ラピッドプロトタイピングは現代の工業デザインの中核的な原動力となり、概念的な革新と物理的な検証の間に重要な架け橋を築いています。

本質的に、デジタル モデリングは物理的な製造技術と深く融合したもので、抽象的なデザインを具体的かつ測定可能な物理モデルに変換し、製品開発の初期段階で製品の機能、美観、実用性を迅速に検証します。

ラピッドプロトタイピングの意味を理解することは、プロセスの最適化に役立つだけでなく、反復サイクルの加速にも役立ちます。

JS Precision は、ラピッドプロトタイプサービスを提供しており、付加製造 (SLA/DLP など) と CNC 加工技術を統合し、ロボットジョイントプロトタイプの開発において金属複合部品を迅速に反復することで、設計検証サイクルを業界平均の 60% に短縮することに成功しています。

JS は、年間1,000 件を超える非常に複雑な注文を処理してきた経験を活かし、ハイエンド製造におけるラピッドプロトタイピング技術の役割を、実験ツールとしてだけでなく、学際的なコラボレーションによるイノベーションのインフラストラクチャとしても再定義しています。

コア回答の要約

| コアディメンション | 主な回答 | プロジェクトへの価値 |

| コア定義 | ラピッドプロトタイピングは、機能、美観、使いやすさを検証するために、デジタルモデルを物理的なプロトタイプに変換する反復的なプロセスです。 | これは、単に「モデルを作る」だけでなく、研究開発リスクを軽減し、市場投入までの時間を短縮するための中核ツールです。 |

| コアプロセス | 5 つのコアステップ:要件定義 → デジタル モデリング → プロトタイピング → 多次元テスト → 反復最適化。 | プロトタイピング プロセスが効率的かつ目標指向的であることを保証する、実証済みの体系的なフレームワークを提供します。 |

| 技術の選択 | 主にプロトタイプの目的によって異なります。3Dプリントは複雑な形状に適しています。CNC加工は高精度で高強度の機能テストに適しています。 | 適切なテクノロジーを選択すると、コストと時間を最大 30% 節約でき、当社の専門家が最適なソリューションを提供できます。 |

| コスト管理 | コストは材料、人件費、後処理によって決まります。インテリジェントなプロセスプランニングと無料のDFM分析により、効果的な最適化が可能になります。 | JS Precision は、内部効率の最適化により、プロトタイプあたりのコストを業界平均の 60% に抑えることができます。 |

| 最終目標 | 迅速な反復により、最低コストと最短サイクル時間で設計の実現可能性を検証し、大量生産のための信頼できるベンチマークを提供します。 | これにより、重要な決定をより迅速に下し、最も成功する可能性の高い製品の方向性にリソースを集中させることができます。 |

重要なポイント

この記事の詳細を読む前に、私たちの核となる結論と行動ガイドラインを以下に示します。

1. 反復速度が市場競争力を直接決定づける:ラピッドプロトタイピングの核となる価値は「迅速な」反復にあります。設計・テスト・改善サイクルを50%短縮することで、製品をより早く市場に投入し、競争優位性を獲得することができます。

2. 成功は目的の明確化から始まります。プロトタイプの作成に着手する前に、その明確な目的を定義します。コンセプトの証明、機能性のテスト、外観の評価など、どのような目的が考えられますか?これは、技術の選択とコスト管理に直接関係します。

3.CNCプロトタイピングのコストは制御性に優れています。当社と協力して製造可能性の設計分析を行うことで、機能性に影響を与えることなく、構造の最適化と材料の代替によってコストを大幅に削減できます。

4. サプライヤーではなくパートナーを選択する: JS Precision のような優れたカスタム プロトタイプ製造業者は、製造だけでなくエンジニアリングの洞察も提供し、お客様の技術パートナーになります。

5. 見積もり取得は洞察への第一歩: ラピッドプロトタイピングサービスの見積もり依頼は、単に価格比較のためだけでなく、専門家による無料コンサルテーションを受ける機会にもなります。コスト分析の透明性こそが、協力関係の基盤であると私たちは考えています。

ラピッドプロトタイピングの核となる定義は何ですか?

