Prototype CNC machining often faces extreme challenges in the manufacturing of high-end product prototypes such as microsensors for medical devices and precision connectors for aerospace:

In terms of precision in machining threads that are 10mm deep in holes of diameter 1.6mm along with an error tolerance of ±2μm, because once the threads are not properly done, the entire set of prototypes would fail in functional testing.

What kind of manufacturing nightmare do you face when your product prototype needs to process precision threads with depths several times the diameter in hair like thin holes? Small-diameter deep hole tapping is one of the identified top problems for prototype CNC machining, which directly affects the functionality and testability of high value-added prototypes.

This article will examine this challenge and reveal cutting-edge CNC machining technology that guarantee precision threading tolerances and offer a guide to ensure that only superior prototype CNC machining services are used to guarantee success on the first attempt at your critical prototypes.

Core Answer Summary

| Core Issues | Technical Points | Business Value |

| Challenges of Small-Diameter Deep Hole Tapping | Removal of chips, susceptibility to tool breakage, inadequate cooling, ratio of depth to diameter greater than 5 and diameter of hole less than 3mm are critical boundaries of this process. | Even grasping the difficulties can help to avoid prototype failure and reduce development time. |

| Value of High-Precision Thread Tolerances | Adherence to tolerances specified by ISO 965 (6H grade) ensures reliable connectivity. | Micron-level precision eliminates potential design changes that could occur during mass production. |

| Advanced Technology and Process Solutions | High-pressure center-outlet tapping, high-speed tapping, peck tapping, and thread milling. | The presence of the above advanced technologies ensures the qualification of prototypes. |

| Selection Criteria for Professional Suppliers | Assess equipment, case studies, CMM quality control, and DFM. | Quality partners speed up your product development cycles. |

Key Takeaways:

- Small deep hole tapping is the ‘litmus test’ for the prototyping phase because it determines the effectiveness of functional testing based on its success or failure.

- Precision Equals Performance: Precision threading tolerances must be precisely stated and upheld, it is the numeric limit for the reliability proof of the prototype.

- Technology Defines Boundaries: High-pressure cooling and high-speed spindles are required to help solve problems of chip removal and cooling, and where hard materials or deep small holes are involved, thread milling provides a better method of cutting.

- Choice is Strategy: In prototype CNC machining, your supplier should have the skills set and facilities to overcome problems like these at the cutting-edge of technology. JS Precision is an expert in this type of challenge.

Why Choose JS Precision? Prototype CNC Machining Deep Hole Tapping Guide

Providing high-end prototype manufacturing as a CNC machining expert, the ultimate mastery of the cutting-edge process lays the core competitiveness for JS Precision and is also the core pillar of our professional credibility.

Equipped with ultra-high-speed Swiss-imported spindle (up to 60,000 RPM) with radial runout ≤1μm, we boast a high-pressure center cooling system with 100 Bar to solve precisely chip removal and cooling problems.

Within the last three years, we have completed more than 2000 small deep hole tapping projects for over 500 medical and aerospace customers, processed to the ISO 13485:2016 standard. Projects included difficult-to-machine materials like titanium alloys and high-temperature alloys. Challenging tapping projects with a depth to diameter ratio >8:1 achieved 100% delivery.

With more than 8 years of average experience in prototype machining, our engineering team will support you through the full process, starting from DFM design optimization to precision inspection. We shortened clients' prototype development cycles by as much as 40%, which saves tens of thousands of dollars on trial-and-error costs.

If you are struggling with a small deep hole tapping project, contact JS Precision's engineering team immediately. Provide your material, thread specifications, and tolerance requirements, and you will receive a customized solution within 24 hours. Let our professional team help you mitigate risks and accelerate product launch.

What Is Prototype CNC Machining? Why Are Tiny Deep Hole Threads So Important?

Prototype CNC machining plays a very important role from design to mass production. Small deep hole tapping, as a core process, directly determines the effectiveness of the prototype functionality.

