CNC machining services near me tends to be the first choice of many when in need of CNC machining services. Yet, it seems that when a project requires immediate CNC machining assistance, does this "closeness" necessarily resonate with "value"?

What feeds the price gap between traditional facilities within geographical areas and global online CNC machining services is nothing but an extensive race of speed, skill, and resourcefulness.

This article will not only give a detailed breakdown of the hidden cost of "Local" and "Online" models, but also a whole range of decision factors from the design optimization to supplier selection to help you source the best production partner anywhere in the world.

Key Answer Summary

| Your Core Concerns | Key Decision Dimensions | Core Value Offered by JS Precision |

| Design for Manufacturing | DFM Analysis & Collaboration Among Engineers | Free professional DFM report, early intervention avoids 80% of later cost overruns. |

| Quality & Precision | Equipment Capabilities (e.g., 5-axis), Material Expertise | Some of the imported multi-axis CNC machining centres have expertise in CNC machining aluminum parts, ensuring tolerance as high as ±0.025mm. |

| Flexibility & Economy | Small batch production costs, iteration speed | Optimized low volume CNC machining process with no MOQ restrictions can support rapid prototyping to pilot production. |

| Service Model Selection | Local Convenience & Comprehensive Online Value | As a leading online CNC machining services provider that combines digital convenience with top-tier manufacturing quality, we provide globally optimal solutions, beyond local limitations. |

Key Conclusions

- Selecting a supplier means essentially choosing its engineering abilities or equipment strength rather than its physical location.

- Online CNC machining services offer modern solutions through more efficient and cost-effective solutions available through instant quoting, transparent process, and global supply chain.

- For complex designs and strict tolerance requirements, professional manufacturers with multi axis CNC machining centres are irreplaceable.

- Early stages of DFM implementation, whether selecting local or online options, can help cut costs substantially and even hasten development.

Why Refer To This Guide? The Value Of JS Precision's Online CNC Machining Services

Wrong selection of suppliers nowadays in a very complicated CNC machining industry results in project delays, cost overruns, or even poor product performance.

This guide is more operational than a theoretically advisory one and summarizes JS Precision's practical experience in 15 years of precision manufacturing service for more than 5000 clients worldwide to help you avoid the selection pitfalls.

As one of the leading online CNC machining services, JS Precision's core value is reflected in the following three dimensions:

- Technical strength: With 200+ imported CNC machining centers, including 50+ five-axis CNC machining centres, we are capable of dealing with the complex CNC machining aluminum parts precisely.

- Data-driven service capabilities: Self-developed online quotation system, accurate quotation in 3 minutes, real-time visualization of project progress.

- Cost control benefit: By integrating the global supply chain, the average cost in low volume CNC machining is 30%-40% lower than with local service providers.

Besides that, JS Precision has passed the ISO 9001:2015 and AS9100D quality system certifications, with a complete inspection report given for each batch of product.

About 80% of our customers are high-end manufacturing: medical equipment, aerospace, and industrial automation, including projects for Tesla and Siemens.

For instance, we offered low-volume CNC machining services for an aerospace parts company and delivered 50 high-precision aluminum alloy parts within a period of 12 days. The tolerances were within ±0.02mm and thus resulted in a 40% increase in efficiency compared to the client's previous local service provider.

If you are looking for a reliable CNC machining partner for your project, contact JS Precision's engineering team immediately. Tell us your part requirements and project timeline, and we will provide you with a free technical assessment and customized solutions to help you avoid detours in your project.

Near Me Or Online CNC Machining Services: How Should I Choose?

Struggling between CNC machining near me and online CNC machining services? The key is all about matching your project needs. This section compares the differences between the two to help you go for one in a shorter time, based on your priorities.

Advantages and Disadvantages of Custom CNC Machining Near Me

The advantages of custom CNC machining near me include physical accessibility: face-to-face communication to avoid deviations, 24-48 hour pickup for simple parts, and convenient adjustments over reworks.

