CNC machining services often leave clients in a dilemma: have you ever received an astonishing quote for a small batch of precision parts, only to hear that mass production can bring unbelievable unit costs? The reason behind this is not some mystical calculation but driven by the precisely calculated pricing logic behind the CNC machining services.

This is the kind of query that regularly comes into JS Precision. Customers are eager to control their costs but are concerned about suppliers' inability to adapt in response to changed volume productions.

This guide combines 15 years of practical experience in CNC machining. Whether you are searching for superior aluminum CNC services or are urgently in need of localized CNC machining services near me, this article will do an in-depth analysis, right from inquiry to acceptance of the whole chain, to help you obtain the best value for any order quantity.

Core Answer Summary

| Core Dimensions | Core Mechanisms | Your Strategy |

| Pricing Structure | Quote = Fixed Cost + Variable Cost × Quantity. A small batch has a high proportion of fixed costs, whereas a large batch amortizes the cost and hence offers a lower price. | Share production planning to get the optimal pricing tier. |

| Cost Drivers | Material, complexity, precision, and quantity are the factors that determine the cost of CNC machining metal parts. Proprietary processes are up-front costly for custom machining services. | Use DFM to optimize design for reductions in the cost of complicated parts. |

| Quality Verification | Best online CNC service core verification includes samples and test reports, adding professional process advice-not just the lowest prices. | Proactively request samples and test data as core evaluation criteria. |

| Service Acquisition | Full technical documentation is needed to provide precise pricing for a custom machined part. For reliable CNC machining services near me, the processes should be transparent and the response time fast. | Prepare your drawings and clear requirements to select a one-stop solution partner. |

Why Choose JS Precision? Pricing Strategies For Small And Large Batch Production Of CNC Machining Services

JS Precision, which I am working for, has 15 years of experience in the CNC machining industry.

Our quality management system strictly follows the International Organization for Standardization (ISO) ISO 9001:2015 quality management system standard, which provides a framework for our process stability and continuous improvement, ensuring that every project can be completed with high quality within the predetermined budget and time.

We have served more than 5,000 clients from every part of the world, including aerospace, medical devices, automotive parts, and consumer electronics, dealing with projects from single custom prototype to mass production amounting to 100,000 units.

For instance, we completed a small-batch trial production of 100 precision titanium alloy parts for an aerospace client and delivered qualified products within just 12 days.

We completed an order of mass production, 50,000 sets of aluminum alloy structural parts for an automotive client, and optimized the process to save up to 30% of the unit cost for our client.

And we solved the complex curved surface parts mass production problems for a consumer electronics client and improved the yield from 85% to 99.5%.

This guide sums up the practical experience of our team in handling tens of thousands of orders. Each point can be justified with real projects, and you can fully trust the suggestion inside.

Want to experience CNC machining services that balance flexibility and cost? Reach out to us, state your order quantity and product requirements, and we are in a position to assign an engineer to you to provide a no-cost full-cycle cost planning solution from prototype to mass production.

How Does Pricing For CNC Machining Services Work? Breaking Down Fixed And Variable Costs

The pricing structure of CNC machining services itself explains the phenomenon that large and small batches have huge price differences. Many customers will only consider the ultimate unit price without considering the cost allocation logic, which is a big flaw in purchasing decisions.

Unveiling the core pricing model:

