From canvas and wood of the Wright brothers to today's airplane silver wings, the history of aviation materials has been one of vying for every ounce of weight reduction. In this last battle between strength and lightness, a single metal is the only selection of the masters of the skies: aluminum alloy.

It's not the most powerful metal, nor does it handle the heat, but it idealistically finds equilibrium with stringent aerospace demands using its unparalleled strength-to-weight ratio and cost.

This guidebook, developed based on JS Precision's expertise in sheet metal fabrication, extensively elaborates on how aluminum alloys meet tough demands of aerospace, from performance to manufacturing, application to innovation, for convenient reference.

Core Answer Summary

| Core Aerospace Needs | Solutions Provided by Aluminum Alloys | Key Values |

| Extremely lightweight | Low density (approximately 2.7 g/cm³) and extremely high specific strength (strength/density). | Improved fuel efficiency, increased range, and increased payload. |

| High strength and durability | Significantly enhanced strength through heat treatment (such as T6 temper) and alloying (addition of copper, zinc, magnesium, etc.). | Withstands aerodynamic loads and pressure cycles during flight. |

| Excellent corrosion resistance | A dense oxide film naturally forms on the surface, which can be further enhanced through anodizing. | Extended service life, reduced maintenance costs, and adaptability to complex environments. |

| Excellent workability | Excellent sheet metal forming, machining, extrusion, and joining performance. | Facilitates the fabrication of complex aerodynamic shapes with high production efficiency. |

| Affordability and recyclability | Costs significantly lower than titanium alloys and composites, and 100% recyclable. | Low lifecycle costs, consistent with sustainable development. |

How Do Aluminum Alloys Meet The Harsh Requirements Of Aerospace? From JS Precision's Manufacturing Practice

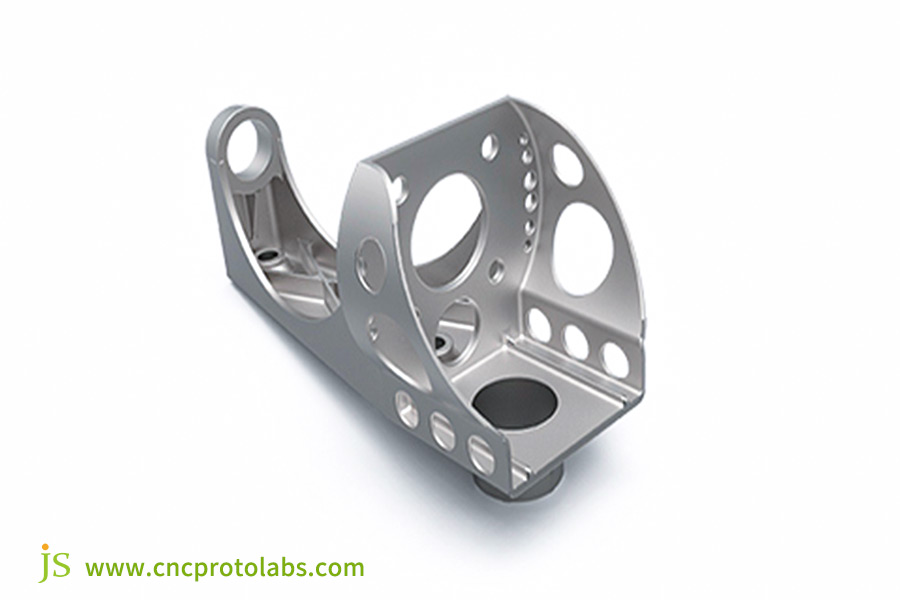

JS Precision boasts a rich 15-year experience of aerospace sheet metal fabrication and has produced over 5,000 high-precision sheet metal parts for over 200 aviation entities around the world.

For example, the firm used 7075 aluminium alloy in a bracket project in space station to achieve a contour accuracy of ±0.1mm with 8% weight saving of component parts. The entire project, from design verification to delivery, was accomplished in 35 days.

In manufacturing passenger aircraft fuselage skins, friction stir welding provided a solution to the weld cracking issue of 2024 aluminum alloy, bringing up the weld pass rate from the industry average of 92% to 99.5%.

Our technical capability and supply chain optimization in the field have been featured by TechBullion, further demonstrating industry recognition of our technical capabilities.This guide draws on the technical expertise gained from these real projects, providing you with sensible and practical sheet metal fabrication solutions.

JS Precision provides custom sheet metal fabrication manufacturing for the aerospace industry. We can customize components to your requirements and provide solutions within 72 hours of order, precisely matching performance requirements in hostile environments. Working with us is working with reliability.

Aluminum Alloy Is The Ideal Material For The Aerospace Industry, Why?

Aerospace material selection is a battle between performance and weight, and aluminum alloys are the ideal option due to their many advantages.

The King of Specific Strength

Specific strength is the ratio of a material's strength to its density and is a direct determinant of an engineering component's ability to weigh off against reduced strength. Here is the comparison of specific strengths of three standard aerospace materials:

| Material | Strength (MPa) | Density (g/cm³) | Specific Strength (MPa/(g/cm³) |

| Typical Steel | 600 | 7.8 | Approximately 25 |

| Titanium alloy | 900 | 4.5 | Approximately 80 |

| 7075 Aluminum alloy | 570 | 2.8 | Approximately 75 |

As the table shows, the strength in tension of aluminum alloys approaches that of titanium alloys and more than doubles that of commercially available steel, making it possible for substantial weight saving without loss of strength.