However, its shortcomings are very apparent:

It is mainly three-axis equipment, and thus, can hardly deal with complex parts, the price is 25-50% higher than online CNC machining services, the material selection is limited, unable to meet special requirements such as 7075-T6 aluminum alloy. It is only suitable for simple and urgent orders with flexible budgets or used in short-term projects.

What exactly are the real benefits of online CNC machining services?

Online CNC machining services are one after another becoming the mainstream, with comprehensive value including: instant quotation upon uploading drawings, integration with high-end CNC machining centres including five-axis centers, more cost-effective low volume CNC machining, and standardized and controllable whole process.

JS Precision's online CNC machining services support real-time progress and inspection reports, allowing for full control even remotely.

How To Select Reliable Online CNC Machining Partners?

The advantages of online CNC machining services are obvious, while the quality of service providers in the market varies greatly. Choosing the right partner is crucial for truly reducing costs and increasing efficiency. Below is a proven evaluation framework.

Beyond the Website's Surface: Delving into Core Technical Strength

Core technical strength refers to the core guarantee of machining quality. In the evaluation, emphasis should be laid on the following:

- Equipment Configuration: Does it have advanced CNC machining centres such as five-axis linkage and high-speed milling? Provide the equipment list and factory inspection report.

- Machining Accuracy: The ability of the standard tolerances to reach consistently ±0.025mm. Case study availability for handling complicated parts.

- Material Expertise: Is the company proficient in CNC machining common materials such as aluminum parts? Are they able to provide material certificates and machining process solutions?

JS Precision has more than 100 five-axis CNC machining centers with a German Heidenhain control system, which is able to control precision down to 0.001mm. They offer professional complex machining of aluminum alloys such as 7075-T6 and 6061-T6.

Communication Efficiency and Quality Assurance System

High-quality online CNC machining services are characterized by a comprehensive service system:

- Communication Response: Is there a professional engineering team providing technical support with a response time within 24 hours?

- Quality Certification: Has the company obtained international quality system certifications such as the ISO 9001 standard or AS9100 standard?

- After-Sales Guarantee: Is there any warranty period? Is it possible to solve quality-related concerns in time?

In the standards set by the International Organization for Standardization (ISO) 9001:2015, manufacturing service should be equipped with a whole-process quality control system. JS Precision abides by the standard by designing 12 quality control points from reviewing the drawings to inspecting the products.

Worried about choosing the wrong online CNC machining services partner? JS Precision offers free sample processing services, allowing you to verify our processing quality and service capabilities before signing a formal cooperation agreement. The entire process is risk-free and involves trial and error.

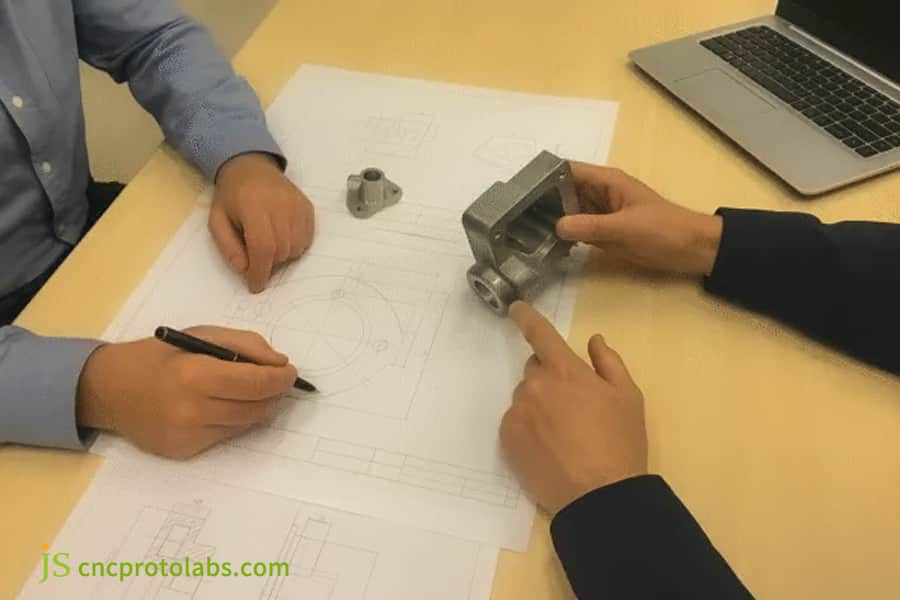

Figure 1 The key to finding a suitable CNC machining partner is to establish a cooperative relationship based on trust, quality, and communication.