Prototype CNC Machining: A Bridge from Digital Model to Physical Verification

In other words, CNC machining prototype is a rapid manufacturing of parts using precision computer-controlled cutting of solid blanks for design verification and functional testing. Its core value lies in high fidelity, material authenticity, and rapid iteration, therefore, it is one of the most important applications for CNC machining during the development phase.

Critical Points and Common Challenges of Tapping Small-Diameter Deep Holes

The term "small deep holes" stands for threaded holes whose diameter < Φ3mm and whose depth to diameter ratio > 5:1. Machining of small deep holes faces three major challenges:

1.Chip Hell: Chips easily accumulate and clog in confined spaces, causing a sudden spike in spindle torque and directly damaging the thread profile.

2. Tool Hell: Slender taps have extremely poor rigidity, easily vibrating during machining, and may even break instantaneously, making them impossible to remove.

3. Ineffective Cooling: Traditional external cooling methods cannot deliver coolant to the cutting edge, leading to continuous heat accumulation, workpiece deformation, and rapid tool wear.

How to determine if a part has reached the critical point for tapping small deep holes? Submit your 3D drawings, and JS Precision will provide a free feasibility analysis, along with a complimentary "Prototype CNC Machining Small Deep Hole Tapping Pitfall Avoidance Guide".

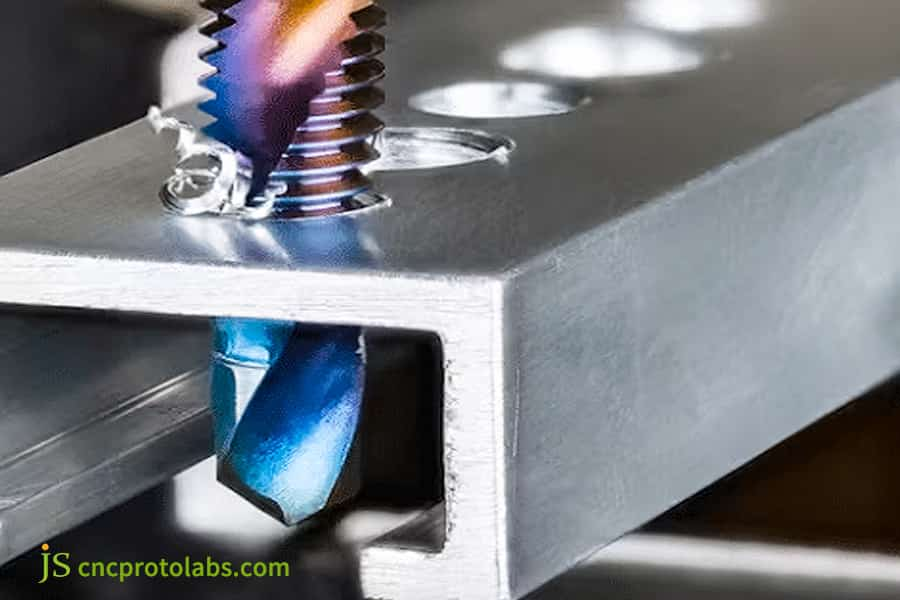

Figure 1 A tap is inserted into a drilled hole illustrating the tapping process in machining.

Why Does' Almost 'Tapped Hole Tolerance Ruin Your Functional Prototype?

The precision tapped hole tolerance represents the “lifeline” of prototype functional verification. Small tolerance variations can cause a failure of the development process as a whole.

Demystifying Precision Thread Tolerances: The Direct Link Between ISO 965 Standards and Functionality

Precision thread tolerances (such as 6H grade) are within the deviation range specified in ISO 965-1:2013 to ensure uniform pre tightening force of the mating parts, guarantee anti vibration, fatigue strength, and sealing performance. Exceeding the tolerance will result in distorted test results.

The Cost of Uncontrolled Tolerances

If the tolerances are uncontrolled, a number of chain reactions would occur.

- It would result in the failure of the prototype assembly process. Consequently, it would result in the disruption of the functional testing process.

