After years of working in the field of industrial automation, I know a core contradiction: Speed and precision. Every day, we are pushing robots to be more agile and production lines to be smarter, but the foundation that supports all of this is those indispensablecustomized mechanical parts, and the acquisition process itself often becomes a bottleneck for project acceleration.

Whether you are in a hurry to verify a breakthrough prototype or need to produce key components in small batches,the time window is extremely limited,and the reliability of equipment operation cannot be compromised.

What is the most troublesome thing? It is to quickly find a truly reliable partner. The traditionalcustom CNC machiningmanufacturing process often means repeated communication, long waits for quotations, and concerns about the final quality and delivery time.

This uncertainty consumes a lot of energy from our engineers and project managers, and seriously slows down the pace of the entire project. We can't afford it. What we need is clear and transparent prices, reliable delivery cycles, and consistent high quality, and the sooner the better.

This is why an efficient online CNC machining service platform has become so critical.It must be able to directly hit the pain points, allowing us to focus our precious time on core innovation rather than repeatedly struggling to find and wait for parts.

1.Solution Summary:

| Pain points | Solution | Key Value Points |

| The traditional quotation process is slow | Upload drawings for 3 minutes to obtain real-time quotes, adjust parameters in real-time to view price changes. | Say goodbye to waiting → Accelerate project decision-making pace. |

| Unstable quality of customized parts | Realize ± 0.01mm precision machining, integrated molding of complex parts, and free selection of metal/engineering plastic materials. | Zero misalignment of components → Improving equipment reliability. |

| Small batch production is difficult | Minimum order quantity of 1 piece to 1000+pieces, flexible acceptance, CNC machining and surface treatment can be completed in one stop. | Eliminate multiple connections → Simplify supply chain management. |

| Difficult to predict design risks | Professional engineers provide free DFM feedback to optimize designs in advance and avoid risks. | Avoiding trial and error costs → First version is qualified. |

| Opaque progress | Full process online progress tracking, real-time push of production nodes. | Accurately control nodes → ensure timely delivery. |

2. Solution Core: From A Drawing To A Precise Entity

Today I want to talk to you about how we turned a design drawing into the perfectly fitting chassis mounting plate of the automation equipment in your hand. The core is one: use precision and efficiency to land your design firmly.

Handle complex shapes and form them in one go:

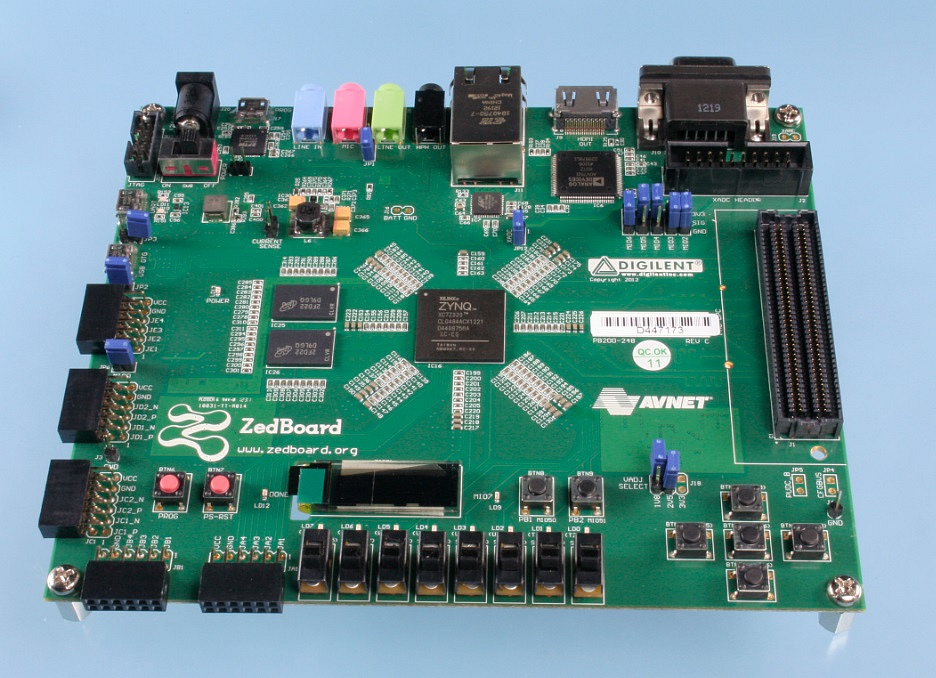

Look at the "body" of this board. The corners are not regular squares, and there are various windows and cuts in the middle. Our3-axis CNC milling machineis the best for this project. Whether it is the 6061, 7075 aluminum alloy you specify, or various strong engineering plastics, as long as the drawing is in place, the machine can accurately mill the entire shape and the hollowed-out areas inside in one go according to the set path. It saves the trouble of piecing together multiple processes, and the integrity and precision are guaranteed.