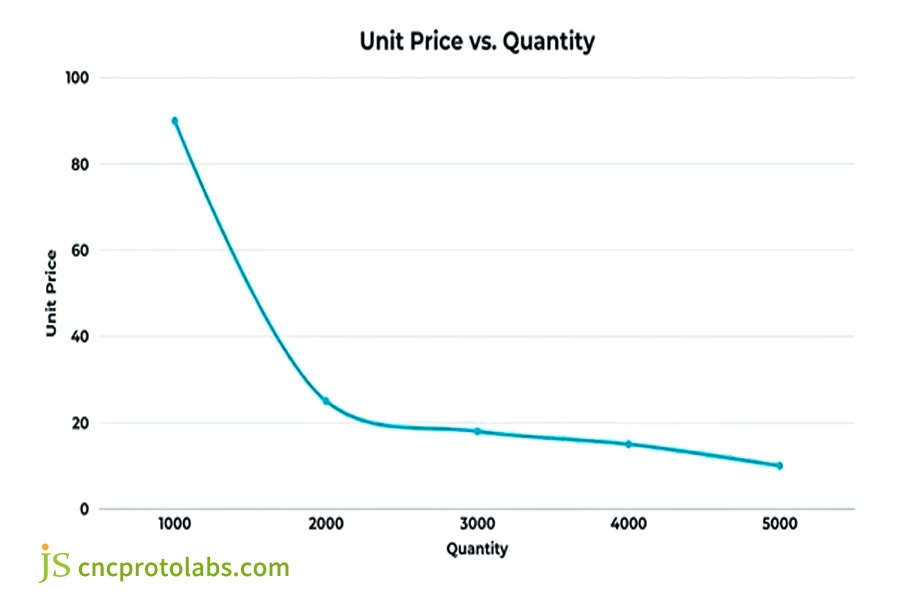

The formula is: Total Price = One-time Fixed Cost + (Unit Variable Cost × Quantity). This is a very important formula to understand the price difference and applies to all CNC machining projects.

Cost Analysis for Small Batch Orders: Why Does the Unit Price Appear Higher?

In small batch orders, from 1 to 100 units, the one-time fixed cost is extremely high: programming costs US$200-800, process design US$150-400, etc. When all fixed costs are spread over a small quantity of products, the unit cost shoots up.

What customers are paying for is essentially "knowledge, preparation, and start-up" in return for flexibility, not having to invest in equipment technology.

Economies of Scale in Cost Analysis for Large Batch Orders: How does it reduce the unit price?

In large-volume orders, fixed costs are fully amortized in 1000 pieces or more, and the unit price is mainly dependent on variable costs such as raw materials and machining time. Batch procurement (saving 10% -20%), specialized fixtures (improving efficiency by 30%+)+process optimization, variable cost reduction, significant economies of scale.

Comparison of the cost structure between small batch and large batch production (taking 6061 Aluminum Parts as an example)

| Type of Cost | Small Batch (10 pieces) | Large Batch (10,000 pieces) |

| Programming Fee | $300 (Amortized $30 per piece) | $300 (Amortized $0.03 per piece) |

| Tool/jig Preparation | $500 (split $50 per item) | $800 (split $0.08 per item) |

| Raw Materials | $100 ($10 per item) | $90,000 ($9 per item) |

| Machining Time | $400 ($40 per item) | $30,000 ($3 per item) |

| Tool Wear | $50 ($5 per item) | $15,000 ($1.5 per item) |

| First Piece Testing | $200 (split by $20 per item) | $200 (split by $0.02 per item) |

| Total Cost Per Unit | $155 | $13.63 |

It demonstrated how costs per unit decrease by 91.2% when orders rise from 10 to 10,000 units. Utilizing a full-scale service provider such as JS Precision allows for optimal product lifecycle costs.

Figure 1: Unit Price vs. Quantity graph.As the output increases, the unit price will significantly decrease.

What Are The Main Factors Contributing To The Final Price Of CNC Machining Metal Parts?

Besides order quantity, five core factors jointly determine the cost of CNC machining metal parts:

1. Material Cost: stainless steel and titanium alloys are much more expensive than aluminum and ordinary steel. The price of the raw material of titanium alloy is 5~8 times that of 6061 aluminum.

2. Geometric Complexity: Deep holes, micro-threads, and complex-curved surface increase programming and machining difficulties, deep hole machining efficiency is only 1/3 of ordinary holes.

