Prototype development services act as the essential bridge between product concepts and success. In a competitive market environment, the gap between product concepts and success relies heavily on the speed of prototype product development. Entrepreneurial single-minded actions tend to result in time-consuming and costly prototype product creations.

This article will help you understand the basic value of professional prototype development services that can help you maximize the success rates of your products with the help of professionals. This can be done with the help of rapid prototyping technology.

Core Answer Summary

| Core Questions | Key Answers | Value Brought to You |

| What does complete prototype development service comprise? | Starting from the design to manufacturing to test, it develops the concept into measurable entities. | The closing of the loop reduces the cost of communication and associated risks while guiding clearly in the right direction. |

| How does one balance speed, cost, and performance in developing prototypes? | Combination of various technologies for the early optimization of DFM. | Efficient iteration within budget, avoiding rework and accelerating time to market. |

| Why try a professional service provider instead of internal trials? | They have mature processes, equipment, and technology that are too challenging to match for an internal team. | Focus on the core aspects for more reliability, efficiency, and lower cost of prototypes. |

Key Takeaways

- Speed of iteration defines the market window: Prototyping capabilities can deliver 30%-50% faster product development, which can help manage uncertainty.

- Early testing avoids disasters later on: Integrated prototyping can now find as much as 80% of design problems early on, saving over a tenfold cost of engineering changes in the later design phases.

- Design determines manufacturing costs: the DFM assessment from expert service companies can result in the optimization of the manufacturability of parts as much as 25%.

- The key role of technology matching in cost-effectiveness: CNC machining is used for high-precision functional tests, while 3D printing is more economical and quicker in complex configuration verification.

Why Trust This Guide? The Complete Process Of JS Precision Prototype Development Services

The company, being an expert with 15 years of experience in the prototype development services, established the prototype development solution system across various industries with reference to their practical experiences of serving more than 5000 clients worldwide.

For example, customizing high-precision connector prototype parts for clients in the semiconductor industry, ensuring a 0.8mm center distance tolerance between channels, ±0.005mm shortening the delivery time by 50% compared to the industry standard accelerating the R&D process for clients etc.

Our team consists of more than 100 senior engineers, of which 80% have more than 10 years of working industry experience in their field, which helps us precisely identify and mitigate various complex prototype-specific technical challenges precisely.

Rapid prototyping is another of our major areas of expertise in which we have achieved a reduction in lead times of 30% on an average through iterative improvement in technology and processes itself.

Our service is quality system certified to the ISO 9001-2015 standard.Our equipment is of established quality, all being of German and Japanese provenance CNC machinery ensures all our prototypes are made to precise tolerances of within ±0.025mm.

We have completed more than 100,000 prototype projects as of now, and we have successfully maintained a customer satisfaction rate of 98.5%, working with companies across the board of the Fortune 500 list as well as top startups.

Choosing JS Precision means receiving not just a prototype product, but also comprehensive engineering support and risk management throughout the entire process.

Want to learn how we can customize prototype development services solutions for your industry? Submit your project requirements now, and our engineers will provide you with a free technical assessment and quote within 24 hours.

What Exactly Are Prototype Development Services?

Prototype development services are no longer just processing services, but the core support that runs through the entire product development process.

Beyond Manufacturing: Integrated Product Realization Process

It integrates design engineering/factory management, multi-process manufacturing, post-processing, assembly, and testing. The core of the matter is to produce a physical model that can be directly functionally verified, which avoids manufacturing risks from the very beginning.

End-to-End Stages and Deliverables

The whole process consists of five phases: concept review, DFM optimization, selection of process and materials, manufacturing prototype, and quality inspection and delivery. These include physical prototypes, manufacturability reports, and mass production recommendations that may be provided to support subsequent mass production.

Core Business Value: Reduction of Lifecycle Risk

Early physical verification can save a lot in mold costs afterwards. High-quality prototypes can also support financing and customer acquisition to seize market opportunities.

