Gear machining services are an essential support for power transmission in industry.

Gears, as the most fundamental components of power and motion transmission, have a direct impact on equipment performance, depending on the accuracy and reliability of the gears. In the face of such complex demands as robot joints and gearboxes, it is essential to find a precise and efficient gear machining partner.

The purpose of this article is to systematically analyze the essence of gear machining services, and it will thoroughly expose the production processes and customization options of bevel gears, helical gears, and spur gears.

It will also show you how to get customized solutions and highly competitive quotes immediately to meet your technical requirements from professional service providers (such as JS Precision, which is located in China and provides services worldwide).

Core Answer Summary

| Core Questions | Key Answers | Value for You |

| What does professional gear machining service include? | One-stop service, from spur gear machining to bevel gear manufacturing process. | Professional engineering support to ensure manufacturability and high-performance gears without design compromise. |

| How is customized gear manufacturing, like non-standard helical gears, carried out? | Custom helical gear manufacturing is the embodiment of design in the real world through the CNC machine. | Breaking through the limitations of standard parts and creating unique competitiveness in product transmission components. |

| Why is hardened tooth surface finishing essential? | Hard gear finishing services is the solution to deformation, precision, and quality. | Reduce cycle-cycle failure rates. Optimize ROI. |

Key Takeaways:

- Precision is performance: Noise, efficiency, and life are directly related to the precision of the tooth profile, i.e., AGMA, and surface finish, i.e., Ra.

- Process is the measure of capability: The machining of complex helical gears, bevel gears, etc., requires multi-axis CNC machines. The bevel gear machining, helical gear manufacturing process, is critical.

- Customization is the key to innovation: Custom helical gear manufacturing is beyond the realm of standard parts. It offers endless possibilities.

- One-stop service: Machining to hard gear finishing services helps to save your valuable time and energy.

Why Trust JS Precision's gear machining services?

JS Precision has been in the gear machining industry for 15 years and during this period has gathered valuable experience by working with more than 2000 high-end clients in over 50 countries worldwide. So, we can be seen as a reliable partner.

We also have certification in quality systems namely, ISO 9001:2015 and IATF 16949. Our main machining tool brands are DMG MORI (Germany) and Mazak (Japan). Our technical team is well experienced being in gear machining for over 8 years on average.

They have the technical knowledge to meet different customer demands from spur gear machining to complex bevel gear manufacturing process.

SPC (Statistical Process Control) technology has made it possible for us to carry out 100% in, machine inspection on critical dimensions ensuring AGMA 12 gear precision and surface roughness Ra as low as 0.2m.

As per ISO 6336-1:2019 standard, consistency in gear manufacturing is the key factor to guarantee the reliability of transmission systems, and that is the very principle that has guided our company in production.

Practical case studies have been used to show our capabilities further:

For instance, we helped a German automaker parts supplier to reduce the bevel gear meshing noise. We changed the bevel gear machining process along with hard gear finishing services, and as a result, the gear noise was lowered from 85 dB to 72 dB, the gear lifespan increased by 3 times, and the manufacturer saved more than $100, 000 annually.

If you are looking for a gear machining services partner that combines technical expertise and delivery assurance, contact JS Precision's engineering team immediately. Tell them your project requirements, and we will provide you with a free process feasibility analysis and preliminary solutions.

What Is Gear Machining Services And How Does It Meet My Project Requirements?

Gear machining services are not simply performing the machining. they are, instead, a comprehensive solution system, covering the entire lifecycle of gears and perfectly matching the specific requirements of different industries.

Beyond Single Machining: A Comprehensive Power Transmission Solution

The main idea behind gear machining services is one, stop integration. JS Precision offers:

- Design Consultation: Design optimization of gears and improvement of their manufacturability.

- Material Selection: Selection of suitable materials based on operating conditions.

- Precision Machining: Machining of gears using hobbing, shaping, and milling, including spur gear machining and helical gear manufacturing process.

