Automotive gear manufacturing constitutes one of the main pillars of the automotive industry, hence, it has a direct impact on how well the transmission system performs and its durability.

One of the processes involved in gear manufacturing, which is of great importance, is gear machining. This process requires extremely precise control over accuracy throughout the whole gear production process.

The fast growth of automotive electrification and hybridization has led to a constant upgrading of the technical requirements of automotive gear manufacturing, thereby, posing new challenges in the areas of material selection, process innovation, and customized design.

This article will thoroughly discuss the main issues in automotive gear manufacturing, thus servicing the needs of automakers and parts suppliers by providing them with the professional guidance for choosing partners and overcoming production difficulties.

Core Answer Summary

| Core Questions | JS Precision's Answers | Value Brought to You |

| How is the whole automotive gear manufacturing process carried out? | One-stop precision manufacturing services are offered from gear design and gear machining to mass production. | Simplifying the cooperation process and ensuring gear precision and production efficiency. |

| What is the solution of gear manufacturing problem caused by electrification/hybridization? | By optimizing tooth profiles and material processes, providing customized transmission solutions. | Solving NVH problems and being compatible with the requirements of new energy vehicles. |

| What are the solutions for aluminum gears selection and manufacturing? | We offer aluminum gears exclusive processes and coatings to make customized products. | Vehicle lightweighting is achieved, and the performance and weight reduction requirements are balanced. |

| Ways to select a trustworthy partner in gear manufacturing? | Giving 5 evaluation dimensions and gear manufacturing screening guidelines. | Doing away with cooperation risks and finding proper partners in no time. |

| How to choose between gearbox repair and new manufacturing more economically? | Offering full lifecycle costing and repairability diagnosis. | Reduce maintenance expenses while at the same time ensuring reliability and economy. |

Keyaways:

- Gear machining precision, material compatibility, and process compatibility are the main pillars of automotive gear manufacturing, which, in turn, have a major impact on vehicle transmission performance.

- The need for electrification and hybridization is leading to technological innovations, which, in turn, put more rigorous demands on gear speed, NVH, and durability.

- In the case of aluminum gears, which mainly target lightweighting, it is necessary to carry out special process adaptation and, thus, are one of the core application scenarios in the case of custom gears.

- You can't decide on a precision gear manufacturing company simply by looking at one factor. You need to get a thorough evaluation from multiple dimensions, such as equipment, certifications, and case studies.

- JS Precision has the capacity to deliver full-scenario solutions that address different pain points in transmission gear manufacturing.

Why Trust JS Precision On Automotive Gear Manufacturing?

Automotive gear manufacturing requires knowledge and hands-on experience to be successful in the field.

JS Precision is a company that has been developing this area for several decades, having recently remanufactured an 800V electric drive gear for a global Tier-1 supplier, where besides increasing its durability by more than 50%, the problem of the early pitting at the peak torque of 3200N·m has also been successfully solved.

Our primary capabilities encompass the whole gear tooling operation, from precision forging to ultra-precision grinding, and we have thus achieved independent research and development.

We have more than 50 world-class gear grinding machines from KAPP and NILES, and we are constantly able to achieve ISO 5 level precision. Our procedures are AGMA Q14 certified thus providing a solid quality guarantee.

One of JS Precision's major strengths is also its ability to customize and implement solutions.

In this context, to meet electrification trend in the automotive gear manufacturing industry, we have formed a devoted new energy gear customization technology team, which not only allows us to quickly seize customer customization needs but also efficiently integrate the whole process from DFM analysis to sample delivery.

Quality-wise, the company has introduced the IATF 16949 system along with SPC control for main processes to be able to provide products of a consistently high quality no matter the size of batch, even for customized orders, keeping precision at mass-production level.

As a professional precision gear manufacturing company, JS Precision is equipped with rich experience in addressing the issues of high-speed, high-torque gear manufacturing.

JS Precision also offers a one-stop solution from design collaboration to mass production to its clients. The supplied gears can still operate stably even when peak torque goes beyond 3200N·m, which is one of the reasons why JS Precision has been a long, term partner of many global car, makers.

Looking for a reliable partner in the automotive gear manufacturing field? Contact JS Precision's engineering team immediately, submit your gear design requirements, and receive a free, customized gear machining process solution precisely matched to your production needs.

What Is Automotive Gear Manufacturing And Why Is It Critical?

