Custom CNC milling tasks have long spanned all areas of high-tech production: in the same shop, a precision machine tool is milling intricate parts for an aircraft with tolerances down to ±.01mm, and another machine is ‘carving out’ the heavy base for a large machine out of a steel ingot.

These are not two different worlds but rather a microcosm of the daily capabilities of modern custom CNC milling services. With so many suppliers at their disposal, being able to strike the right balance of quality, speed, and cost-effectiveness while choosing the right service supplier to partner with is essential.

This guide will show you the answers and reasons why China CNC milling services are an essential and smart option for the worldwide supply chain.

Core Answer Summary

| Challenges/Considerations | Key Solutions | Core Value |

| Seeking a Balance of Quality, Speed, and Cost | Deeply understand the factors influencing CNC milling precision and cost structure, and clarify your project priorities. | Make informed supplier selection decisions to achieve the best return on investment. |

| Ensure the Success of Complex Projects on First Attempt | Choose a partner who can provide a complete technical solution covering design optimization and process planning, along with a clear CNC milling quote. | Reduce project risks and ensure efficient transformation from drawings to finished products. |

| Pursue Long-term Stable Cooperation | Go beyond the initial price and evaluate the supplier's comprehensive capabilities in engineering support, supply chain management, and technology upgrades. | Achieve sustainable competitiveness and stable supply chain support. |

Key Takeaways

- The salient feature of custom CNC milling is the unprecedented precision, material compatibility, and complex geometry replication achievable.

- The total cost is impacted by a host of variables, such as materials, labor, and post-processing, as opposed to merely unit cost.

- Selection of a services provider in China lets you tap into the value that can be generated through engineering, as well as an effective and fast-acting supply chain.

- A solution with a quote containing suggestions for optimization is the starting point for judging the professionalism of a supplier.

JS Precision Custom CNC Milling: Triple Optimization Of Quality, Speed, And Cost

Within the realm of sophisticated CNC milling, JS Precision has established strong roots of trust through our devoted cultivation over 15 years, utilizing our strong competence and data.

We have over 20 precision machines that are equipped with 5-axis CNC milling machines, temperature control equipment for the workshop, as well as a coordinate measuring machine (CMM), which makes us capable of doing ultra-precision machining with an accuracy of ±0.005mm. We have also supported many world customers in various industries such as aviation, medical, and auto sectors.

The core advantage is our "three in one" optimization capability:

- Quality: Through front-end DFM review with Design for Manufacturing, whole-process inspection, back-end traceability system, every batch of CNC milling machine parts comes up to the standard.

- Speed: By using a mature CAM programming library and agile supply chain, the delivery cycle for complex parts has been reduced by an average of 30%.

- Cost: Through process optimization and improved material utilization, we have helped global clients reduce manufacturing costs by over ten million US dollars cumulatively.

Over 1,000 high-end industry customized projects have been successfully delivered, including titanium alloy parts with a tolerance of ±0.02mm machined for an aerospace client in Europe and rapid 7-day delivery of small batches of precision parts for medical companies.

As the ISO 9001:2015 quality management system emphasized, stable technical capability is the core of cooperation. JS Precision has passed this system certification and also possesses global service qualifications.

If you are looking for a reliable custom CNC milling partner, feel free to contact our engineering team immediately, submit your part requirements, and you can receive a free customized DFM analysis report and optimization solution.

Beyond Price: The Real Advantages Of Custom CNC Milling Services

CNC milling is a far more precise form of “cutting.” Custom CNC milling services provide value far beyond its cost, and it has definitely disrupted the design and production industries.

Matchless Performance in Complex Geometries

CNC milling can accommodate complex geometries that cannot otherwise be machined by traditional machining processes. At JS Precision, the 5-axis machinery is used in multi-angle cutting that helps create complex parts in a single pass without having to use several clamping processes.

Highly Versatile and Consistent Materials

The custom CNC milling services are compatible with different materials such as aluminum, steel, titanium alloys, as well as engineered plastics. The company’s strict controls ensure the consistency of the dimension of the parts, which leads the industry in batch stability.