- Heat Treatment: Carburizing and quenching resulting in HRC58-62 hardness.

- Finishing: Hard gear finishing services for enhanced precision.

Core Application Areas: From Micromotors to Giant Gearboxes

JS Precision offers gear machining services for various application scenarios:

- Automotive: Gears for gearboxes and motor drive gears.

- Robotics: High-precision and low-noise joint gears.

- Aerospace: Light and high-strength actuating gears.

- Medical: Miniature precision transmission gears.

- Energy: High-load gears for wind turbine gearboxes.

Want to learn about specific implementation plans for gear machining services in your industry? Submit your application scenarios and core requirements directly. JS Precision will provide you with targeted technical white papers and case studies to help you quickly select the right solution.

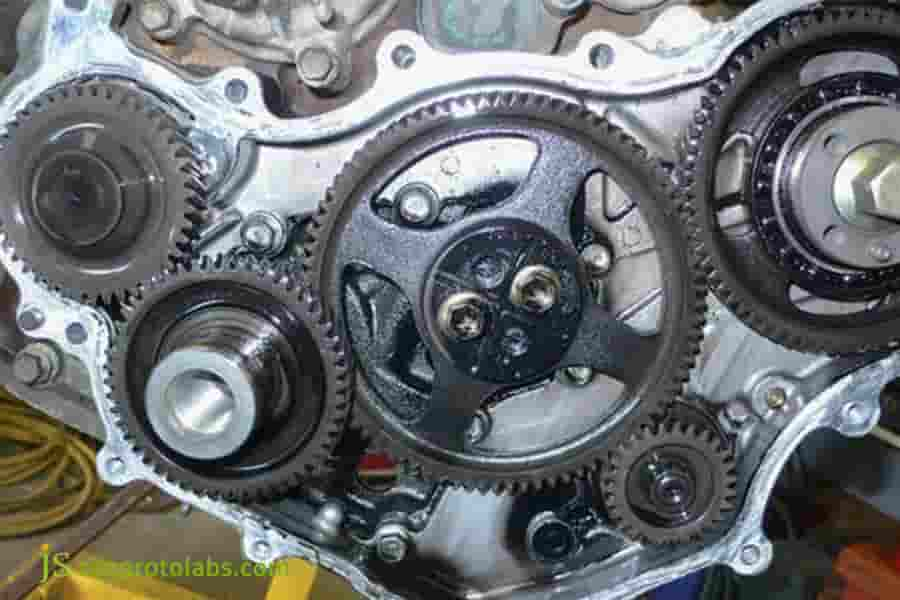

Figure 1 Disassembled timing gear set from an automotive engine, with metal surfaces showing oil gloss.

Figure 1 Disassembled timing gear set from an automotive engine, with metal surfaces showing oil gloss.

What Unique Challenges And Advanced Methods Does The Bevel Gear Manufacturing Process Face?

The manufacturing process of bevel gear has always been a technical difficulty in gear machining field due to its complex spatial geometry structure.

The progressiveness of bevel gear manufacturing process and the rationality of bevel gear manufacturing methods directly determine the meshing accuracy and service life of the gear.

Key Steps in Bevel Gear Manufacturing

The complete bevel gear manufacturing process includes the following steps:

- Forging: Die forging guarantees the metal composition is consistent in each part.

- Rough machining: Milling operation to form the tooth grooves.

- Semi-finishing: Using a special tool to gear the milling machine, allow the gear to be machined with some remaining material after the semi-finishing step.

- Heat treatment: Carburizing and quenching to HRC58-62.

- Finishing: Gleason/Oliven manufacturing technology, five-axis CNC machining.

- Inspection: Three-axis inspection to guarantee the accuracy of meshing.

How to ensure perfect meshing and low noise of bevel gears?

JS Precision has overcome the core technical difficulties in the bevel gear machining through the following three methods:

- Five-axis linkage: Guaranteeing the curvature and taper of the tooth surface.