プロトタイピングは、デジタル設計システムを物理モデルに変換し、機能性、美観、実用性を検証する重要なプロセスです。その核心は、製品開発の初期段階で、迅速かつ低コストのラピッドプロトタイプ反復を通じて潜在的な問題を特定し、ソリューションを最適化することです。

プロトタイプとは、単に物理的な物体を製造することではなく、物理的な検証を通してコンセプトと現実のギャップを埋めることです。特に複雑なシステム開発のプロセスでは、図面では表現できない構造上の欠陥、ヒューマンマシンインタラクションの矛盾、あるいは材料の性能限界などが明らかになることがあります。

現代のラピッドプロトタイピング技術は、積層造形とCNC加工技術を組み合わせ、単一材料の限界を打ち破り、金属プラスチックハイブリッド構造の急速成形を実現し、航空宇宙、ロボット工学などのハイエンド分野の現代のプロトタイピングにおける応用境界をさらに拡大します。

ラピッドプロトタイピングの意味をより深く理解したいですか?今すぐ無料の技術相談をご予約ください。カスタマイズされたプロトタイプソリューションをご提供し、製品開発サイクルを加速いたします。

ラピッドプロトタイピングの 5 つのステップは何ですか?

1. コンセプト段階:要件と目標の明確化

市場調査やユーザーインタビューなどを通じて、製品のコア要件が特定され、プロトタイプの機能、性能、コストの限界が決定されます。 この段階では、構造的な実現可能性やユーザーエクスペリエンスといった主要な設計前提を検証するために、ラピッドプロトタイプが必要かどうかを明確にする必要があります。

2. 設計段階:デジタルモデリングと最適化

CADソフトウェアを使用して3Dモデルを作成し、STL/STEPなどの形式でファイルを出力します。 設計者は、パラメトリック調整とシミュレーション解析(例:応力試験、動力学シミュレーション)を通じて設計を最適化し、ラピッドプロトタイピング技術で実現可能かどうかを初期評価します。

3. 構築フェーズ:ラピッドプロトタイピング

プロトタイプを作成するための適切なプロセスと材料を選択します。

- 3D プリント:複雑な幾何学的構造に適しています (例: 感光性樹脂 SLA、ナイロン粉末 SJS)。

- CNC 加工:金属または高精度プラスチック部品 (アルミニウム合金、ABS など) に使用されます。

- ミキシング技術:印刷技術と切断技術を組み合わせて表面品質を向上させます。

このフェーズの中心となるのは、迅速なプロトタイプの効率的な作成であり、通常、最初のバージョンは1 ~ 3 日で完成します。

4. テストフェーズ: 多次元検証とデータ収集

ラピッドプロトタイプの完全テスト:

- 機能テスト:機械特性 (耐荷重性、シーリングなど) と電子システムの安定性の検証。

- ユーザー テスト: UI モデルなどのインタラクティブなプロトタイプを通じて対象ユーザーからのフィードバックを収集します。

- 環境テスト:極端な温度、湿度、振動条件下での耐久性のシミュレーション。

テスト結果は定量的に記録し(変形率や摩耗率など)、設計指標と比較する必要があります。

5. 改善段階:反復的な最適化と最終化

試験データに基づいてCADモデルを調整し、弱点(構造強度の向上や公差の修正など)を的確に最適化します。 ラピッドプロトタイピングプロセスを繰り返し、すべての検証基準を満たすまでプロトタイプの新バージョンを作成します。 最終的なプロトタイプは、金型や設計図面を作成するためのベンチマークとして使用され、量産における一貫性を確保します。

ラピッドプロトタイピングは、テストループを設計・製造することで、従来の開発サイクルを50%以上短縮し、単一イテレーションコストを80%削減できます。特に、医療機器やスマートハードウェアなど、不確実性が高いプロジェクトの迅速な開発に適しています。

一般的に使用されるプロトタイピング モデルの種類は何ですか?