Major technological innovations in the automotive gear manufacturing sector lead to advancements in the industry. Accuracy in gear machining is the main factor that decides gear performance and durability, hence, it plays a key role in upgrades of the transmission system.

The Basis of Power Transmission

Gears represent the heart of gearboxes and differentials, thereby, their quality determines the vehicle power and fuel consumption. They make alterations in speed and torque, thus, lack of precision might not only cause the production of abnormal noises but also the lowering of efficiency.

Main Components of Gear Manufacturing

JS Precision complies with the standardized precision manufacturing processes in order to ensure both the performance and precision of gears:

- Precision Forging: Improving the flow of the blank's streamline and increasing its resistance to impact.

- Rough Machining: Carrying out the blank initial machining of the shape and controlling the basic tolerances.

- Tooth Machining: Getting the first tooth profile shaping by means of rolling and shaping processes.

- Carburizing and Quenching: Carburizing at a high temperature of 930℃, resulting in a tooth surface hardness of HRC58-62.

- Precision Gear Grinding: CNC grinding for obtaining ISO 6-7 precision, thus, perfecting the tooth profile and direction.

Material and Process Coordination

Automotive gear materials have steadily evolved and nowadays typical examples are high-grade carburizing steels such as 20CrMnTiH. Along with the change of material, manufacturing technology also has been upgraded to CNC machining and online inspection, which in turn improved gear machining accuracy and efficiency (ISO 1328-1:2013 precision standard).

Performance Parameters of Commonly Used Materials in Automotive Gear Manufacturing

| Material Type | Tooth Surface Hardness (HRC) | Yield Strength (MPa) | Tooth Surface Hardness (HRC) | Carburized Layer Depth (mm) | Applicable Scenarios |

| 20CrMnTiH | 950-1100 | 650-750 | 58-62 | 0.8-1.2 | Pure Electric Reducer Gears |

| 40Cr | 750-850 | 550-650 | 50-55 | 0.5-0.8 | Manual Transmission Low-Speed Gears |

| 20MnCr5 | 1000-1200 | 700-800 | 59-63 | 0.9-1.3 | Hybrid Transmission High-Speed Gears |

| 17CrNiMo6 | 1100-1300 | 800-900 | 60-64 | 1.0-1.4 | High Torque Drive Axle Gears |

| ADC12 (Aluminum) | 280-320 | 160-180 | — | — | Automotive Auxiliary Drive Aluminum Gears |

How Is Electric Mobility Reshaping Automotive Gear Manufacturing?

Electrification brings new requirements to the automotive gear manufacturing industry, and the requirements for gear design and processing in direct drive electric motors far exceed those of traditional fuel vehicles, making it a direction for industry upgrading.

Higher Speeds and More Stringent NVH Requirements

The electric direct drive gears turn at such high speeds of 16, 000-20, 000 rpm, that gears set extremely high demands on the components: dynamic balancing has to be at a G2.5 level or even higher, and a precise tooth profile modification is necessary to reduce squealing, since no engine noise is present to mask the electric drive noise.

Anti, galling and Lubrication Challenges

As there is no engine noise with electric drives, the noise from gear meshing becomes very noticeable and can sometimes lead to insufficient lubrication. To improve anti-galling capabilities, DLC coatings are required, and at the same time, lubricants need to be upgraded to meet high-speed requirements.

Want to solve the NVH pain points of automotive gear manufacturing in the electric drive era? Upload your gear drawings now, and JS Precision will provide you with professional gear profile modification solutions to optimize high-speed gear performance.

Figure 1: A detailed cutaway illustration of a differential gear assembly in an orange housing, showing the internal gearing mechanisms.

Figure 1: A detailed cutaway illustration of a differential gear assembly in an orange housing, showing the internal gearing mechanisms.

What Are The Key Challenges In Hybrid Transmission Gear Manufacturing?

The complex operating conditions of hybrid transmissions pose severe challenges for transmission gear manufacturing, requiring gears to be compatible with dual power outputs and higher performance and durability requirements.

Impact and Durability during Mode Switching

The start stop and torque superposition of the hybrid system engine will generate instantaneous high loads, requiring excellent impact resistance and toughness of the gears. The core hardness needs to be controlled at HRC35-45, balancing wear resistance and impact resistance.

Heat Management and Space, Efficient Manufacturing

The highly integrated hybrid gearbox limits the gear design space, and dual power sources generate more heat. JS Precision saves space and optimizes oil passage cooling through the integrated design of gears and shafts.