- In-machine inspection: Real-time correction of errors in dimension.

- Pairing grinding: Optimizing the contact area, with noise levels less than 80 decibels.

| Machining Stage | Cumulative Pitch Error | Tooth Profile Error | Surface Roughness Ra | Applicable Scenarios |

| Rough Machining | ±0.05mm | ±0.03mm | 3.2-6.3μm | Low Precision Transmission |

| Semi-Finish Machining | ±0.02mm | ±0.015mm | 1.6-3.2μm | General Industrial Equipment |

| Finish Machining | ±0.008mm | ±0.005mm | 0.4-0.8μm | High Precision Transmission |

| JS Precision Standard | ±0.005mm | ±0.003mm | 0.2-0.4μm | High-End Equipment and Automotive Industry |

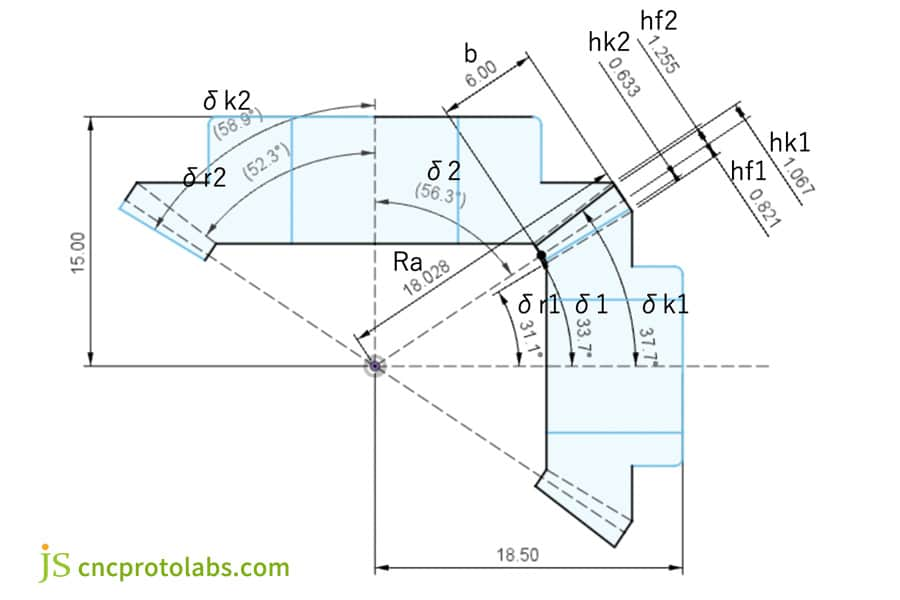

Figure 2 A high-precision bevel gear pair, and the key parameters marked on the surface of the golden small gear indicate that it is specifically designed for precision transmission systems.

Figure 2 A high-precision bevel gear pair, and the key parameters marked on the surface of the golden small gear indicate that it is specifically designed for precision transmission systems.

What Are The Essential Differences In Machining And Performance Between Helical Gears And Spur Gears?

Helical gears and spur gears are the two types of gears most commonly used. The differences between the helical gear manufacturing process and spur gear machining directly result in different performance characteristics, thus the selection between them has to be precisely matched with their working conditions.

Helical Gear Manufacturing: Striving for Perfect Smoothness & Quiet Operation

The core of the helical gear manufacturing process is to address the difficulty of spiral angle machining:

- Needs very accurate linking of CNC indexing heads for projecting the continuous tooth surfaces.

- Heliacal angle 8°-25°, with very close control over tooth direction error.

- Smooth meshing, 30%-50% higher load capacity, and 10-15 decibels lower noise.

- Ideal for high, speed, high, load working situations such as gearbox and robot applications.

Spur Gear Machining: A Fast and Straightforward Way of Power Transmission

The process of making spur gears is easy and fast:

- The gears can be made by hobbing or shaping machines, which makes the cost low and the efficiency high.

- There are no axial forces, hence the installation and maintenance are easy.