Seamless Transition from Prototype Phase to Mass Production

The problem existing in the industry concerning the case of "qualified prototypes but difficulties in mass production" can be overcome ideally by custom CNC milling services. By following the standards of ASME Y14.5-2018, JS Precision can ensure an uninterrupted flow from prototyping to large batch production without any changeover in equipment or processes.

Material Matters: How Your Choice Impacts CNC Milling Precision

CNC milling precision can be affected by machinery as well as material properties. Selection of the correct material and knowing its machining properties are essential to achieve accuracy and manage costs.

Hardness and Tool Wear

The greater hardness of the material translates to faster tool wear, which easily impacts dimensions. For instance, titanium alloys have a high hardness compared to aluminum. At JS Precision, matching tools and cutting data with constant checks on tool wear enable high precision.

Coefficient of Thermal Expansion

The The difference in the coefficient of thermal expansion of the material will result in easy deformation of the machined pieces. JS Precision maintains the cnc milling precision through the proper control of coolant temperatures.

Internal Stress and Machining Deformation

Large workpieces are likely to deform because of the internal stress released. JS Precision reduces deformations by pretreatment and symmetric processing to provide quality to large CNC milling services.

Decoding The Cost: Key Factors In Your CNC Milling Quote

Comparing total prices when receiving a CNC milling quote can be misleading because it will blind the eye. Price transparency in understanding cost structure empowers informed choices.

Material Cost and Utilization

The specification and brand of the raw material will directly affect the base cost, while the efficiency of programming and layout determines material utilization. Optimizing the layout scheme, JS Precision can improve material utilization by 15%-20%, thus significantly reducing the extra expenses brought in by materials waste.

Programming and Setup Time

CAM programming for complicated custom CNC milling parts necessitates more precise path planning, while machine tool debugging also requires more time. The described approach is a necessary technical investment for ensuring machining quality and, therefore, is a major component of the quotation.

Machining Time

Pure cutting time depends on the geometric difficulties of a part, its precision, and the cutting parameters. Complex surfaces increase cutting time, so do the small holes and deep cavities that form them. High precision requires using slower cutting speeds to maintain quality.

Post-processing and Inspection of Quality

The additional processing involved in deburring, heat treatment, and anodizing, and precision inspection, including the use of the CMM, costs extra. Yet, this stage of production is very important and cannot be eliminated.

To get an updated and clear CNC milling quote, upload your drawings and requirements related to 3D on JS Precision. Thereafter, we will offer you an updated CNC milling cost breakdown and ensure that each penny is effectively spent with no extra unwanted CNC milling costs.

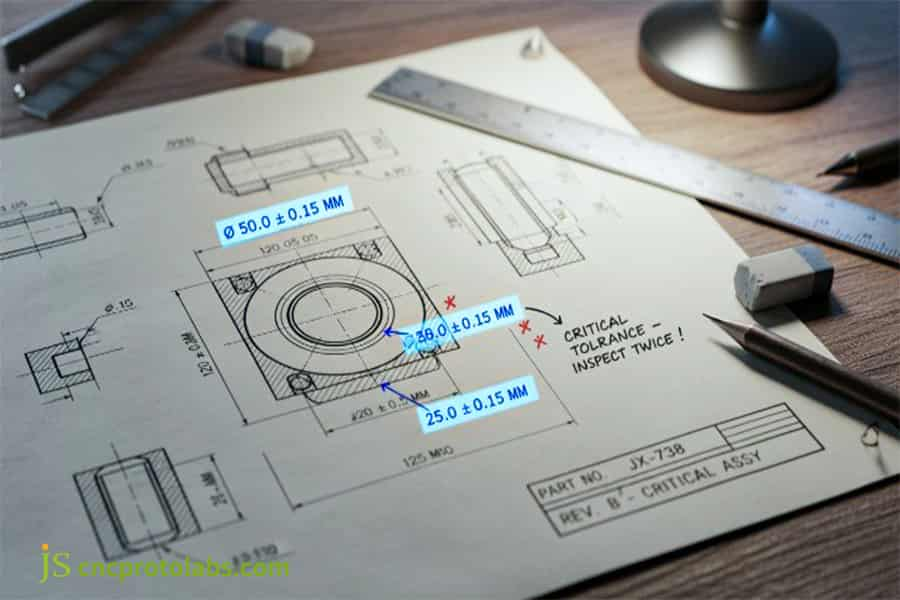

Figure 1 If the difficulty of the parts is high and the structure is complex, requiring more skilled and professionally trained mechanics to process them, then the production cost will increase.

