When making cutting-edge products such as drones and robots, we are eager to make parts lighter, stronger and more compact. As JS engineers, we understand this pursuit too well. But one reality is: after designing a perfect3D modelon the computer, we encounter bottlenecks in the actual processing stage.

In the past, when working with some traditional processing plants on complex parts, the experience was really hard to describe. Just getting a clear CNC machining price requires a long wait, andthe final quotation may exceed expectations, making the budget difficult to control.

More importantly, in the face of complex geometric features or multi-angle processing requirements, many suppliers are insufficient in experience and ability, resulting in unstable precision of finished products, and even failing to meet design requirements. Finally, the long production cycle directly drags down the key progress from prototype verification to product launch.

We empathize with this dilemma of design being unable to land due to manufacturing capacity limitations.

1. Summary Of Core Answers

| Partial | Pain points/key points | Our capabilities/customer value |

| Is innovative design constrained by manufacturing capabilities? |

Traditional processing pain points:

• Slow and opaque quotation

• Accuracy does not meet the standard

• Long delivery cycle

|

Resolve the core contradiction: For high-performance design, matching agile manufacturing capabilities.

|

|

Example of precise "carving" of complex brackets

|

Strict requirements for parts:

• 7075 aluminum alloy curved surface

• ± 0.02mm tolerance

• High surface quality

|

Technological strength:

• 5-axis overall milling

• Precise hole position control

• Sandblasting+anodizing

|

| Why choose online CNC services? |

Pain points in the manufacturing process:

• Price lag

• Difficult to respond to small batches

• Lack of risk prediction

|

Three major advantages:

① Minute level real-time quotation → Cost transparency

② Flexible production of 1-500 pieces → supports iteration

③ Online process+free DFM → risk avoidance

|

| Successful cases of agricultural drones |

Customer Challenge:

• 3-week cycle, high scrap rate

• R&D progress is hindered

|

Delivery of results:

• Confirm the quotation on the same day

• 5-axis technology with 7-day delivery

• Verify 2 weeks in advance

|

| Quality assurance system |

Quality concerns:

• Accuracy fluctuations

• The process is opaque

|

Double protection:

• ISO9001 certification+Coordinate Measuring Machine (CMM)

• Full traceability → FAI report/material certification

|

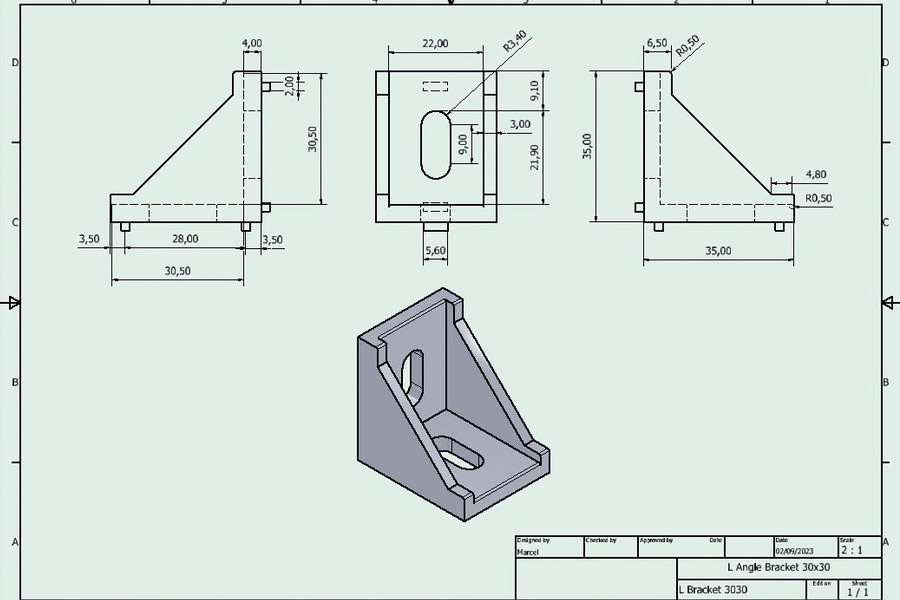

2. Solution Core: See How A Complex Bracket Is Accurately "Carved"

As shown in the picture, I will "disassemble" thishigh-performance drone motor seat (bracket)for you to see how we accurately build it. This job is not easy. Every curved surface and hole position must be carefully carved, all relying on the strongCNC processing capabilities. Focus on these three aspects:

A piece of aluminum ingot to a complex shape:

This bracket is not pieced together. Instead, it is milled directly from a whole piece of 7075 aviation-grade aluminum alloy. Weuse a 3-axis or 5-axis CNC machining centerto ensure that the parts are both light and strong.