- Medium low speed light load adaptation, high speed is prone to noise generation.

- Usable for common transmission, e.g. small motors.

| Performance Indicators | Helical Gears | Spur Gears | Applicable Working Conditions Differences |

| Operating Noise | 65-75dB | 75-90dB | Helical gears are more suitable for noise-sensitive applications. |

| Load Capacity | High (above 1500N·m) | Medium (below 800N·m) | Heavy-duty equipment prefers helical gears. |

| Machining Cost | Higher (20%-30% higher than spur gears) | Lower | Cost-sensitive, simple transmissions can choose spur gears. |

| Precision Grade | Up to AGMA 12 | Up to AGMA 10 | High-precision requirements prefer helical gears. |

| Axial Force | Yes | No | Space-constrained scenarios need to consider the impact of axial force. |

How To Carry Out Custom Spiral Gear Manufacturing To Meet The Design Requirements Of Non-Standard Gears?

In the production of top, notch equipment, it is often difficult for standard gears to meet the performance of customized ones, which is why custom helical gear manufacturing has become a major technical breakthrough in addressing the limitations.

Based on the international standard ISO 3408, 5:2006 for determining the load capacity of gears, the parameters of non, standard gears need to be tightly aligned with the operating load and transmission characteristics to maintain the stability of the operation.

JS Precision utilizes a flexible process solution and professional engineering support to convert non, standard designs into high, performance products.

Breaking the Business Standard Boundary of Customized Helical Gears

- Parameter Customization: Module 0.5, 10, Helix Angle 0, 45.

- Structural Customization: Irregular Holes, Special Keyways.

- Material Customization: Special Steel, Engineering Plastics Processing.

- Surface Treatment: Galvanizing, Chrome Plating, and other anti, corrosion and wear, resistant treatments.

Initiating Customization: Which Key Information Is Needed?

Customization Needs: 2D/3D drawings. Basic gear parameters. Material and heat treatment requirements. Precision grade. Operating parameters.

Additional Notes: Drawings need to indicate dimensional tolerances clearly, parameters should contain the main items such as module and the number of teeth, and operating conditions must specify speed, torque, and temperature range.

| Material Type | Hardness (HRC) | Tensile Strength (MPa) | Applicable Temperature (°C) | Typical Applications |

| 1045 Carbon Steel | 45-50 | ≥600 | -20~120 | General Mechanical Transmission |

| 4140 Alloy Steel | 58-62 | ≥1000 | -40~200 | Medium to High Load Transmission |

| 17-4PH Stainless Steel | 42-48 | ≥930 | -50~300 | Corrosion Resistant Applications |

| POM Engineering Plastic | - | ≥60 | -40~100 | Low Noise, Lightweight Requirements |

| Titanium Alloy | 35-40 | ≥860 | -100~400 | Aerospace, High-End Equipment |

Want to quickly launch a custom helical gear manufacturing project? You can directly upload your drawings and parameter requirements, and JS Precision will provide a process assessment and instant quotation within 24 hours, enabling your non-standard designs to be implemented quickly.

Figure 3 Gear engineering drawing with detailed dimensions, angles, and symbolic annotations.

Figure 3 Gear engineering drawing with detailed dimensions, angles, and symbolic annotations.

Why Is hard gear finishing services An Indispensable Last Step For High-Performance Gears?

Gears undergo micro, deformation after heat treatment, which is one of the main sources of inaccuracy. By means of precise correction, hard gear finishing services has grown to be the core process in the realization of the ultimate performance of gears, its significance being especially felt in top, of, the, range transmission systems.

Correction of Tooth Profile Accuracy and Surface Integrity, Sublimation after Quenching

At the heart of hard gear finishing services is the correction of heat treatment deformation:

- Using grinding and honing operations to accurately eliminate deformation.

- Raising accuracy from AGMA grade 9 to grade 12, with a tooth pitch error within 0.008mm.

