From space shuttle tanks to specialty bike frames in your living room, high-strength welding is the cornerstone of a product's life. In the pursuit of utmost strength, there are two technologies that lead the pack.

One is the reliable old MIG welding, honed like an art. The other is high-tech, precision laser welding, precise like surgery. Which among them can provide unparalleled ruggedness to your project?

This article will discuss the nature of welds to reveal what makes the two processes different in terms of strength, cost, and applications. It will help you make the right choice.

We will not only contrast the theoretical strength difference but also combine real-world manufacturing conditions to analyze how to select the lowest-cost and most reliable process path for your sheet metal welding parts.

Core Answer Summary

| Comparison Dimension | Laser Welding | MIG Welding |

| Core Principle | Uses a high-density energy laser beam to melt material. | Melts continuously fed welding wire by an electric arc. |

| Strength Performance | Typically offers higher fatigue strength and consistency with an extremely minimal heat-affected zone. | Offers high static strength but larger heat-affected zone that may impact base material performance. |

| Suitable Materials | Flexible, especially excellent for dissimilar metal welding (e.g., aluminum-steel). | Flexible, with much material tolerance for slight rust or oil marks. |

| Suitable Thickness | Thin to medium-thick plates (usually 0.5mm - 10mm). | Very wide range, suitable to thin to thick plates, especially excellent for thick plates. |

| Welding Speed | Very high. | Slow to medium. |

| Thermal Deformation | Very low. | Reasonably high. |

| Weld Appearance | Elegant, no or little post-processing involved. | Need to clean up welding slag and splashes, usually requiring polishing. |

| Equipment Cost | Very high (hundreds of thousands to millions of US dollars). | Low (thousands to tens of thousands of US dollars). |

| Operation Skills | High, professional engineers needed for programming and operation. | Relatively low, managed by experienced welders. |

| Optimal Scenarios | High-volume, high-accuracy sheet metal welding parts that require strict appearance standards. | Small-series production, prototype manufacture, maintenance, and thick-plate structural parts. |

Why Trust? JS Precision's Practical Welding Strength Principle

Why trust JS Precision among so many options? Because we understand that true weld strength comes from meticulous attention to detail. From material pretreatment to parameter optimization, our engineers ensure that every weld achieves over 95% of the theoretical optimal state, making your product inherently indestructible.

Our principles are based on data from hundreds of successful projects. By establishing a database of materials, parameters, and properties, we can control heat input tolerance to within ±5% for laser welding of 6061 aluminum alloy, improving weld strength stability by 30%. For MIG welding of high-strength steel, our multi-pass welding process reduces distortion to 60% of the industry standard.

This isn't just theory; it's a proven, production-proven commitment.

Choosing JS Precision means choosing data-driven welding reliability. Give your next sheet metal welding prats project a competitive edge from the very first weld. Consult our engineers today for a customized strength solution tailored to your needs.

Deconstructing Welding Strength: What Determines Weld Durability

Before we can even compare the two technologies head to head, first we have to define what we are mean by "strength". Strength is a great deal more than just "not fracturing when pulled apart".

1.Tensile Strength: Strength to resist being pulled apart. This is the most basic measurement.

2.Fatigue Strength: The ability of a weld to resist repeated alternating loads without cracking and fracturing. It is crucial for sliding parts (e.g., robot arms and bicycle frames).

3.Impact Toughness: The ability of a weld to resist an impact or collision. It measures whether the weld is "brittle" or "tough."

So what are the forces behind these strengths? The key lies in the metallurgical behavior when welding:

