Imagine a material that combines ancient reliability with modern precision: bronze, an alloy that has carried human civilization for millennia, is reborn at the 21st-century CNC machining centers.

From naval submarine components that must be spark-free to heavy machinery bearings that require lifelong lubrication, CNC machining bronze has become the silent hero in high-performance applications owing to its superior wear and corrosion resistance with a self-lubricating aptitude.

With years of experience in CNC machining at JS Precision, this article will take you deep into the world of precision CNC machining bronze parts and show how this technology can turn this classic material into key components driving modern industrial development.

Summary Of Key Answers

| Comparison Dimensions | Advantages of CNC Machining Bronze | Challenges of CNC Machining Bronze |

| Material Properties | Excellent wear resistance, seawater corrosion resistance, low coefficient of friction, non-magnetic. | Relatively high material cost, relatively soft and prone to scratches. |

| Machinability | Easy chip breakage, good heat dissipation. | Specific requirements for CNC machining tools, need to control built-up edge. |

| Typical Applications | Bearings, bushings, gears, valve components, marine engineering accessories. | Not suitable for high-rigidity, lightweight applications. |

| Post-processing | Various surface treatments can be performed to further improve performance. | Some treatments (such as electroplating) require special pre-treatment. |

How To Achieve Efficient And Precision Machining Of Bronze? JS Precision Key Guide

Efficient and precision machining of bronze calls for choosing the right experienced partner. With a depth of 15 years in the field, JS Precision has gathered rich practical experience in CNC machining bronze.

We have processed bronze sensor parts with an accuracy of ±0.005mm (suitable for satellite attitude control systems) for a well-known aerospace client, mass-produced wear-resistant bronze gears for leading automotive manufacturers up to 500 pieces per day, and customized bronze connectors resisting underwater pressure for marine engineering companies up to 300 meters.

In total, we have finished more than 2000 CNC machining bronze projects, and the product qualification rate has always been over 99.8%. In regard to industry-related certifications, we took advantage of ISO 9001 and AS9100.

These ensure that our machining processes meet international standards and top demands from leading industries. With these, we can accelerate meeting the quality system audit requirements from clients and collaborate with aerospace, automotive, and other high-end industries.

This guide is based on our real-world project experience; it covers key aspects of the whole process, so you can rely on it.

If you need effective and accurate CNC machining bronze services, the professional team at JS Precision can provide machining solutions according to customer requirements with an advanced CNC machining center. Just provide your design documents, and we will take care of the rest.

What Is CNC Machining Bronze, And Why Is It Indispensable In Precision Engineering?

Having learned about JS Precision's capability, one may ask what is CNC Machining Bronze.

CNC machining bronze alloy essentially employs a computer-controlled CNC machining center to substractively process the bronze alloy, resulting in high precision and extremely repeatable CNC machining parts. The minimum positioning accuracy can be as high as 0.001mm, far beyond that of traditional manual machining.

Bronze is not a single material but a family of alloys, and composition does vary directly with performance. Tin bronze contains 5-15% tin, while aluminum bronze contains 5-12% aluminum. This is the reason why it is indispensable in precision engineering:

In marine engineering, bronze works stably in seawater with a salinity of 3.5%. In heavy-duty equipment, the compressive strength of bronze is 600 MPa.

Moreover, bronze has been widely used in medical equipment such as surgical instruments on account of its non-magnetic properties and good biocompatibility. For example, the stability of bronze prevents the jamming of parts during surgery in joint components of orthopedic surgical instruments.

Overall Manufacturing Process Of CNC Machining Bronze Parts

Having explained the meaning and significance of CNC machining bronze, here is the full process flow in the manufacture of CNC Machining Bronze Parts, wherein every process or step has a great implication for quality in the final product:

1. Digital Design:

First, we receive the 3D model given by the client, in a format supported by STL and STEP. Using SolidWorks and Mastercam software, our engineers will conduct manufacturability analysis and develop the G-code needed for the CNC machining center. Machining simulations are also conducted to find and avoid any collision risks.

2. Material Preparation and Clamping:

In the project, appropriate CNC bronze blanks are chosen in accordance with the requirements, for instance, aluminum bronze blanks are relieved of stresses at 600-700℃. The blanks shall be fastened by polyurethane tooling in such a way that scratch marks are avoided. At the same time, hydraulic clamps control the clamping force in the range of 50-100N to avoid distortion.