- Worse still, it would result in it being difficult to attribute the issue of whether it is a design issue or a manufacturing issue.

- It would result in unnecessary design changes, which would result in the waste of weeks and tens of thousands of dollars.

Below is a comparison table indicating the effect of the different grades of tolerance:

| Tolerance Grade | Application Scenarios | Fit Accuracy | Failure Risk | Test Validity |

| 6H (Precision Grade) | Medical and Aerospace Key Components | Extremely small clearance, uniform preload | <0.5% | 99%+, reliable data |

| 7H (General Grade) | General Mechanical Parts | Moderate clearance | 5%-8% | Approximately 85%, potential for misjudgment |

| 7H (General Grade) | Non-critical Connections | Larger clearance | >15% | <70%, cannot reflect the true design |

How To Use Cutting-Edge CNC Machining Technology To Overcome Small Diameter Deep Hole Tapping?

In view of the small deep hole tapping, only advanced CNC machining technology will be able to solve the problem fundamentally, ensuring its quality and efficiency.

High-Pressure Penetration Cooling System

The core solution is the high-pressure center-outlet water spindle with 80-100 Bar. The coolant directly reaches the cutting zone to provide powerful chip removal and cooling of the tool. This is a must-have technology when machining viscous materials, which can extend tool life by more than threefold.

Ultra-High Speed and Ultra-Precision Spindle

High speeds of 40,000-100,000 RPM reduce cutting forces and load on the tool. Spindle radial runout ≤1μm to quality hole wall and thread integrity enhances tool life.

Pecking Tapping and Adaptive Control

Pecking tapping removes chips through segmented advance and retraction, solving the chip removal problem. Adaptive control monitors torque in real time, automatically retracts the tool in case of an anomaly for the protection of the workpiece and tool, achieving reliable machining.

Need a compatible CNC machining technology solution? Call the JS Precision technical hotline, specify your material and thread specifications, and a process engineer will tailor a solution for you.

When Should We Give Up Traditional Threading And Choose Precision Thread Milling Services?

Precision thread milling services represent the superior method in certain applications compared to conventional tapping, which has up until now provided a dependable alternative in the machining of small-diameter deep holes.

Thread Milling Principle

Thread milling is a method of machining. Through the three-axis linkage movement of CNC, the milling cutter moves along a helical path to "carve" threads.

Because the diameter of the tool is smaller than the diameter of the thread hole, the chips can be discharged laterally and can fundamentally avoid the "struggle for survival" of chip clogging in tapping. This is an advanced process to handle complex threads in prototype CNC machining.

Overwhelming Advantages and Application Scenarios of Thread Milling

Thread milling has three core advantages over conventional tapping:

1. High flexibility: A tool can machine threads of different diameters and pitches, reducing tool costs.

2. High quality: Lower cutting force and less thermal deformation give a much better thread surface finish, Ra<0.8μm, and accuracy consistently reaches 6H tolerance.

3. High Reliability: Due to no reverse tool retraction process, there are no risks of chip breakage and clogging, thus making the process highly suitable for blind holes and deep small-diameter holes.

Here is a key comparison table between thread milling and conventional tapping:

| Comparison Dimensions | Conventional Tapping | Thread Milling | Advantages | Applicable Differences |

| Chip Removal | Poor, prone to clogging | Good, lateral chip removal | Thread Milling | Choose milling for depth-to-diameter ratio > 5:1 |

| Tool Life | Short, 50-100 holes | Long, 500-800 holes | Thread Milling | Choose milling for hard materials |

| Machining Accuracy | Medium, 7H grade | High, stable 6H grade | Thread Milling | Choose milling for precision prototypes |

| Equipment Requirements | Ordinary spindle | High-precision three-axis linkage | Conventional Tapping | Choose tapping for simple threads |

| Scrap Rate | 5%-10% | <1% | Thread Milling | Choose milling for small batch prototypes |

Want to see more success stories of Precision thread milling services? Visit JS Precision's case library now to browse similar project solutions in the medical and aerospace fields, or contact us for detailed technical parameters and machining videos.