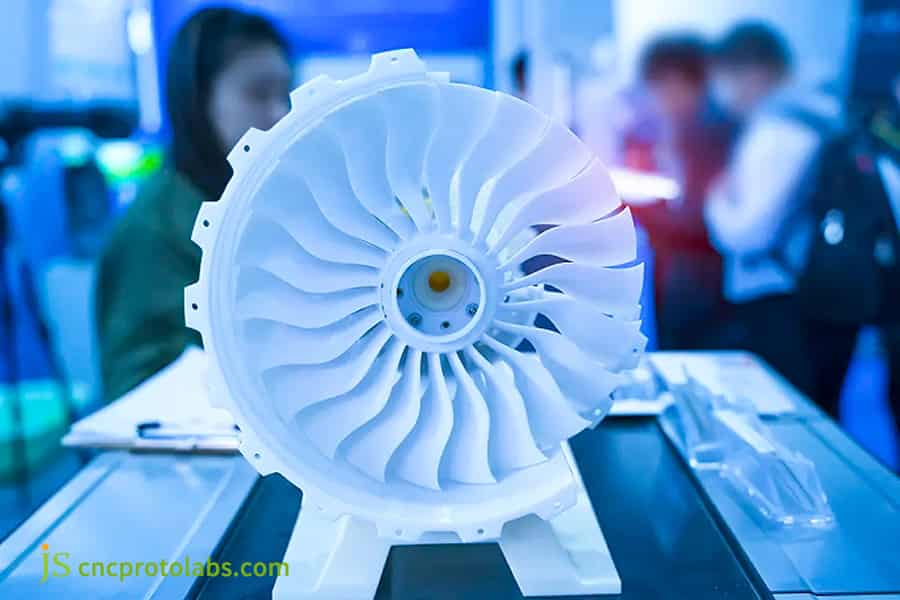

Figure 1 Prototype production services provide enterprises with the opportunity to test the functionality, aesthetics, and usability of their products before they are launched.

Figure 1 Prototype production services provide enterprises with the opportunity to test the functionality, aesthetics, and usability of their products before they are launched.

How Do Rapid Prototyping Services Compress Your Development Timeline?

Rapid prototyping services accelerator of product developmental activities are perceived as key accelerators of the developmental cycle, efficiency being another beneficiary of technological upgrade.

Technology Matrix: Matching Different Fidelity Requirements

Different prototype requirements correspond to different technologies. The core technology parameters are compared below:

| Technology Type | Applicable Scenarios | Delivery Cycle | Accuracy Level | Material Range | Price Range (USD) |

| 3D Printing (SLA/DLP) | Appearance Part Verification | 24-48 hours | Layer Accuracy 0.05mm | Photosensitive Resin, Nylon | 200-800 |

| CNC Machining | Functional Test Parts | 5-10 working days | ±0.025mm | Metal, Engineering Plastics | 800-5000 |

| Vacuum Molding | Small Batch Testing | 7-14 working days | ±0.1mm | ABS, Silicone | 500-2000 (single piece) |

| Soft Mold Injection Molding | Mass Production Process Verification | 10-18 working days | ±0.08mm | PP, PC, PA | 1000-3000 (mold fee) |

Accelerated Iteration Cycle: From Weeks to Days

Generally, the traditional machining method takes 2-3 weeks, while the rapid prototyping services can take 72 hours, which is helpful in verifying the design every week.

Cost-Effectiveness: Significant Long-Term ROI

According to industry data, for each dollar invested in the rapid prototype development activity, five to ten dollars can be saved in the future in the form of modification and recall costs.

Need to accelerate your product development with rapid prototyping services? Contact JS Precision engineers now, tell them your project timelines and precision requirements, and we will customize the fastest prototype delivery solution for you.

What Goes Into Professional Prototype Fabrication For Test-Ready Models?

The prototype fabrication is crucial for the embodiment of a digital design and, directly related to prototype quality, testing effectiveness is the very core support for successful product development and prototyping.

Precise Conversion from Digital to Physical

The main process consists of CAD standardization, CAM programming, high-precision machining, and post-processing optimization, with strictly guaranteed precision at every stage.

Customers should provide overall engineering drawings, including tolerances, assembly datums, and surface requirements for accuracy in machining.

Material and Process Matching

Selection of materials for application: 7075 aluminum alloy for structural test, PPSU for chemical resistance, and SLA printing and painting for appearance verification.

The core performance parameters of commonly used engineering materials are as follows, providing a basis for selection:

| Material Name | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Temperature Range (°C) | Applicable Process |

| Aluminum Alloy 7075-T6 | 560 | 503 | 150 | -60~120 | CNC Machining |

| POM (Polyoxymethylene) | 70 | 48 | 120 | -40~100 | CNC/Injection Molding |

| PTFE (Polytetrafluoroethylene) | 28 | 15 | 50 | -200~260 | CNC Machining |

| Titanium Alloy Ti-6Al-4V | 950 | 860 | 300 | -250~315 | 5-Axis CNC Machining |

| Photosensitive Resin (SLA) | 55 | 55 | 85 | -10~60 | 3D Printing |

It is also possible for different processing routes to the same material to have different performance attributes. For a CNC machined POM part, dimensional stability is better compared to a 3D-printed one.