What Tolerances Can CNC Milling Machine Parts Achieve?

Tolerances are a core indicator for high-requirement parts, requiring multi-stage coordination for assurance. Industry-standard precision levels and application scenarios are as follows:

| Precision Level | Tolerance Range | Applicable Scenarios |

| Standard Precision | ±0.025mm | Most mechanical parts and assemblies, meeting general usage requirements |

| High Precision | ±0.0125mm to ±0.005mm | Key automotive components, precision instrument parts, requiring high-performance machine tools and strict process control |

| Ultra-Precision | < ±0.005mm | Core aerospace components, optical parts, medical precision devices, requiring temperature-controlled workshops and specialized equipment |

JS Precision is able to dynamically change the process plan based on demands and maintain stable machining precision ranging from standard precision to ultra precision. Whether it is general mechanical parts or high-end core parts, we can supply CNC milling machine parts based on tolerance requirements.

Figure 2 Calculating the tolerance of CNC machining refers to determining the allowable deviation range of its dimensions based on the design specifications of the part.

Strategies To Reduce Vibration In Large CNC Milling Services

In large cnc milling services, vibrations cause inaccuracies, reduce tool life, can easily result in defects in the part, and also result in increased costs.JS Precision addresses this issue effectively by following a process.

- Process Optimization: Using an advanced toolpath like trochoidal milling, the cutting forces are kept constant, preventing collision between the tool and workpiece, and damping out vibrations where they occur.

- Dedicated tooling and fixtures: The design for custom-made tooling with a necessary stiffness and a rationale for support point locations for the work piece can increase work piece stability, which in turn is the key to reducing vibrations.

- Dynamic CNC Machine Control: The advanced and high-end CNC machine control technology used encompasses active vibration compensation, which enables it to recognize and correct vibration occurrences with precision and speed.

- Scientific Parameter Selection: After identifying the "chatter stability domain diagram" of your work-piece-tool fixtures, carefully choose your rotational speed and depth of cuts to avoid the parameter regions where the likelihood of resonance is high.

If your research project involves the machining of large-sized components and you face any problem of vibrations during machining, you can get assistance from JS Precision regarding large CNC milling services. Our experts will then devise a specific machining strategy against possible vibration to ensure the accuracy of the machined parts as well as to optimize machining expenses.

Figure 3 One of the most challenging problems in milling is chatter - a vibration that can lead to poor surface finish, shortened tool life, and decreased milling efficiency.

How To Ensure The Quality Of Custom CNC Milling?

Custom CNC milling needs complete control in a machining process, as not even the last inspection can guarantee a correct result. A complete quality control system with a set procedure for every stage has been set in place at JS Precision.

- Front-end Design Review: Before the machine shop work, our engineering team conducts a thorough analysis of customer-supplied drawings for manufacturability purposes and makes recommendations for optimizing wall thickness and sharp angle structures.

- Process Control: Inspection points are established where important processes occur using high precision inspection tools. There is real-time monitoring of dimensional information, with deviations immediately corrected to avoid producing defective product lots.

- Full Dimension Report: After the machining of the parts is completed, a comprehensive inspection is carried out using a coordinate measuring machine to generate a detailed inspection report, and data is used to prove that the CNC milling machine parts meet the specification requirements.

- Standardization and Traceability: We formulate work instructions to ensure that all procedures are standard for the operators, and we also create a traceability system for the parts to document information pertaining to the whole process, from raw materials to processing.

From Complex Design To Reality: How To Get a Detailed Plan & Quote

The process for the implementation of complex custom CNC milling designs would include getting a solution with optimization suggestions and quotations. JS Precision simplifies the process and makes collaboration efficient.

Step 1-Clear Requirements:

Please provide complete 3D model data first, such as STEP or IGES format drawing, 2D drawing, material preference, and the expected usage and special requirements of the product, like treatment method requirements for the surface or tolerance standard.

