While depending on a robust gear train, the heavy-duty excavator raises tons of cargoes with its massive arm. In a Swiss watch, tiny gears drive the passage of time with every movement, with precision down to millimeter levels. From heavy loads to minute details, gears are the "silent heart" of modern industry.

However, the manufacturing of such precision gears is considerably more complicated than just cutting metals.

I have put together this guide to help solve various problems in gear machining and advance your projects smoothly. It will take you inside the world of gear machining, showing how JS Precision, with the superior gear manufacturing process, becomes your partner for trusted gear cutting services.

Key Answer Summary

| Comparison Dimensions | Mass Production of Standard Gears | High-difficulty Custom Gear Machining |

| Core Processes | High-efficiency processes, such as hobbing and gear shaping. | Multi-process composite (e.g., hobbing + scraping), five-axis linkage machining. |

| Tool Type | Standard-specification gear-cutting tools. | Non-standard custom tools for special tooth profile/materials. |

| Material Applicability | Commonly used medium carbon steel, cast iron. | High-performance alloy steel, special brass, engineering plastics, etc. |

| Precision Control | National standard 7-8 grade. | Up to national standard 3-4 grade (AGMA 10-12 grade). |

| Core Challenges | Balancing cost and efficiency. | Complex geometry, heat treatment deformation control, economy under extremely small batch sizes. |

| JS Precision Solution | Automated production line. | Full involvement of engineers, rocess simulation and prediction, customized tooling and heat treatment solutions. |

Are Gear Machining Projects Being Successfully Manufactured? JS Precision's Key Authoritative Processes

In any given gear machining project, the right choice of partner is indispensable. A company like JS Precision has already accumulated ample practical experience in the field of gear machining.

We have been deeply involved in this field for 18 years, serving over 600 clients across 25 industries, including automotive transmissions, industrial automation, and new energy equipment, completing over 120,000 gear machining orders.

For example, we machined double helical gears for a new energy vehicle manufacturer's drive system. Modules from 3 to 8 were precisely machined, and the yield rate was maintained stably at 99.9%.

In addition, our products include big transmission gears with an outer diameter of 800mm, module 20, for mining machinery clients. The accuracy reached a high level of national standard 4, far beyond the requirement of the client.

We have also handled numerous urgent requests. As an example, the delivery of non-standard gears in 48 hours to save a production line for our clients was made possible through meticulous control over every step of gear machining process.

Each point of the guide is verified in our real projects, so you can completely trust its professionalism.

If your company is engaged in a gear machining project, JS Precision can support and guide it with our mature gear machining process and extensive experience in the industry. Please provide your gear drawings and technical parameters, and we will quickly complete the expert review and provide a solution. Welcome to choose our professional services.

What Is Gear Machining? A Precision Technology Beyond “Simple Cutting”

Many people think gear machining is just cutting metal into tooth shapes, but it is much more-it is a precision technology that requires multi-process collaboration, and that is what we are practicing at work every day.

Basic Definition

Gear machining is not only the cutting of the tooth shape but also a complete gear machining process system that includes turning, drilling, heat treatment, and finishing. JS Precision controls precision from the blank.

For example, in turning, high-precision CNC lathes are used to ensure that the datum surface tolerance is within 0.005mm, laying a foundation for the subsequent tooth profile machining. This is an essential prerequisite for good gear machining.

Core Objective

The main purpose of gear machining is to manufacture tooth profiles capable of ensuring smooth, efficient, low-noise, and long-life transmission.

We treat every single gear as a systems engineering project, right from intervening in the design stage. For instance, tooth profile parameters are preoptimized by us in accordance with every customer's transmission load requirements to ensure manufacturability and final performance of the gear. That's the core principle of excellent gear machining.

Whether you need standard or precision gear machining services, JS Precision can create gears to meet your needs through a complete gear machining process. We will follow up on the whole process from design to delivery. Welcome to contact us to start a collaboration.

Unveiling The Gear Manufacturing Process: The Birth Of A Gear

Understanding each step in the gear manufacturing process can help you better control project progress and quality. A qualified gear undergoes five core processes, each requiring meticulous attention.