Aluminum Vs. Steel: What’s The Fundamental Shift In Designing And Making Aluminum Gears?

The trend towards lightweighting is resulting in aluminum gears becoming an exciting new frontier in automotive gear manufacturing. Since aluminum gears are different in performance compared to steel ones, various changes are needed in the design and manufacturing processes. As such, they are considered a principal application for specialized gears.

The Two Sides of the Lightweighting Coin: Benefits and Limitations

Aluminum gears weigh 60% less than steel gears, thus reducing transmission inertia and increasing fuel economy. On the other hand, they have lower strength and wear resistance, thus surface hardening or composite materials are necessary to make up for these properties.

Specialized Fabrication and Post-Processing Techniques

Aluminum gears cannot be subjected to the steel gear forging and carburizing processes, hence, they are primarily precision cast or sintered, thus are considered custom gears. JS Precision enhances their wear resistance by applying coatings.

Comparison of Core Performance of Aluminum Gears and Steel Gears

| Performance Indicators | 6061 Aluminum Gear (After Coating) | 20CrMnTiH Steel Gear | Difference | Applicable Scenarios | Processing Difficulty |

| Density (g/cc) | 2.7 | 7.85 | -65.6% | Lightweight Auxiliary Drive | Medium |

| Gear Surface Hardness (HRC) | 40-45 | 58-62 | -30.0% | High Torque Main Drive | Low |

| Tensile Strength (MPa) | 310 | 1050 | -70.5% | Short-Distance Commuter Vehicles | High |

| Coefficient of Thermal Expansion (10^-6/°C) | 23.6 | 11.7 | +101.7% | Normal Temperature Operating Conditions | Medium |

| Weight Reduction Effect | 60% | 0 | — | New Energy Vehicle Companies | High |

| Manufacturing Cost (USD/piece) | 15-20 | 8-12 | +66.7% | Traditional Fuel Vehicles | Low |

Figure 2: A comparison showing a stack of steel pipes next to a pile of aluminum rods, representing raw materials for gear production.

Figure 2: A comparison showing a stack of steel pipes next to a pile of aluminum rods, representing raw materials for gear production.

JS Precision Case Study: Extending BEV Reducer Gear Life By 50% For a Global Tier-1 Supplier

Challenge

A global Tier-1 supplier was developing reduction gears for a new generation 800V electric drive platform. Initial prototypes showed early pitting corrosion during durability testing at a peak torque of 3200 N·m.

The actual lifespan of the original gear design was only 80% of the design target, thus failing to meet mass production requirements. Hence, they decided to get the technical support from JS Precision.

Solution

After the intervention of JS Precision, we went back to the basic needs of the customer's 800V electric drive platform and came up with a comprehensive and high-end customized solution that totally and very specifically met the issues of early pitting corrosion and insufficient lifespan:

1.Design Collaboration:

Establish a specialized engineering team to deeply communicate with customers, perform topology modification on the tooth surface (including tooth top modification and tooth direction drum modification), accurately optimize load distribution, reduce gear edge contact stress by 15%, and reduce pitting hazards from the design level.

2.Material and Process Upgrades:

In order to get the peak torque 3200 N·m, a material upgrade is made by employing ultra-fine grain carburized steel (20CrNiMoH) that is capable of improving the gear's overall toughness and pitting resistance significantly.

At the same time, the carburized layer depth tolerance is changed from ±0.2 mm to ±0.15 mm, and the high-pressure gas quenching (cooling rate controlled at 80-100/min) mode is chosen to effectively minimize gear deformation and guarantee accuracy stability.

3.Ultra-precision Machining:

After the gear grinding process, a precision ultra, precision grinding process is implemented. By using diamond abrasive, the grinding pressure is kept at 0.15-0.2 MPa and the rotation speed at 800-1000 r/min, which helps to improve the tooth surface roughness from Ra0.6 μm to below Ra0.2 μm, thus significantly enhancing tooth surface finish and resistance to wear and pitting.

Results

In the end, the optimized gear passed the bench durability test smoothly, with a calculated fatigue life increase of over 50% and NVH performance meeting customer standards.

It successfully helped the customer's project to be mass-produced on schedule, and JS Precision became its preferred precision gear manufacturing company in the Asia Pacific region.