Figure 1 The key to finding a suitable CNC machining partner is to establish a cooperative relationship based on trust, quality, and communication.

Case Study: JS Precision Helps Medical Drone Enterprises Overcome The Difficulties Of Complex Arm Mass Production

In high-end manufacturing and industrial projects, success is largely dependent upon the emergency response and technical abilities of the supplier. The following is a case study that shows how JS Precision helped a client overcome a major problem through online CNC machining.

Challenge

A medical drone startup in Silicon Valley faced a pressing issue—producing a crucial part of a joint arm. The part, made of 7075-T6 aluminum alloy, is a complex part that requires thin walls, measuring 0.8mm in thickness at its most slender part, while a tolerance of ±0.05mm is essential. The client needs 200 parts in just a month for testing purposes.

The customer had contacted few "custom CNC machining near me" suppliers, but there were major challenges in that suppliers had only three-axis CNC machining centers, which were unable to handle complex curved surface machining, as quoted at as high as $800/set, in addition, the project timeline was up to 8 weeks, which was beyond the customer financing milestone.

JS Precision Solution

1.72-Hour Rapid Response & DFM Optimization:

After receiving the client's 3D model, the JS Precision engineering team promptly started working on the DFM analysis and provided a detailed report within 72 hours. We advised optimizing internal cavity corners from right angles to a 0.5mm radius, which could reduce the machining time by 15% and enhance part strength, thereby avoiding the risk of cracking in thin-walled areas.

2. Five-Axis Linkage Strategy for One-Step Molding:

The complex curved surface and deep cavity were machined by imported German five-axis CNC machining centres and a specially designed hydraulic fixture, solving several problems such as accuracy errors caused by multiple clamping operations and tolerance within ±0.03mm.

3. Digitalization of Processes for Transparency in Delivery:

Customers can see in real time the production schedules, videos of key processes taken, and first-piece CMM inspection reports through the online platform at JS Precision, thereby avoiding repeated communication and greatly improving efficiency in collaboration.

Results:

JS Precision successfully manufactured and transported 200 units of various components through air freight within 23 days, 9 days ahead of schedule, and reduced costs to $520 per unit, 35% below those cited from local sources.

The customer testing resulted in all performance indicators meeting the criteria in medical drones, hence aiding the customer in passing the funding milestone. Subsequently, the customer signed a 3-year long-term mass production agreement with JS Precision, with a cumulative order amount exceeding $2 million.

If you also face challenges such as complex parts machining, urgent delivery deadlines, or cost control, contact JS Precision's engineering team to explain your project needs in detail. We will tailor a solution to help your project land quickly.