Process One: Raw Material Preparation

Select the matching raw materials first, then precision machine the basic shape of the gear, and grind it to ensure the flatness and perpendicularity of the reference surface to lay the foundation for subsequent processes.

This step is the starting point of the gear manufacturing process, the accuracy of the reference surface has a direct influence on the accuracy of the subsequent tooth profile machining.

Process Two: Rough Machining of Tooth Profile

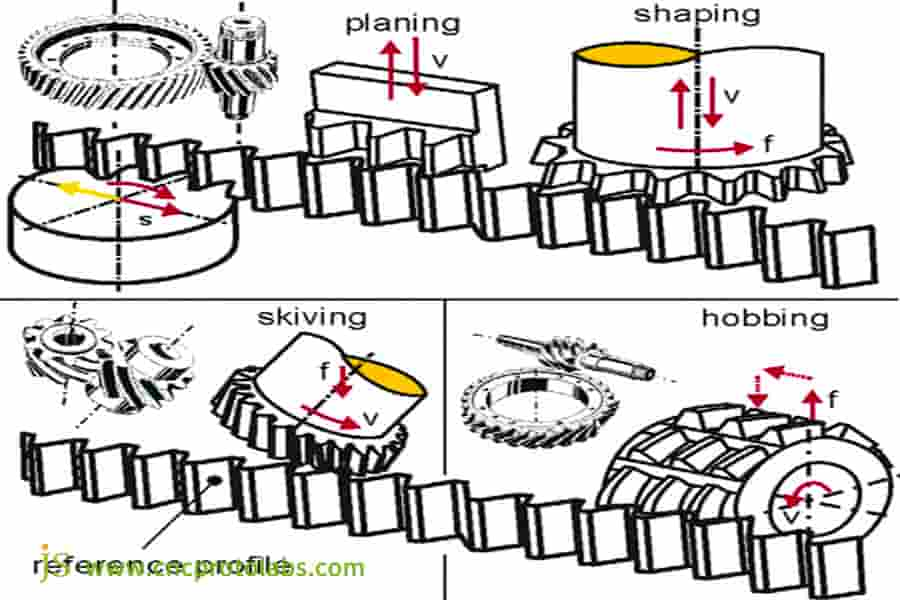

Commonly used methods include hobbing, shaping, and milling. The right process is selected for a particular type of gear. For example, cylindrical gears are preferably made by hobbing since the process can be done with higher efficiency, while shaping is utilized for complicated tooth profiles to better ensure tooth integrity.

During the gear machining process, this is an important step in profiling the teeth.

Process Three: Heat Treatment

The method adopted for different materials is different. For instance, 20CrMnTi is carburized and quenched, while 42CrMo is tempered. Its purpose is to give the gear surface hardness and core toughness, improving its service life. This step directly determines the mechanical properties of gears during the gear manufacturing process.

Process Four : Finish Machining

The general methods used are shaving, grinding, and honing, which are used to correct the deformation after heat treatment.

For example, grinding is done on gears with hardened tooth surfaces, which can achieve grade 5 or higher precision according to national standards, shaving is used in gears whose tooth surfaces are soft, with high efficiency and lower cost. This step is crucial for obtaining high precision in the gear manufacturing process.

Process Five: Inspection and Verification

All the parameters, such as tooth pitch, tooth profile, and tooth direction, are inspected by a gear measuring center to make sure every gear is 100% qualified. This step is the last checkpoint in the manufacturing process of gears and the guarantee of our quality commitment to customers.

| Process Stage | Key Operations | Core Objectives | Common Equipment |

| Slab Preparation | Precision Turning, Grinding | Guarantees the accuracy of the datum surface for the follow-up process. | High-precision lathe, grinder. |

| Rough Machining of Tooth Profile | Hobbing, Shaping, Milling | Initially forms the tooth profile & basic dimensions are ensured. | CNC hobbing machine, shaping machines. |

| Heat Treatment | Carburizing, Quenching, Nitriding | Improves hardness and toughness of gears, enhancing service life. | Continuous carburizing furnace, quenching furnace. |

| Finish Machining | Shaving, Grinding, Honing | Corrects deformation, attains ultimate precision and surface finish. | CNC grinding machines, shaving machines. |

| Inspection and Verification | Full Parameter Inspection | Ensures gears are 100% qualified and meet technical requirements. | Gear measurement center. |

Figure 1:During gear hobbing, the cutting tool continuously meshes with the gear being machined, and gear shaving is the subsequent process of gear machining. gear machining process.

