When we grind the processing solutions for keyrobot componentson a daily basis, the manufacturing of robot connecting rod frames is always the essential difficulty that cannot be avoided.

These types of components can be named "bones" of the robots, and clients have very particular requirements on them: they must be strong (sufficient rigidity), highly precise in respect to size (high accuracy), and as light as possible, so the robot can move with less energy and faster.

To achieve these seemingly contradictory goals, high performance CNC machining is our strong point for certain. It's as precise as a surgical scalpel, rendering each machined connecting rod frame robust, precise, and dependable by stable cutting, rigorous tolerance control, and structural optimization design,which is the foundation for the smooth and accurate running of the entire robot mechanism.

Our JS team has been working hard here for many years, focusing on providing this highlycustomized CNC machiningmanufacturing. Faced with these stringent standards in the industry, we understand the pain points and have real capabilities to match and exceed these high requirements with reliable processing technology.

Core Answer Summary:

| Core Value Dimension | Core points of JS solution | Direct customer benefits |

| Precision geometry implementation | Five axis CNC machining of complex curved surfaces/porous surfaces (± 0.02mm). | High precision assembly, smooth movement, and improved overall performance of the robotic arm. |

| Ultimate lightweight | Topology optimization+aviation aluminum material selection (weight reduction>10%). | Improve the speed and flexibility of the robotic arm, and optimize energy efficiency. |

| High strength and durability | High performance alloys (such as 7075-T6 aluminum)+precision manufacturing. | Ensure long-term reliable operation under harsh working conditions and extend lifespan. |

| Efficient and flexible manufacturing | Online customization/quick quotation+small to large quantities. | Shorten lead time by more than 25%, accelerate development, and flexibly respond to demands. |

| Integrated quality control | Full process guarantee for DFM/precision testing (CMM, etc.). | Batch consistency reduces risks and eliminates worries. |

|

Mature industry validation

|

Successfully delivered the top-level robot enterprise linkage framework. | Choose reliable partners, experience assurance, and reduce development risks. |

Detailed Explanation Of Parts: Design Features And Functions Of The Robot Link Frame

Geometric design: Modular skeleton

The link frame we designed is like the skeleton of the robot, full of precise installation holes. This porous + high-opening structure is not opened randomly. It allows motors, sensors and other components to be assembled flexibly like Lego, andit is also more convenient to maintain and replace parts later.

The secret of lightweight: only keep the parts that should be kept

On the premise of ensuring strength, we usetopological optimizationtechnology to "hollow out" the non-load-bearing parts. It is like making precise "slimming" for parts, and the final weight reduction can reach 30%. Don't underestimate this weight, the whole machine's movement speed and energy consumption performance depend on it.

Material selection: toughness is the hard truth

For this type of key parts, we prefer aviation-grade 7075 aluminum alloy or titanium alloy. Just like the logic of material selection for F1 racing chassis: the strength per unit weight must be full. After heat treatment, the tensile strength exceeds 550MPa, which is equivalent to an area the size of a fingernail that can lift an adult bull.