What are the benefits of doing this?

- First, the structural strength is super high, which is completely different from welding or assembly parts.

- Second, it can be extremely lightweight, which is very critical for drones.

Simply put, it is to useCNC machining partsto form a light, strong and complex structure in one go.

Accurately positioned "ears" and holes:

There are four asymmetrically distributed "ears" on the bracket to fix the motor. The difficulty lies in ensuring the absolute accuracy of their spatial position and the dimensional tolerance of each hole.We can control it steadily within ±0.02mm. This means that the machine will not shake when installed and will be firmly locked even in a high-vibration environment. This is all thanks to our advanced measurement and processing technology, whichavoids the common loosening problem.

Not only good-looking, but also durable:

The uniform matte texture on the surface is not just for beauty. We first do sandblasting and thenhard anodizing.

This film is very critical:

- It greatly improves the surface hardness and resists scratches and wear.

- It has super corrosion resistance, is not afraid of oil and moisture erosion, andgreatly extends the life of parts. Beauty is additional, practicality and durability are fundamental.

JS process depth vs. common practices in the industry

|

Core process points

|

Deep practice and advantages of JS | Common industry practices or limitations |

|

Material and processing

|

7075-T6 aviation aluminum integral milling: tensile strength ≥ 572MPa, ensuring lightweight and high strength. | 6061 aluminum is commonly used, with low strength (≈ 310MPa), or welding/assembly is used to introduce potential weaknesses. |

|

Accuracy control

|

± 0.02mm full process control: including "ear" positioning and aperture. Utilize online measurement + compensation technology. | The tolerance of ± 0.05mm is common, and the control of complex geometric tolerances is unstable. |

|

Surface treatment

|

Customized hard anodizing: film thickness 30-50m, hardness HV ≥ 400, salt spray test>500 hours. Sandblasting pretreatment ensures uniform adhesion. | Ordinary anodized films are thin (10-20 μ m), have low hardness (HV ≈ 200-300), and have average corrosion resistance. |

|

Dealing with complex structures

|

Multi axis linkage strategy optimization: Customize machining sequence and parameters for thin-walled, deep cavity, and asymmetric features to effectively control deformation. | Insufficient estimation of deformation in complex structural processing, relying on later correction or sacrificing design. |

"This motor seat perfectly demonstrates how JS uses precision CNC machining and deep process understanding to turn a piece of aluminum into a reliable and durable core component. Want the key parts in your project to have this precision and strength? Contact the JS team immediately, and we will help you to land the design firmly!"

3. Why Choose Our Online CNC Machining Service?

Let me talk about why choosing our onlineCNC machining servicesis the most reliable:

Advantage 1: Fast and accurate quotation, knowing the cost

We value efficiency the most.You upload 3D drawings on our platformand get an accurate quotation within a few minutes. No need to wait for emails or calls, you will know the cost immediately, saving worry and time.

Advantage 2: It can be done for 1 piece or hundreds of pieces, very flexible

People who are engaged in R&D know that testing and changing designs are common. Whether you just make a sample of 1 piece to try, or have hundreds of orders to produce, our custom CNC machining manufacturing service can take it steadily, ensuring that every job is done with precision and good quality, fully meeting your needs at different stages.

Advantage 3: The whole process can be done online, and experts can help check

From getting a quotation, placing an order, to checking which step has been completed at any time, everything can be done online and clearly. The most important thing is that our engineering team is not a decoration! We will doDFM analysisfor you for free, and help you find and solve possible problems before production, so as to avoid delays and waste of money.This is the core value of our online CNC machining services, making complex things simple, and there is professional support.

4. Success Case: Providing Key Structural Parts For An Agricultural Drone Company

Customer Background: A technology company that develops new pesticide spraying drones.

Difficulties faced by customers:The designed motor mounting bracket must be very light, extend the flight time, and be super strong, and the shape is also very complex. The previous supplier was slow to do it (it took 3 weeks!), and the scrap rate was high, which seriously slowed down the project progress.