How To Choose Gear Cutting Tools For Different Gear Types?

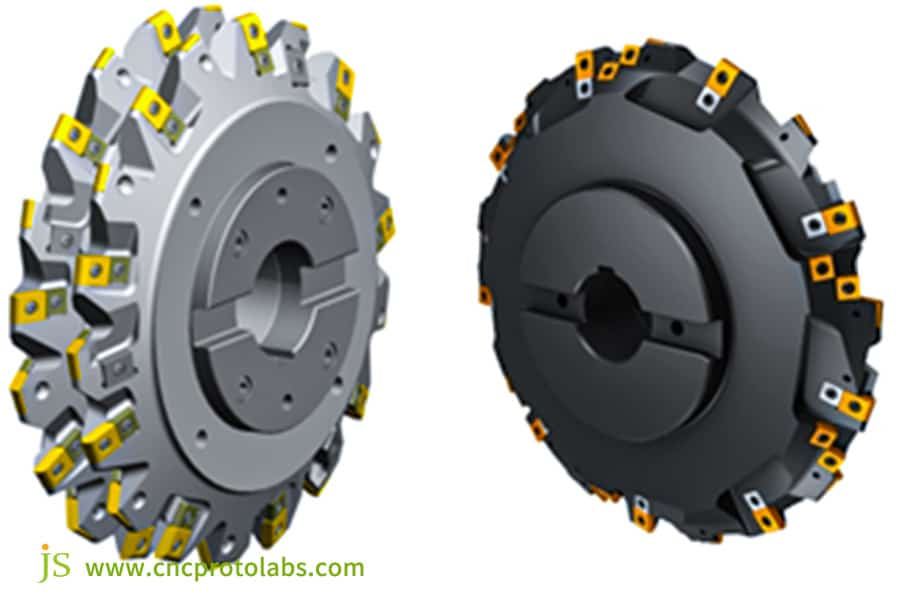

Choosing the right gear cutting tools can improve the efficiency of gear machining by more than 30% while ensuring the quality of machining. Different types of gears have greatly different gear cutting tools, and we will provide the most suitable selection according to the type, material, and quantity of customer gears.

Cylindrical Gears:

Hobs are the first choice. Continuous cutting with hobs is highly efficient and versatile for mass production. For instance, in the case of machining cylindrical gears, the module range can be 1-10, which would require high-speed steel hobs, but in the hardened condition, carbide hobs are needed for better wear resistance.

Bevel Gears:

Bevel gears have complex tooth profiles and require the precision matching of the milling cutter and gear parameters for smooth transmission, thus, there are dedicated spiral bevel gear milling cutters. We will customize the milling cutter according to the number of teeth and module of the bevel gear to ensure machining accuracy.

Worm Gears:

A fly cutter or hob matching the parameters of the worm gear exactly is needed. Using a module of 2 as an example, when machining the worm gear, a corresponding worm gear hob must be used to ensure accuracy in meshing between the worm gear and worm, thereby reducing transmission noise.

Small Module / Non-Standard Gears:

These normally need customized gear cutting tools, for either their unique dimensions are outside of standard tool capacity or their special tooth profile cannot be fulfilled with any standard tool. With strong tool customization and optimization capability, JS Precision is able to design and make dedicated gear cutting tools according to customer gear drawings in a very short time.