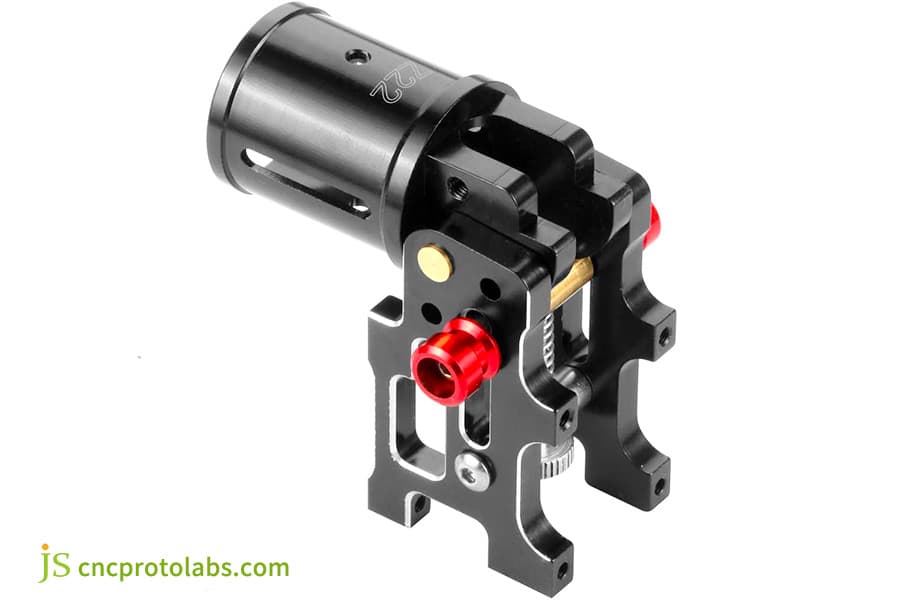

Figure 2 Aluminum alloy articulated arm for unmanned aerial vehicles

Figure 2 Aluminum alloy articulated arm for unmanned aerial vehicles

From Concept To Finished Product: How To Ensure That Your CNC Machining Parts Design Is Efficiently Manufactured?

Regardless of "CNC machining service near me" or online CNC machining options, a project's cost as well as project timeframe will depend naturally upon manufacturability. Experienced analysis of design manufacturability along with design optimization is a prerequisite prior to efficient manufacturing.

Design and Engineering: The Value of Simulation and Collaboration

Early Collaboration with Manufacturers: Simulation predicts machining problems as well as the stress test for CNC machining aluminum parts. JS precision engineers could be involved to ensure optimally designed structures.

Preparing for Efficient CNC Machining with Design

Optimized design can improve efficiency and reduce costs. Key points are as follows:

| Design Elements | Optimization Suggestions | Expected Results |

| Wall Thickness | Minimum wall thickness not less than 1mm (aluminum alloy). | Avoids machining deformation and tool damage. |

| Rounded Corners | Set inner corners with R0.3-R0.5mm rounded corners. | Reduces tool wear and shortens machining time. |

| Tolerances | Use ±0.1mm tolerance for non-critical dimensions. | Reduces machining difficulty and increases productivity. |

| Hole Positions | Maintain hole spacing ≥2mm. | Avoids hole wall cracking and ensures structural strength. |

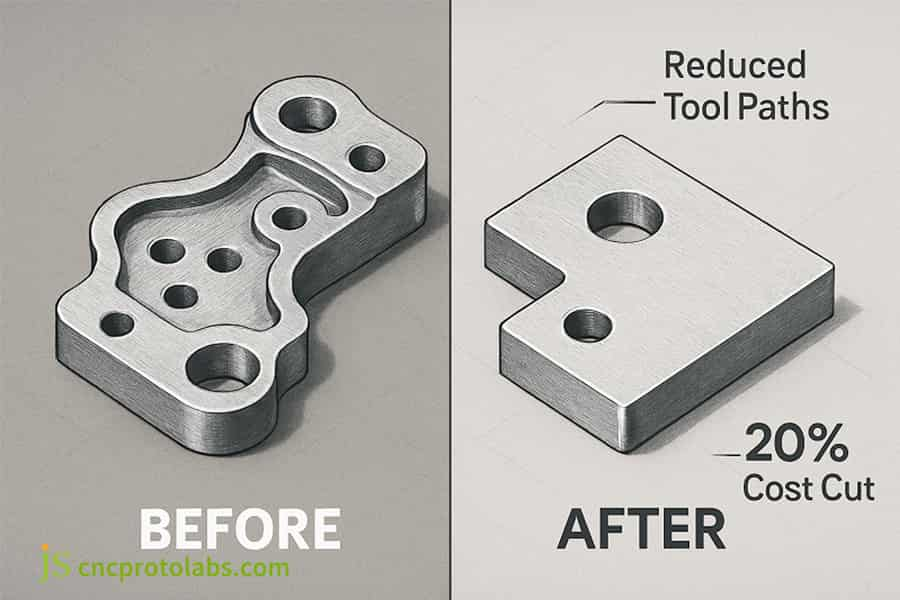

For example, a customer originally designed an aluminum alloy part with a right angle inside corner. After JS Precision suggested optimizing it to R0.5mm rounded corner, the processing time was reduced by 20% and the scrap rate decreased from 8% to 1%.

