It's a common problem in production: you're about to produce a batch of decorative items in your workshop and can't quite decide whether a piece of metal is bronze or brass. Or when designers are designing exterior walls for seaside buildings, they may struggle with which one is more weather resistant: bronze vs brass.

Bronze and brass, both of which are part of the "copper alloy" clan, may seem rather much alike but are really quite different. Their choice determines the soul, performance, and lifespan of the product.

This book will guide you through this ultimate showdown of red metals, demonstrating how to recognize them in a flash like a material wizard and choose the perfect one for your project.

Core Answer Summary

| Comparison Aspect | Brass | Bronze |

| Core Composition | Copper + Zinc | Copper + Tin (Modern bronze also includes aluminum, silicon, manganese, etc.) |

| Typical Color | Bright golden yellow, similar to gold. | Dark reddish-brown, grayish-gold, similar to old coins. |

| Typical Applications | Ornamental pieces, musical pieces, plumbing parts, cartridge casings, locks. | Bearing, gears, marine parts, sculptures, springs. |

| Corrosion Resistance | Good, especially in freshwater. | Excellent, especially in saltwater and aggressive industrial exposures. |

| Mechanical Properties | Medium strength, good ductility, easily machinable. | High strength, good wear behavior, slightly brittle. |

| Unusual Attributes | Easily machinable, relatively sharp sound. | Self-lubricating and wear-resistant, deep rich tone. |

| Cost Considerations | Generally low (zinc less expensive). | Typically high (tin and other materials are more expensive). |

Why Believe In JS's Material Identification Experience?

Material identification and processing skills are critical to addressing actual issues in the sheet metal fabrication industry, and JS has considerable experience in this field. We have extensive hands-on experience with custom sheet metal fabrication manufacturing and have completed many brass vs bronze projects.

From simple brass fittings cutting and bending to sophisticated bronze curtain wall welding, to precision custom sheet metal fabrication parts, we have developed a mature technical system.

Our engineers are experienced in the properties of various materials, such as H62 brass and C65500 silicon bronze. Our engineers can identify materials accurately by composition and performance testing before processing, repeatedly averting rework caused by errors in material identification.

This manual is an abridgment of our staff's years of hands-on experience with brass vs bronze determination and processing problem solving. Everything that was ever recommended or advised has been tested in real projects and is highly professional and pragmatic.

JS has extensive experience in the field of custom sheet metal fabrication manufacturing, and can accurately identify brass vs bronze and provide processing services. In case you have a query, please submit the project information and we will respond to you in no time to facilitate you to move smoothly through your sheet metal fabrication project.

Beyond Color: Decoding The Composition

To move beyond appearances and be able to distinguish brass from bronze, the answer lies in composition—the basic difference between the two.

Brass has a predominance of copper and zinc, and zinc content typically falls between 10% and 45%. Different contents of zinc give brass different colors: reddish in low-zinc brass, and yellowish in high-zinc brass.

Bronze originally was a copper-tin alloy, but today elements such as phosphorus, silicon, and aluminum are added to produce types such as silicon bronze and phosphor bronze.

This very composition difference results in the performance and production of brass and bronze having distinctly divergent characteristics.

Brass vs Bronze: How Are They Made?

Beyond the knowledge of composition, differences in manufacturing processes for making brass and bronze also take direct importance and affect end performance and application environments.

Brass manufacturing first melts copper and zinc in a furnace at 900 ℃ -950 ℃ in proportion. After the metal is completely melted and mixed evenly, it is poured into a mold and cast into ingots.

Then, it is rolled and stretched to produce sheet metal fabrication parts commonly used, such as plates and pipes. Zinc and copper have close melting temperatures, which makes smelting convenient to regulate and allows for effective large-scale manufacture of brass.

The production of bronze varies depending on the elements introduced. For example, silicon bronze (C65500) requires smelting silicon and copper above 1000°C. The atmosphere during this process has to be tightly controlled in order to prevent oxidation of silicon. After casting into ingots, they are forged and rolled into shape.

Depending on the different properties of the introduced elements, bronze production becomes more complex and affects its range of use and cost of processing.

JS provides online sheet metal fabrication services and is familiar with the manufacturing characteristics of brass vs bronze, and can accurately machine various parts. Simply order online and we will arrange production at once to ensure timely delivery.

Brass Or Bronze? Five-Minute Tips For Rapid Identification Of Metal

Quickly want to know if it's brass or bronze? No need for complex equipment, these tips are sufficient:

First Glance: Color

Brass tends to be a bright golden yellow, such as plain brass doorknobs, bronze tends to be darker, often reddish-brown or dark green, such as bronzy old statues. Be warned, however, that surface treatment may change the color, so this is only a preliminary assessment.