JS's solution:

- Quick start:The customer uploaded the 3D model on our online cnc machining services platform on the same day, and received a quote and confirmed the order on the same day,without wasting a minute.

- Core technology manufacturing:The difficulty of this bracket lies in the complex surfaces at multiple angles and the strict accuracy requirements (±0.02mm). We used a5-axis linkage machiningcenter.

What are the benefits?

- One clamping, all surfaces, all holes, and all fine structures are all done! This guarantees accuracy to the greatest extent and avoids the errors that may be caused by repeated disassembly and assembly.

- Equal emphasis on speed and quality: From the time the order was placed,it only took 7 working days for all parts to be deliveredin good condition. This speed is much faster than the common cycle in the industry.

The key to achieving a breakthrough (difference from conventional processing):

| Key dimensions | Common challenges |

JS company's solution

|

The achieved effect

|

| Complex structure processing | Multiple processes and clamping make it difficult to ensure accuracy. |

5-axis CNC completes the entire process in one clamping.

|

Ensure overall accuracy (± 0.02mm) and eliminate clamping errors. |

| Lightweight target | Relying solely on materials and insufficient structural optimization. | Topology optimization design+high-precision thin-walled machining technology. | Tested to reduce weight by 21% while meeting all strength indicators. |

| Quality and efficiency |

Long processing cycle, relying on post screening.

|

Process monitoring+first piece full-size 3D scanning confirmation. |

Scrap rate<1%, delivered on time within 7 working days.

|

Results:

Our intervention enabled the customer's project verification phase to be completed two weeks ahead of schedule. The customer's chief engineer's evaluation was very pertinent:JS's service response is fastand the results are reliable. It is like an extension of our design team, allowing us to focus more on core research and development.

"Don't worry about complex and high-demand parts. Try our online CNC machining services, with fast response, professional technology, and reliable delivery, so that your project can run faster and more steadily. Need to get a tricky part? Talk to me anytime!"

5.Our Quality Assurance System: Online Convenience, Offline Rigor

As an engineer at JS, let me talk to you about our proudquality assurance system. The core is online convenience and offline rigor.This is the foundation for us to make every product well:

(1) With certification in hand, the system is more reliable:

Our company has actually won the ISO9001:2015 internationally recognized quality management system certification. This means that from order acceptance to delivery, the entire process is governed by clear and standardized standards, not just casually.

(2) Precision inspection, every piece is serious:

Quality is not just talk. Our workshop is equipped with professional "real guys" such as Hexagon's three-coordinate measuring machine (CMM), projector, height gauge. We will use these equipment to carefully check and repeatedly check the key dimensions, shape and position tolerances of eachcustom CNC machiningmanufacturing product to ensure that the processed parts fully meet your drawing requirements. Online communication is convenient, but we are absolutely "serious" in offline inspection.

(3) Full record, traceable at any time:

From the time the materials you selected enter our warehouse to the final packaging and shipment of the finished products, we have recorded every important step in between. If you need it, we can provide a complete document package, which includes material certificates and all dimensional inspection reports of parts from beginning to end (such as FAI/FQC reports).This is clear and can be checked at any time, giving you more peace of mind.

Simply put, we use this solid system, coupled with professional equipment and a serious attitude to ensure that every product delivered to you is of high quality. Leave it to us with confidence!

6.Call To Action: Don’t Let Creativity Stay On The Drawing, Make It Come True Now!

Don’t let production block your good ideas!We know that engineers’ time is precious, and the most feared thing is that the design is made, but the production can’t keep up. Our team is dedicated to solving this pain point - providingparts manufacturing servicesthat understand your engineers, so that you can focus on innovation and leave the manufacturing to us.

Want to try it? Zero risk:

- Free quotation, with a bottom line in mind:Don’t guess how much it will cost! Send us your CAD drawings now, and we will give you an accurateCNC machining priceimmediately. Simple operation, fast and transparent.

- Confidentiality, absolutely in place!Your design is your hard work, and we fully understand it. Before cooperation, we sign a confidentiality agreement (NDA) in black and white. This is a basic operation and must be.

- Intellectual property, locked in a safe:Your drawings, your designs, ownership will always be yours. We are only responsible for processing according to your requirements, and willnever disclose or abuse them. You can rest assured about security.

Don’t wait, upload the drawings,and let’s get started! Your innovation deserves to be implemented quickly and safely.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com