Figure 3 By simplifying geometric shapes (avoiding the use of complex curves, deep grooves, and unnecessary features) to improve manufacturing convenience.

Figure 3 By simplifying geometric shapes (avoiding the use of complex curves, deep grooves, and unnecessary features) to improve manufacturing convenience.

How To Choose CNC Machining Centers To Obtain The Highest Quality Prototypes?

CNC machining centers are the core of machining accuracy and efficiency. Choosing a supplier with suitable equipment is key to obtaining high-quality prototypes.

Multi-Axis Machining and Complex Geometry

Different equipment has significantly different machining capabilities:

| Equipment Type | Machining Range | Applicable Scenarios | Accuracy Level |

| Three-Axis CNC | Simple Planes, Hole Systems | Basic Parts | ±0.05mm |

| Four-Axis CNC | Complex Surfaces, Multiple Faces | Medium-Complexity Parts | ±0.03mm |

| Five-Axis CNC | Complex Surfaces, Deep Cavities | High-Precision Complex Parts | ±0.025mm |

Machines with complex parts require five-axis machines. 50% of JS Precision’s business is five-axis machines, and these machines are capable of handling complex machining operations.

Material Selection: Why is Aluminum the Favorite for Prototype Making?

CNC machining aluminum parts are the preferred choice in prototype manufacturing because they are light in weight, easy to machine, average in strength, and have standardized cost implications.

6061-T6 exhibits good mechanical properties as a whole, while 7075-T6 demonstrates high strength.

Choosing the right CNC machining centres and materials for prototyping? JS Precision engineers can recommend the optimal equipment and material solutions based on your project needs, and provide free technical consultation to help you create high-quality prototypes.

Figure 4 Numerical control machining plays a crucial role in turning complex designs into reality.

Figure 4 Numerical control machining plays a crucial role in turning complex designs into reality.

How To Maximize Cost-Effectiveness During The Low Volume CNC Machining Phase?

Low volume CNC machining is an important step in the transition between prototype and bulk production. Finding the balance between cost and reward is a core concern that most clients have.

Economics of Small-Batch CNC Machining

The cost advantages of low volume CNC machining are two-fold:

- No need for mold: Compared to the process of injection molding, there can be saving of tens of thousands of dollars on the cost of the mold itself and can be used for production needs of 10-1000 pieces.

- Controllable costs: Though per unit cost is high when compared to mass production, the cost is relatively much lower than that of 3D printing, especially if metal is involved.

- Flexibility: Such designs are very flexible and can be adapted rapidly to suit the situation.

The industry statistics show that in producing less than 100 metal parts, the overall cost of low volume CNC machining is 40% to 60% less expensive compared to 3D printing, yet possessing greater machining accuracy.

| Machining Batch (pieces) | 6061-T6 Aluminum Alloy Single-Piece Machining Cost (USD) | Production Cycle (Working Days) | Average Tolerance Control (mm) | Material Utilization Rate (%) | Single-Piece Post-Processing Cost (USD) |

| 10 | 85.6 | 5 | ±0.025 | 72.3 | 12.8 |

| 30 | 62.4 | 7 | ±0.025 | 78.5 | 9.6 |

| 50 | 51.2 | 9 | ±0.020 | 81.7 | 8.3 |

| 80 | 45.8 | 12 | ±0.020 | 84.2 | 7.5 |

| 100 | 42.3 | 15 | ±0.015 | 86.9 | 6.8 |

| 200 | 38.5 | 20 | ±0.015 | 89.4 | 6.2 |

Note: Prices are based on JS Precision 5-axis CNC machining. Centres' quote for standard parts does not include logistics and design optimisation costs. Prices are subject to change, depending on part complexity.

