Often the problem is not the poor skills of the welder,but the wrong choice of process at the beginning.‘Faster welding' does not equate to 'more suitable welding'.

Summary Of Core Answers:

MIG and TIG welding are complementary processes with no absolute advantages and disadvantages.

| If your primary objective is... | Preferred Process | Critical Cause | Typical Application Scenarios |

| Extremely high welding speed/productivity | MIG welding | Continuous wire feed,high deposition rate | Long weld,heavy plate structural parts,batch production |

| Ultra beautiful/precision weld | TIG welding | Arc concentration,no splash,accurate thermal control | Thin-wall parts,appearance parts,pipes/pressure vessels |

| Wide field construction/adaptability | MIG welding | Good wind resistance,easy automation | Building frame and maintenance of heavy equipment |

| Dissimilar metals/difficult-to-weld | TIG welding | Precise control of molten pool, with or without filler | Aluminum,magnesium,titanium alloys,copper alloys |

This guide will provide you with a clear 3-step decision framework that explores the core principles and differences between MIG and TIG,reveals their best practices in different materials and application scenarios,and demonstrates how professional metal welding services select the best solution for customers through a case study of a medical device housing.

Why Trust This Guide?

At JS,we're not just welders,we're the client's connection engineering partner.

We know that MIG welding is not only about speed but also about evaluating the effect of its heat input on sheet deformation.TIG welding is chosen not only for aesthetics but also for special skills and AC power required on highly reflective materials such as aluminum.

We understand how the metallurgical properties of different alloys affect weld integrity and this is directly related to the ultimate properties of the metal welding parts and the metal welding price.

We have successfully delivered thousands of custom metal welding manufacturing products,from engineering machinery chassis subjected to severe vibration to bioreactor piping requiring zero leakage to sophisticated aerospace components.

We know how to accurately match the most suitable welding process according to material thickness,joint design,performance requirements and cost budgets.This knowledge of metallurgy,thermodynamics and practical experience is our core value.

In precision welding,are you suffering from unstable weld quality and delayed delivery?Select JS for immediate communication and customization of welding solutions.

Wise Choice:Three Decision Frameworks For MIG And TIG Welding

Which one is better?Before that,answer these three key questions first.

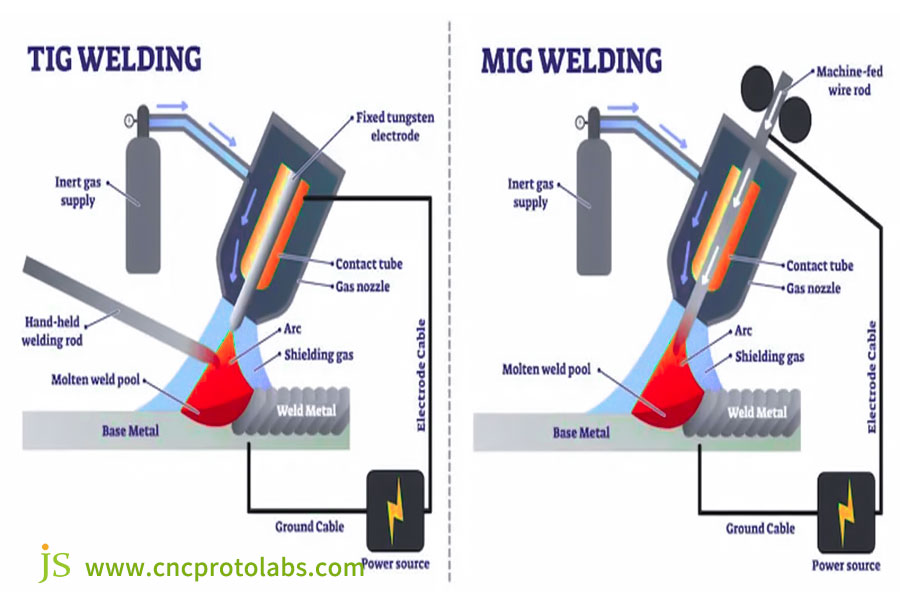

Understanding the Fundamental Differences-Working Principles of MIG and TIG

MIG and TIG are two common welding processes in the field of welding.Their similarity lies in the use of arc and shielding gas,while their essential difference lies in the electrodes used to generate the arc.

To understand the difference between these two processes,you must first understand their working principles.

MIG welding process

MIG uses solid or flux cored welding wire as the electrode,and thin welding wire is continuously fed into the welding gun(sometimes referred to as the welding torch)through a wire.Due to the melting of welding wire during use,this type of electrode is called a consumable electrode.