Listen to the Sound: Identify the Tone

Gently strike the metal surface with a little hammer. Brass will sound out with a clear, resonant note and long reverberation, while bronze will produce a dull, short reverberation. This test can be tried at any point during your workshop.

Find the Chips: Find the Texture

If possible, scrape the metal inconspicuously with a tool. Brass chips are small and yellowish in color, and bronze chips are coarse and reddish-brown in color. Bronze chips are also harder, so it will be more difficult to scrape them.

Ultimate Method: Chemical Analysis

If these tests fail, chemical testing must be done. For example, when nitric acid is spilled on the surface of a metal, brass will yield a green copper salt and white zinc salt precipitate, bronze will primarily yield a green copper salt precipitate. However, the process will weaken the metal and should only be done when unavoidable.

| Identification Methods | Brass Performance | Bronze Performance |

| Color | Bright golden yellow | Reddish brown, dark green |

| Sound | Long, crisp echo | Dull, short echo |

| Chips | Fine and yellowish | Rough, reddish brown |

| Chemical Analysis | Green and white precipitates | Mainly green precipitates |

JS is familiar with the most important points of distinguishing bronze from brass and can offer material identification services for your sheet metal fabrication project. You're not sure if the material is right, send us a sample and we'll rapidly test and offer a quote. Sheet metal fabrication price is clear and competitive.

Hardcore Teardown: The Ultimate Performance Showdown

To distinguish brass from bronze, one must highlight performance differences as the major factors that directly determine their applications. The following comparison highlights strength and hardness, and friction coefficient and self-lubricity:

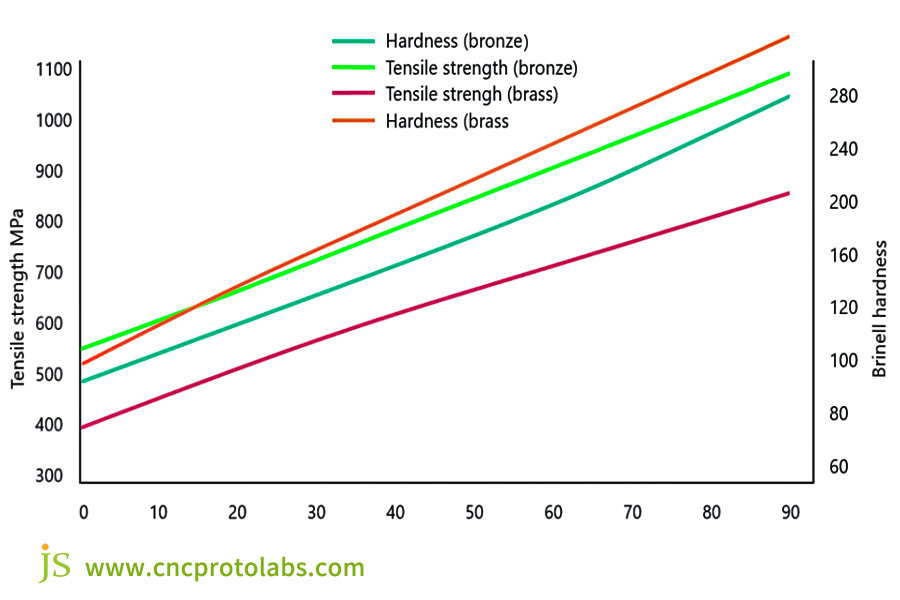

Strength and Hardness

The hardness and strength of brass are all determined by the zinc content. With about 30% of zinc content, it will be of higher strength, and H62 brass gives a Brinell hardness of about 60 HB.

Bronze, on adding other metals such as tin and silicon, is usually of higher strength and hardness. C65500 silicon bronze will give a Brinell hardness of 100-120 HB and is therefore very useful in high-wear and high-strength application.

Friction Coefficient and Self-Lubricity

Brass has a friction coefficient of about 0.3-0.5 in dry conditions and poor self-lubricity and is therefore used in components that do not require frequent sliding.

Bronze (especially phosphor bronze) has low friction coefficient of about 0.15-0.3 and good self-lubricity, reducing wear even without lubrication. It is normally employed in sliding elements such as bearings and gears.

| Performance Measures | Brass (H62, say) | Bronze (C65500, say) |

| Brinell Hardness (HB) | Approximately 60 | Approximately 100-120 |

| Tensile Strength (MPa) | Approximately 300 | Approximately 450 |

| Coefficient of Friction (Dry Condition) | 0.3-0.5 | 0.15-0.3 |

| Self-Lubrication | Poor | Good |

By understanding these performance differences, you can accurately choose brass vs bronze based on the performance requirements of the project.