1. コンセプト検証プロトタイピング モデル:コア設計コンセプトは、ラピッド プロトタイピング モデルによって検証されます。ラピッド プロトタイピング モデルは、多くの場合、低コストの材料 (段ボールや発泡スチロールなど) を使用して迅速に構築され、製品の形式やインタラクティブ ロジックなどの基本コンセプトの実現可能性に重点を置いています。

2. 機能プロトタイピングモデル:機械構造の強度、電子システムの安定性、ソフトウェアアルゴリズムの効率など、特定の機能モジュールに焦点を当てたプロトタイピングテスト。通常、3D プリントや CNC 加工などの技術を使用して、主要コンポーネントの正確な復元を実現します。

3. ビジュアルプロトタイピングモデル:外観を主眼に、高精度3DプリントまたはCNC彫刻技術を用いてプロトタイプを作成し、製品の色合わせ、材質の質感、ヒューマンマシン比などを明確に表現します。 コンシューマーエレクトロニクスや自動車内装など、視覚的な要素が重視される分野で広く用いられています。

4. インタラクティブ プロトタイピング モデル:センサーやモーターなどのハードウェア コンポーネントを統合し、基本的な操作機能を備えた物理モデルを構築し、ユーザーがインタラクション プロセス (ボタンのフィードバックや画面のタッチなど) を直接体験できるようにサポートし、インテリジェント ハードウェア開発で広く使用されています。

5. ユーザー テスト プロトタイプ モデル:対象ユーザー グループ向けに設計されたプロトタイプの試用版で、A/B テスト、シナリオ シミュレーションなどの方法を通じてユーザー エクスペリエンス データを収集し、多くの場合、迅速な反復的な最適化と組み合わせて製品の使いやすさを向上させます。

適切なラピッドプロトタイピング技術を選択するにはどうすればよいでしょうか?

中核的な意思決定要因

1. プロトタイプの目的

- 機能検証:機械的負荷がかかる場合は、CNC 加工または金属 3D プリント (SLM など) を優先する必要があります。

- 外観検証:表面の滑らかさを重視する場合は、光硬化型3Dプリント(SLA)またはCNC彫刻を選択できます。

- ユーザーテスト:組み立て時のインタラクションが必要な場合は、シリコン複製またはフレキシブル マテリアル プリント (TPU) が推奨されます。

2. 必要な材料

- プラスチック原型: ABS、PLA(FDM)、ナイロン(SLS)、透明樹脂(SLA)。

- 金属プロトタイプ:アルミニウム合金(CNC)、チタン合金(SLM)、ステンレス鋼(DMLS)。

- 複合材料:炭素繊維強化ナイロン (SLS)、ガラス繊維 (CNC)。

3. 費用予算

- 低コストの迅速な検証: FDM (1 個あたり 10 ~ 40 ドル)、SLA (1 個あたり 40 ~ 80 ドル)。

- 精度要件: SLA (± 0.05mm)、SLS (± 0.1mm)。

- 量産テスト生産: CNC加工(数量に応じて単価が下がります)。

4. 配送時間

- 切実な要件: 3D プリント (1 ~ 2 日)、シリコン複製 (3 ~ 5 日)。

- 精密加工: CNC加工(5〜10日)、金属印刷(7〜14日)。

当社では、これらの要素に基づいてお客様の選択を最適化するために、ラピッドプロトタイピングサービスのお見積りをご提供しています。VDI 3405-2019付加製造品質基準によると、適切な技術マッチングにより、反復コストを30%削減できます。