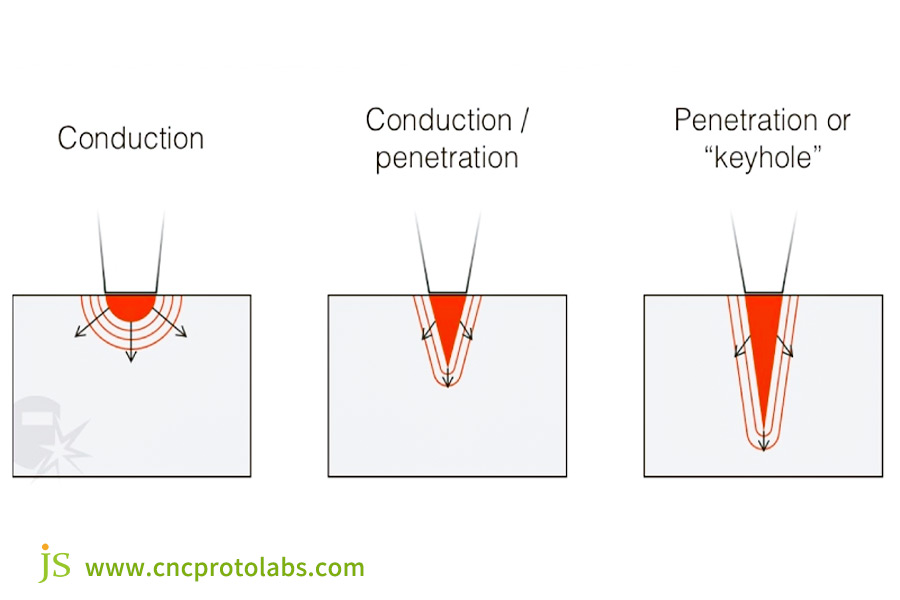

1.Heat-Affected Zone (HAZ): This is the area of the base material which is heated but not melted during welding. Due to its high concentrated energy and high speed, laser welding creates an extremely narrow HAZ that barely changes the original base material properties.

MIG welding does have high heat input and greater HAZ. This may cause the material to soften (strength reduction) or become brittle (toughness reduction).

2.Weld Defects and Contamination: Laser welding produces very few or no defects such as pores (bubbles) and slag inclusions. They are stress raisers that decrease fatigue strength significantly. With proper shielding gas, laser welding produces very clean welds with a very low defect rate.

3.Weld Geometry: The laser welding produces thin, deep welds with a "nail" appearance. The MIG welding produces shallow, wide welds that resemble a "wedge". Their performance varies in various conditions of directional stresses.

Knowledge of these fundamental principles illustrates the reason why different processes offer different strength performances.

Faced with complex strength concepts, you need experts who translate them into actual productivity. JS Precision engineers are experts in materials science and welding metallurgy. We possess the ability to select the most suitable process for your custom sheet metal welding manufacturing job in order to avoid strength threats from the outset.

Laser Welding Vs. MIG Welding: In-Depth Comparison Of Strength And Quality

Now let's get to the point and make a direct comparison from various dimensions.

Penetration Capability: Deep Penetration vs. Multi-Pass Welding

- Laser Welding: In thin-medium plates (such as sheet metal welding parts), laser welding possesses an enormous depth-to-width ratio capability for one pass. But in thick plates, it requires very high power, which is uneconomical.

- MIG Welding: It relies on pressure of the arc for penetration. In the case of thick plates, it normally uses groove opening and multi-pass welding. Although speed is low, it can achieve full penetration safely.

In summary: For thin plates, laser welding has a huge advantage. For thick plates, MIG welding is cost-effective and handy.

Welding Speed and Deformation: A Revolution in Speed and Accuracy

- Laser Welding: It has a very high speed and highly focused heat input. This causes very minor total thermal deformation of the workpiece. This is a deciding advantage for accuracy parts and appearance parts (such as chassis and look-alike components).

- MIG Welding: It has a low speed and dispersed heat input. The workpiece shows a tendency towards extreme warping deformation. Subsequently, straightening is required, which increases cost and time.

Appearance and Post-Processing: Art of "Fish Scale Patterns" vs. Pragmatism

- Laser Welding: The welds are usually smooth and flat with lovely "fish scale patterns" or linear look. They have excellent appearance consistency and usually do not require grinding or minimal grinding. They can be used directly for high-end products.

- MIG Welding: Welds are covered with spatter and slag, having a rough appearance. They usually require grinding and slag removal to produce a stunning surface.