| Gear Type | Recommended Gear Cutting Tools | Tool Advantages | Applicable Scenarios |

| Spiral Gears | High-Speed Steel / Carbide Hobs | High efficiency, versatile, suitable for batch processing. | Automotive transmissions, motor drives. |

| Bevel Gears | Dedicated Spiral Bevel Gear Milling Cutters | Matches the complex bevel gear tooth profiles for smooth transmission. | Engineering machinery, marine transmissions. |

| Worm Gears Dedicated Worm Gear Hobs | Fly Cutters Features | Ensures meshing accuracy, reduces transmission noise. | Elevator traction machines, precision instruments. |

| Small Module / Non-Standard Gears | Dedicated Tools | Meet the demands of special size and tooth profile. | Medical equipment, micro motors. |

No matter which type of gear you need to choose gear cutting tools for, JS Precision can provide professional advice and even customize specialized tools. We will combine your production needs with a balance between efficiency and cost. Please contact us for tooling solutions.

Figure 2:Semi-finish, tangential insert gear milling cutters.Gear milling cutters with tangentially mounted inserts are quite common.

Why Is Choosing The Right Material Half The Battle In Gear Manufacturing Process?

Material is the "skeleton" of gears. Proper selection of materials can increase the service life of gears by more than 50% and reduce the difficulty of subsequent gear machining process. Different materials have greatly different performance characteristics. We will suggest the most suitable material according to the customer's application scenario.

Steel:

20CrMnTi is the "king of carburizing steels." The surface hardness can reach HRC58-62 after carburizing and quenching. The toughness of the core is good, and it is suitable for high-load applications such as automotive drive gears.

42CrMo represents quenched and tempered steel. After quenching and tempering, it enjoys high strength and good plasticity, and it can be applied for medium-load industrial gears and is commonly used in machine tool transmission systems.

Cast Iron:

HT250 has good vibration damping and lower cost, though the strength is not as high as for steel. It's suitable for large, low-speed gears, such as low-speed transmission gears in mining machinery that reduce vibration and noise during transmission.

Non-ferrous Metals:

Include brass and tin bronze, which are wear-resistant and self-lubricating, therefore, no extra lubrication is needed in running. This can be applied to the worm gears, such as those in the elevator traction machines, to reduce the cost of maintenance.

Engineering Plastics:

POM and nylon are lightweight, low-noise, and corrosion-resistant, making them suitable for light-load, corrosion-resistant environments in machinery such as gears for food processing. They are non-polluting materials and operate under low noise.

Figure 3:When designing a gear that is going to be subjected to a corrosive environment or needs to be non-magnetic, a copper alloy is usually the best choice.

Exceeding Standards: Confronting The Particularities Of Custom Gear Machining

Compared with the standard ones, non-standard gears are much more difficult in custom gear machining. Usually, there are three major difficulties: complex geometry, heat treatment deformation, and cost-effectiveness in small-batch production. However, JS Precision effectively addresses these challenges.

Challenge 1: Complex Geometry

Many non-standard gears have non-involute tooth profiles or special profile modification requirements that cannot be met by ordinary equipment.

Our strategy involves the use of a five-axis CNC machining center or wire EDM. 5 axis CNC machining allows multi-dimensional cutting, whereby complicated tooth profiles could be easily machined, while wire EDM makes high accuracy possible with tolerances controllable within 0.002mm, which can meet special profile modification needs.

Challenge 2: Heat Treatment Deformation Control

Gears with an irregular shape are likely to suffer unpredictable deformation because of heat treatment, meaning low precision.

Our solution is to predict the deformation trend through process simulation software and perform reverse compensation in the early stage of processing.For instance, we should reduce the size of the tooth profile by 0.01mm in advance to offset the expansion after heat treatment. Meanwhile, utilizing gear grinding after heat treatment for precise correction has ensured gear accuracy.

Challenge 3: Economic Efficiency of Small Batch Production

Custom gears are often produced in small batches. Custom cutting tools are expensive, and process debugging is complicated, so many manufacturers are unwilling to undertake such projects.

Our service is small-batch and low-cost custom gear machining, featuring flexible process combinations and smart scheduling. For example, small orders of the same type for different clients can be combined and debugged, with some process sharing to lower tooling and debugging costs.

If you have custom gear machining needs for non-standard gears, JS Precision can help you solve various problems with professional technology and flexible solutions. We'll follow up on everything from design optimization to production delivery, ensuring the quality and delivery time for such non-standard gears. Welcome to choose our services.