"Perfection is not a small detail, but details make perfection. As the automotive master Henry Ford said, we know that every contour detail of the equipment chassis is related to the overall performance and must be meticulous."

Precise hole position is the lifeline of smooth assembly

- These large and small holes on the board are the key to installing motors, sensors, circuit boards (PCBs) and support columns.

- This is what we care about most:The diameter of each hole and the distance between holes can be controlled within thetolerance rangeof ±0.01mm. This means that all your components can be aligned and installed like a puzzle, without the embarrassment of not being able to match or install.

- For holes that require threaded connection, our equipment can directly "tap" on site to make standard threads in one step.

Be thrifty and make good parts have good prices

Like this mounting plate, the main feature is cutting and punching on the plane (also called 2.5D structure in the industry), which is exactly the strength of our intelligent production. Especially through our onlinecnc machining servicesplatform, after you upload the drawing, the system can quickly understand the design intent and automatically calculate the optimal and most material-saving machining path. With higher efficiency and less waste,the final cnc machining price you get will naturally be more competitive.

"As quality management expert William Edwards Deming said: Quality is not tested, but designed and produced."

Not all parts are suitable for the same machining method. If you choose the right method, the cost can be reduced:

| Characteristics of Processing Requirements | Challenge traditional methods | Advantages of JS's online CNC services | The impact on costs |

| Flat contour+hole/groove (2.5D) | Multiple processes or special fixtures are required. | Intelligent path optimization, completed in one clamping. | Significantly reduce working hours and fixture costs. |

| Small and medium-sized batch (<100 pieces) | High single item cost and difficult production scheduling. | Automatically arrange orders and aggregate similar orders for production. | Enjoy the advantage of near bulk unit price. |

| Material utilization rate | Manual discharge is prone to waste. | AI automatic nesting maximizes the utilization of sheet metal. | Directly reduce the cost of raw materials. |

| Urgent sampling/minor modifications | Long communication cycle and slow response. | Online real-time quotation, quick confirmation of production. | Shortening delivery time is saving money. |

A good chassis mounting plate is the cornerstone of stable operation of the equipment. At JS, we start from understanding the drawings, and use solid technology and intelligent online CNC machining services to ensure that every detail is accurate and reliable, while precisely controlling costs, so that your good design can quickly become high-quality parts at a reasonable CNC machining price. When the drawings are sent, we will immediately give you a clear account, and work together to make the equipment chassis stable and good!

3. Why Choose JS's Online CNC Machining Service?

As an engineer at JS, I am often asked by customers: Why choose your online CNC machining services? The answer is very direct:We make the acquisition of high-quality precision parts faster, simpler and more transparent. This is not only a slogan, but also the core of our service design.

Core advantage 1: fast quotation, clear price, budget you decide

Pain point solution:Say goodbye to the long email exchanges and days of quotation waiting in the traditional mode.