Beyond Strength: A Full Comparison Of Cost, Skills, And Applicability

Strength is necessary, but not sufficient. Overall project cost and technical feasibility are also necessary. These have direct bearing on sheet metal welding price structure and workability of the project. The below table indicates the full cost make-up of the two processes.

| Cost Factor | Laser Welding | MIG Welding |

| Initial Equipment Investment | Very high (100,000−1,000,000+) | Low (5,000−50,000) |

| Labor Cost | Low (mechanized operation, high-skilled engineers involved). | High (dependent upon skilled welders, longer working hours). |

| Consumable Cost | Extremely low (no wire to be welded in autogenous welding, gas consumption negligible). | Medium to high (continuous wire and shielding gas consumption). |

| Post-Processing Cost | Extremely low (negligible deformation, satisfactory surface appearance, little or no grinding). | Medium to high (serious deformation requiring straightening, slag and spatter removal essential). |

| Unit Cost (Small Batch) | High. | Low. |

| Unit Cost (Large Batch) | Can be extremely low. | Medium. |

| Optimal Economic Scale | Mass production | Small-run production, prototype building. |

Equipment and Technical Threshold: Automated Intelligence vs. Artisanal Technology

Laser Welding: It is "programmed". It requires high-power lasers, precision robots, expert fixtures, and rigorous safety protection. It requires extremely high technical qualifications for operators and maintenance personnel. Professional engineers are needed for programming and process design.

MIG Welding: It is "hand-welded." Equipment is relatively simple and has minimal workshop environment needs. A skilled welder can master it. It has high flexibility and is very versatile for multi-variety, small-lot production modes.

Material Adaptability: The Picky vs. the Pragmatic

Laser Welding: It is "finicky". It requires absolutely clean joints and small assembly gaps. For highly reflecting materials such as aluminum and copper, special parameters and technological treatments are required. Otherwise, there will be defects.

MIG Welding: It is "practical". It can accommodate minor rust and oil stains on the material surface. It is easier to use under less-than-ideal working conditions and has greater tolerance.

Worried that sheet metal welding price will be beyond your means? Please send your requirements to JS Precision. We provide transparent quotation system for online sheet metal welding services. You can obtain accurate quotations with process optimization suggestions in no time. This allows you to control cost and receive maximum value. Our experts will help you slice the total cost of ownership, not the original quote.

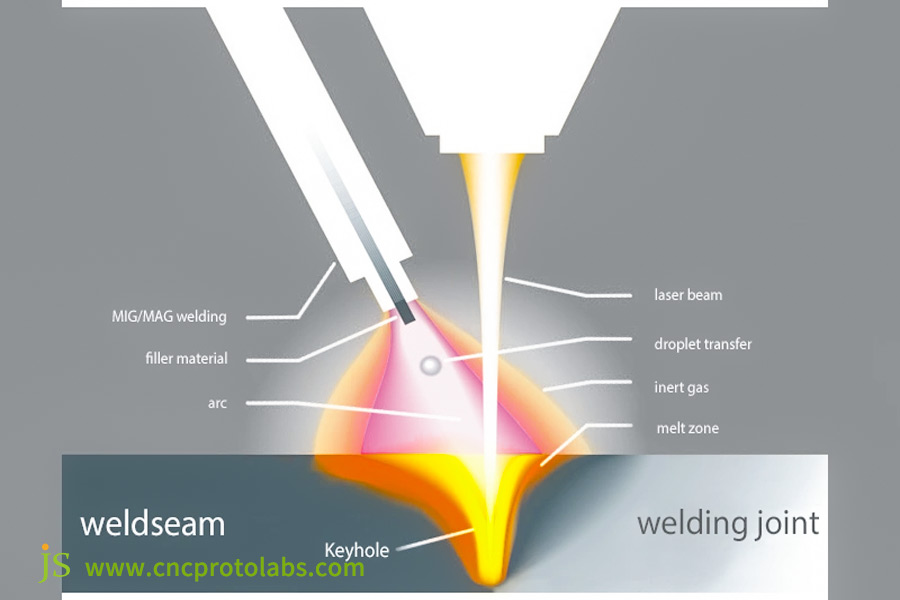

The King Of Welding Dissimilar Metals: Who Can Make "Impossible Combinations"?

In the manufacturing sector, especially in electric vehicles, aerospace, and consumer electronics production, the need for welding dissimilar metals together is now more than ever on the increase. Laser welding is where it's at in such situations. It provides so many answers that traditional welding cannot. The table below is a contrast of the two methods in welding dissimilar metals.

| Consideration Dimension | Laser Welding | MIG Welding |

| Heat Input | Very low | High |

| Cooling Speed | Very rapid | Slow |

| Intermetallic Compounds (IMC) | Little formation, thin layer. | Extensive formation, thick and brittle layer. |

| Joint Toughness | Good | Poor, prone to brittle fracture. |

| Typical Applications | Battery copper-aluminum joints, automotive steel-aluminum body structures. | Not typically suited for high-use dissimilar metal welds. |

| Success Rate and Consistency | High | Low |

Advantages of Laser Welding: Its extremely low heat input and exceedingly high cooling rate can effectively prevent the formation of hard intermetallic compounds at the interface of dissimilar materials such as copper-aluminum and steel-aluminum. This not only guarantees that the welded joint has sufficient strength but also ensures that it contains some level of toughness.