Want to improve the lifespan and performance of your electric drive gears? Consider JS Precision's case study. Contact us now for a free cost and performance improvement calculation after gear optimization.

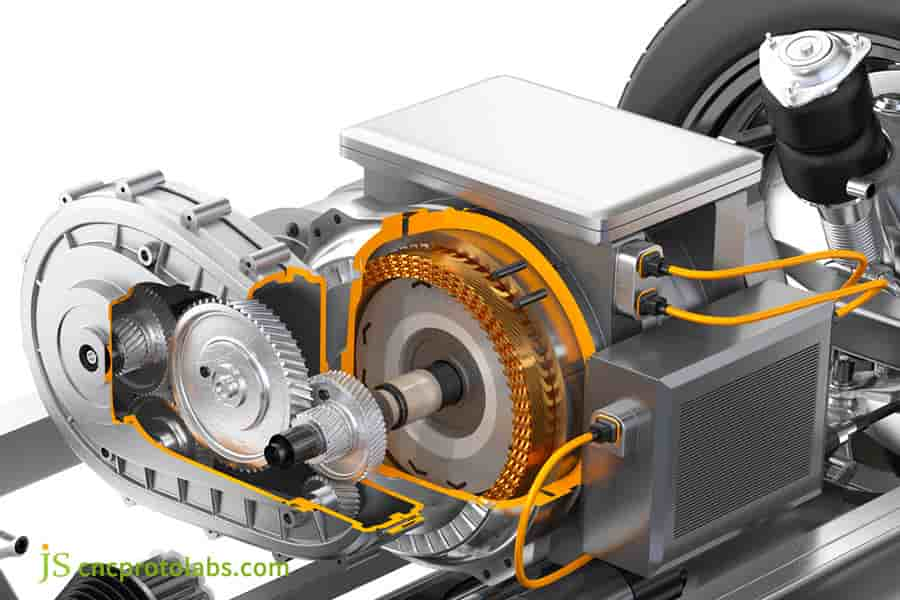

Figure 3: A 3D cutaway illustration of an electric vehicle gear reducer, featuring a central motor with copper windings connected to a metal gear set.

Figure 3: A 3D cutaway illustration of an electric vehicle gear reducer, featuring a central motor with copper windings connected to a metal gear set.

How To Find And Evaluate a Reliable Gear Manufacturing Company?

In the field of automotive gear manufacturing, it is crucial to choose reliable partners. A high-quality gear manufacturing company list is the foundation, and only through scientific evaluation can suitable partners be found.

Extensive Review of Major Data

Instead of just company information, a high-quality gear manufacturing company list should present the company's main equipment, IATF 16949 certification, machining accuracy, and cases of manufacturing for new energy.

Five Main Evaluation Aspects and Practical Checkpoints

- Technical Capabilities: Can you provide answers for tooth profile and tooth direction modification based on working conditions?

- Equipment Level: Do you have the latest gear grinding machines and gear measuring center?

- Quality System: Are you implementing IATF 16949 and SPC for the key processes?

- Industry Experience: Have you been involved in the mass production of pure electric and hybrid gears?

- R&D Strength: Do you have a materials research laboratory? Are you able to respond quickly to technical requirements?

Communication Guide from Inquiry to Sample

The customer inquiry should provide the gear load spectrum, installation space, etc., and the customer should require the supplier to give a preliminary process solution and risk analysis as a means of assessing their professionalism.

Want to obtain a professional gear manufacturing company list and learn evaluation methods? May I inform you of your requirements? JS Precision will provide you with a free screening guide to quickly find a reliable precision gear manufacturing company.

When Should You Consider Custom Gears For Your Automotive Application?

Standardized gears are fitted to general needs and are capable of meeting those needs effectively, but in the case of special operating conditions, the production of custom gears becomes a necessity. Aluminum gears, as a lightweight customized product, have become the favorite choice of automakers.

The Decision Boundary Between Standard and Customized Products

If you use gears with custom specifications different from the standard, you should look into using custom gears: non-standard module/pressure angle, irregular structure, extreme operating conditions, or fast iteration for prototype development.

How Customization Can Become a System-Level Solution

Custom gears make the whole process work better, for example, by optimizing tooth profiles to reduce stress and eliminating abnormal noises. Aluminum gears help with lightweighting in auxiliary drives, and the integrated smart design feature provides a solution to the space challenge.

Gearbox Repair Vs. New Gear Manufacturing: What’s The More Economical Choice?