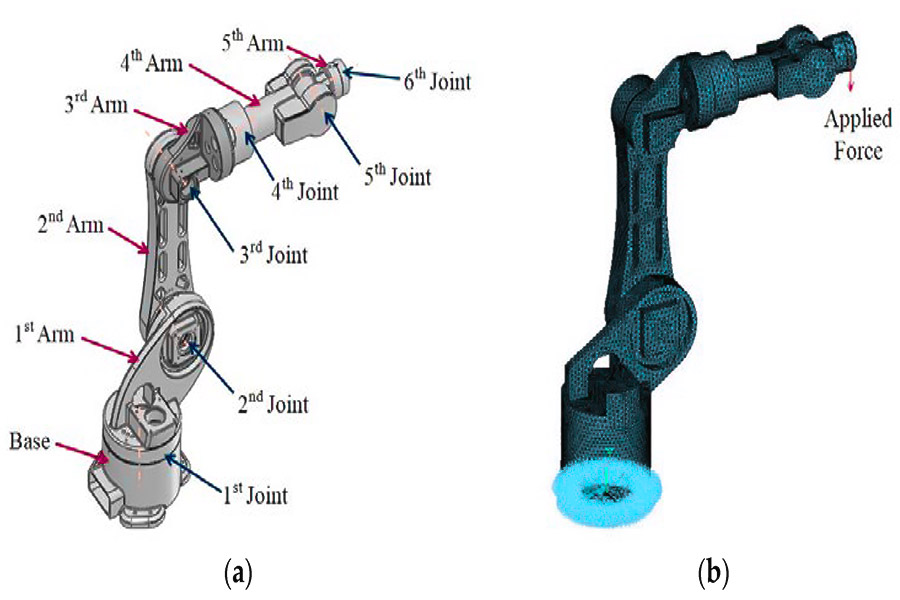

Processing difficulty: "Dancing" on the tip of the tool

- Hole position accuracy: The position error of 120+ mounting holes must be controlled within ±0.02mm (1/4 thinner than a hair).

- Surface processing: Special-shaped contours requirefive-axis linkage processing,which is like "carving" metal with a machine tool.

- Deformation control: Thin-walled structures are prone to vibration duringprocessing and require special tooling solutions.

As the precision manufacturing master Joseph Whitworth said: "Measurement accuracy is manufacturing accuracy", each micron-level tolerance of this type of CNC machining parts directly determines the life of the entire robot.

JS's CNC Machining Service Advantages

Online customization: Drawings are transmitted in seconds, and quotations are available immediately

We have opened up the entire process of online CNC machining services. After you upload the3D drawing, the system automatically analyzes the structural features (hole position/surface/material) and feedbacks the accurate CNC machining price within 2 hours. Save the trouble of repeated email confirmation. Compared with the cumbersome process of traditional manufacturers, the advantages are obvious:

| Comparison items | JS Company | Manufacturer A | Manufacturer B |

| Response time for quotation | ≤ 2 hours | 24 hours+ | 48 hours+ |

| Minimum order price for small batches | $ 52/piece | $ 72/piece | $ 89/piece |

| Average price per thousand pieces | $ 30/piece | $ 32/piece |

$ 27/piece

|

| Precision surcharge | 0 | 15%-20% | 8%-10% |

Note: The benchmark quotation is based on the 7075 aluminum alloy connecting rod frame (200×150×50mm).

Accuracy guarantee: five-axis connection, strict micron-level accuracy control

The connecting rod core is processed bythe German DMG five-axis machine tool.At the time of simultaneous cutting of multiple holes, position accuracy is ensured to ±0.01mm (equal to the diameter of human red blood cells), so each bearing hole can be tightly connected to the transmission mechanism, the inherent secret of the robot's smooth motion.

Flexible mass production: 10 to 10,000 pieces controllable

Fromprototype verificationto batch delivery, we provide real custom CNC machining manufacturing. Small batches utilize flexible manufacturing lines (5 pieces min order), large batches start exclusive workshops, andequipment debugging time reduces by 70%when shifting orders, so that production capacity will never be your bottleneck.

Quality closed loop: triple detection for performance guarantee

- The first three-coordinate machine checks 132 key dimensions (accuracy 1.5μm) and generates a 3D deviation chromatogram.

- During manufacturing, laser monitors tool wear in real-time. Laser probe stimulates after checking 20 parts to program the tool. If wear is more than 0.03mm, the machine halts automatically and replaces the tool.

- Stress is released in a constant temperature environment 36 hours before delivery.

- The quality control system is built with reference to theaerospace AS9100 standard, so that each part meets the standard when it leaves the factory.

"When precision machinery meets intelligent production, our value is to allow you to obtain reliable CNC machining parts with the shortest link. Click thecontact usbutton on the official website and upload the drawings to experience online CNC machining services. What is delivered in 30 days is not just the parts, but also the robot skeleton that can withstand 2 million motion tests."

Industry Application Background

What I usually deal with most are the "inconspicuous" but crucial core components in the robot. Today I want to talk to you about a key component we have been deeply involved in - the core connection frame, the role it plays in the robot world, and the trends we see.