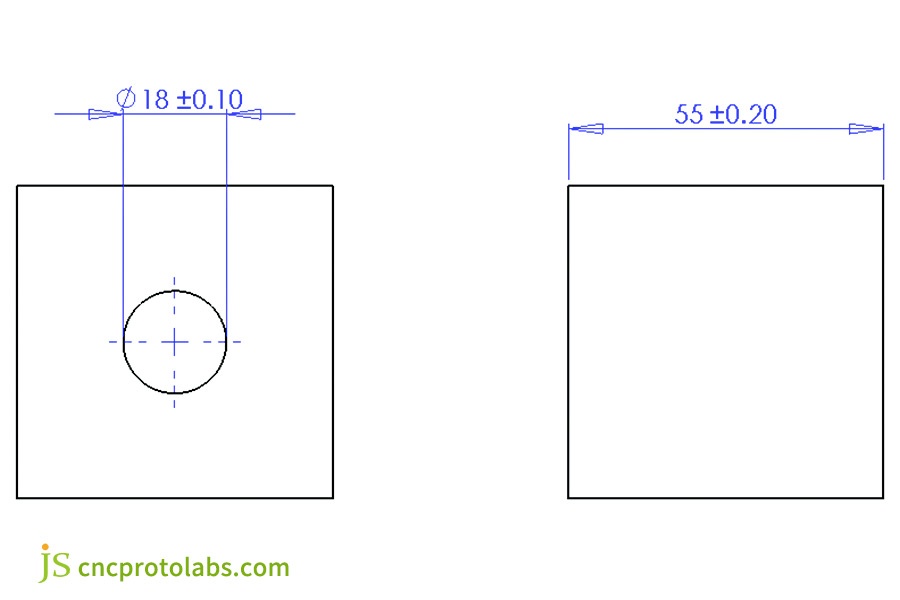

3. Tolerances and Surface Finish: The tighter the tolerances, the higher the cost. The rise exponentially in a co-relation from ±0.01mm to ±0.05mm. Special Requirements: Additional processes like mirror polishing will need special requirements.

4. Order Quantity: Directly impacts cost amortization per unit. Small batches result in less dilution of cost and higher unit prices, whereas large batches exhibit substantial economies of scale.

5. Requirement on Post-processing: Heat treatment, anodizing, etc., which adds costs in US$5-15/piece and lead time due to the surface area and coating thickness.

Example of Cost Differences for Different Tolerance Requirements (Taking φ20mm Shaft Parts as an Example)

| Tolerance Requirements | Machining Equipment | Machining Time for Single Piece | Increase in Per-Piece Cost (USD) | Applicable Scenarios |

| ±0.1mm | Ordinary CNC Lathe | 10 minutes | 0 | Non-Matching Parts |

| ±0.05mm | Precision CNC lathe | 15 minutes | 8 | General matching parts |

| ±0.01mm | High-Precision CNC | 30 minutes | 25 | Core Matching Parts |

| ±0.005mm | Ultra-precision machining equipment | 60 minutes | 60 | Precision instrument parts |

Figure 2: Setting strict tolerances will significantly increase the price of parts, as higher precision will lead to increased production time and manual inspection costs.

How To Find And Choose The Best Aluminum CNC Service?

Because of its light weight, high strength, and corrosion resistance, aluminum is a rather popular material in CNC machining. However, an aluminum CNC service has distinctive features, the selection of which by a supplier requires attention to professional capabilities.

Special Features of Aluminum Machining

Aluminum features low hardness and is prone to deformation, besides sticking to the cutting tool. It also often requires high surface finishes that put stringent demands on equipment, cutting tools, and process parameters.

Four Dimensions to Assess a Supplier

- Manufacturing: Is the supplier equipped with high-speed machining centers, specialty aluminum cutting tools, and an efficient cooling system?

- Processing Knowledge: Can the supplier provide successful case histories that concern the typical challenge handling of thin-walled, deep cavity threaded parts in aluminum?

- Quality Control: Does the supplier adopt high-precision testing equipment like coordinate measuring machines and provide test reports?

- Material Management: The supplier uses high-quality aluminum ingots, such as 6061 and 7075. Does it provide material certificates?

JS Precision has been focused on aluminum CNC service for 15 years equipped with 20 high-speed machining centers and special aluminum machining tools. With over 10,000 projects in aluminum parts completed, they can perfectly solve all kinds of aluminum machining challenges.

Looking for high-quality aluminum CNC service? Upload your aluminum part design drawings now, and note "Aluminum Part Machining Consultation." We will offer a process assessment report and an accurate quote within 24 hours while providing free material certificates and test reports to give you peace of mind when purchasing.

What Do You Need To Prepare In Order To Get A Quotation For Custom Machined Parts?

The key to a correct quote in custom machined parts is complete information. Complete information means never having to experience large quote discrepancies and inefficient communications. Below is a "Perfect Quote Checklist":

- 3D Model Files: STEP, IGES formats. Core information source-helping suppliers accurately assess difficulty of machining.

- 2D Engineering Drawings: PDF, DWG formats stating key dimension, tolerances, geometric tolerances, and surface roughness.

- Material Specifications: To grade and temper, such as Aluminum 6061-T6, Stainless Steel 304.

- Quantity Requirements: Specify prototype, small batch trial production, and long-term estimated quantity.

- Finishing and Standards: Specify whether heat treatment, anodizing, etc., is to be applied, and what quality standards are followed, e.g., ISO 9001.

- Delivery Requirements: Indicate time, place, and whether any expedite service is needed.

The more detailed the information provided, the more accurate the quote will be and the less the communications costs will be later on.

In The Time Of Online Ordering, How To Check The True Quality Of Any Best Online CNC Service?