Generally speaking,MIG welding is performed using semi-automatic or automatic arc welding.

Due to the fact that welding wire is also used as a welding filler material,the diameter and composition of the welding wire may vary.The specific type of welding wire used depends on factors such as metal type,thickness,and joint shape.

In addition,the protective gas used is usually a mixture of 75% argon and 25% carbon dioxide.This mixed gas can promote weld penetration and reduce the porosity of the weld bead.

TIG welding process

TIG welding process also uses electric arc for welding.Unlike MIG,TIG uses tungsten with a high melting point as the electrode.When the welding electrode heats up but does not melt,it becomes a non consumable electrode.

Its welding pool is protected by pure inert gases(helium,argon),usually 100%argon.If carbon dioxide is mixed,it will promote the formation of tungsten oxide and lead to premature wear of tungsten electrodes.

Comparison of Key Process Characteristics-Speed,Quality,Cost,and Operation

From the brief explanation of these two processes,it can be seen that there are significant differences between them.

In addition to these fundamental differences,important welding characteristics such as speed,quality,cost,and operation should be comprehensively compared.

Weld Strength

And if TIG is used correctly,it will keep the weld bead clean and tidy,without producing many holes or other defects that may weaken the welding effect.The fewer defects,the stronger the joint.

If a V-shaped groove is ground or cut on the joint before welding,MIG welding can achieve good penetration.If the welding gun is positioned correctly and moved at an appropriate speed,it can also help form a strong MIG weld.

Welding Speed

In addition,MIG welding machines automatically supply electrode/filling materials,resulting in a rounder and wider arc and better heat dissipation.

Welding Aesthetics

The neat and 'stacked' welding points produced by TIG welding are almost the standard for beautiful welding seams.

Additionally,when the project does not require a perfect appearance,MIG welding machines can be used.MIG is also commonly used on steel that requires painting or on steel welds with coatings.

Learning Difficulty

When using TIG welding,it is necessary to carefully clean and prepare the metal to be welded,ensure proper operation,and avoid cutting corners in order to produce high-quality welds.

Cost

In contrast,MIG welding requires less preparation work and has lower equipment and consumables costs.In addition,the speed advantage of MIG welding also reduces the cost per foot of weld bead.

The following is a comparative analysis of the two summaries:

| Characteristics | MIG Welding | TIG Welding | Winning Scene |

| Welding Speed | ★★★(extremely fast) | ★(slow) | Long weld seam,mass production(MIG) |

| Weld Appearance/smoothnes | ★★(good,may have spatter) | ★★★(excellent,no spatter) | Appearance parts,precision parts(TIG) |

| Heat Input Control | ★★(medium) | ★★★(extremely precise) | Thin plate,thermal sensitive material(TIG) |

|

Learning Difficulty

|

★★★(relatively easy to get started) | ★(difficult,requiring high skills) | Rapid deployment,general maintenance(MIG) |

| Material Adaptability | ★★★(steel,stainless steel preferred) | ★★★(aluminum,titanium,dissimilar metals preferred) | depends on the material |

| Equipment and Consumables Costs | ★★(moderate) | ★★(moderate to high,especially for gases) | Depending on specific needs |

| Environmental Adaptability | ★★★(good wind resistance) | ★★★(good wind resistance) | Outdoor/ventilated environment(MIG) |

Material Adaptability-Steel,Aluminum,Stainless Steel...

Material oriented decision-making:

- Carbon steel/low alloy steel: MIG is the preferred option.TIG is only used for extremely thin parts or root welds with extremely high requirements.

- Stainless steel: TIG welding is an ideal choice for high-quality welds on thin plates,exterior parts,and without back protection requirements.In addition,if you need high productivity,perform ectopic welding,or handle complex joints,using pulsed current for MIG welding stainless steel may be a better choice.

- Aluminum and aluminum alloys: TIG welding(AC)is the absolute first choice for thin plates(<6mm),precision parts,and high-quality requirements(high cleanliness,good control).MIG welding has an advantage in production efficiency for medium thick plates(>3mm)and is commonly used in automotive and marine structures.

- Titanium/magnesium/copper alloy: TIG welding is the mainstream or even the only choice due to its extreme sensitivity to atmosphere purity and heat input.

There is actually no superiority or inferiority between TIG and MIG.Not sure how to choose the process for your project?Hand it over to JS,and we will develop a customized welding plan based on your project requirements and industry standards,optimizing joint strength and ensuring durability.