Figure 2 Thread milling is a process that uses rotating cutting tools to machine threads along the thread path.

Figure 2 Thread milling is a process that uses rotating cutting tools to machine threads along the thread path.

Which Industries Require Professional Small Diameter Deep Hole Tapping Prototype CNC Machining Services The Most?

Prototype CNC machining services related to tapping small-diameter deep holes are indispensable in high-precision industries such as medical, aerospace, and high-end electronics.

| Industry | Material | Thread Specification | Aspect Ratio | Tolerance | Annual Demand |

| Medical Devices | Ti-6Al-4V, 316L | M1.2-M2.5 | 5:1-8:1 | 6H+ | 800-1200 cycles |

| Aerospace | Inconel 718, TC4 | M2-M3.5 | 6:1-10:1 | 6H | 500-800 cycles |

| High-end Electronics | 6061 Aluminum, PEEK | M1.6-M2.0 | 4:1-6:1 | 6H-7H | 1200-1500 cycles |

| Precision Instruments | SUS304, H62 | M1.0-M1.8 | 5:1-7:1 | 6H | 700-900 cycles |

Why do they choose to outsource to professional service providers?

The companies in these sectors make use of the prototype CNC machining services outsourcing for the following reasons:

- They don’t possess equipment such as ultra-high-speed, high-pressure cooling systems.

- They cannot afford the cost of trial and error in micro-tools.

- They require the supplier's expertise in Design for Manufacturability, which can help them in designing parts with respect to CNC machining.

Case Study: Conquering M1.6x10 Deep Hole, JS Precision Assists In Zero Defect Delivery Of Miniature Sensor Prototype

Tackling small-diameter deep holes is a true test of prototyping CNC machining capabilities. The following case showcases JS Precision's technical prowess.

Challenge

A certain aerospace company requires a pressure sensor housing made of 17-4PH stainless steel (H1100, HRC 40-45), with M1.6 × 10mm threads (depth to diameter ratio>6:1) to be machined, with a tolerance of 6H level and 100% pass stop gauge testing. The first batch of 5 pieces will be used for rigorous vibration testing.

JS Precision Solution

The engineering team of JS Precision, after making an in-depth analysis, came up with a customized solution of machining:

1. Process Selection: Considering the high hardness of the material and the large depth of the hole, traditional tap tapping is abandoned and precision thread milling services are adopted to avoid cutting and chip removal problems at the root.

2. Tools and Parameters: Custom-made ultra-fine particle carbide thread milling cutters (0.8mm diameter), in combination with ultra-high-speed cutting (45,000 RPM) with micron precision in feed rates (0.005mm/tooth) and oil mist for minimizing thermal deformation.

3. Quality Control: Apart from performing 100% go/no-go gauge inspection of the threaded parts, high magnification optical projection was carried out to analyze and measure their thread profile, and CMM Coordinate Measuring Machine was employed to verify the value of its pitch diameter deviation.

Results

Finally, all 5 prototype parts from the first batch successfully passed the test with a surface finish of Ra < 0.8μm on threads, while the deviation of the pitch diameter is within ±1.5μm. The customer's vibration test passed in one go, with no signs of looseness at the threaded connection, fully meeting the requirements for use in aerospace environments.

The entire project from confirming the drawing to receiving an accepted prototype in hand just took 5 working days, saving our customer more than 3 weeks of trial-and-error effort.

Want to achieve zero-defect delivery for your small-diameter deep hole tapping project? Contact JS Precision now, tell them your project challenges and requirements, and we will replicate our successful experience, providing full-process support from process design to quality inspection, allowing your prototype development to avoid detours.

Figure 3 Pressure sensor with installation thread

Figure 3 Pressure sensor with installation thread

How To Choose The Right CNC Machining Prototype Partner For Your Project?

Choosing the right CNC machining prototype partner can accelerate product development. A four-step evaluation method helps you accurately select the right partner.