Among automotive transmission maintenance, gearbox repair is completely different from gear manufacturing new.

Accurate Diagnosis: the Basis for Determining Repairability

The repairability of the gearbox requires professional testing: gear pitting corrosion<5%, wear<0.1mm, no out of tolerance of the box, no irreversible damage to the bearings, if exceeded, a new one is required.

Repair Process and its Efficiency Limit

Beyond the use of laser cladding and gear surface grinding, other common gearbox repair methods can restore only the fundamental performance level. Nevertheless, these methods provide a precision that is 1-2 grades lower than newly manufactured parts, so they are not suitable for high-speed operation.

Whole Life Cycle Cost Analysis Model

Life cycle cost is very important: the initial cost for repair is only 30%-50% of the cost of a new part, with a cycle time shorter, but the life span is only 40%-60% of a new part, new parts have the same reliability as original equipment manufacturers (OEMs).

Want to determine whether to choose gearbox repair or new manufacturing for your gearbox? Send your test data to JS Precision, and we will provide you with a free life cycle cost calculation and the most economical decision advice.

Figure 4: Close-up of a technician's hands adjusting metal gears within the dark interior of a gearbox housing.

Figure 4: Close-up of a technician's hands adjusting metal gears within the dark interior of a gearbox housing.

FAQs

Q1: What precision grade is typically required for automotive transmission gears?

The precision level of automotive transmission gears depends on the type of transmission. In most cases, manual transmission gears are made to ISO 7-8 standards, whereas top-tier automatic transmission and electric vehicle speed reducers are made to ISO 5-6. The key element is the control of the tolerances for the tooth profile and tooth direction.

Q2: What are the differences between carburizing and induction hardening in automotive gear applications?

Carburizing and quenching can create a carburized layer with a depth of 0.8-1.2mm. Thus, the tooth surface will be very hard, which is ideal for automobiles core gears that have to bear high loads. Induction hardening creates a layer depth of 2-5mm, thereby simplifying the process of deformation control and thus it is more suitable for low speed large module automotive gears.

Q3: Why are electric vehicle reduction gears particularly sensitive to noise?

Unlike electric vehicle reduction gears, internal combustion engine transmission gears have the engine noise to mask the gear noise, the absence of which in EVs causes the high-frequency noise of the motor to be easily coupled with the gear meshing frequency, thereby emanating a very noticeable whistling sound. Hence, noise control requirements are very stringent.

Q4: Are special cutting tools necessary for machining aluminum gears?

It is essential to use special cutting tools when machining aluminum gears, most commonly sharp PCD (polycrystalline diamond) tools that perfectly stop aluminum chips from sticking to the tool and also help to raise the surface finish of aluminum gears.

Q5: From drawings to obtaining a testable gear sample, how long does it generally take?

JS Precision can produce the first steel samples for standard automotive gears within 3-4 weeks from complete design data. As for complex custom gears or aluminum gears, they need more time for development due to their special processes.

Q6: Are you able to supply third, party testing reports for gears?

JS Precision is capable of supplying third-party testing reports for gears. The company is equipped with a Zeiss gear measuring center and can provide ISO standard full-parameter testing reports. Besides, we can also arrange for professional testing by a third-party notary office if required.

Q7: What if my project is at a very low production volume and still in the R&D stage?

JS Precision is ready to take on small batch R&D orders. The company offers a range of services from prototype development to mass production and always regards small batch R&D projects as a good starting point for long-term collaboration.

Q8: How do you control gear quality consistency in mass production?

JS Precision manages mass production using the IATF 16949 quality system. Key processes are subject to SPC statistical process control, and each batch is sampled and measured to ensure quality consistency.

Summary

The automotive gearmaking industry is on the verge of a complete makeover where electrification and lightweighting are the main drivers. Breakthroughs in automotive gear manufacturing technology, ranging from material innovation to gear machining processes, bring the products of automakers to a higher level of competitiveness.

The key factors when selecting a partner are, primarily, their technology, quality, and their problem-solving capabilities.

JS Precision is a reliable partner to consider whether you are just screening a list of gear manufacturing companies or have specific gearbox repair or new design issues that require a solution.

Reach out to us anytime, share your needs or drawings, and our engineering team will deliver a professional technical & business report just within 24 hours, which will serve as a basis for us to together enhance the next generation vehicles' performance.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com