The rise of online manufacturing platforms really made it a lot easier to choose the best online CNC service, but the quality can vary significantly.

The International Electrotechnical Commission (IEC) ISO/IEC 17050:2004 conformity assessment standard provides a standardized method for supplier capability verification and is an important basis for evaluating the reliability of online manufacturing services.

Below are four practical steps to help avoid pitfalls:

- Detailed Case Study: Study the project library for cases with similar complexity and materials in order to learn about process-related problems and solutions.

- Request samples and reports: The good service providers never hesitate to provide the physical samples along with the test reports for the direct verification of quality and compliance.

- Communication professionalism: How easily can the engineering team understand your requirements and provide you with valuable suggestions on DFM?

- Warranty conditions: Review how non-conformities are treated, policies on any delay in delivery, and agreements related to data confidentiality.

As one of the most experienced best online CNC service providers, JS Precision has a publicly available case library, comprehensive sample services, and a strict quality assurance system. Our engineering team provides DFM advice from the very beginning of communication to ensure project smoothness.

Do you want to verify the true strength of the best online CNC service? Contact JS Precision with your part requirements. We'll be providing relevant case studies for reference, moreover, we can also mail similar samples with test reports free of charge so that you can experience our machining quality and service level firsthand.

How Does Order Quantity Reshape Pricing For CNC Machining Services?

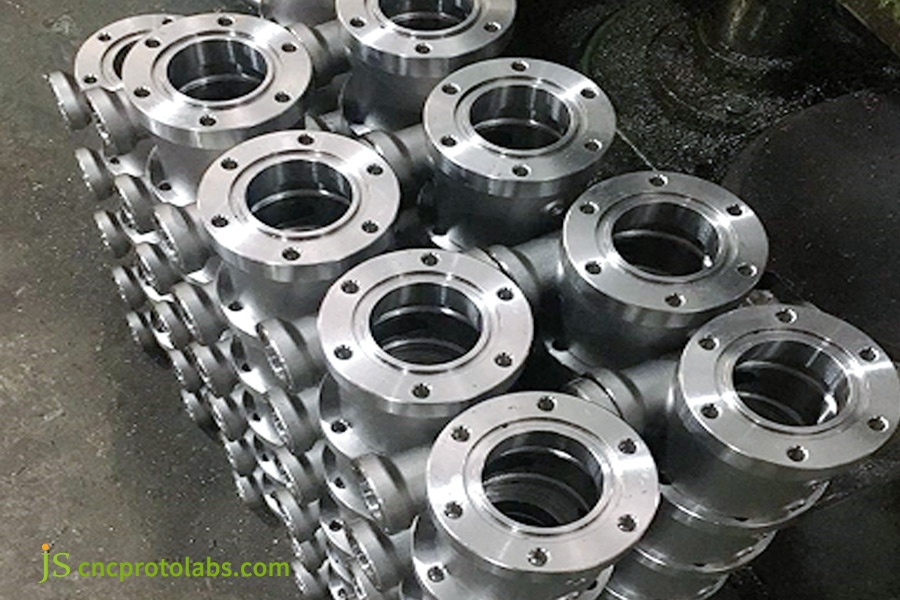

The order quantity will be the central factor that affects the pricing of a service using the CNC machining process. Pricing strategies vary sharply according to the order size:

1. Prototype Stage (1-10 pieces): In this stage, the main concentration is to cover the fixed costs, hence, rapid delivery will be pursued to meet the needs of design verification. High unit price, $180-250 USD, short cycle time, 3-5 business days.

2. Small Batch Trial Production(50-500 pieces): cost optimization with process optimization, Special fixture & optimized toolpath are used. Unit cost reduction of 40% to 60% compared with the prototype stage: USD $80-$120. Cycle Time: 10-15 business days.

3. Medium to large-scale production (1000-10000 pieces): Maximizing economies of scale, utilizing dedicated production lines, bulk procurement of raw materials, reducing single piece costs by another 30% -50% ($35-60), with a cycle time of 20-30 working days.

From prototype to volume production, JS Precision supports the whole process seamlessly. It allows advanced feasibility in mass production and avoids increases in cost due to design changes.

Figure 3: Numerical control machining can meet the needs of both small batch production and medium batch production. However, as the order volume increases, the unit cost will decrease.

Custom Machining Services Vs. Standard Products: Just Where Is The "Customization"?

The essential difference between custom machining services and a standard product lies with the "customized solution," whose value will be reflected in four dimensions:

- Dedicated Engineering Investment: Analysis of the process, direct programming, and tooling design focuses on characteristics pertinent to the parts.