Quality Control: Ensuring the Prototype Conforms to Product Standards

The quality control system established at JS Precision follows standards set in ISO 13485, with the major components being first article inspection, CMM test, and functional verification.

Why Is Rapid Prototype Development Key To Incorporating User Feedback?

At the heart of rapidly responding to users' feedback is rapid prototype development it enables product design to evolve around actual needs and align product development and prototyping efforts with the market.

- Achieving a Truly Agile Product Development Loop: The construction of a closed loop of “Prototype Release - Feedback Collection - Iterative Optimization - Secondary Testing” can be done in one week.

- Improving Product-Market Fit (PMF): Practical case studies illustrate its importance: Wearable technology increased comfort level by 40 percent through optimization of three prototype iterations consumer electronics companies enhanced user satisfaction by 35% through verification of a prototype.

- Business Mitigation: Turning My Assumptions into Verified: Ones Low-cost prototype iterations can check the validity of the original assumptions, thus bypassing subjective product completion.

Figure 2: 3D printing rapid prototyping and finished products. Rapid prototyping helps to obtain clear and actionable user feedback.

Figure 2: 3D printing rapid prototyping and finished products. Rapid prototyping helps to obtain clear and actionable user feedback.

How Does Prototyping During Development Systematically Mitigate Risk?

Prototyping during product development is a key means of systematically managing development risks, identifying and resolving potential issues throughout the entire process to ensure smooth project progress.

Risk Layering and Prototype Verification Strategy

Accurate matching and verification strategy based on development stage:

- 3D printing is used to verify the form of human-machine engineering in the conceptual stage.

- CNC prototype testing is used to test the structural function in the engineering stage.

- Soft mold injection molding is used to verify the feasibility of mass production in the production stage.

Identifying and Resolving Technical and Supply Chain Risks

Prototype verification may also show potential technical concerns such as lack of adequate material dissipation, assembly, as well as supply chain concerns like acquisition of raw materials, etc.

An electronics firm, in order to avoid concerns like overheating during mass productions, made use of prototype testing to eliminate concerns like heatsink thickness, while an automobile parts firm made use of prototype verification in acquiring materials during the process of production.

Quantifiable Benefits: Higher Investment Success Rate

Research shows that projects that adopt a systematic prototyping process can increase market acceptance by 23%, reduce overspending risk by 35%, and lower later engineering change costs by more than 10 times.

What Unique Advantages Do Custom Prototype Development Services Offer?

Custom prototype development services are designated for the most complicated and non-standard projects, deeply embedded in engineering support. It's one of the core warranties for high-end product development and prototyping.

Addressing Non-Standard and High-Performance Challenges

Providing tailor-made solutions to meet the demanding requirements: fabrication of the micro-medical catheter, adapting high temperature sensors, precision control of complicated internal flow channels.

Typical customized process parameters are as follows, matching high-performance requirements:

| Customized Process Type | Machining Range (mm) | Dimensional Tolerance (mm) | Surface Roughness (μm) | Applicable Materials | Minimum Feature Size (mm) |

| 5-Axis CNC Precision Machining | 0.5~1000 | ±0.005~±0.025 | 0.8~3.2 | Metal/Engineering Plastics | 0.15 |

| Micro/Nano Machining (Medical Grade) | 0.1~50 | ±0.001~±0.005 | 0.2~0.8 | Medical Stainless Steel/PTFE | 0.05 |

| Special Alloy Machining | 5~800 | ±0.01~±0.03 | 1.6~6.3 | Inconel/Titanium Alloy | 0.3 |

| High-Precision Vacuum Molding | 10~500 | ±0.05~±0.1 | 3.2~12.5 | Silicone/ABS/PC | 0.5 |

| Complex Internal Flow Channel Machining | 5~300 | ±0.02~±0.05 | 1.6~6.3 | Aluminum Alloy/Plastic | 0.2 |

Overcoming challenges through customized technologies, such as micro/nano fabrication of medical catheters and optimization of alloy processes for high-temperature components.

Seamless Integration from Engineering Consulting to Production Transformation

We provide full-chain services, covering consulting on materials and multi-process manufacturing of prototypes, guaranteeing its compliance with mass production requirements and delivering cost-effectively.