主流技術と適用可能なシナリオの比較

| テクニカルタイプ | 材質の種類 | 正確さ | 料金 | 生産速度 | 典型的なアプリケーション |

| FDM | PLA/ABS/ナイロン | ±0.1~0.3mm | 低い | 速い | 機能プロトタイプとシンプルな構造コンポーネント。 |

| サービスレベル保証 | 感光性樹脂 | ±0.05mm | 中心 | もっと早く | 外観検査、透明部品、精密部品。 |

| SLS | ナイロン/複合素材 | ±0.1mm | 高い | 中心 | 完全に機能的かつ軽量です。 |

| CNC加工 | 金属/プラスチック | ±0.01~0.05mm | 最高 | 遅い | 大量生産前の高強度テストと最終確認。 |

| シリコン複製型 | シリコン型+PU樹脂 | ±0.2~0.5mm | 低(バッチ) | 速い | プロトタイプモデルと小規模パイロット生産。 |

ご予算とスケジュールをお知らせいただければ、 CNC プロトタイピングのコストを正確に管理できるように、複数のテクノロジーの比較プランをご提供いたします。

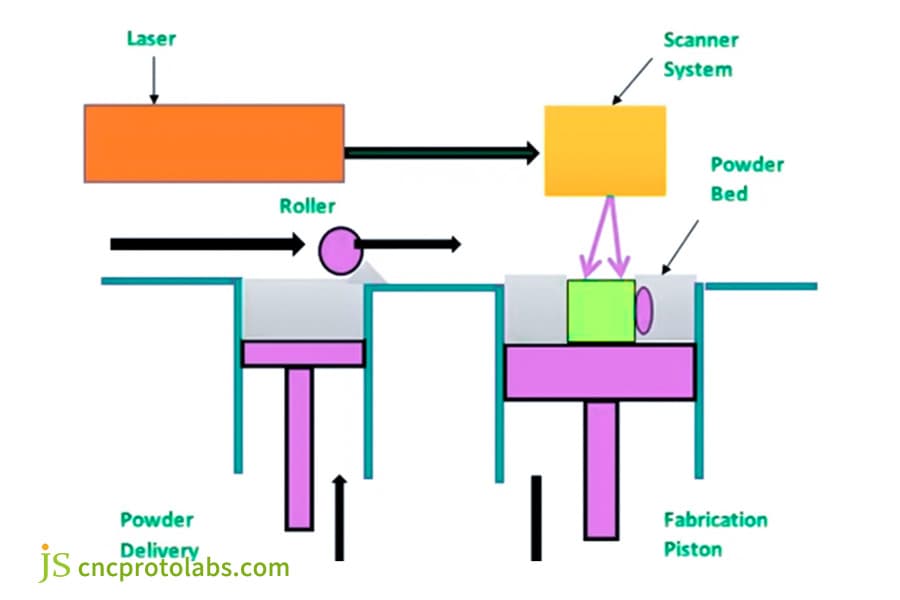

図 1: ラピッドプロトタイピング技術の原理を示す概略図は、粉末床上でのレーザースキャンシステムの層ごとの処理プロセスを明確に示しています。

3D プリントと CNC プロトタイピングの違いは何ですか?

ラピッドプロトタイピングの分野では、3D プリントと CNC プロトタイピングが、製造原理、材料の適用性、プロセス特性が大きく異なる2 つの主流テクノロジーです。