- Flexible Materials and Processes: The fabrication process is completely based on customer-specified materials and processes, without any limitation imposed by the existing solutions.

- Deep Intellectual Property Binding: Exclusive ownership of parts and process solutions is protected via confidentiality agreements.

- Supply Chain Integration Services: From raw material purchasing to assembly, with one-stop service to simplify management.

During custom machining services, one pays for exclusivity in solutions and control in production, which means that the cost of ownership is reduced in totality.

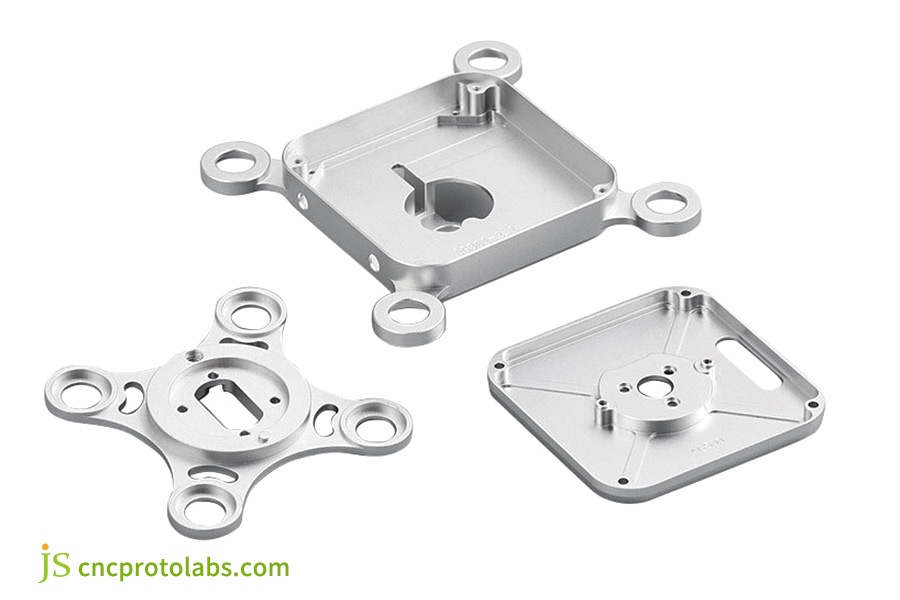

Case Study: Mass Production Of 10,000 Drone Fuselage Frames, 40% Cost Reduction Achieved

Initial Customer Challenge

The drone bracket made from 7075 aluminum alloy is a deep cavity and thin-walled part containing many high-precision mounting holes, requiring the highest standards of strength and weight.

For the first 10 pieces prototype unit price, USD 280 was given. Obviously, such a high cost prevented expansion in the marketplace, and the client urgently looked for a supplier capable of closing the gap between prototype and mass production, balancing quality and cost.

JS Precision's Solution

1. DFM Optimization: The engineers came to know that the integral deep cavity milling accounted for 70% of the total machining time and was highly susceptible to deformation. We suggested a modular structure that would ensure strength while reducing the milling time by 60% and enhancing rigidity in parts.

2. Process and Supply Chain Improvement: A linkage fixture was made that increased capacity for single-batch machining from 1-4 pieces, sourcing scales are utilized to offer a discounted price on material 7075 aluminum alloy, discounting the raw material cost by 12%.

3. Tiered Cost Approach: Tier pricing and a delivery schedule for prototypes, small batches, and large batches were developed in support of the scaling up of production by the client in line with market feedback but with minimal early risk.

Final Results

This was the sequential cost reduction: from $280 for a prototype of 10 units to $260, for a small batch of 500 units, it further went down to $120. The unit cost was only $168 when the order quantity reached 10,000 units-a 40% reduction compared with the price for the original prototype.

It considerably improved the product's competitiveness for the client, culminated in a successful market launch, and translated into long-term cooperation with orders of more than 20,000 units on a regular basis.

Staged Cost Comparison of Drone Fuselage Frames

| Production Stage | Quantity | Original Design Unit Price (USD) | JS Precision Optimized Unit Price (USD) | Cost Reduction | Delivery Time |

| Prototype Stage | 10 units | 280 | 260 | 7.1% | 7 working days |

| Small Batch Trial Production | 500 units | 150 | 120 | 20% | 15 working days |

| Mass Production | 10,000 units | 280 | 168 | 40% | 30 working days |

Do you have a demand for cost reduction in mass production of custom machined parts? Upload your part design drawings immediately, with the note 'Mass production cost reduction consultation', and we will provide you with free DFM optimization and phased quotation solutions, achieving a cost reduction of up to 40% through custom machining services.

