by doing business with us.

Are Price Differences Among Different Metal Welding Methods Significant?

There is no best welding method, just the one that works best. Material, thickness, quantity of production, and beauty determine the selection. Being aware of the cost difference between welding methods will allow you to control sheet metal welding prices.

Price Comparison of Common Welding Methods

| Welding Method | Welding Cost Per Foot (USD) | Ideal Applications | Strengths | Weaknesses |

| MIG/MAG Welding | 5-15 | Thin plates, high speed of welding, general structure welding. | High weld quality, good appearance, low deformation, easy to operate for a variety of metals. | Poor weld appearance, high deformation when welding thin plates. |

| TIG Welding | 15-30 | High precision, special metal processing, high appearance requirements of weld. | High weld quality, good weld appearance, low deformation, able to process a variety of metals. | Slow speed, poor efficiency, high cost, high technical demands. |

| Stick Welding | 8-20 | Outdoor application, thick plates, repair welding, low appearance weld application. | Simple equipment, less complicated to use, can be applied to various environments, medium cost. | Low efficiency, poor appearance, heavy slag, environmental pollution. |

Low-priced MIG/MAG welding for mass metal welding production, high-priced but high-quality TIG welding for high-class custom sheet metal welding manufacturing work, and special environments applicable for Welding prices are moderate.

Welding price difference for different quantities of production (stainless steel sheet as an example)

| Production range (units) | Price of MIG/MAG welding per unit (USD) | Price of TIG welding per unit (USD) | Preferred method of welding |

| 1 - 50 | 80 - 120 | 150 - 200 | TIG welding (small batches, precision top priority). |

| 51 - 200 | 60 - 90 | 120 - 160 | Employ as conditions demand (balancing cost and accuracy). |

| 200 + | 40 - 70 | 90 - 130 | Cost-driven MIG/MAG welding (large orders). |

JS offers a variety of metal welding processes, recommending the most suitable approach based on your needs and effectively controlling sheet metal welding prices. Choose our online sheet metal welding services to obtain an economical welding service for your application.

Thickness And Complexity: Two Important Factors Affecting Quotations

In metal welding project quotations, material thickness and structural complexity directly impact the sheet metal welding price. Understanding their impact helps accurately estimate costs.

Material Thickness

Heat Input and Time Cost: The thicker the material, the greater the heat input and the greater the welding time. Welding a steel plate of 10mm thickness, for example, can take more than double the time to weld a 5mm plate, increasing labor and equipment costs.

Consumables: Thicker material uses more filler material such as welding wire and electrodes. For example, how much wire is consumed to weld a meter of 10mm steel plate is two to three times of that for a 5mm plate, which sums up into increased consumables cost.

Pretreatment and Post-treatment: Pre-treatment of thicker material such as beveling and surface cleaning is difficult and time-consuming. Post-treatment such as stress relief and grinding also sums up to cost.

Structural Complexity

A 20-piece welded item is very costly in relation to a workpiece of the same weight comprising 5 pieces because:

Longer time to assemble: Since there are numerous pieces, assembly is complex, and adjustment and positioning take a lot of time.

More positioning difficulty: Complex positioning tools are required, and they are costly and need rework since positioning is not precise.

Explosive growth in welding time: The large quantity of parts generates more weld joints, and there is a complex series of welding to deal with deformation, which enhances the time considerably.

Details Determine Success: 7 Key Details To Take Into Account When Quoting Custom Welding Parts

When quoting custom sheet metal welding manufacturing projects, specificity is what makes quotes accurate and the project advance. The following are 7 specific details to pay attention to:

1. Provide complete engineering drawings: One of the key conditions, which will have specifications such as dimensions, form, and welding joint type, otherwise, the suppliers will struggle to provide an accurate quote.

2. Material details: Material grade, size, and surface finish. Welding difficulty and cost of different materials can be significantly divergent. For example, it is costlier to weld stainless steel compared to common carbon steel.

3. Welding process and standards: Specific requirements must be identified. Different acceptance criteria have different cost. TIG welding is costly compared to MIG welding, and aerospace standards are costly compared to industrial standards.

4. Weld appearance and finish requirements: Increased appearance requirements result in additional post-processing. For example, smooth weld grinding can increase costs by 10%-20%.