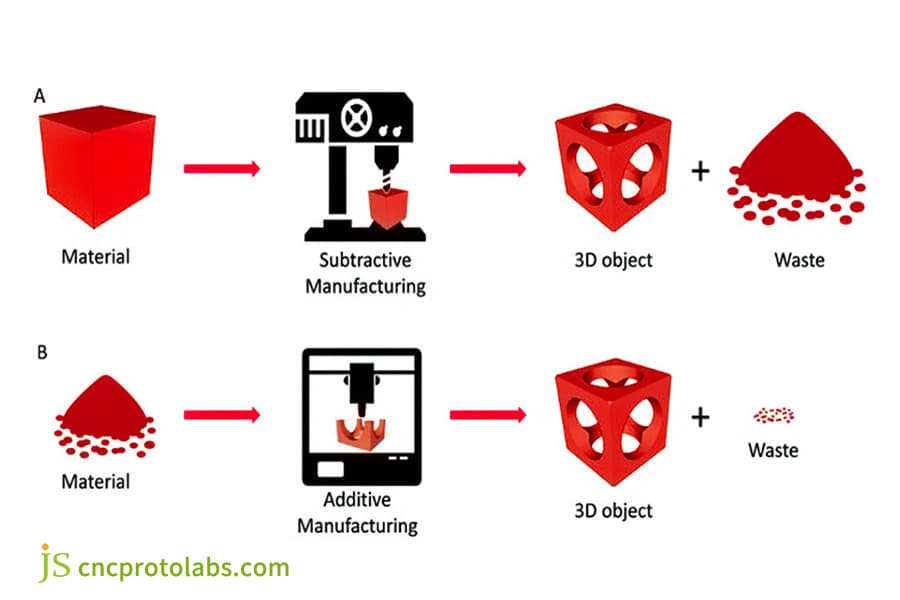

1. 製造原則

- 3D プリント (付加製造): JS Precision は、プラスチックや金属粉末などの材料を層状に積み重ねて 3D を形成することで、複雑な幾何学的構造に金属レーザー溶融 (SLM) 技術とポリマー SLA 技術を活用します。

- CNC加工(減算型製造):工具パスプログラミングに基づいて切削工具で原材料(金属やプラスチックなど)を切削し、余分な部分を取り除きます。高精度な機能部品の製造に適しています。JS Precisionは5軸CNC工作機械を備えており、精密金型鋼、アルミニウム合金などの複雑な輪郭加工を実現できます。

2. 材料の適用性

- 3D プリント: 材料の選択肢は限られており(一般的に ABS、PLA、チタン合金など)、一部の材料は機械的特性が弱いです。

- JS Precision は、航空宇宙グレードのアルミニウム合金や耐高温エンジニアリングプラスチックなど、工業グレードの強度と耐腐食性の要件を満たす 50 種類以上の材料 (金属、プラスチック、複合材料) を提供しています。

- CNC 加工: 幅広い材料適応性があり、硬質合金 (ステンレス鋼、チタン合金など) や高靭性材料 (炭素繊維など) を加工できます。

- JS プレシジョンテクノロジーのハイライト: CNC 設備は複雑な表面加工をサポートし、医療機器向けの 0.02 mm の薄肉構造を実現し、材料処理能力を実証しています。

3.プロセス特性の違い

| 寸法 | 3Dプリントの利点 | CNCの利点 | JS プレシジョンテクノロジーバランスポイント |

| 材料利用率 | 材料の無駄を削減します(必要なものだけ)。 | 材料の無駄が多い(処理手当が必要)。 | JS Precision は、スマートなパス プランニングを通じて CNC の廃棄率を削減し、3D プリントによって金属粉末のリサイクルをサポートします。 |

| 表面品質 | 再加工が必要な表面粗さ(Ra50~200μm)。 | 表面平滑性(Ra0.8~3.2μm)。 | JS Precisionの特殊な後処理装置は、3D プリント部品の表面粗さをRa 1.6 μm に最適化できます。 |

| 処理精度 | ± 0.1~0.5mm(モデルによって異なります)。 | ±0.02~0.1mm(高精度工作機械では±0.005mmまで)。 | エラー補正アルゴリズムを採用し、CNC 加工精度を 30% 向上させ、3D プリントでは熱ベッドキャリブレーションにより寸法安定性を最適化します。 |

| 複雑性への適応性 | 従来のプロセスでは製造できない中空グリッドや不規則な表面などの複雑な構造を製造できます。 | 一般的な形状に適しており、追加の薄壁/サスペンション サポートが必要です。 | JS Precision革新的なハイブリッド製造モデル: CNC 粗加工 + 3D プリントの微細機能、バランスのとれた効率と精度。 |

- 3D プリントを選択:要件が迅速な反復、複雑な構造の検証、または低コストの試行錯誤に重点を置く場合。

- CNC プロトタイピングを選択:機能テスト、高精度の生産準備、または材料性能の検証が目的の場合。

図 2: 積層造形(ラピッドプロトタイピング)と減算造形の主な違いを説明し、材料の蓄積と廃棄物がほぼゼロになるという利点を強調します。

ラピッドプロトタイピング技術に最も依存している業界はどれですか?