Case Study: JS Precision Saves A Shutdown Production Line With 48-Hour Emergency Delivery

For a client, one minute's stop in the line may mean huge losses. Once, our gear cutting service saved a million-dollar production line within 48 hours-a sure example of rapid response.

Client's Pain Point

A car parts manufacturer's automated production line was in breakdown because of the breakage of an important non-standard gearbox gear. That gear was of double helical form, with peculiar teeth and made from the high-hardness alloy steel material 42CrMo.

The client contacted a few manufacturers and they all gave an indication of at least 7-day delivery time. Due to the daily down-time of the production line, the losses were mounting to $50,000 a day and thus the client needed a new gear as soon as possible.

How Did JS Precision Respond?

We immediately initiated our emergency response process upon receipt of the request for assistance.

- Also, a dedicated team of reverse engineers, process engineers, and operators was put together within 2 hours.

- The reverse engineering was performed by precisely measuring the coordinates of the damaged gear using a Coordinate Measuring Machine, also, the reconstruction of the model in 3D was done within 3 hours.

- Then, the traditional rough grinding was skipped, and the compact process chain of "turning → heat treatment → hard turning → gear grinding" was adopted to shorten the processing time.

- Custom gear cutting tools and high-precision CNC gear grinding machines from inventory were used finally. With dedicated personnel monitoring quality, continuous production for 24 hours was achieved.

Results and Data

From the receipt of the damaged piece to the delivery of the new gear, it only took 48 hours, 5 days in advance of customer requirements, while the precision of the gear reached the national standard level 5, much more than the customer requirement of level 6, thus helping the customer successfully avoid more than $250,000 losses caused by downtime.

Customer feedback: "JS Precision is not only a supplier but also an insurance policy for our production line. We will definitely put priority on you for future gear needs." Since then, this customer has established long-term relations with us and has been placing stable gear cutting service orders with us every month.

If there is a sudden shutdown on the production line and you need gears in an extremely short period, the JS Precision gear cutting services can provide an emergency response to deliver qualified gears within 48 hours to minimize the loss due to downtime. Please feel free to contact us anytime.

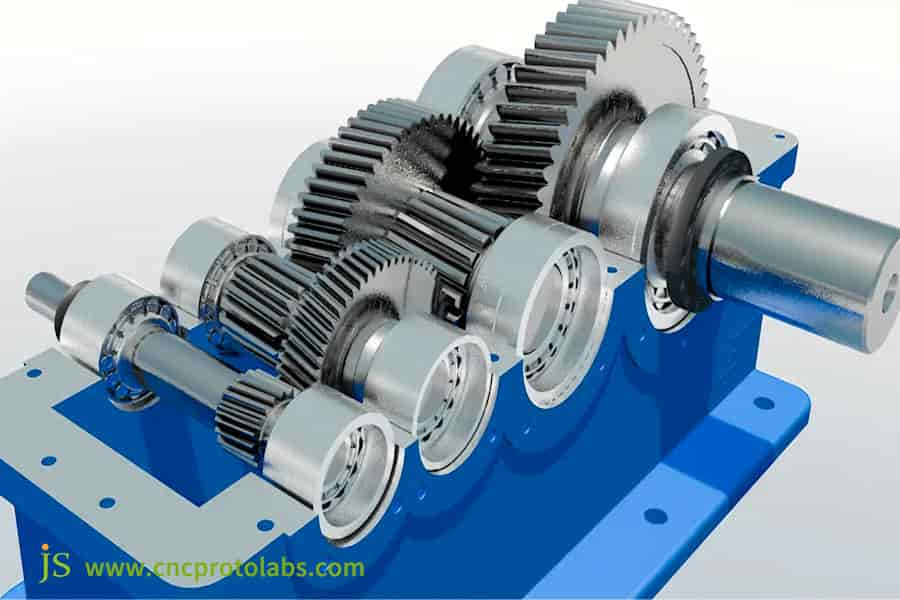

Figure 4:custom industrial gearbox

How To Start Your Gear Machining Project? Partner With JS Precision

Starting a project in gear machining is not complicated: just four steps to turn your needs into a qualified product, including full transparency and efficiency by working with JS Precision.