Simplify the Supply Chain and Faster Iteration

High-quality online CNC machining services are available with a one-stop solution for low-volume CNC machining:

- Material Procurement: The introduction of global high-quality material suppliers for more cost-effective raw materials.

- Post-processing Services: Covering a full range of post-processing processes including anodizing, sandblasting, and electroless nickel plating.

- Logiistics Integration: Partner with international giants in logistics providing door-to-door services and shrinking the delivery cycle.

With the low volume CNC machining service from JS Precision, customers can finally have everything managed in a single place-from material procurement all the way to finished product delivery. This mitigates the hassle of dealing with multiple suppliers and increases the speed of product iteration by more than 30%.

Want to control costs and accelerate iteration in the low volume CNC machining stage? Tell JS Precision your production volume, delivery requirements, and budget range, and we will develop the optimal production plan for you, achieving a perfect balance between cost and efficiency.

FAQs

Q1: What is the typical lead time for online CNC machining services?

For a company dealing in PC material components such as CNC machining aluminum parts, JS Precision has a normal delivery time within 5 to 10 business days. Similarly, JS Precision has varying delivery times depending on the total demand for mass production orders, as fast as 3 days can be arranged.

Q2: What are the smallest/largest part sizes you can process?

JS Precision's capabilities stretch from small parts that are just 10mm to large parts measuring 1200 x 800 x 500mm. Depending on the parts' complexity and equipment model used for the workpiece manufacturing at JS Precision.

Q3: How do you ensure accurate online communication and avoid making mistakes?

JS Precision ensures accurate communication through three processes:

- A standardized checklist that specifies core requirements such as part size, material, and tolerance.

- The 3D model annotation review, where engineers and customers jointly confirm key dimensions.

- To confirm the final process and send the process plan for customer review before production.

Q4: What are some commonly used aluminum alloy grades for CNC machining of aluminum alloy parts?

The most commonly used aluminum alloy grades include 6061-T6, for good overall performance, suitable for most applications, 7075-T6, for high strength, suitable for load-bearing parts, 5083, corrosion resistant, suitable for outdoor use, and 2024, high fatigue strength, used in aerospace.

Q5: Can I get photos or videos of the machining process?

Yes. JS Precision provides high-definition photos or videos of the first piece and key processes. Through our online transparent service, customers could view the status in real time to help you understand the entire production progress.

Q6: What surface treatment options are available?

JS Precision provides various surface treatment services, such as anodizing in several colors, sandblasting, electroless nickel plating, passivation, and painting to fit the appearance and functional needs of various products. All surface treatments comply with international environmental standards.

Q7: What is your standard machining accuracy?

JS precision employs high-class CNC machining centers that provide an average precision of 0.025mm during the machining process. If a part requires more precision than 0.025mm, we can ensure an accuracy of 0.01mm through process optimization for the part's structure itself.

Q8: Do you support orders with mixed materials or multiple parts?

Fully supported. It is allowed to order more than one part of different material (aluminum alloy, stainless steel, titanium alloy) or different designs in one order. JS Precision will provide uniform handling and shipping of your order and optimize the logistics costs. Also, a uniform quality report will be issued to make your quality acceptance easy.

Summary

However, the basic trade-off for "CNC machining services near me" and online CNC machining services centers on the ability to balance "immediate accessibility" and "overall value." Location plays no particular significance, it's the engineering capabilities of the supplier that make the project succeed or fail.

JS Precision utilizes its elite-level CNC machining centers along with its proficiency in CNC machining aluminum components to turn distance into speed, or in other words, precision manufacturing services without the constraints of geographical distances.

Upload your 3d designs today and obtain a free DFM analysis report and immediate quotation with JS Precision. Our experience and expertise enable you to successfully make the most out of your project.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com