JS Precisionのオンライン CNC 加工および 3D 印刷事業の特性に応じて、ラピッドプロトタイピング技術の応用を以下のように分析します。

自動車産業

1. JS 精密技術協会:

- 合理化されたコンポーネントの迅速な反復をサポートするために、軽量のアルミニウム合金/カーボンファイバーのプロトタイプが利用可能です。

- 複雑なパイプライン システムを 3D プリントすると、検証サイクルが 80% 短縮されます。

- 自動車用電子コネクタ金型の CNC 精密加工。

2. 業界の要求:

- 新エネルギー車のバッテリーアセンブリの構造検証。

- 自動運転センサーブラケットの迅速テスト。

- 量産前に内部部品の外観検査を実施します。

航空宇宙

1.JS 精密技術協会:

- チタン合金/超合金のプロトタイプはFAA 認証要件を満たしています。

- 精密鋳造金型の製造により、研究開発サイクルが50% 短縮されます。

- 複雑な空力プロファイルの風洞試験モデル。

2.業界の要求:

- プロトタイプエンジンのタービンブレードの検証。

- 衛星アンテナ展開機構の機能試験。

- 宇宙船のドッキング機構の機械シミュレーション。

医療機器

1.JS 精密技術協会:

- 生体適合性材料のカスタムインプラントプロトタイプ。

- 手術シミュレーター 3D プリント (骨/臓器モデル)。

- 迅速に納品できるカスタマイズされたリハビリテーション機器。

2.業界の要求:

- 人工関節の摩擦特性の検証。

- 歯科インプラントの咬合テスト。

- 圧力分布解析カスタマイズされた矯正器具。

工業デザイン

1.JS 精密技術協会:

- 50 以上のマテリアル ライブラリがコンセプトの検証をサポートします。

- フルカラー3Dプリントされた外観評価モデル。

- 鋳造マスターモールド(シリコンモールド・樹脂モールド)の迅速製作。

2.業界の要求:

- 家庭用製品の人間工学テスト。

- 輸送車両の内部配色の検証。

- ロボットの関節動作シミュレーション。

当社のラピッドプロトタイプサービスは、これらの高需要分野をカバーし、1,000 件を超える複雑な注文に対応してきました。業界の要件をすぐに送信して、業界の専門家との面談をスケジュールし、カスタマイズされたソリューションを入手してください。

業界のリーダーがカスタムプロトタイプ製造業者として JS Precision を選ぶ理由とは?

包括的なカスタムプロトタイプメーカーとして、複雑な問題解決における緊密な連携力とエンジニアリング経験を誇りとしています。私たちは単なる製造サービスプロバイダーではなく、コンセプトから量産まで、テクノロジーパートナーとしてお客様をサポートいたします。

真の「カスタマイズ」を実現するにはどうすればよいでしょうか?

徹底的なニーズ分析:当社はお客様のエンジニアリング チームと緊密に協力し、「何をする必要があるか」だけでなく「なぜそれが必要なのか」を探り、革新的なソリューションを提供します。

マルチテクノロジープラットフォームの統合: CNC加工、3Dプリント、成形、板金加工を行う能力を備えているため、生産能力の制限を考慮することなく、最適な技術ルートを客観的に推奨することができます。

強力なプロジェクト管理と技術サポート:スムーズなコミュニケーションと問題の迅速な解決を確保するために、各プロジェクトにアカウント マネージャーが割り当てられます。

ケーススタディ:医療機器メーカー向け高密閉シェルプロトタイプのカスタマイズ

課題:顧客は、複雑な内部流路と高い耐圧性を備えた透明なシェルのプロトタイプを必要としており、生体適合性があり、完全に透明で、高度に密閉された材料を必要としています。

JS Precisionのカスタマイズソリューション:特定のプロセスに縛られることはありません。最終的なソリューションは、寸法精度とシーリング面を保証する高精度CNC加工ボディと、フォトポリマー3Dプリントによる内部部品を統合したもので、一体成形により組み立て工程を削減します。

結果:プロトタイプは最初の試みで圧力テストに合格し、クライアントの検証時間を少なくとも2週間短縮しました。ここにカスタムプロトタイプメーカーの真の価値があります。

複雑なカスタマイズのニーズがありますか?プロジェクトの課題をお知らせいただければ、無料のケーススタディにお申し込みいただき、業界のリーダーが当社を通じてどのようにコストを削減できるかを知ることができます。

図3:カスタマイズされた高密閉シェルのプロトタイプ

プロトタイプ製造のコストを管理するにはどうすればよいでしょうか?