- Surface Ra 0.2-0.4m, leading to better pitting resistance.

- Gear fatigue life can be increased by 2-3 times.

Brand Value of hard gear finishing services: Long, Term Benefits

Hard gear finishing services can be a high, yield investment:

- The cost per unit is increased by 15%, 30% (US$50-80 rise for module 2 gears).

- The lifespan is increased from 8, 000 hours to more than 20, 000 hours.

- Saving on downtime maintenance costs, the annual operating expenses are cut by 10%-20%.

How To Quickly Obtain a Precise Gear Machining Quotation That Meets My Technical Requirements?

One of the most significant steps in beginning a gear machining project is to first acquire a precise quote. JS Precision, a gear manufacturing company, offers an easy and customer, friendly way to get a full quote including the process details, cost breakdown, and the turnaround time, without lengthy communication, through a transparent and efficient process.

Instant Quotation System: An Air of Transparency and Efficiency to Starting a Project

1. Mode of Inquiry: An online form is filled with basic data such as gear type, specifications, material, precision, and quantity, and a quote at least is gotten.

2. Posting of Drawings: The 2D/3D drawings are sent to the assigned e-mail address, and the process is analyzed, and a quote with precision is given within 24 hours.

3.Connecting Directly with Engineers: One can get in touch with the engineer and communicate with him through instant messaging for real, time Q&A and quote calculation.

The price quotation will be inclusive of material, machining, heat treatment, and hard gear finishing services. Standard parts delivery time: 2-3 weeks, customized parts delivery time: 4-6 weeks, rush orders available.

Going from Inquiry to Delivery: A Professional Team Work Guarantees a Successful Project

- Process Review: Understand the drawing and check its feasibility. Also give DFM optimization tips.

- Solution Agreement: Clarify the process route, such as specific plans for adapted bevel gear manufacturing methods and precision machining processes.

- Official Quotation: Prepare a quotation with cost, delivery time, and quality standards.

- Production Follow-up: Synchronize progress and proactively provide feedback on key milestones.

- Delivery and Acceptance: Provide inspection reports to ensure product quality.

Want to get your gear machining quote immediately? Submit your gear drawings or core parameters, noting "Quick Quotation." JS Precision will prioritize your needs and provide accurate calculations within 24 hours, allowing you to quickly advance your project.

Case Analysis: JS Assists In Upgrading The Noise Reduction Of High-Speed Packaging Machine Spiral Gear Set

Client Challenge:

A European high, end packaging machinery manufacturer confronted two major issues related to the core cutter drive unit's helical gear set:

- Noise levels at a frequency of 3000 RPM reached as high as 92 dB and thus, the working environment was considerably affected.

- The wear and tear of the gear set appeared so quickly (less than 8000 hours) that maintenance cost skyrocketed and such expenses were recurrent.

After analysis, it was found that the original supplier's helical gear manufacturing methods had defects, with excessive tooth profile errors leading to severe vibration.

JS Precision's Solution:

1.Deep analysis and custom design:

Engineers utilized 3D scanning to copy the original gear, during this process, the integration of parameter deviations from the original supplier's helical gear was found out.

The team suggested upgrading the precision from AGMA grade 9 to grade 12, and optimizing the helix angle (from 15 to 17) to achieve better meshing. Following this, the custom helical gear manufacturing process was launched.

2. Precision Machining and Hardened Tooth Surface Finishing:

After the precision hobbing, the 4140 alloy steel had been selected, and the operations such as carburising and quenching were done to obtain a tooth surface hardness of HRC60, 62.

After that, a German, imported CNC gear grinding machine was employed to carry out the hard gear finishing services, where the tooth profile and direction tolerances were tightly controlled within 0.015mm, and the surface roughness Ra was constantly maintained at 0.3m.

3.Pairing and Inspection:

To verify that critical dimensions comply with the design specifications, 100% coordinate measuring machine (CMM) inspection of paired gears was carried out. Noise testing of the gear mesh was performed on the machine, and the contact area was set to the best position.