3. Precision Machining:

Milling (800-1500 rpm), turning (0.05-0.2 mm/r), and drilling operations are performed on a CNC machining center. JS Precision optimizes the cutting parameters and uses special CNC machining tools for alloys to guarantee high efficiency and precision in dimension.

4. Quality Inspection:

All critical dimensions are fully inspected using a coordinate measuring machine with an accuracy of ±0.001 mm. This is combined with a surface roughness tester (Ra≤0.8 μm) and a projector. The additional sample is taken from every 20 parts machined for re-inspection to ensure batch consistency.

For parts with special precision requirements, such as tolerance ±0.003 mm, a laser measuring instrument is used for secondary inspection. Hardness and tensile strength tests are also performed on samples. No defective products are allowed to leave the factory.

5. Post-processing and Delivery:

Surface treatments like polishing and electroplating are done according to the requirements, followed by cleaning with industrial alcohol. Each item is individually packaged in bubble wraps. The delivery time for domestic orders is within 3-5 days and international orders within 7-15 days. A quality inspection report is attached to the delivery.

In the CNC machining bronze parts, JS Precision pays attention to every detail. With professional CNC machining tools and technology, we provide you with high-quality products. Welcome to inquire about cooperation.

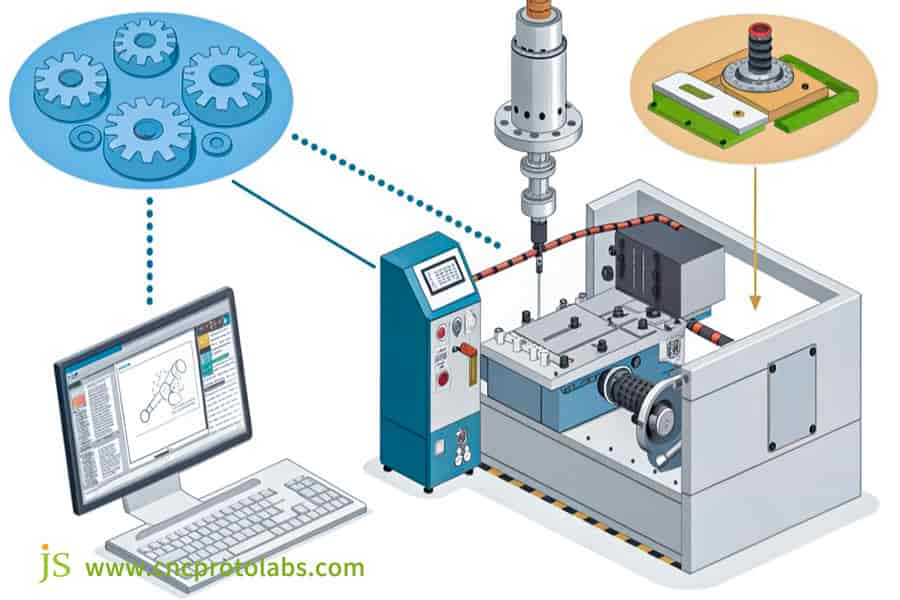

Figure 1: Diagram illustrating the precision CNC milling workflow for bronze parts: from CAD design to final quality inspection.

Key Showdown: Core Differences Between Aluminum CNC Machining Service And CNC Bronze Machining

Many customers wonder why not choose the more common aluminum alloy? The following table compares the core differences between the two and helps you make clear your choice:

| Comparison Dimensions | Aluminum CNC Machining Service | CNC Bronze Machining |

| Material Properties Strength | High weight-to-weight ratio, lightweight, with 200MPa/(g/cm³) and a density of 2.7g/cm³, poor wear resistance of 0.05mm³/(N・m), weak resistance to seawater corrosion at 0.1mm per year, good electrical conductivity at 377S/m. | Strength: low weight-to-weight ratio, heavier (8.8g/cm³, 150MPa/(g/cm³)), excellent wear resistance, with a wear rate of 0.01mm³/(N・m), strong resistance to seawater corrosion, with an annual corrosion rate of 0.01mm; good electrical conductivity at 150S/m. |