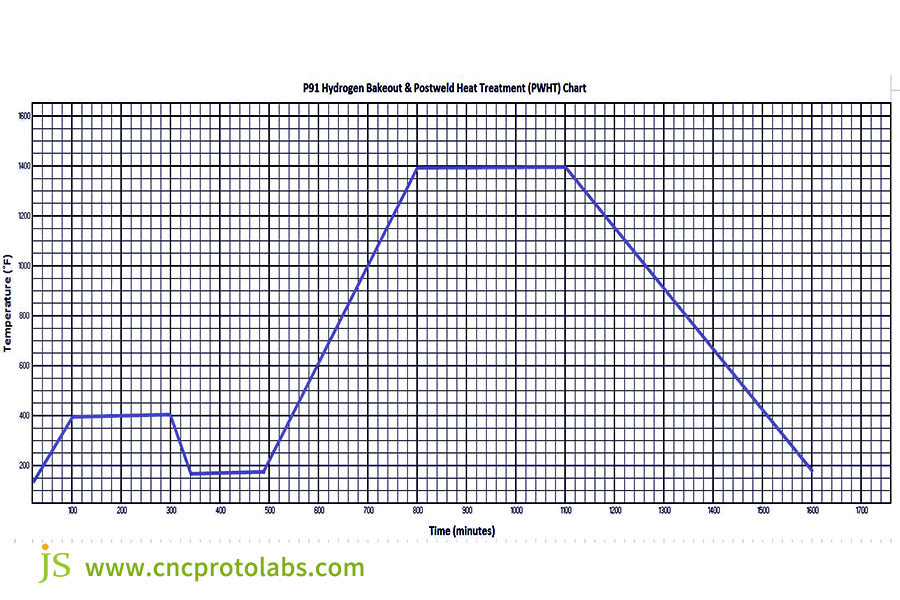

5. Post-processing requirements: Cleaning, painting, and heat treatment are all expensive. For example, painting needs to be priced by paint type and thickness.

6. Establish target levels: Prototyping, small series, and large series have different production procedures and costs. Large series can spread fixed costs and improve efficiency.

7. Expected delivery time: The expediting costs more, and hence their mention enables the suppliers to make precise bids.

Custom sheet metal welding manufacturing quotes cannot be obtained without an understanding of these factors.JS will take you through this step by step and provide you with a precise sheet metal welding price. Choose our online sheet metal welding services to obtain a quote that best suits your requirement.

Three-Step Direct Access: How To Get Instant, Transparently Welding Quotes On JS Platform?

To receive instant accurate metal welding quotes with ease, JS platform offers an effortless and convenient solution. Get clear sheet metal welding prices in three straightforward steps that enable you to proceed with your custom sheet metal welding manufacturing projects:

Step 1: Upload Design Files

JS platform offers an easy means to upload your weldment design files in any format you prefer, either CAD drawings or 3D models. Uploading is quick and easy, taking just a few minutes. Upon upload, the system performs an automatic initial inspection to check file integrity and readability.

Step 2: Intelligent Process Review

It is far more than an estimate quote. JS Precision Manufacturing's talented engineers and intelligent system will review your design files in real-time. We will evaluate manufacturability and cost optimization and make professional recommendations.

Should your design include complex weld joints, for example, engineers might recommend simplifying the joint design to save money and improve the efficiency of manufacturing. With the intelligent process review, you can instantly detect design faults and hone your design.

Step 3: Obtain an Interactive Quote

After you pass the review process, you will be shown a comprehensive interactive quote. The quote clearly lists all the fees, such as low-level processing fees, material charges, and post-processing fees, giving you a proper understanding of the composition of sheet metal welding price,achieving price transparency and no hidden costs.

You can also adjust related parameters in the quote, such as production quantity and delivery date, to your needs. The system will automatically update the quote, making it easier for you to compare costs and make more informed decisions.

Case Study: How JS Overcame The Welding Difficulty Of Huge Structural Parts For An Environmental Protection Equipment Maker

Client Background and Pain Points

A prominent environmental technology firm needed to weld numerous large stainless steel water treatment tanks for a large-scale water treatment project. The tanks were sheet metal welding parts, which required extremely high weld quality and resistance to corrosion.

However, the company approached several traditional fabricators and discovered that the sheet metal welding prices they were quoting were extremely high, much more than the project's budget.

Moreover, the traditional fabricators were unable to meet the stringent distortion control and weld corrosion resistance, which put the project in limbo. The company had to find a supplier in a hurry who would provide good quality at low prices for metal welding.

JS's Solution

After the discovery of the problems faced by the customer, JS immediately established a professional project team to provide a custom solution.

1.Design Optimization

JS engineers carefully reviewed the tank design drawings provided by the customer. We discovered that certain continuous welds on the tank not only led to excessive welding cost but also had the tendency to easily induce weld deformation.

Hence, our engineers recommended replacing part of the continuous welds with intermittent welds. This minimized heat input and weld deformation significantly without compromising tank strength.