Four-Step Evaluation Method: A Comprehensive Review from Equipment to Communication

A good partner for CNC machining prototype, besides doing the machining, looks into risks, optimizes designs to save costs and improve efficiency, and shortens time to market.

- Technical Consultation: Verify high pressure spindle speed, maximum speed, and so on.

- Quality Verification: Verify thread inspection processes (go/no-go gauge or CMM) to prevent possible quality concerns.

- In-depth Process Analysis: Inquire about the material adaptation process and reasons, and assess the ability to propose solutions.

- Collaboration Assessment: Evaluate them for their active proposal of Design for Manufacturing when evaluating the potential of their collaboration.

Beyond Processing: Treating Suppliers as Strategic Extensions of Development Teams

The ideal CNC machining prototype partner must not only be capable of machining, but also be able to offer early warnings, or solutions for alternatives and design optimization. The early warning refers to early warnings about risk, while design optimization is about optimizing designs.

FAQs

Q1: What are the most commonly used materials for tapping small-diameter deep holes? Which are the most difficult to machine?

For tapping small diameter and deep holes, stainless steels (and their varieties like 304 and 316) and aluminum alloys are chiefly employed. Titanium alloy stocks, high temperature alloy stocks, and quenched mold steels are the most difficult to machine, since their cooling efficiency and tool performance requirements are extremely high.

Q2: What hole depth is considered a "deep hole," and what special processes are required?

For tapping, a ratio of depth to diameter above 3:1 calls for delicate tapping, whereas above 5:1 demands special tapping operations such as peck tapping or milling.

Q3: How do I specify the requirements for small threaded holes on my drawings?

The drawings must show clearly: thread specification (for example M2x0.4), tolerance grade (for example 6H), effective thread depth, hole bottom type (flat bottom hole or drill tip), and material and heat treat status.

Q4: Which is more expensive, thread milling or traditional tapping?

In terms of single piece tooling cost, thread milling cutters are considered to be costlier. But taking into consideration factors like tool life, reliability, flexibility, and scrap rate, thread milling might have a less total cost for deep-hole machining of hard materials or prototype machining.

Q5: How to ensure the quality of the pilot hole before tapping small deep holes?

In order to ensure a quality pilot hole, a high-precision, high-rigidity drill bit should be employed, with drilling carried out in a peck drill cycle, provided that a sharp cutting edge of the drill bit is maintained. These are very important prerquisites for tapping holes. The verticality and diameter accuracy of the bottom hole are important prerequisites for successful tapping.

Q6: What are the remedies if a tap breaks inside the hole?

After a tap has broken, it is possible to use the EDM (Electrical Discharge Machine) for cutting off the broken portion. However, it is a time-consuming process. In actual practice, it is best to avoid breaking before it happens.

Q7: How to verify whether the high precision claimed by the supplier is genuine?

The solution to the challenge of verifying high precision lies in requiring the manufacturer to check their inspection results for threads of comparable specifications, particularly the thread pitch diameters as measured by the CMM, instead of just being satisfied with the claim "go/no-go gauge passes."

Q8: What unique advantages does JS Precision have in handling such difficult problems?

JS Precision is equipped with Swiss-grade ultra-high-speed spindles (up to 60,000 RPM) and high-pressure cooling systems. It boasts numerous successful cases in small-diameter deep hole tapping for the medical and aerospace industries and provides full-process engineering support from DFM to precision inspection.

Summary

Small diameter deep hole tapping is not an insurmountable barrier to production but rather the proving grounds of prototype CNC machining capabilities. Selecting a company with cutting edge equipment, process knowledge, and a full quality system will turn this "manufacturing nightmare" into a "prototype highlight."

With years of devoted experience, JS Precision is a master in small-diameter deep hole tapping with micron levels of precision on your high-end prototypes.

Take action now! Upload your 3D designs and receive a complimentary DFM Report and Price Quote package in under 24 hours. Let JS Precision's expert team pave the way for you and kick-start your innovative gear designs with our precise manufacturing solutions.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com