| Machining Experience | The chips are continuous and easy to handle, tool life is approximately 800 pieces/tool, a wide range of cutting fluids are available, parameter settings are simple, machining efficiency is 30% higher than bronze. | The chips are short and fragmented, which need to be cleaned up in time, tool life is about 500 pieces/tool, it requires 8%-10% water-soluble cutting fluid, the parameters need precise adjustment. |

| Application Scenarios | Suitable for applications where weight is a factor while wear resistance requirements are low, such as for electronic casings and lightweight structural parts. | Suitable for harsh environments-sea water, high temperatures-heavy-duty jobs, parts required for marine machinery, and bearings. |

| Cost and Maintenance | The estimated cost of the material is about $2/lb, the machining labor rate is about $50/hour, while annual maintenance cost accounts for 10% of the part value. | Material costs approximately $8/lb, machining labor is $60/hour, and annual maintenance costs 5% of the part value. |

For instance, the housing of an electronic device can be made 40% lighter by using an aluminum alloy, for a marine valve, the corrosion resistance of bronze is the only choice. In practice, selection must be done with comprehensive judgment based on specific working conditions.

If you are in a quandary about choosing between aluminum CNC machining services and CNC bronze machining, JS Precision's engineering will help analyze your needs and propose a suitable machining solution based on our advanced CNC machining center.

How To Choose The Best CNC Bronze Alloy For Your Project?

Choosing the right CNC bronze alloy is important: different alloys have significantly different properties and applicable scenarios. The table below can help you quickly compare core parameters:

| Alloy Type | Key Components | Core Properties | Typical Applications |

| Tin Bronze | 5% - 15% Sn | High wear resistance, tensile strength 500-700MPa. | Transmission gears in automobiles, heavy-duty bearing. |

| Aluminium Bronze | 5%-12% Al | Resistant to seawater corrosion, yield strength 300-500MPa. | Marine rudder bushings, chemical pipeline connectors. |

| Phosphorus Bronze | 0.5-1.2% P | Excellent Elasticity, Fatigue Life up to 10^7 Cycles. | Electronic connector, mobile phone charging interface spring clip. |

| Lead Bronze | 5%-20% Lead | Excellent self-lubricating properties, coefficient of friction 0.15-0.25. | High speed machine tool spindle bearings, heavy-duty sliding components. |

JS Precision Professional Advice: We will recommend a suitable bronze alloy based on the project's mechanical stress, working environment, and taking your budget into consideration.

For any projects involved in high and low temperature environments, we will test the performance of alloy materials in performance stability from 40℃ to 150℃. In addition, material samples can be provided for salt spray and wear testing to make sure the part performance is balanced with cost.

Figure 2: Aluminium bronze combines copper and 9-12% Aluminium. It provides strength and high resistance to seawater.

Overcoming Challenges: Issues Common In CNC Machining Bronze, Solutions By JS Precision

The next challenge, after alloy selection, is machining it. Following are some common problems and solutions compiled by JS Precision:

Challenge 1: Built-up Edge

BUE forms from friction and adhesion between chips and the tool rake face in the process of bronze cutting, especially when using tin bronze at 200-250℃. The effect of BUE reduces the surface finish from Ra≤0.8μm to Ra≥1.6μm, which affects assembly accuracy, such as excessive gear meshing clearance, and significantly shortens tool life by 20% to 30%.

Moreover, JS Precision uses sharp CNC machining tools with a rake angle of 15°-20°, adjusts the feed rate from 100 to 80 mm/min, and uses special cutting fluid for cooling, with an 8%-10% concentration in order to effectively suppress the built-up edge.

Challenge 2: Scratches and Deformation Due to Material Softness

During hot working, it has low hardness of HB80-200 and gets easily indented during clamping. It deforms 0.1-0.2mm while machining.

Flexible polyurethane tooling of 50 Shore A hardness is used by JS Precision, with the clamping force accurately controlled at 50-100N. Climb milling is used during machining, which is done with a cutting force that is 30% less compared with conventional milling, process supports are given to areas that are easily deformable to ensure a perfect part surface.

Challenge 3: Dimensional Stability

Bronze has a good thermal conductivity of 50W/(m・K), and a 10°C rise in the temperature of machining will increase the dimension by 0.018mm.