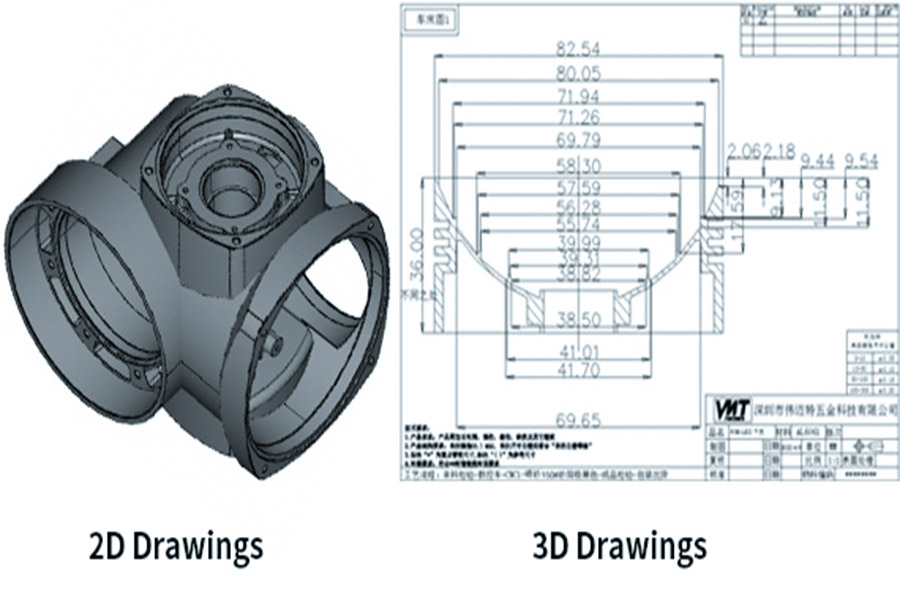

JS's advantages:You only need to upload general3D drawings(such as STEP/IGES) on our platform to get detailed custom CNC machining manufacturing quotes in a few minutes.

Value:Price structure is clear and visible. You can adjust materials (such as 6061 aluminum to 7075 aluminum), quantity orsurface treatment(such as anodizing, sandblasting) in real time, and the system will update the quotation instantly, so that budget planning is accurate and correct. You control the cost, rather than passively accept it. What you see is what you get, no hidden fees.

Core advantage 2: Strong flexible customization capabilities, covering from prototype to mass production

Rich material library:We provide dozens of common metals (aluminum, steel, copper alloys, etc.) and engineering plastics (POM, Nylon, PEEK, etc.) to meet different performance requirements.

One-stop service:We are not just processing. FromCNC milling and turningto various surface treatments such as sandblasting, anodizing, electroplating, etc., we can do it. What you receive in the end is CNC machining parts that can be assembled directly, saving you the trouble of secondary coordination with suppliers.

Quantity flexibility:1 prototype verification? No problem. Hundreds of small batches? Also competent. No matter how much, we can accept it, and we guarantee that everything meets the same strict quality standards to ensure consistency.

Core advantage 3: Full process online, efficient procurement

Pain point solution:Simplify the cumbersome offline communication and order tracking process.

Our advantages:From uploading drawings -> getting instant quotes -> confirming orders -> online payment -> real-time tracking of production progress, all links can be completed online on our platform. Convenient and efficient.The process is clear and traceable.

Professional support embedded: Our experienced teamof engineers is not a decoration. After you submit the drawings, we will carefully look at your design and provide you with professional manufacturability (DFM) feedback to help you discover problems that may affect production or costs in advance, optimize the design before production, take fewer detours, and avoid later troubles.

| Traditional processing pain points | JS online CNC service solution | The core value we bring to you |

| Slow and opaque quotation | Online real-time and accurate quotation. | Save days of waiting and make costs fully transparent. |

| Difficult to accept small orders/high cost | Starting from 1 piece, intelligent production scheduling optimizes costs. | Fast prototyping, small batch production, and cost-effectiveness. |

| Difficulty in process dispersion/coordination | CNC+one-stop post-processing completion. | Effortless and worry free, what you get is the finished parts. |

| Process black box/difficult to track progress | Full process online visual management. | Keep track of the status at all times, plan more reliably. |

| Post exposure of design risks | Engineer pre DFM feedback. | Avoiding problems in advance to ensure a successful outcome. |

"Choosing JS's online CNC service means choosing a combination of efficiency, transparency and professional support. We are committed to making custom CNC machining manufacturing as simple as online shopping, while ensuring that you get high-precision, high-quality CNC machining parts. Upload your drawings now to experience the new way of efficient and transparent precision manufacturing, and accelerate your project."

4. Take Action: Turn Your Design Into A Physical Object Quickly

Seeing everyone's demand for efficient processing quotes and services, I fully understand the mood of wanting to advance the project quickly.

The most important thing to do: get a quote now!

Don't hesitate! Upload your CAD file directly and you can get an accurateCNC machining quoteimmediately, and it's completely free! This is the first and fastest step of our service.

Why is it worth a try?

Try our JS online CNC machining services. This system is created by our engineering team to solve the actual procurement pain points. It can help you save tedious communication and waiting, making the entire ordering process simple, transparent and efficient. Whether you need a singleCNC machining partsor batch production, the process is greatly simplified.

What to do next?

Get a quote now: Click here to upload your file to get started:https://www.cncprotolabs.com/contact-us.

Technical questions? Contact our engineers directly to chat:https://www.cncprotolabs.com/, we are always ready to answer your specific processing questions.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com