Shop Floor Perspective: Machinability Differences And Cost Considerations

The machinability differences of bronze vs brass have a direct cost and efficiency impact, and therefore are a significant consideration in material choice.

Brass is ductile and soft, which makes laser cutting easy as well as bending in sheet metal production. It's fast, cuts smoothly, and requires minimal post-processing. H62 brass sheet, for example, can be cut using a laser at more than 1 meter/minute, suitable for batch processing of sheet metal fabrication parts.

Bronze, however, is hard to process because of its hardness and reduced ductility. C65500 silicon bronze is hard to machine and requires additional laser power, 20% slower compared to brass. Bending requires strict tooling and parameters not to lead to deformation. Only phosphor bronze and special materials have good processing characteristics with specific processes.

Regarding cost, H62 brass sheet stands at around $8 per kilogram, while C65500 silicon bronze is around $12 per kilogram.

Brass is highly effective in processing and is low in cost. When performance requirements are not high, choosing brass can reduce the sheet metal fabrication price Though it is more expensive, bronze possesses better weather and wear resistances, reducing maintenance costs in the long term.

JS understands the differences in processability between bronze and brass, streamlining processing procedures and minimizing sheet metal fabrication prices. Whether you require sheet metal fabrication parts processing, we will develop a plan based on the material's characteristics, striking an efficiency and cost balance.

Lifespan Contest: What Factors Influence Their Longevity?

In the choice of bronze vs brass, durability is a key factor in product life, with the following determinants:

Environmental

Under dry conditions, both brass and bronze will form an oxide film to avoid corrosion. But under humid, high-salt, or chemically exposed environments, there are clear differences.

For example, in sea-coastal towns, high salt air can cause "zinc removal corrosion" of brass. This leaches away the zinc, resulting in porous copper having red spots on the surface and with reduced strength. The life of service is typically 5-8 years.

Silicon bronze, on the other hand, forms a stable oxide film, which results in a life of service of 15-20 years.

Composition

The more zinc present in brass, the worse its corrosion resistance. Low-zinc brass has better corrosion resistance than high-zinc brass. The introduction of additives like silicon and phosphorus in bronze results in significantly better corrosion resistance, and silicon bronze enjoys better corrosion resistance than traditional tin bronze.

Surface Treatment

Electroplating, painting, or passivating of brass or bronze creates a protected layer, making it more corrosion-resistant. Chrome plating on brass parts, for example, keeps dezincification corrosion very effectively in check and extends working life in moist conditions.

Understanding these variables will allow you to choose the stronger bronze vs brass based on the project environment.

Case Study: Choosing An Advanced Curtain Wall - Aesthetic, Workmanship, And Weather Resistance Triple Test

Project Background

A seafront city art gallery needed decoration for an exterior wall, comprising many intricate, three-dimensional curved sunshade louvers,and is required to be resistant to high salt corrosion by the seaside (with a lifespan of 20 years+).H62 brass was first selected because its yellowish color matched its artistic quality and ease of curved surface processing.

Manufacturing difficulties and issues arose

During the creation of prototypes, H62 brass proved to be successful in bending and cutting tests. However, during welding, zinc (with a content of 38%) is prone to volatilization, and the weld seam has many pores and a strength of only 60%, which does not meet the structural safety requirements.And it produces toxic smoke, which was not in accordance with environmental regulations.

Dezincification corrosion was observed within three months of simulated testing, with a lifespan of less than 20 years and requiring replacement of materials.

JS's material and process solution

After some testing and optimizations, the JS engineering team recommended the utilization of silicon bronze (C65500) as an alternative:

- Silicon bronze has excellent corrosion resistance with a service life of more than 25 years in marine environments well above requirements.

- Silicon bronze is weldable, emits no significant volatiles, and results in high-strength welds.

For cutting, a 4000W high-power fiber laser cutting machine was used (3000W for cutting brass) to ensure cutting speed and cutting quality with accuracy error not exceeding 0.1mm.

For bending, a special 3D curved mold was used. A CNC press brake was employed to bend stepwise, the accuracy of each step being inspected. This solved the issues of bending due to the low ductility of silicon bronze.

Welding was performed using TIG welding with accurate silicon bronze wire. Regulated temperature and shielding gas flow produced weld strength of over 90% of the parent material, without any toxic fumes.