Competitive Advantage Bringing Complex Innovations to Market Faster

Companies can, therefore, hasten the realization of a concept with external capabilities for customization without having to invest hugely in equipment to focus on core innovations.

Have complex prototype development needs? Tell JS Precision your specific challenges, and we will tailor a custom prototype development services solution to help you overcome technical difficulties.

Figure 3 Rapid prototyping has become an indispensable tool in modern industries by shortening development cycles, strengthening collaboration, reducing risks, and promoting innovation.

Figure 3 Rapid prototyping has become an indispensable tool in modern industries by shortening development cycles, strengthening collaboration, reducing risks, and promoting innovation.

When Is a CNC Machining Prototype Service The Optimal Choice?

High-precision, high-strength CNC machining prototype service, with its advantages, has become a prominent solution in high-performance product development and prototyping, etc.

Irreplaceable Technological Advantages

The core advantages are reflected in three aspects:

- Consistent materials and mass production, and truly measurable mechanical properties.

- Tolerance up to ±0.05mm, surface roughness Ra≤0.8 μm, meeting precision assembly requirements.

- Isotropic performance, no interlayer weaknesses, suitable for harsh testing scenarios.

Typical Application Scenarios Decisions

CNC machining prototype service is preferred for the following scenarios:

High load/wear resistance/thermal and conductive function testing, hole shaft thread fittings with tolerances exceeding ±0.1mm, small-scale trial production of 50-500 pieces and fixture manufacturing, and engineering verification that requires consistency with the performance of mass-produced materials.

Integration into Rapid Development Processes

Complex cavities are quickly prototyped with 3D printing, while key functional parts are precision-made with the precision machinery of CNC technique, with the new collaboration model of “3D printing + CNC machining.”

Need high-precision, high-strength prototypes? Choose JS Precision's CNC machining prototype service, upload your drawings, and we will provide you with precise machining solutions and quotations.

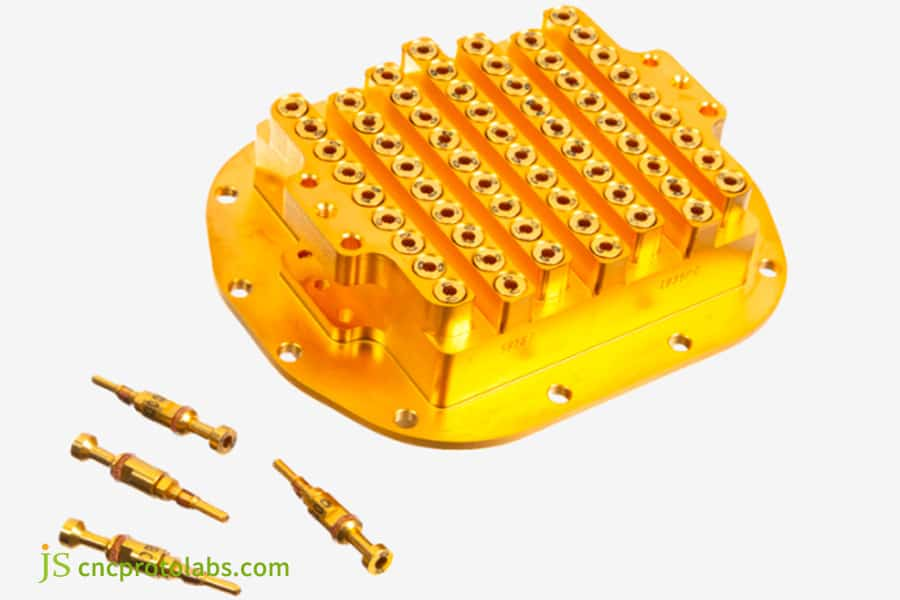

Case Study: JS Precision Overcomes The Manufacturing Limits Of Quantum Prototypes With a 0.8mm Pitch

Customer Challenge

A quantum computing company in North America wanted to produce a working prototype of an ultra-high frequency connector used in the control of qubits.

The core difficulty of this prototype lies in the 64 channel design, with a channel center distance of only 0.8mm, and the insulation material is extremely difficult to process PTFE (polytetrafluoroethylene).

Previous suppliers the client had worked with were found to charge extreme costs, well above $3,000, with some suppliers requiring 6-week delivery time.