Step 2 - Manufacturing Feasibility Analysis:

Drawing analysis will be performed by the JS Precision engineering team within a day, supplementing a manufacturing feasibility assessment report including but not limited to wall thickness rationality, tolerance feasibility, and suggestions for the adjustment of assembly relationships.

Step 3-Received Integrated Solution:

Process route planning, recommended materials and heat treatment scheme, surface treatment suggestion, estimated delivery time, clearly layered CNC milling quote to present a clear overview of the whole project process.

40% Cost Reduction: JS Precision Overcomes ±0.02mm Titanium Alloy Thin-Wall Part Manufacturing Challenge

Client Challenge

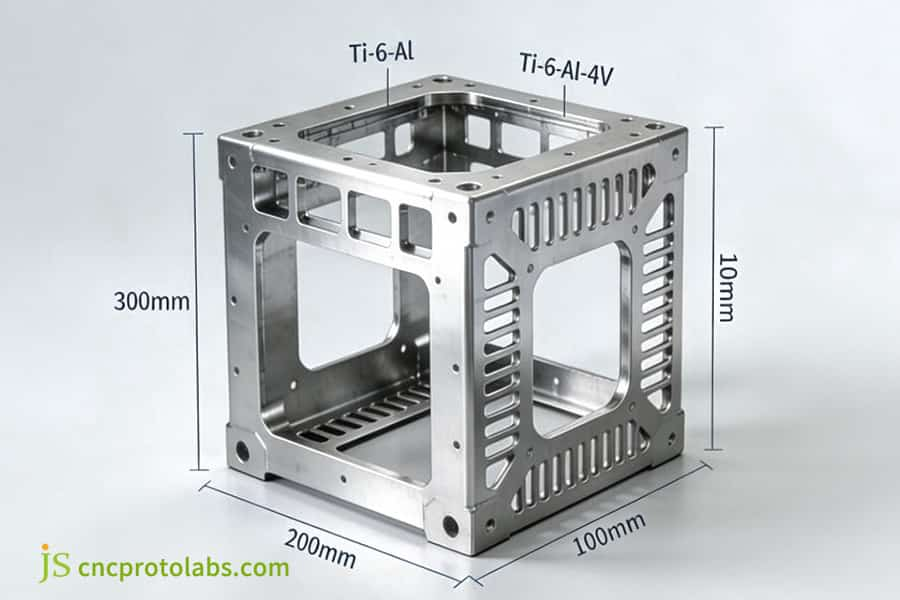

The challenge arises when a European aerospace firm required the production of an airborne communication bracket measuring 300x200x150mm, made of the Ti-6Al-4V titanium alloy. The product required tolerances of ±0.02mm, a minimum wall thickness of 1.2mm, and a 30% reduction in weight.

The required original European supplier was quoting a steep price of $24,000 with a 16-week lead time. Thus, the buyer was facing a dilemma with respect to the price as well as the long-lead-time component requirement.

JS Precision Solution

After acquiring the project, the JS Precision team has designed a solution with multiple dimensions:

1.Design Optimization:

Engineers identified that there was generous material wastage within the structure created by a single deep cavity. They suggested that this particular structure should be modified to a “hollowed out rib" structure, thereby providing part rigidity with more than 30% reduced milling.

2.Process and Flow Optimization:

Faced with the difficulty in machining titanium alloys and high cutting heat, the high-pressure internal cooling tool was used along with the trochoidal roughing strategy to improve the efficiency of roughing by 50%. The semi-finish stress relief and correction processes were added to avoid finishing after dimensional deformation.

3.Improved Quality Control:

To ensure that every single dimension met the tolerance requirement of ±0.02mm, 100% inspection of all assembly interfaces was performed with a CMM.

Results

Eventually, JS Precision reduced the overall manufacturing costs by 40% while fully meeting all performance standards-passing strength tests on the first attempt-and stringent tolerance requirements.

The final quotation turned out to be just $14,400, while the delivery cycle was shortened from 16 weeks to less than 13 weeks. This successfully helped the customer resolve his dual challenges of cost and delivery time, thus continuing his project on schedule.

If you also face similar challenges in machining complex parts, whether it's material difficulties, precision requirements, or cost pressures, contact JS Precision. We will use customized solutions to help you overcome bottlenecks and achieve cost reduction and efficiency improvement.