ラピッドプロトタイピングのコスト管理には、材料、生産、生産後のメンテナンスなどの要素を総合的に考慮する必要があり、 主な戦略は次のとおりです。

| 指標 | 業界平均 | JS Precisionテクニカル指標 | 振幅を増やす |

| 単一プロトタイプのコスト | 120ドル | 72ドル | 40% ↓ |

| 初回利回り | 68% | 91% | 34%↑ |

| 環境影響要因 | 0.72(エネルギー消費量/汚染度が高い) | 0.35(グリーン製造) | 51% ↓ |

| 材料利用率 | 45%~60% | 85%~92% | 35%~50% ↑ |

| 処理サイクル | 12~24時間 | 6~18時間 | 30%~50% ↓ |

| スクラップ率 | 8%~15% | ≤1% | 85%-94% ↓ |

| 人件費の割合として | 25%~35% | 12%~18% | 30%~45% ↓ |

| メンテナンス費用(10,000/年) | 15~25歳 | 8~12歳 | 40%~55% ↓ |

JS Precision社のコスト管理の中核技術

1. 材料リサイクルシステム

- 金属粉末リサイクルラインを構築(SLM工程廃粉末再利用率92%)

- エンジニアリングプラスチック再生粒子技術を開発(ABS/PCリサイクル材料の性能保持率90%以上)

2. インテリジェントなプロセス最適化

- AIパラメータ推奨システム:履歴データに基づいて最適な処理パラメータの組み合わせを自動的に選択します。

- 動的切削力補正:工具の摩耗を減らし、工具寿命を 3 倍に延ばします。

3. デジタル品質管理

- オンライン座標測定: 初回検査時間が2 時間から 15 分に短縮されました。

- デジタル ツイン アナログ: 潜在的な設計上の欠陥の 87% が早期に特定されます。

4. グリーン製造技術

- ドライカット技術: クーラント使用量を 100% 削減し、エネルギー消費量を 28% 削減します。

- 低温焼結プロセス: 焼結温度が従来の 1200°C から 600°C に低下し、エネルギーが 45% 節約されます。

5. 柔軟な生産システム

- 高速金型交換装置: CNC 金型交換時間は 4 時間から 30 分まで。

- インテリジェントな倉庫管理: 資材回転効率が 60% 向上しました。

ISO 14001:2015環境マネジメントシステム規格に基づき、当社のグリーン製造プロセスは環境影響要因を51%削減します。詳細なコスト分析表をご希望ですか?今すぐカスタマーサービスにご連絡ください。コスト削減・効率改善プランを無料でカスタマイズいたします。

よくある質問

1.プロトタイプの製作にはサポート構造の追加が必要ですか?

試作製造においてサポート構造を追加するかどうかは、プロセスの種類によって異なります。 例えば、FDMやSLAを用いてサスペンション構造を印刷する場合、変形を防ぐために仮のブラケットを追加する必要があり、完成後は取り外して研磨する必要があります。 粉末の自立性により、SLS技術では通常追加のサポートは必要ありませんが、表面の滑らかさに影響を与える可能性があり、再処理が必要になります。

2.ラピッドプロトタイピングの表面が粗い場合はどうすればいいですか?

ラピッドプロトタイピングにおける粗い表面は、研磨、サンドブラスト、化学研磨などの処理が可能です。 例えば、3Dプリント部品では、サンドペーパーや化学薬品を用いて層状のパターンを除去し、CNC加工と研磨によって平滑性を向上させ、機能要件や外観要件を確実に満たします。

3.試作品の製作にはどのくらい時間がかかりますか?

試作の製作時間は、工程や複雑さによって異なります。シンプルなプラスチック部品(FDMなど)は数時間で完成しますが、金属部品や精密構造(CNCなど)は1~3日、後処理(研磨/コーティング)は1~2日かかります。 小ロットのカスタマイズや複雑な設計の場合は、製作サイクルが長くなる場合がありますので、具体的な要件については事前にご相談ください。

4.プロトタイプをそのまま量産に使用できますか?