Final result

Upon installation, the reddish-brown bronze sunshade louver system harmoniously blends in with the museum's artistic design, with the smooth curves that were widely acclaimed by the client as well as the designer. A subsequent full inspection after one year of installation confirmed the silicon bronze louvers to have full resistance to corrosion, a sound and even oxide coat, and unchanged integrity.

This project demonstrates the advantages of silicon bronze in high-end curtain walls and also demonstrates JS Precision Manufacturing's professional capabilities in brass vs bronze material selection and sheet metal fabrication process optimization.

The Art Of Selection: How To Choose The Winner For Your Project

After we've described brass vs bronze, we'll conclude when to choose between the two and help you with picking the "winner":

When to Use Brass?

Brass is more suitable if the application has the following conditions:

- High aesthetic requirements require a bright golden color, such as decorative parts or furniture trim. Brass color can enhance aesthetics.

- There is mostly cutting and bending but no complex welding, such as simple sheet metal fabrication parts. Brass can gain excellent processability and high efficiency, which can reduce sheet metal fabrication price.

- Dry use conditions and lack of extreme conditions like high salt and humidity, e.g., equipment enclosures in buildings. Brass is suitable for economy and durability in dry conditions. For example, for indoor ornamental brass strips, H62 brass can meet these conditions.

When to Use Bronze?

Bronze is better to use if the job meets the following conditions:

- Severe applications, such as beach environments or chemical facilities, require superior corrosion protection. Bronze (especially silicon bronze) is resistant to corrosion and extends lifespan.

- Bronze offers greater hardness and strength for items requiring high wear protection and strength, such as bearings, gears, and curtain wall components, and is able to withstand heavy loads and friction.

- Welding is required and high strength is required for the weld seam,such as large metal structures, bronze is of great weldability and can form high-strength welds. For example, silicon bronze is the best choice for Seaside Museum's curtain wall.

Choosing brass vs bronze is not an absolute binary choice, it's a comprehensive consideration based on the appearance of the project, processing technology, working condition, and cost budget.

JS may recommend the appropriate brass vs bronze material based on project needs and provide custom sheet metal fabrication manufacturing services. Simply provide us with the project details, and we'll balance the pros and cons and recommend the optimal material. We'll also provide transparent sheet metal fabrication prices, so you can easily make your decision.

FAQs

Q1: I've seen some "bronze" products which are very shiny and brass-like in appearance. Why is this?

This is usually brought about by surface treatment, either through electroplating, polishing, or chemical coloring. Chrome plating on bronze parts, for example, gives a shiny metallic look, while fine polishing contributes to the shine as well. Key ways to identify bronze from brass include looking for stamps , weighing, or tapping out of sight somewhere for the sound.

Q2: Is stainless steel a superior option compared to all of them?

Not necessarily. Stainless steel offers superior strength and resistance to corrosion. However, it costs more (about $15/kg), compared to brass ($8/kg) and bronze ($12/kg), which increases the sheet metal fabrication price. It is also difficult to work with and its high hardness results in bad cutting and springback on unwinding after bending. It is also lacking the self-lubricating quality of bronze and the appearance of brass.

Q3: Why do my brass sheets form microcracks on the outer surface after bending?

This is principally due to insufficient material ductility or too small bending radius. Using hard brass has poor ductility and will crack. More suitable for better ductility is half-hard brass or soft brass. The bending radius should be ≥ 1 times the material thickness (1T). For near radius bends, use low-zinc brass (less than 10% zinc content), which offers better bending properties and reduces cracking.

Q4: Why do my brass faucets occasionally form red spots?

This is an indication of "dezincification corrosion" on the brass. When the water comes in contact with the brass. Water oxygen and minerals dissolve the zinc, depositing porous, red copper and creating red spots. Dezincification corrosion deteriorates the structure and could result in leaks and cracks with time. Selecting "arsenic brass" or "low-zinc bronze" can help remedy this issue and make the faucet last longer.

Summary

Brass and bronze, cousins of metal with ancient histories of thousands of years, are even now incapable of being replaced in contemporary industry and art. Having a grasp of the subtle but significant differences between them is the secret to eliminating guesswork and reaching engineering excellence. Remember, there are no "better" materials, only "more suitable" ones.

Confused about selecting materials for your next project? Don't let the wrong decision result in expensive failure. Get advice from our materials experts today for a free consultation and guidance specifically for your application.

Or, provide your part drawing and we'll provide you with a one-stop-shop online sheet metal fabrication services of material selection, processing, and cost savings. We'll provide fast quotes, upfront sheet metal fabrication prices, and standard processing procedures to ensure delivery of quality sheet metal fabrication parts and project completion.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com