When our JS engineers put their heart and soul into designing truly cutting-edge parts, such as demandingrobot joints, extremely precise optical mounts, or drone gimbals that must be both feather-light and rock-steady, the goal is very clear: Extreme lightweight, top-notch strength, and highly integrated functions.

But experience tells us that the more sophisticated and complex the design, the more difficult it is to turn it from a drawing into a perfect object.The core question is:Which manufacturer on the market can really master this level of complexity and make it exactly right?

We are all too familiar with this dilemma. Everything went well in the conception and drawing stages, but once you take the drawings to the processing plant, reality throws cold water.

Many conventional factories usually have two reactionswhen they see those complex curved surfaces, tricky internal cavities, or multi-angle precision matching features: either they wave their hands and say "can't do it", or they quote a frighteningly high price and a long delivery time. This is not the end. In order to meet the requirements, you often need to communicate details repeatedly, modify the plan back and forth, and even try to produce samples many times. Your project progress is dragged down little by little in this tug-of-war.

More importantly, the finalCNC machining priceis often like a mystery, which is not revealed until the end. This uncertainty makes the cost budget completely out of control, making you very passive, and the whole manufacturing process is simply exhausting.

"As management guru Peter Drucker has observed: If a plan cannot be turned into action, it is just a good wish. And if an action lacks a careful plan, it is just a waste of time. But there is a gap between plan and action, between ideal and reality."

1.Summary Of The Core Answer:

| Design pain points | Technical solutions | Service advantages |

| Difficult to process complex structures | 5-axis linkage machining: Complete complex features in one clamping process, eliminating duplicate positioning errors. |

Instant and accurate quotation:

Upload model → Intelligent analysis → Real time quotation.

|

| High precision requirements at the micrometer level |

Micron level control (± 0.015mm): CMM online inspection ensures zero clearance during assembly.

|

Flexible batch support:

From 1 prototype to 1000 pieces in mass production, seamless switching and delivery.

|

| Lightweight and strength balance |

Customization of aviation grade materials: 7075 aluminum/titanium alloy cutting anti deformation process.

|

Free DFM optimization:

Engineer pre review design to avoid cost risks.

|

| High cost uncertainty |

Transparent pricing engine: Adjust parameters online and view price changes in real-time.

|

Full process tracking:

Automatic push of production nodes and visualization of progress.

|

2. Core Reveal: How A High-Difficulty Part Was Created in Our Hands

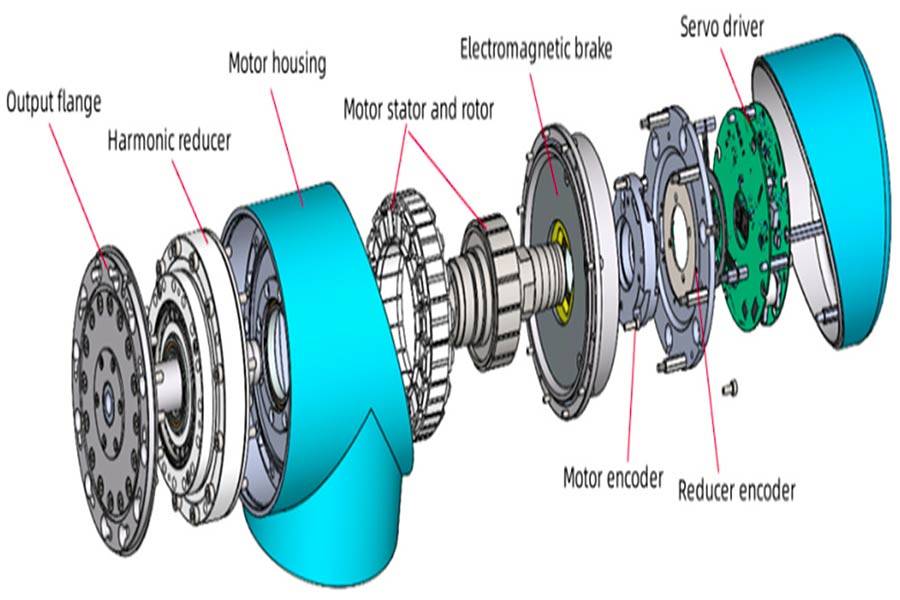

Look,this is a typical robot joint,created by the custom CNC machining manufacturing service we provide to our customers. Every design of it seems to pose a challenge to the machining process, but we succeeded.

How to turn such precision design into reality? Let's take this part as an example to analyze JS's core coping capabilities:

Challenge 1: Polyhedron and complex surface processing → Solution: 5-axis linkage CNC processing

Where is the difficulty?

Look at the places with support ribs, internal hollowing, and arc clamping in the picture. Using traditional3-axis machinetools to process such features, it is impossible to get all angles at once, and it isnecessary to clamp several times. Repeated clamping will inevitably introduce cumulative errors, and the position accuracy will be destroyed, which will eventually affect key performance such as the smoothness of robot movement.