通常、プロトタイプは量産開始前に調整が必要です。 例えば、3Dプリント部品の場合は金属などの量産材料の置き換えが必要になる場合があり、CNCプロトタイプの場合は金型の最適化が必要になる場合があります。 直接変換すると性能やコストの問題が発生する可能性があるため、段階的な検証が推奨されます。

5.正確な見積もりをもらうにはどうすればいいですか?見積もりは無料ですか?

A5: 3Dファイルをオンラインでアップロードしていただくだけで、材料費、人件費、後処理費など、透明性のある価格をご提示いたします。お見積もりはすべて無料で、ご契約は一切不要です。明確な費用設定こそが、あらゆるコラボレーションの第一歩だと考えています。

6. 最低注文数量の制限はありますか?1個からの試作品も製作できますか?

最小発注量(MOQ)に制限はありません。単品プロトタイプから小ロットまで、数量に関わらず、お客様のイノベーション検証をサポートすることに注力しています。

7.設計図や知的財産はどのように保護されますか?

私たちはクライアントの知的財産保護を生命線と考えています。プロジェクト開始前に、法的拘束力のある秘密保持契約を締結することも可能です。当社のデータ管理システムはISO認証を取得しており、お客様のデザインは絶対的に安全です。

8.コスト削減に役立つ設計最適化係数 (DFM) を提供していますか?

はい、お問い合わせごとに無料のDFM分析を実施いたします。弊社のエンジニアが製造性、コスト効率、パフォーマンスの最適化をご提案し、初期段階からコスト削減を実現します。

まとめ

現代の製品開発プロセスにおいて、ラピッドプロトタイピングは、プロトタイピングモデルの反復によって、コンセプトから現実への変革パスを再定義します。積層造形法であれ、減算型プロセスであれ、ラピッドプロトタイピングの核心は、最小のコストと最短サイクルで設計の実現可能性を検証し、イノベーションのループサイクルを加速することです。

消費者向け電子機器の洗練された外観から航空宇宙分野の高性能コンポーネントまで、ラピッドプロトタイプ技術は、複雑な構造を視覚化し、機能をテスト可能にすることで、材料とプロセスの限界を押し広げ続けています。

将来、プロトタイピング モデルは、企業が市場の不確実性に対処し、業界のイノベーションを継続的に俊敏性と精度へと推進するための戦略的ツールになるでしょう。

あなたの創造性は、可能な限り最もプロフェッショナルな方法で現実化されるに値します。

3D設計ファイルを今すぐアップロードして、ラピッドプロトタイピングサービスのお見積りをご依頼ください。当社の専門チームが、コンセプトから完成品まで、プロジェクトがスムーズに進むよう、プロセス全体を通してサポートし、市場における成功への道筋を導きます。

免責事項

このページの内容は情報提供のみを目的としています。JS Precision Servicesは、明示的または黙示的を問わず、情報の正確性、完全性、または有効性について、いかなる表明または保証も行いません。第三者サプライヤーまたはメーカーが、JS Precisionネットワークを通じて性能パラメータ、幾何公差、特定の設計特性、材料の品質および種類、または製造技術を提供すると推測しないでください。これは購入者の責任です。部品の見積もりが必要な場合は、これらのセクションの具体的な要件をお知らせください。詳細については、お問い合わせください。

JSプレシジョンチーム

JS Precisionは、カスタム製造ソリューションに注力する業界をリードする企業です。20年以上の実績と5,000社以上の顧客基盤を有し、高精度CNC加工、板金加工、 3Dプリント、射出成形、金属プレス加工、その他ワンストップ製造サービスに注力しています。

当社の工場には、ISO 9001:2015認証を取得した最先端の5軸加工センターが100台以上あります。世界150カ国以上のお客様に、迅速、効率的、かつ高品質な製造ソリューションを提供しています。少量生産から大規模なカスタマイズまで、お客様のニーズに最速24時間以内の納品で対応いたします。JS Precisionをお選びいただくことは、効率性、品質、そしてプロフェッショナリズムの選択を意味します。

詳細については、当社のウェブサイトをご覧ください: www.cncprotolabs.com

リソース