JS Precision reduces the depth of cut to 0.3mm, feeds the cutting tool at a rate of 80mm/min, and keeps the temperature. The cooling oil circulation system, with a quantity of 20L/min (oil temperature 20-25 ℃), is put into the CNC machining center. Then, carry out 4 hours of constant-temperature aging to eliminate internal stress, ensuring micron-level precision.

CNC machining bronze still faces many challenges. JS Precision has mature solutions and can provide you with a variety of high-quality CNC machining tools and technologies. You are welcome to choose our services.

Choosing The Best Surface Treatment For Your CNC Machining Bronze Parts

The surface treatment after machining will improve both the performance and appearance of the bronze parts. Common methods include:

Polishing and Electroplating:

The polishing process involves both 800-grit coarse polishing with a pressure of 0.3 MPa and 2000-grit fine polishing with a pressure of 0.1 MPa to achieve Ra≤0.4μm.

Electroplating includes nickel plating, which is about 5-10μm in thickness with no corrosion after 500-hour salt spray testing and chromium plating (HV800 hard), three times wear-resistant. Suitable for ocean-going equipment and decorative pieces, price about US$5-8 pieces.

Chemical Passivation:

5%-8% chromate passivation liquid treatment at 25-35℃ for 10-15 minutes forms a 5-10μm oxide film, indoor storage for 1 year without rust, with dimensional change ≤0.001mm, suitable for electronic connector and precision-fitted parts, cost $1.5-2 per piece.

Oiling or Waxing:

For oiling, select 20-30 cSt rust-preventive oil, the method of application is spray, 5-10 μm thick. For waxing, use industrial paraffin wax at 50-60℃. Dip the pieces in it for 5-10 seconds so that a film forms. The cost is only $0.5-1 per piece, suitable for short-term rust prevention during storage and transportation.

Why Choose JS Precision: Our engineers can provide professional surface treatment recommendations based on intended use, budget, and performance requirements of the part to help you find a balance among cost, performance, and appearance.

JS Precision will offer you the proper surface treatment for your CNC machining bronze parts. We manufacture using advanced CNC machining centers to make quality products. Please feel free to contact us if you need any.

Figure 3: Comparison of surface finishes for bronze parts: polished, electroplated, and passivated, showcasing enhanced durability and appearance.

Case Study: JS Precision Manufactures Key Bronze Bushings For High-Performance Marine Steering Systems

Practical examples, rather than theoretical knowledge, better illustrate the value of CNC machining bronze. Here's a specific case:

Customer Pain Points

A marine equipment manufacturer was in need of custom bronze bushings for a marine steering system: outer diameter 50mm, inner diameter 30mm, length 100mm. In its application, the bushing would be subjected to a very high (50kN) lateral load, was expected to operate submerged in seawater for extended periods, and maintenance access was to be minimized.

Yet, it was at this point that the previous normal brass bushings only lasted 3 months with 0.2mm wear, maintenance costs reached $5,000 USD per month, and two days of ship downtime per month at a loss of approximately $20,000 USD each caused immense losses.

The solution by JS Precision

1.Material Selection: We did the failure analysis and found that the original bushing problem resulted from insufficient hardness-HB80. A high-strength aluminum bronze alloy, HB180-220, was recommended with 8% aluminum. Samples were provided for 500 hours of neutral salt spray testing with no corrosion. The material was finalised after customer approval.

2.Precision Machining: A five-axis CNC machining center (Model DMG MORI CMX 50 U) was used with special CNC machining tools with a TiAlN coating, the radius of the cutting edge being 0.03mm. In addition, the parameters applied were as follows: speed 1200 rpm, feed rate 80 mm/minute, depth of cut 0.3 mm, climb milling to ensure Ra ≤ 0.8 μm, and the temperature of cooling oil was controlled at 23±2 ℃ to avoid deformation.

3.Surface Treatment: The parts are coarsely polished with 800 grit at 0.3MPa and finely polished with 2000 grit at 0.1MPa. The friction coefficient decreases from 0.25 to 0.18, which will reduce wear when in use. Then clean the surface with industrial alcohol.

Results

The customer experienced a 300% increase in the life span of their CNC machining bronze parts, extending from 3 months to 9 months. The maintenance cost reduced to $1500 per month, thus, the customer's monthly savings increased by $3500. Ship downtown was shortened to 3 days per year.