Disadvantages of MIG Welding: Due to its high heat input and slow cooling, it readily forms a thick, brittle intermetallic compound layer at the weld interface. This renders the weld vulnerable to brittle fracture. It is usually not recommended for high-stress dissimilar metal welding.

Therefore, if you are looking for a solution for steel-aluminum battery connection sheets (or aluminum-copper) or steel-aluminum lightweight body vehicles, laser welding is effectively the only choice.

Case Study: The Quest For "Perfect Welds" For High-End Electric Bicycle Frames

Customer Challenge

A high-end electric bicycle manufacturer had to weld the frames of its new model that was made from 6061 aluminum alloy. The requirement was very high in terms of specifications.

The welds were required to be very elegant in order to match the high-end brand image.The strength was required to be very high in order to withstand harsh off-road abuses. Deformation was to be controlled in order to preserve the assembly precision of the subsequent transmission system and battery bay. The tolerance requirements were very high.

Limitations of Traditional Solutions

Conventional MIG welding was used during the prototype period. The strength testing was barely enough, but heat deformation caused minute distortion of the frame.This significantly made assembly much more complicated.

Moreover, the weld appearance was poor and required a lot of grinding. This severely affected production efficiency and product appearance. It could not meet the brand's high-end positioning.

JS Precision's Laser Welding Solution

We purchased a 6kW fiber laser welding robot system and a precision turntable for them to achieve multi-station simultaneous operation. Following the characteristics of 6061 aluminum alloy, the optimal parameter combination was determined by the orthogonal experiment method. The parameters were 3.2kW power of laser, 4.5m/min welding speed, and +0.3mm defocus amount.

A sine wave oscillating weld technology (oscillation amplitude 0.6mm, frequency 200Hz) was used to enhance molten pool disturbance. It enhanced the weld grain size up to 20-30μm. A specially designed profiling argon shielding fixture was used to regulate the local oxygen concentration to less than 50ppm.

This ensured that the weld metal gloss ΔE ≤ 1.5. The interpass temperature was regulated with excellent precision in the range of 80±5℃ by a real-time temperature field monitoring system.

Results

- Strength: The weld withstood 100,000 fatigue cycles (load range 500-1500N). Its tensile strength was 310MPa, or 95% of the base metal.

- Appearance: Welds were flat and smooth, exhibiting uniform fish scale appearances. They became a visual signature of the product and required almost no follow-on processing.

- Precision: Minimum thermal distortion was maintained. Precision of critical mounting holes was maintained within ±0.1mm. Efficiency during assembly was improved by more than 50%.

- Efficiency: 3 times faster welding speed. This provided stability and consistency in mass production.

The customer was eventually able to successfully roll out a high-end product featuring "iconic laser welds". It became a major selling point in the market. It had an ideal balance of strength, appearance, and productivity efficiency.

Does your product also face the triple challenge of strength, appearance, and efficiency as well? JS Precision's custom sheet metal welding manufacturing solution can cope with such complex requirements. We invite you to send special cases and technical consulting. This will bestow on your product a special edge. We're committed to transforming every challenge into your winning edge.

Decision Guide: Five Steps To Secure The Optimum Welding Approach For Your Product

Answer the following five questions and the answers will clearly guide you to the most suitable process for you. This decision tree will allow you to place your direction extremely quickly. It proves useful when you consult through online sheet metal welding services as it allows you to express your needs better.

1.Material and Thickness?

- Thin plates (< 3mm), dissimilar metals, highly reflective materials (aluminum, copper) -> Laser Welding has highest priority.

- Thick plates (> 6mm), carbon steel, materials with contamination or enormous assembly gaps -> MIG Welding would be more suitable.

2.Production Volume and Speed?

- High-volume production, high requirements for production cycle -> The automation advantage of Laser Welding is clear.