JS solution:

The biggest advantage of the5-axis machining centerwe use is"one clamping, all done".No matter how complex the part is, the tool can accurately cut from the optimal angle. This ensures that the positional relationship between all features on the diagram is exactly the same, and fundamentally eliminates the error of repeated positioning. Do robot joints need to move smoothly? This is the foundation of the foundation.

Challenge 2: Micron-level precision and strict tolerance → Solution: Closed-loop precision control system

Where is the difficulty?

Focus on the"C"-shaped clampin the figure, as well as the precision mounting holes for motors and bearings. The tolerance requirements in these places are extremely demanding, and often require the tolerance to be strictly controlled within ±0.015mm (micron level). If it is a little bit off, the fit will be loose or tight, which will destroy the stability of force transmission and the performance of the entire joint will collapse.

JS solution:

Precision is not shouted, butguaranteed by hard-core equipment and processes.During the processing, our advanced machine tools themselves have high-precision feedback systems. But this is not enough. EveryCNC machining partsmust be fully inspected by a high-precision three-coordinate measuring machine (CMM). Let the data speak, and ensure that it is 100% consistent with the requirements of the drawings, and never rely on luck.

Challenge 3: Coordinated realization of lightweight and structural rigidity → Solution: Material science and process optimization

Difficulty:

The purpose of the large-area hollowing design in the figure is very clear: to reduce weight to the maximum without sacrificing strength, which is a test of processing capabilities. High-performance materials such as 7075 aviation aluminum and titanium alloy have fine structures and are extremely challenging. Incorrect cutting parameters, poortool selection, and inadequate cooling can easily cause internal stress in the material, resulting in deformation of parts, which may result in inaccurate dimensions or even direct scrapping.

JS solution:

With in-depth understanding of material cutting characteristics and adeep process database, we have a set of field-proven process databases for different materials (such as aviation aluminum, titanium alloy, and special steel). From tool selection, cutting parameters, to coolant strategy, we can accurately control.

There is only one purpose: to minimize the internal processing stress of the material while cutting efficiently, ensuring that the parts are both light and strong without deformation.

JS's unique process control points:

| Control link | Common practices | Depth control points of JS | The benefits it brings |

| Benchmark uniformity | Multiple clamping, the benchmark is prone to change. | Single benchmark for the entire process: 5-axis clamping at once, all processing based on the same precise origin. | Eliminate cumulative errors and ensure absolute accuracy between features. |

| Real time precision assurance | After processing, spot checks were conducted and problems were discovered late. | Process monitoring+online compensation: real-time feedback from the machine tool, automatic fine-tuning of the tool path; 100% CMM full inspection. | Immediate correction of issues to prevent the outflow of defective products. |

| Stress management | Relying on experience or simple heat treatment. | Material process intelligent matching: optimizing cutting parameters based on material databases; Precision aging treatment may be necessary. |

Maximize the suppression of machining deformation and improve stability.

|

| Quality transparency | Provide basic reports. | Full size data package: Key dimension CMM measurement data report provided with the goods. | The customer has a clear understanding of the true quality status of the parts. |

"The perfect landing of complex parts requires not only high-end equipment, but also deep process understanding and strict process control. From 5-axis precision linkage to micron-level control, to the taming of material stress, JS focuses on turning your cutting-edge designs into top-level custom CNC machining manufacturing parts stably and reliably. Don't let manufacturing hold you back, leave the complex challenges to us, and talk about your project!"

3. Why Is JS's Online Service The Best Choice For Your Precision Manufacturing Needs

Hello everyone, I am an engineer at JS. We know that when you are looking for aCNC machining partner, what you value most is transparent quotation, flexible production and professional support. This is the core value of our online platform. In the following three points, I will clearly explain our advantages from the perspective of an engineer:

Say goodbye to vague quotations, and see prices in real time

The most troublesome thing is the vague quotation of complex parts. Waiting for emails and phone calls, the results may not be accurate. The core of our online CNC machining services platform is to solve this problem.