When To Choose TIG?When To Choose MIG?

MIG application

- Thicker work pieces: MIG welding with continuous wire feeding has significant efficiency and can quickly fill materials in large quantities.Therefore,it is suitable for welding thicker materials or larger work pieces.

- Long weld bead: Due to the fast and efficient nature of MIG welding technology,it is more suitable for situations where the weld bead is long and requires long-term operation.In contrast,TIG welding process requires multiple shutdowns and restarts to replace new welding rods or adjust their positions,increasing the risk of welding defects.

- Difficult position: MIG welding only requires one hand to operate,making it easier to maintain balance in difficult positions.

- Production: MIG welding speed is faster and can fill more solder.When high productivity is required,MIG welding is the preferred method.

- Inexperienced welders: For inexperienced MIG welders,the more accessible MIG process can help them make suitable weld passes for the project.

TIG application

- Thin materials: Compared to MIG,TIG welding is more suitable for thinner metals that are prone to warping and burning through,as they can produce precise and clean welding.

- Experienced welders: Skilled welders often use TIG welding to process aluminum,copper,stainless steel,and other rare metals.

- Fitter or workshop operation: If the operator is not in the working position,the TIG welding effect will be poor.But fitters or workshop operations usually do not exceed the working position,so this type of operation is very suitable for TIG welding.

- Short distance: TIG welding is most suitable for short distance welding,such as pipeline joints.

- Fine or precise work pieces: When the final product must have a beautiful appearance,TIG welding is usually the preferred choice.In addition,TIG welding can also control heat and prevent warping and burning when welding thinner and finer metal parts.

When choosing a technology for your project,you can refer to the differences between the two welding techniques and the advantages of each technique.Whether TIG or MIG,JS can fully leverage its technological advantages to provide reliable and durable welding for your metal parts.

Practical Case Study:Custom Stainless Steel Seal Housing For Biomedical Sensors

Real challenges best test the value of decision frameworks.This case demonstrates how trade-offs can be made.

Project Background:

A medical device manufacturer requires a very small 316L stainless steel housing with 100%air tight welds,clean inner cavities,no oxidation/splashes,and smooth appearance without discoloration.

Challenges and our interventions:

Customer initially considers MIG welding for fast delivery.

JS's Analysis: Applying a 4D Framework.

Material/thickness: 316L stainless steel,wall thickness only 1.2mm->TIG advantage area(accurate heat input).

Quality requirements: air tightness,cleanliness,appearance->TIG advantage area(no splash,good inert protection).

Efficiency: Small size,medium quantity->acceptable TIG(slower than MIG but quality first).

JS's solutions and values:

High-skilled manual TIG welding process with high-purity argon backing protection.

Result: The welding seam perfectly meets the air tightness requirements,the inner cavity is free of any oxidation and discoloration,the outer surface is smooth as a whole,and no complicated post-treatment is required.

Key Takeaway: Although MIG is tempting in terms of efficiency,strict medical grade requirements make TIG the best choice.

Through professional custom metal welding manufacturing decisions,we avoid potential leakage risks and expensive rework,delivering truly reliable metal welding parts.

As the quality management master Edwards Deming said,the selection of process technology is like opening up a road in the forest.Not only consider the difficulty of cutting,but also look forward to the smoothness of the road in the future,i.e.the balance between short-term cost and long-term development.

FAQs

Can I MIG weld aluminum?How does it work?

Authority answer: Yes,but:

- Special pulse MIG power supply.

- Push-pull or high-precision wire feeding system(soft aluminum wire).

- Argon protection.

Is TIG welding really much more expensive than MIG?

TIG welding is typically more expensive per piece man-hour.However,TIG usually saves a lot of costs and time for cleaning splashes,polishing and reworking,especially for precision parts.

The total cost of TIG may be more competitive for low volume,high quality requirements.

Which welding method is more suitable for a novice?

Its continuous wire feed mechanism simplifies operation and is highly tolerant of gun angle and arc length.TIG welding requires two-hand coordination,accurate control of arc length and heat input,and steep learning curve.

OIt is recommended that beginners build confidence from MIG.

Summary

Are you in doubt about process selection for critical metal welding parts?Let professional analysis avoid risks for you!

At JS,we provide metal welding services based on engineering insights.Whether it's MIG vs.TIG decision consultation,or custom metal welding manufacturing,we're committed to providing you with the best solutions.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com