- Small-batch production, prototypes, maintenance -> Economic versatility of MIG Welding is better.

3.Quality and Appearance Requirements?

- Low deformation demands, good aesthetic appearance, no or minimal post-processing -> Laser Welding is preferred.

- Low aesthetic requirements, as long as strength meets the standards -> MIG Welding is qualified.

4.Budget Range?

- Sufficient budget for initial equipment investment, seeking minimum unit cost -> Invest in Laser Welding.

- Low budget and low volume production -> Choose MIG Welding or outsource to manufacturers equipped with MIG.

5.Technical Feasibility?

- High-precision and cleanliness requirements are possible by joint preparation -> Laser Welding is feasible.

- Complex working environment, not possible to have perfect joint preparation -> MIG Welding is less stringent.

Expert Tips: Maximise Your Welding Strength And Quality?

Regardless of what process you are employed, then best practice can take the result further.

1.General Best Practices

Joint Preparation is the Key: Properly clean off to remove oil spots and oxide films. Tight assembly and uniform gaps.

Shielding Gas is a Money-Saver: Shielding gas of correct purity (e.g., 99.99% argon) and flow rate are the bottom line for preventing weld oxidation and defects.

2.MIG Welding Optimizations

Optimize the relationship of wire feed speed and voltage to maintain arc stability.

While welding heavy plates, adopt a multi-pass welding strategy. Carefully remove interpass slag in advance to avoid incomplete fusion.

3.Laser Welding Optimizations

Fiber Laser Welding with Filler Wire: For applications with minor gaps or to alter weld composition, adding special filler wire can fill the gaps and increase weld strength as well as toughness.

Parameter Monitoring to Precision: Modulation of parameters such as laser power, welding speed, and defocus amount is the core approach to coping with different materials and geometries.

FAQs

Q1: Simple way to establish whether a weld is performed by Laser Welding or MIG Welding?

Consider three main points.

- Appearance. Laser welds are likely to be extremely thin, elegant, and smooth. MIG welds are wider and may have excess slag.

- Heat-affected zone. Laser welding HAZ is extremely thin and nearly invisible. MIG welding HAZ is much wider and may be stained.

- Spatter. Laser welding will have minimal spatter and the area beyond the weld is spotless. MIG welding will have more spatter points.

Q2: Is Laser Welding really stronger than MIG Welding?

It can't be generalized. In automatic, high-accuracy conditions, for thin and medium plates, the welds of lasers are more homogeneous and higher fatigue strength. That is its inherent strength. But even in static tensile strength, high-quality MIG welds by an excellent welder can also be very strong. So, the strength of laser welding is more in the much higher stability and homogeneity of quality.

Q3: Can Laser Welding be used for maintenance?

Yes, although it is usually reserved for repairing high-value precision components such as molds, aerospace, and medical equipment. It requires extremely high standards for positioning and fixturing of parts. Process development cost is also high. Therefore, by and large, flexible maintenance conditions, it is less economical and convenient as a portable MIG torch for welding.

Q4: Thin-plate and thick-plate are the features of my product. Am I allowed to use both technologies simultaneously?

Absolutely. This is a very smart and economic "hybrid manufacturing" strategy. For example, you can initially use laser welding to complete all precision thin-walled components and welds with strict appearance requirements. Then use MIG welding to assembly-weld the major load-carrying thick-plate structures. JS Precision's engineering staff can evaluate the feasibility and most effective implementation path of this hybrid process on your behalf. This offers you the optimal balance between quality and cost.

Summary

Laser Welding and MIG Welding cannot be substituted for one another. They are two powerful equipment of the new manufacturing arsenal to solve all kinds of problems.

Laser Welding is superior in automated mass manufacturing and high-quality custom sheet metal welding manufacturing with fast speed, accuracy, low deformation, and high fatigue life. MIG Welding is indispensable in prototype manufacturing, low-batch manufacturing, and maintenance engineering due to its versatility, low barrier, and high capability in working on thick plates.

Are you looking for a reliable welding solution for your project? JS Precision offers professional laser welding and MIG welding facilities. Prototype to mass production, we can provide sheet metal welding parts with excellent strength, lovely appearance, and utmost cost-effectiveness.

Contact our engineering experts today for free process analysis and tailored quotations. Make your products competitive due to firm welds!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com