JS Precision Solution

JS Precision developed a bespoke prototype development services solution designed for the particularly demanding task:

1.Deep DFM design and customized process:

After analysis by the engineering team, it was proposed to change the overall design to an aluminum PTFE aluminum sandwich split structure, which avoids the deformation problem of deep hole machining with pure PTFE. At the same time, specialized micro diameter cutting tools and low-temperature cooling strategies were customized to reduce machining deformation.

2.Five-axis precision machining collaboration:

Five-axis high-precision CNC machining was employed separately on the aluminum-alloy casing, with a tolerance requirement of ±0.025mm, and the insulation layer made of PTFE material. This precision machinery collaboration assured the accumulation error of the three parts did not exceed 0.05mm, thus satisfying the condition that the center distance was 0.8mm.

3.One-stop integration and test:

With selective gold plating on the contact surfaces under consideration as being conductive, the precise arrangement of individual layers in a clean environment was carried out within our workshops. Preliminary signal integrity tests through the assessment of the S-parameters were conducted using a network analyzer for immediate usage.

Quantitative Results

In the process, JS Precision, based on its core technological capabilities, achieved three major breakthroughs:

- The delivery time was reduced from 6 weeks down to 3 weeks, representing a 50% reduction. This has allowed rapid delivery of a functional prototype, ready for system integration testing.

- The result is better than the design target by over 15% for insertion loss and inter-channel crosstalk in the prototype at a frequency of 40GHz, thus providing a big margin in performance.

- Overall project cost was substantially lower compared to the local quote in North America, saving the client more than 40% of early-stage R&D funds.

Want to replicate the successful development of such high-precision prototypes? Submit your complex machining requirements, and JS Precision's 5-axis machining engineers will provide you with customized technical solutions to precisely solve machining challenges.

Figure 4 Multi channel high-speed line integrated connector suitable for quantum computers

Figure 4 Multi channel high-speed line integrated connector suitable for quantum computers

FAQs

Q1: How long does a complete prototype development project typically take?

Design complexity, process selection, and number of iterations in the project cycle. Here are approximate time frames: simple 3D printing projects take approximately 1-2 weeks, complex CNC machining projects take approximately 3-6 weeks, and standard CNC machining has a lead time of 5-10 days.

Q2: What is the approximate starting cost of prototype development services?

The cost for prototype development services is a function of the process and materials. A simple plastic 3D printed prototype starts at about $200, while a complex metal functional prototype can start upwards of $2000. To give an accurate quote, an evaluation based on the 3D model should be made.

Q3: Does JS Precision support concept design from scratch?

JS Precision supports full-process prototype development services, starting from industrial design and mechanical engineering stages. It transforms clients' sketches or ideas into manufacturable standardized designs.

Q4: Can you use the same materials we plan to use for mass production to make prototypes?

Of course. This is the core advantage of our CNC machining prototype service. JS Precision supports hundreds of mass-production-grade engineering metals and plastics for prototype machining.

Q5: Do you provide surface treatments for prototypes (such as painting, anodizing)?

JS Precision's prototyping service is done in house with painting, anodizing, screen printing, electroplating, and sandblasting facilities to ensure that the appearance and functions of the product resemble as much as possible that of the end product itself.

Q6: How do you ensure the precision of the prototype? Are there inspection reports?

JS Precision uses high-precision equipment such as coordinate measuring machines (CMM) to detect key dimensions, and can provide first article inspection (FAI) reports according to customer needs to fully control prototype accuracy.

Q7: Can you create smart hardware prototypes that include electronic components?

JS Precision can process mechanical parts machining and fabrication of smart hardware casing. We can also professionally help you connect to an electronics assembly factory to achieve system integration of mechanical structures and electronics parts.

Q8: Is small-batch trial production (50-500 units) also within your service scope?

Small batch trial production belongs to JS Precision's core service scope. We specialize in achieving a smooth transition from prototype to small batch trial production through CNC or rapid tooling technology, and efficiently completing delivery.

Summary

The success or failure of product innovation depends on whether ideas can be transformed into verifiable prototypes efficiently and accurately. Prototype development services are the core driving force, supported by scientific processes and technology, making product development more controllable and efficient, laying a solid foundation for mass production.

With JS Precision, one is choosing a prototype development partner that possesses global manufacturing capabilities, rooted in China with decades of engineering experience and seamless services from concept to test-ready prototypes.

Now is the time to turn your ideas into a competitive advantage.

Please send us your design concept or challenge, and JS Precision's expert team will tailor a complete solution from concept to test ready prototype, with transparent pricing and reliable delivery time. Let's work together to shorten the distance between innovation and the market.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com