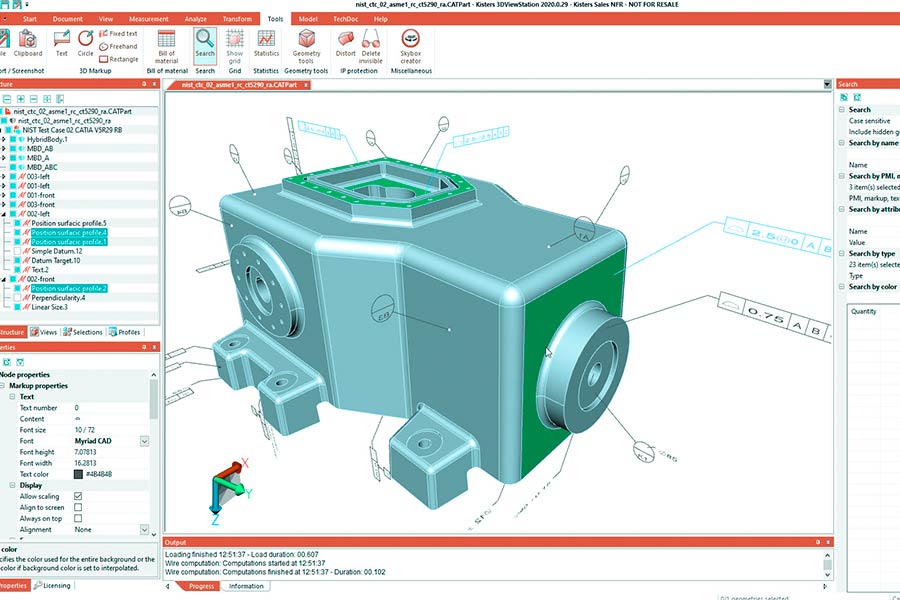

You only need to uploadthe 3D file, and the system can generate a CNC machining price preview immediately based on the 5-axis machining capability. The engineering team will quickly review the complex items. You can also adjust the parameters online, and the price is updated in real time. The budget is completely under your control. Uncertainty? That does not exist.

Seamlessly connect prototype development and small batch manufacturing

The most annoying thing about R&D and product making is the slow prototype proofing. You can't find a factory for small batch processing and have to change suppliers. JS is designed for this stage! Providecustom CNC machiningmanufacturing, even 1 prototype can be made, using our own 5-axis equipment, and the prototype can be delivered as fast as 72 hours. After the design is finalized, there is no need to switch suppliers, just hand it over to us directly to ensure the stability of product quality and save worry and effort.

Free DFM locks manufacturing feasibility

We regard you as a technical partner, not a simple buyer-seller relationship. Before production, our engineers will help you review the drawings for free! Don’t worry about those difficult professional terms. Simply put, it helps you see which parts of the design may be difficult and expensive to process (such as too thin walls, difficult rounded corners, and too strict tolerances), and then gives you practical optimization suggestions. Reduce potential costs and risks in the design stage!

Comparison of core capabilities of JS vs. mainstream platforms

| Key dimensions | Xometry (Platform Aggregation Mode) | JS RPM (www.jsrpm.com) | The value that JS brings to you |

| Core technology control | Outsourcing third-party factories with varying process standards. | Our own high-end 5-axis machining center cluster, with independent and controllable processes. | High consistency in processing, accurate completion of complex parts in one go, and no risk of subcontracting. |

| Accuracy of quotation | Pure system quotation, complex parts are prone to deviation. | AI pre quotation+engineer real-time review (especially for miscellaneous items). | The price is closer to the actual cost, reducing disputes over subsequent adjustments. |

| Prototype delivery speed | Relying on outsourcing factory scheduling, standard parts take 3-5 days+. | Own production capacity, priority channel for prototype parts (fastest 72 hours). | The iteration speed of research and development has significantly improved. |

| Engineering support depth | The DFM report requires a paid/simplified version, with limited optimization suggestions. | Free deep DFM, one-on-one communication with engineers, providing executable solutions. | Avoiding design pitfalls in advance significantly reduces production risks and costs. |

| Industry focus | Wide coverage but shallow depth. | Deeply cultivate high-precision fields (aerospace/medical equipment/precision components). | Understand strict standards and have experience in special materials/processes. |

| Quality traceability | Multi factory collaboration and complex traceability chain. | The entire process is produced in our own factory, and the complete process records are traceable. | Clear quality responsibility and reliable batch production consistency. |

| Response communication | Customer service transfer, slow response to technical issues. | Exclusive engineer docking, direct technical issues to experts, 24-hour response. | Efficient and precise communication, worry free project progress. |

"JS's onlineCNC machining servicesuse the pragmatic attitude of engineers and intelligent platforms to save you time, worry and money when making parts. Transparent prices, flexible manufacturing and professional support are all here. Don't hesitate, upload your drawings and try it out, and experience clear quotes and free design suggestions immediately to accelerate your project!"

4.Call To Action: Unleash Your Design Potential, JS Helps You Manufacture Efficiently

We know thatevery innovative design deserves to be perfectly realized. Don't let the manufacturing link become a bottleneck again-your next breakthrough product should be unimpeded to reality.

Get accurate CNC machining quotes at the threshold, and the design value will be revealed immediately

Are you still worried about the processing possibilities and costs of complex parts? Upload your 3D CAD file now! Ourintelligent platformcombines engineer review to generate an instant and transparent CNC machining price for you for free. Materials, processes, and quantities can be adjusted at will, and prices are visible in real time. A clear understanding of costs will make decisions with confidence. Your design potential deserves a clear starting point.

Professional team escorts, intellectual property rights are absolutely safe

Worried about design confidentiality? We solemnly promise: Sign a legally binding non-disclosure agreement (NDA) as soon as possible, and your intellectual property will be protected in the strictest way. Whether you need to consult the feasibility of complex CNC machining parts, or want to discuss technical details directly with experiencedproject engineers.Click the link below to quickly contact.

Your great design should not be constrained by manufacturing capabilities. Act now:

Get instant quotes online:https://www.cncprotolabs.com/contact-us

Talk directly to project engineers:https://www.cncprotolabs.com/

We look forward to working with you to turn exquisite ideas into precise reality.Upload your design,experience JS's professionalism and efficiency, and take the first step towards successful manufacturing today!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com