Figure 4: CNC Machining UAV Parts Aluminum Aerocraft Fixed Mount Parts

CNC Machining Services Near Me: How To Combine Online And Offline Services

A lot of clients are habituated to searching for "CNC machining services near me" to avail the local suppliers since communication is easy and the response is quicker. But in a globalized world, the definition of "near" has changed.

The value of localized services:

A face-to-face dialogue, ability to respond quickly to urgent needs, saving on local logistics costs, and small-batch projects requiring frequent design changes or expedited delivery.

Providing efficient search and evaluation strategies:

1. Precise online screening: Use long-tail keywords such as "5-axis machining" and "aerospace aluminum" together to quickly identify, on Google Maps or other B2B platforms, which local suppliers have matched technology.

2. Offline capability verification: For important projects, conduct on-site inspections of workshop equipment status, production environment, and management level, focusing on equipment precision, quality inspection processes, and employee professionalism.

The Expansion of "Near Me"

Located in the manufacturing hub of China, JS Precision relies on DDP logistics services to handle customs declaration, transportation, and customs duties, customers just need to sign for the goods locally.

An online communication mechanism ensures every inquiry will be dealt with efficiently within 24/7 hours, bettering the value and reliability of most local workshops and making it a superior "virtual neighbor."

Searching for low-cost CNC machining services near me? Shake off the bonds of geography and call us. Email us your part needs and get complete logistical and delivery solutions for the ultimate in convenience-the "remote neighbor."

FAQs

Q1: What are the usual kinds of hidden fees contained in the quotation of CNC machining services?

The hidden charges include the non-standard document processing, rush fees, special packaging, and minimum spending requirements. Legitimate suppliers such as JS Precision will transparently inform all costs in advance to avoid additional expenses in the future.

Q2: Which one of the following is more expensive with CNC machining, aluminum or stainless steel? Why?

Generally, stainless steel is more expensive to CNC machine. Because of the hardness and strong tendency to work harden of the stainless steel, it creates faster tool wear and slower machining speeds, therefore higher overall machining time and tool replacement costs compared to aluminum machining.

Q3: Can I get a quote for custom parts with just an idea or a sketch?

Difficult to quote. Tool making quote requires specific dimensions, tolerances, and material info. At least a sketch with basic dimensions is needed, preferred is a 3D model. The JS Precision free DFM consultation will help refine the design.

Q4: How can I save money without sacrificing quality for small-batch production?

Reduce machining difficulty through design optimization, utilize more cost-effective materials when feasible (example: 6061 vs. 7075 aluminum), and relax tolerances on non-mating surfaces. Choose suppliers specializing in small lots of production to minimize the fixed-cost per unit amortization.

Q5: What is "Design for Manufacturability"? How does it impact my part costs and delivery time?

Design for manufacturability means design it for easy machining. Relevant recommendations can significantly reduce machining difficulty and shorten working time if followed, thus minimizing the cost and speeding up delivery. JS Precision's DFM consulting can help optimize your design solution.

Q6: Are the logistics and tariffs complicated when CNC machining from China?

Not complicated, as the JS Precision DDP services will take care of the declaration, international transportation, customs clearance, and tariffs in the country of destination. This would leave you without concern for complicated processes, you just have to sign for the parts locally.

Q7: What's the shortest delivery time for urgent prototype projects?

JS Precision can provide urgent, expedited service for simple prototypes of either aluminum or steel with complete 3D models, drawings, and other materials in as little as 3-5 business days.

Q8: What if my results for "CNC machining services near me" are unreliable?

It is recommended to evaluate both online reputation and offline capabilities, and not just focus on geographical distance. You can contact internationally reputable suppliers like JS Precision, we can reliably meet your needs through professional services.

Summary

Understanding the pricing structure of CNC machining services is not about haggling but about creating a transparent, trusting partnership with manufacturing partners through which ideas are jointly transformed into competitive products.

Whether it be prototyping or mass production, JS Precision will exactly match your needs and become a reliable partner in your product development journey, ensuring every investment yields maximum value.

Unlock the full value of your designs now!

You can upload your part files here or directly contact our sales engineers. You will receive a clear and transparent detailed quotation, including manufacturability optimization suggestions, in 24 hours. Allow us to help you precisely control costs and efficiently advance your projects.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com