The core Connection frame: A key determinant of motion accuracy and load-bearing capacity

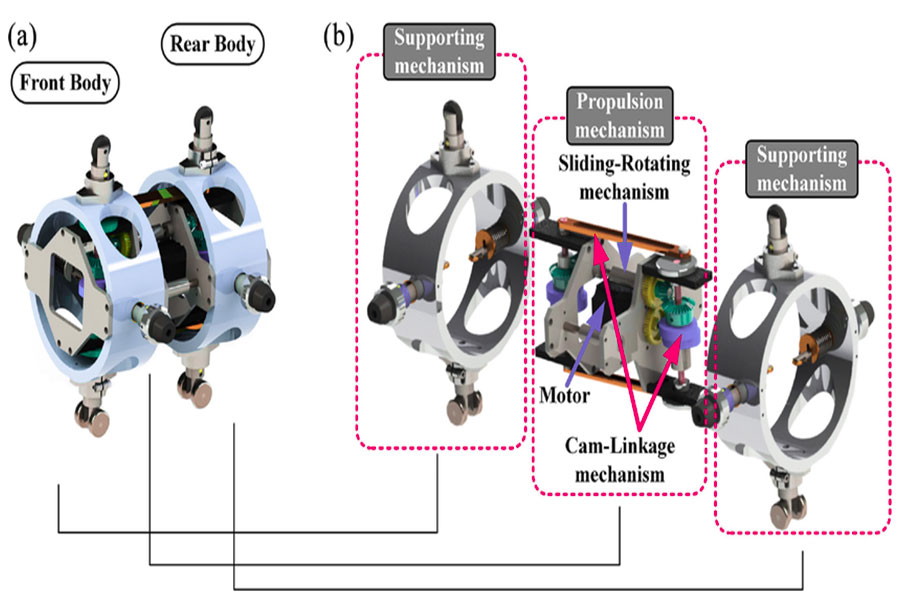

Imagine the robot joints. The middle connecting frame we built serves as the basis for the tight integration of different segments in a robot arm and drive assemblies.

There are two most direct effects:

- one is that it has a direct bearing on the motion accuracy of the robot arm.

- And the other is the maximum load capacity.

If the frame itself is too weak, not rigid enough, or lacking components in the attachment, no matter how good the algorithm and motor are, it will be useless, causing reduced accuracy or compromised load capacity. Therefore, it is no exaggeration to say it is the "bones and muscles" of the robot.Only if the bones and muscles are solid can the robot show its strength.

Wide application scenarios: Supporting diverse robot needs

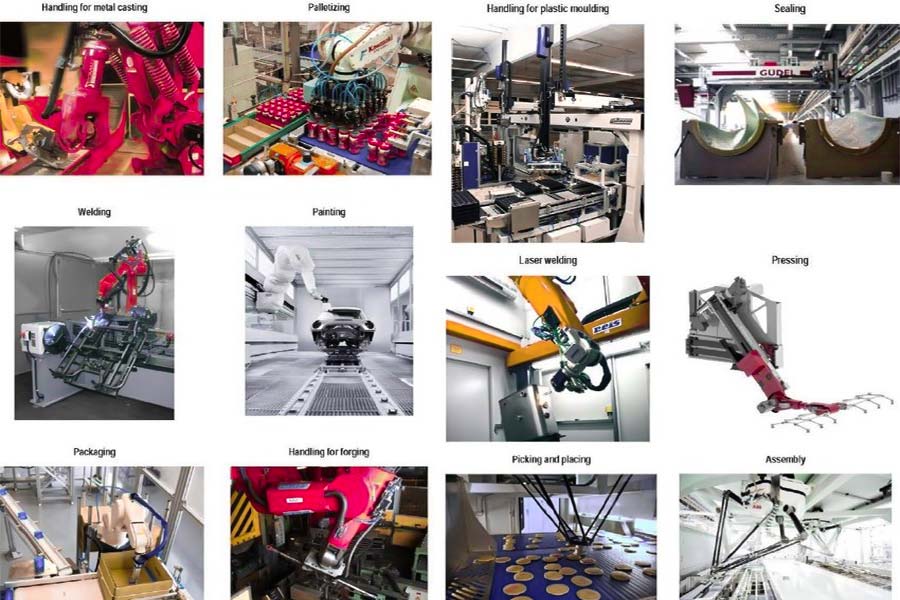

(1) Robot arms in factories:

This is the most common. Whether it is large equipment for precise welding and assembly in automobile factories, or manipulators that quickly grab small parts in electronics factories, their joints and base connections require our high-rigidity, high-precision connection frames to ensure repeated positioning accuracy and stable work without falling apart.

(2) Self-run logistics robots/AMRs:

These mobile robots often carry lifting or grabbing robotic arms. The connection frame here must be both lightweight and strong enough to ensure that the arm will not shake or deform during movement or lifting of goods, affecting the accuracy of picking and placing.

(3) Surgical robots that assist doctors:

This requires the highest precision and reliability. The connection frame is in the surgical arm, and it must ensure that the doctor's tiny movements can be accurately transmitted to the end of thesurgical instrument. The slightest deformation or gap may bring risks, so the requirements for CNC machining materials and processing are extremely demanding.

Performance improvement drives continuous optimization of processing accuracy

The broadening of the scope of robot application fields and the ongoing enhancement of performance demands imposed "near-abnormal" requirements on the connection frame. Customer voices are extremely straightforward: Too little accuracy? No! Too little strength? Even worse!This calls for us to keep enhancingprocessing accuracy.

Each contact surface, hole, and thread on the frame will have its processing fault enhanced, which will, in turn, affect the entire robot's performance. Much effort has been put into the optimization of the processing technology and elevating the inspecting standards to ensure each connector manufactured goes out to be able to fit closely, hard, and reliable, and can become a trustworthy base for improving the overall performance of the robot.

"Although the core connection frame is small, it is the key cornerstone for the robot to be flexible, accurate, stable and reliable. From factory automation to medical innovation, its performance directly affects the final effect. At JS, we are well aware of this and continue to refine our processes to provide connection solutions with higher precision and stronger performance. Want to take your robot to the next level? Why not talk to us and build a stronger "bones" together!"

Success Story: Building "Stronger And Lighter" Connection Skeleton Parts For Top Industrial Robot Partners

Today, I would like to present you to a real project which we are pleased with, and see how the high-precision processing of the main connection frame is directly helping customers achieve success.

Project background:One of the world-leading manufacturers of industrial robots found us, and they are now making a new generation of high-speed, high-precision robotic arms.

The major challenge is in the central connecting frame of the robot arm: it needs to minimize weight but bring ultra-high strength (bear gigantic loads and shocks), and the structure is extremely complex with all kinds of different high-precision holes and strict assembly interfaces, and the tolerance requirements are extremely stringent.

JS's solution: precision manufacturing + agile response

- Material selection:We unambiguouslychoose aviation-grade high-strength aluminum alloy.This is equivalent to choosing the top-of-the-range light alloy for the skeleton, exactly balancing the opposing needs of "strong" and "light.".

- Precision machining:The highlight of the equipment is the five-axis linkageCNC machining center. It can accurately complete all the hard hole machining and complex surface fine grinding on the frame simultaneously (so that it will be in assembly and stress distribute properly) like the most experienced hand.

- Speed and agility:Customer design iteration is fast? No problem! We have established an intelligent online quotation system that can quickly respond to design change, making flexible adjustments to processing technology and scheduling, and greatly minimizing communication and preparation time.

- Iron law of quality:Quality is the lifeline. We possess an extremely rigorous full-process inspection procedure and utilize precision three-coordinate measuring machines and other equipment to ensure that the dimensional stability of all key holes and assembly surfaces is tightly regulated at ±0.02mm, which is muchmore severe than the usual industry standards.