Step 1: Information Provided

Please provide drawings of the gear and technical parameters, module, number of teeth, precision grade, material to be used, application, etc. If the drawing isn't complete, we can help you in making the drawings according to your requirement.

Step 2: Expert Review

Our engineering team reviews your design in 24 hours with manufacturability analysis, process suggestions on which structures can be optimized to reduce costs, and which parameters need to be adjusted for improved performance.

Step 3: Request a Quote

In accordance with the determined process plan, you are to receive a clear and transparent quote within 48 hours. This covers all costs, including materials, processing, and testing without any hidden costs.

Step 4: Production & Quality Assurance

Once your quotation is confirmed by you, we will arrange production without any delay. During the production process, continuous updating of the production progress is done. There will be an issuance of inspection reports for key processes, while full-parameter tests are done on the finished products to ensure that the delivered gears are 100% qualified.

FAQs

Q1: What is the major difference between gear grinding and gear shaving in gear machining?

Gear grinding is the most precise finishing of a hardened tooth surface, up to national standard level 4, and is applicable in demanding applications, but it is inefficient and at high cost. Gear shaving is a kind of soft-tooth-surface finishing, with high efficiency and low cost, the precision grade is up to national standard level 6~7, suitable for general use.

Q2: What is the maximum gear module and size range that can be processed?

We can process modules from 0.5 to 20, meeting the needs of gears from micro to large sizes. The maximum outer diameter can reach 800mm, capable of processing both micro motor gears and large mining machinery gears.

Q3: How to reduce the noise during gear transmission?

The lessening of noise during manufacturing can be done with higher precision machining, such as grinding gears to improve the tooth profile for meshing. In so doing, friction can be reduced, which requires proper lubrication.

Q4: What are the advantages and disadvantages of plastic gears compared with metal gears?

The advantages of plastic gears are lightweight, low noise, corrosion resistance, and low cost. Their disadvantages are that plastic gears have a poor capacity in load, temperature, and wear resistance. Metal gears are thus used under high-load, high-temperature working conditions.

Q5: How to choose the appropriate heat treatment process for gears?

It depends on material and application requirements. High-frequency quenching would be suitable for gears needing a surface hardening treatment with good core toughness. Carburizing and quenching are used in high-load-bearing gears. Precision gears with strict deformation requirements can apply nitriding.

Q6: Do you provide gear design and optimization services?

Yes, we provide comprehensive technical support, from conceptual design to strength verification, and finally to the optimization of processes. Based on your application scenario, structure, and parameters can be optimized by us, in order to implement performance and cost optimization of gears.

Q7: What is meant by gear precision grade, such as national standard grade 7?

Precision grade comprehensively defines the allowable error value of the gear in three aspects, tooth pitch, tooth profile, and tooth direction. The smaller the grade number, the higher the precision. The national standard grade 7 has an error of about 0.01-0.02 mm and is suitable for general industrial transmissions.

Q8: How to improve gear lifespan under harsh operating conditions?

Use tough materials, such as 20CrMnTi. Deep carburized heat treatment shall be conducted to enhance the hardness. Meanwhile, some strengthening methods like shot peening can be used to increase the strength of the tooth surface. Meanwhile, further optimization of lubrication can be carried out in order to further extend the life of gears.

Summary

Gears are the very soul in power transmission, the quality of which directly influences the performance and dependability of the whole equipment. The selection of a gear cutting service requires much more than a machine tool but rather an expert team with professional knowledge in materials, processes, cutting tools, and applications.

JS Precision is your professional and reliable partner in this regard. From standard gears to custom gear machining, we can provide full-process services, meeting the customers' needs either in urgent delivery or precision control.

For any of your gear machining projects, please feel free to visit our website now for a quote or inquiry about your project requirements. You will get a preliminary process plan and highly competitive quote from our professional team within 4 hours. Allow the exquisite craftsmanship from JS Precision to be the cornerstone for your superior product performance.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com