Figure 4 CNC milling of titanium alloy (Ti-6Al-4V) airborne communication bracket

The Strategic Edge: Long-Term Value With a China CNC Milling Partner

Selecting a China CNC milling service supplier not only provides cost-effectiveness, but it also provides long-term strategic partnership advantages that improve supply chain flexibility. JS Precision has extensive experience in China CNC milling, and much more than manufacturing services can be found in our company.

Deep Engineering Collaboration: Early engagement in projects, including suggestions for local design and process optimization, collaborative resolution of engineering difficulties, minimizing design changes, and short development cycles.

Agile Supply Chain and Flexible Capacity: With the assistance of China’s well-developed manufacturing infrastructure, we quickly source the necessary raw materials. We have the capacity, staff, and equipment in reserve, enabling us to dynamically adjust for changes in orders and meet the required deliveries within the stipulated timeframe.

Advances in Technology and Efficiency: We also keep pace with the latest technology trends that work in our Industry and continually update our technology and efficiency improvements. We also give our long-term clients the efficiency gains and thus allow constant cost reductions.

If you wish to build a stable, efficient, and competitive supply chain, consider choosing JS Precision, our China CNC milling partner. We are committed to long-term value and will grow alongside you, addressing the challenges brought by market changes.

FAQs

Q1: What is the typical delivery time from placing an order to receiving the parts?

The delivery time would mainly depend upon the complexity of the parts and the order quantity. For simple and standard parts, delivery takes place within 5-7 business days. For complex high-precision parts or for bulk orders, delivery would take 2-4 weeks. A exact delivery time would be given taking into consideration your exact needs.

Q2: Which file formats do you support for obtaining CNC milling quotes?

To get an exact understanding of our requirements, prefer 3D file formats like STEP, IGES, or X_T. You can also submit us 2D PDF or DWG files that detail the structural requirements of the components accurately.

Q3: Is there a minimum order quantity (MOQ) for small-batch prototypes?

In our case, there are no strict limitations on MOQ. Our main speciality is rapid prototyping of small orders. In addition, we can manufacture one piece. The price per unit, however, will entail programming costs and setting up of equipment.

Q4: What sizes of parts can you handle?

Our equipment has a wide range of processing capabilities, capable of handling small precision parts as well as providing large CNC milling services. It can process large workpieces with a maximum stroke of over 2 meters, meeting different size requirements.

Q5: How do you guarantee the security of my design drawings and intellectual property?

One of our fundamental business concepts is the protection of intellectual property. We have very strict confidentiality contracts with our customers, and we use a secure internal document management system to ensure that your design drawings and technical data do not get disclosed.

Q6: Besides CNC milling, do you provide assembly or other post-processing services?

We can provide a complete solution that encompasses, in addition to basic CNC milling, also anodizing, sandblasting, painting, heat treatment, as well as some simple assembly services for components, so that you can reduce costs involved in supply chain management.

Q7: What materials do you typically use? Can you procure special materials we specify?

We stock commonly used materials, including aluminum, steel, stainless steel, and engineering plastics, which meet the requirements of most projects. In the case of special materials with a specified brand or specification, we can assist in procurement according to your requirements and ensure that the performance of the parts meets standards.

Q8: Will communication and time zone differences be problems when working with service providers in China?

Certainly not. We have an English-speaking professional engineering team and customer service team. Also, depending on the customer's location, we adjust our working hours to adapt to global time zone differences, so that communication is smooth, responses are timely, and there will be no barriers in collaboration.

Summary

Choosing the right custom CNC milling services partner is the key to finding the optimal solution in the "impossible triangle" of quality, speed, and cost.

This requires you not only to pay attention to the specifications of the machine tool, but also to have insight into the supplier's engineering capabilities, quality system, and customer-oriented cooperation philosophy.

JS Precision, an expert in CNC milling China, promises to extend our services to act as your manufacturing team member by providing solutions that go beyond competitive quotations in CNC milling services.

Take action today and feel the difference that collaborating with experts can make!

Please share your 3D drawings and requirements with us to get a comprehensive solution with a transparent cost estimate within 24 hours. We can collaborate to turn your precision designs into outstanding actuality.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com