We helped improve end-customer satisfaction by over 95%. Thereafter, the manufacturer signed a 3-year long-term cooperation agreement with us.

Figure 4: High-precision bronze bushing for marine steering systems, manufactured by JS Precision using 5-axis CNC machining.

Partner With JS Precision For Easy Access To Perfect CNC Machining Parts

It is easy to cooperate with JS Precision to obtain perfect CNC brone parts in the following three steps:

1. Provide your Design:

Please provide 3D model files (supporting mainstream formats such as STL, STEP, and IGES) or 2D drawings with dimensional tolerances specified. Our engineers will review them within 24 hours, also, free DFM suggestions will be provided, such as optimizing wall thickness to 1mm to avoid deformation.

2. Professional Analysis & Instant Quote:

Our engineering team will select the material, plan the process, and calculate the cost for your design; thus, providing you with a transparent quotation within 48 hours-quotation valid for 15 days. For customers who are concerned about the cost, the design can be reworked at this stage, for instance, by changing the surface treatment.

3. Production and Quality Delivery:

The procurement of raw materials will be done immediately after the quotation confirmation (material qualification certificates are provided). You can track the production progress through our platform, which also supports online viewing of quality inspection reports and communicates details.

After production, comprehensive testing will be carried out. Once qualified, the parts are packed in bubble wrap and cardboard boxes, shipped domestically via SF Express, and internationally via DHL. A 3-month warranty is provided after delivery, in case of any quality issues, the response and repair will be done within 48 hours.

FAQs

Q1: What are the major benefits of performing CNC bronze?

The advantages of CNC machining bronze include excellent wear resistance, outstanding seawater corrosion resistance, good self-lubricating properties, and being non-magnetic. It can bear heavy loads under severe environmental conditions and satisfy the requirements of precision.

Q2: What are the differences between bronze and brass in CNC machining?

Bronze offers superior strength, abrasion resistance, and corrosion resistance in CNC machining, making it suitable for heavy-duty conditions in harsh environments. Due to the ease of brass to be machined and inexpensiveness, it suits decorative and conductive parts.

Q3: Which bronze alloy is best suited for manufacturing bearings?

Among them are tin bronze and lead bronze, which are most suitable for the manufacture of bearings. The former has high wear resistance, with the latter having good self-lubricating property. Both reduce friction and wear of the bearing to increase its service life.

Q4: How much more are bronze parts with CNC machining compared to aluminum?

CNC machining bronze parts are 30%-60% more expensive than aluminum, depending on the alloy and the complexity of the part. However, bronze parts have longer lifetimes that will reduce the overall cost of ownership.

Q5: How does JS Precision ensure the dimensional accuracy of precision bronze parts?

JS Precision optimizes the parameters of cutting, controls the temperature to avoid deformation, and uses coordinate measuring machines for 100% quality checking. Rigorous quality control is executed throughout the process to guarantee precision in the dimensions of the bronze parts.

Q6: Can bronze parts be anodized?

Bronze parts cannot be anodized. Only metals like aluminum and titanium can be anodized. Surface treatments common for bronze parts include electroplating, chemical passivation, or oiling.

Q7: Why did my bronze parts discolor after machining?

Discoloring usually occurs in bronze parts after machining because inappropriate cutting fluid or too high a temperature causes oxidation. It can be avoided by using appropriate cutting fluid and by keeping the temperature in control.

Q8: I need DFM feedback for my bronze part design. Can JS provide this?

Yes, JS Precision engineers will offer free DFM feedback on CNC bronze part designs at the quotation stage. These suggestions will be for process optimization and cost control to help optimize the design.

Summary

From ancient ship clocks to modern high-speed bearings, the allure of bronze has endured. CNC machining bronze can translate this allure into reliable solutions that can meet today's most demanding engineering requirements.

JS Precision has many years of experience, uses advanced technology, and offers a one-stop service all the way from designing to delivery. If you choose us, then you have chosen not only an advanced CNC machining center and professional CNC machining tools but also a partner who will perfectly transform your designs into high-quality CNC machining parts.

Upload your designs for bronze parts now to the online quotation platform of JS Precision and enjoy professional, efficient, and reliable CNC machining bronze services. Let our expertise be the solid foundation for the success of your project.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com