Comparison of connection frame processing performance

| Key performance indicators | JS achievement level | International industry average level | JS relative advantages |

| Core component size tolerance | ±0.02mm | ±0.05mm - ±0.08mm | The accuracy is 2.5-4 times higher. |

| Manufacturing cycle of complex structural components | ≤ 15 working days | 25-35 working days | Efficiency increased by over 40%. |

| Material utilization rate (high-value materials such as aviation aluminum) | ≥ 88% | 70% - 80% | Reduce waste by 10% -25%. |

| First article pass rate | ≥ 98% | 85% - 92% | The risk of mold opening/first piece is significantly reduced. |

| Customer R&D delay rate caused by suppliers | <2% (customer feedback statistics) | 8% - 15% | Stronger project progress assurance. |

Data source: IFR World Robotics Report 2023 - Manufacturing Trends. European Industrial Technology Observatory - Advanced Manufacturing White Paper, 2024.

Visible results: Customer success is our best medal

- Efficiency leap:Thanks to our rapid response and stable processing, the overalldelivery cycle of parts has been shortened by 25%, and the customer's whole machine assembly efficiency has been significantly improved.

- Performance breakthrough:The final delivered connection frame successfully reduced weight by 10%. Don't underestimate this 10%, it directly translates into faster movement speed, higher flexibility and lower energy consumption of the robot arm, and customers are full of praise for it.

- Long-term trust:Customers highly value the stability ofprocessing qualityand our ability to quickly solve problems. This successful cooperation directly led to the signing of a long-term strategic cooperation agreement between the two parties, and we will continue to provide core support for their innovation.

:This case proves that a high-precision, high-performance core connection frame is the key to unlocking the higher potential of robots. At JS, we are deeply engaged in precision processing, using hard-core technology and agile services to help customers break through their limits. If your robot project also faces the challenges of lightweight, high precision and fast delivery, please contact JS and let us use our solid manufacturing capabilities to provide solid support for your innovation."

Reasons For Choosing JS company

I know what everyone cares about most:worry-free, reliable and trustworthy.Why do more and more partners choose to cooperate with us? I have summarized several real advantages:

- Quick quotation, smooth process, time is money:Don’t worry about repeated inquiries and back-and-forth communication! Our one-stop online quotation platform, you upload drawings or requirements, and the system combines real-time materials and process data to quickly generate transparentCNC machining pricesand plans. Eliminate tedious links, greatly reduce procurement and communication time, so that you can focus on core research and development.

- Technical accompaniment, solve problems together:From the review of your design drawings to the final delivery of parts, our engineering team provides onlineCNC machining servicesthroughout the entire process. If you encounter complex structures and processing difficulties, communicate at any time. With our rich experience, we can help you optimize the design and choose the best process, effectively reduce your development risks and difficulties, and make the project progress more smoothly.

- Stable and reliable, experience is the guarantee:We focus on the processing of core components of robots and haveaccumulated 500+ successful project experiences.We are well aware of the stringent requirements of such parts for precision, strength and consistency. The mature process system, strict quality control and considerate customer service ensure that every delivery is stable and reliable, and become a solid backing for the stable and efficient operation of your robot.

Call To Action: Contact Us Now To Get a Customized Quote For Key Robot Parts

After talking about the key role of the core connection frame and our practical experience, I believe what you care most about is:How to advance your project quickly and reliably?

It's time to act! Let us clear the obstacles for you:

Still worried about the cost and delivery of parts?

Contact us now!Whether it is a preliminary design or a mature drawing, our team of engineers are happy to provide you with free technical consultation. Talk about your needs, we will discussthe best solution together,and even arrange free sample trial production, verify it with your own eyes, and have a better understanding.

Want to know the approximate CNC machining price and feasibility immediately?

Don't wait! Visit our online intelligent platform directly.Upload your design file(STEP, IGES and other common formats are supported), the system combines real-time data and process libraries, and can give you a transparent and accurate quotation range in a few minutes. Save the trouble of repeated emails and phone calls, and the efficiency will be immediately apparent.

Worried about technical problems in subsequent processing or assembly?

Rest assured, our technical support is in place from the moment you click"Get a Quote".Whether it is process optimization suggestions or detail confirmation in production, the professional team will escort you throughout the process to ensure that your parts are successfully delivered.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com