2.Process Control

JS's technical personnel planned in detail a welding sequence. We weld the tank in different regions and steps based on its structural characteristics, to avoid deformation caused by improper welding sequence. We also controlled parameters such as temperature and current during the welding process to ensure weld quality.

3.Quality Control

JS had conducted extensive testing on the completed tanks. In addition to normal visual inspection and dimension checks, all the welds of key importance were subjected to 100% penetrant testing (PT) to verify whether the welds were flaw-free including cracks and pores, satisfying all the customer's corrosion resistance requirements.

Results and Value

Through JS's technical solutions, the client achieved excellent results and value. The final sheet metal welding price was 15% lower than the client's initial traditional quotation, with notable cost savings on jobs. Moreover, the lead time was minimized by 20%, enabling the client to construct and commission projects within schedule and convincingly win this essential water treatment contract.

Most prominently, the provided large stainless steel water treatment tank completely met the client's quality requirements.Especially the deformation control and weld corrosion resistance have been highly recognized by customers. Not only did this help the client gain credibility on the market, but it also provided a solid basis for long-term cooperation in the future.

JS is an expert in custom sheet metal welding manufacturing and can effectively tackle various welding problems, reducing sheet metal welding prices and shortening delivery times for customers. Choose our online sheet metal welding services to help you overcome project challenges.

Why Choose JS: Five Core Values Beyond Price

In choosing a metal welding manufacturing service company, core values and not cost is the most important. JS is the top choice supplier of custom sheet metal welding manufacturing because we have five core values:

1.Professional Engineering Team

Over 50 experienced welding engineers, averaging over 10 years of experience in the industry, have in-depth knowledge of various processes and materials and provide technical support as well as design optimization solutions for projects.

2.Advanced Process and Equipment Matrix

We possess equipment such as automatic MIG/MAG welding and precise TIG welding to address various projects' needs. We also have new processes such as narrow-gap welding to reduce costs and improve efficiency.

3.Tough Quality Control System

From raw material procurement (testing composition and properties), control of the welding process (appearance and parameters), through to testing the final product (performance and appearance), we have tough quality control from beginning to end.

4.Integrated Seamless Manufacturing Capability

Provide one-stop welding, machining, and surface treatment services and spare yourself the hassle of dealing with multiple suppliers, reducing delivery times, and saving costs.

5.Committed to Success for Both

As a customer's success is our top concern, we prioritize urgent orders as highest priority and provide design and promotion consultancy for customers to achieve project success and gain a win-win situation.

FAQs

Q1: I don't have engineering drawings, but only concept sketches or 3D models. Can I get a quotation?

Yes. With concept sketches or 3D models, JS can provide a metal welding quote. Our engineers will take your concept sketches or 3D models and years of experience in custom sheet metal welding manufacturing to figure out critical design information, evaluate welding processes and costs, and ultimately provide you with a reasonable sheet metal welding price.

Q2: What are the main price differences between small-batch prototype welding and mass production?

The main price differences are threefold:

- Fixed cost allocation. Mass production can allocate fixed costs over more products and thus has lower unit product costs.

- Process and efficiency. Mass production utilizes machine welders with minimal man-hours and maximum efficiency.

- Material procurement. Purchase of bulk consumables allows volume discounting.

Q3: What special metals do you weld?

In custom sheet metal welding manufacturing, we have proprietary weld methods and extensive experience for special materials such as nickel-based high-temperature alloys, magnesium alloys, molybdenum, tungsten, and zirconium. Kindly mention the type of material and we will check for feasibility based on metal welding process requirements.

Q4: If I am receiving Design for Manufacturing (DFM) recommendations during the time I am getting quoted, will the price be altered once these modifications are made?

Usually it will decrease.The main objective of DFM recommendations is to optimize the design and make it easier to weld with regards to the metal welding manufacturing process, thereby cutting costs and improving quality. These modifications may reduce intricate welding processes, reduce consumables, or improve welding efficiency. These modifications directly reduce production costs, which subsequently reduces the sheet metal welding price.

Summary

A true metal welding quote is no longer a case of random waiting or waiting indefinitely. The secret lies in understanding cost factors and choosing a professional, transparent, and technologically advanced partner to avoid quote pitfalls and obtain clear, reasonable sheet metal welding prices.

Choosing JS presents a less hectic experience. Our online sheet metal welding services not just provide you with accurate quotes, but help make your metal welding project a success with our experienced staff, advanced machinery, and extensive selection of services, so you can easily achieve your metal welding project goals.

Experience real quotes in seconds today! Upload your file to receive not only the price but also a free manufacturing feasibility analysis report from our team of experienced engineers. Have JS's expertise power your product's success.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com