Quantitative Results:

- The noise of the gear set operation was lowered from 92 dB to less than 78 dB, thereby greatly enhancing the working environment.

- The estimated lifetime was increased to 20, 000 hours, causing customer savings of nearly $60, 000 in maintenance costs per year.

- It was just 5 weeks from drawing verification to the delivery of the first batch of qualified parts, a response time that was quicker than that of local European suppliers.

If your equipment also faces problems such as high gear noise and short lifespan, please share your specific operating conditions and pain points. JS Precision will provide you with free problem diagnosis and solutions to help upgrade and improve your equipment efficiency.

Figure 4 Precision spiral gears, used for packaging mechanical drive units.

Figure 4 Precision spiral gears, used for packaging mechanical drive units.

FAQs

Q1: What is the highest precision grade of gears you can machine?

JS Precision is capable and backed up to achieve AGMA grade 12 (equal to ISO grade 5, 6) routinely and stably. For dealing with special ones like aerospace and extremely high, tech medical equipment, we can even dare to achieve higher precision levels such as AGMA grade 13 that can accommodate the transmission requirements at the level of the extreme.

Q2: What are the commonly used materials for gears? How to choose them?

The most common materials used for gears are carbon steel (e.g., 1045), alloy steel (e.g., 4140, 20CrMnTi), stainless steel (e.g., 304, 17, 4PH), and engineering plastics (e.g., nylon, POM). Choosing the right material involves considering the operating conditions such as load, speed, temperature, and corrosiveness. Our engineers will be happy to give you professional selection advice.

Q3: How long does it take from receiving drawings to delivering samples?

Standard simple gears (e.g. spur gears) have a sample delivery cycle of around 2-3 weeks, complicated custom or high, precision gears (due to hard gear finishing services such as gear grinding) generally require 4-6 weeks. We can offer expedited services to shorten this down to 1-2 weeks.

Q4: What are the main factors affecting gear machining prices?

The main factors that come into play are the type and complexity of the gear, the cost of the material, the precision grade requirements, the need for heat treatment and finishing, and the quantity of the order. Among these, high, precision machining and special materials are the ones that largely influence the price.

Q5: Do you provide gear heat treatment services?

JS Precision does provide a one-stop service that can include common heat treatment processes such as tempering, carburizing, quenching, and nitriding, etc. We can tailor the heat treatment to the performance requirements of the gear so that gear hardness and toughness can be achieved as per the standards.

Q6: How do you guarantee gear consistency during mass production?

Consistency and stability of gears during large, scale production have been achieved at JS Precision through various measures such as standardized operating procedures, in-machine inspection, first-piece and patrol inspection systems, and combined use of SPC statistical process control along with real, time monitoring of dimensional errors.

Q7: What is the smallest module gear that can be machined?

JS Precision's precision equipment can process micro gears with a module as small as 0.5, suitable for precision instruments, micro transmission devices and other scenarios, and can ensure that the tooth profile accuracy and surface quality meet the standards.

Q8: Does the quotation include VAT and shipping?

The initial quotation is usually the ex-works price (EXW), excluding VAT and shipping. We can assist with logistics arrangements based on your needs and provide a complete quotation including freight and insurance (CIF/DDP) and VAT.

Summary

Even though they are small, gears are the fundamental levers that make the whole mechanical system work efficiently, reliably, and quietly.

Selecting a professional gear machining services provider is effectively hiring an engineering partner who excels at combining precision assurance, technological strength, and customization capabilities, thus ensuring product performance and project efficiency.

Make the right move now and let the expert knowledge be the driving force of your project. Share with us your gear drawings, parameter requirements, or the specific challenges you have.

By leveraging the advanced manufacturing supply chain advantages in China, JS Precision through its extensive process matrix and fast, response engineering team can provide you with the most competitive instant quotes and trustworthy technical solutions, thus helping you turn brilliant designs into durable and top, quality products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com