For example, using aluminum alloy sheet metal parts in a mid-size passenger plane fuselage saves 4.2 tons of weight compared with an all-steel structure, reducing fuel consumption by 120,000 liters annually.

Fatigue Life

Aluminum alloys can resist well over 100,000 cycles of stress because their grain structure does not crack from repeated stress. For example, with about 3,000 takeoff and landing cycles per year, passenger aircraft have a lifespan of well over 30 years for aluminum alloy components.

Even fighter trainer aircraft, with even more takeoffs and landings (about 5,000 per year), have long-lasting aluminum alloy components for 25 years, coping with the thousands of stress cycles experienced by aircraft perfectly.

A Legacy of "Space-Grade"

From the aluminum fuselage of the Wright brothers' flying machine in 1903 to the aluminum alloy framework of the Apollo lunar module in 1969 (2219 aluminum alloy), to the modern Boeing 787 (using 15% aluminum alloy sheet metal components) and solar array supports on the International Space Station, aluminum alloys have remained a perennial favorite in the aerospace industry at all times.

The "League Of Kings" Of Alloys: Widest Used Aluminum Alloy Families In Aerospace

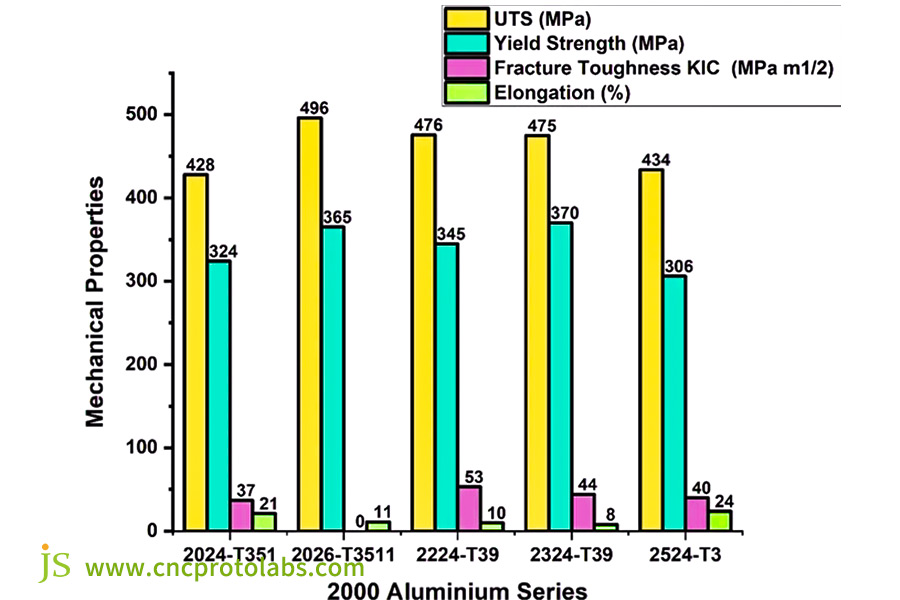

Different series of aluminum alloys, depending on their compositional differences, have distinctive properties, which satisfy the diverse aerospace part requirements:

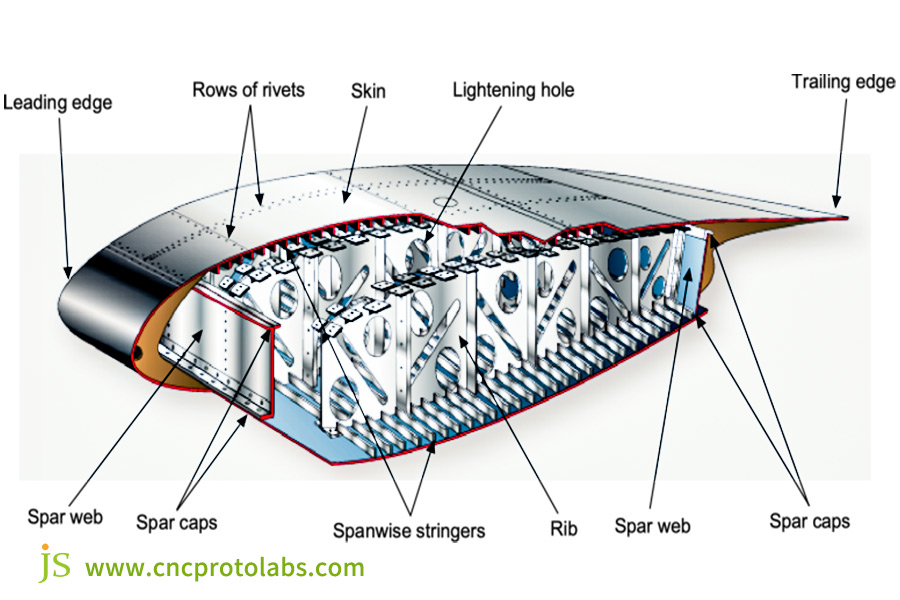

2xxx Series (Al-Cu Alloys): 2024, described as the "king of fuselages," accounts for approximately 30% of aluminum alloy consumption by passenger aircraft. The fuselage skins of the Boeing 737 and Airbus A320 are made mostly of 2024 aluminum alloy, and its fatigue strength is capable of coping with the forces of repeated takeoffs and landings.

7xxx Series (Al-Zn-Mg Alloys): for example, 7075, the "king of wing spars," is among the strongest aluminum alloys in current use. The primary spars of Boeing 787's wings and landing struts of F-16 fighter are all made of 7075 aluminum alloy that can bear the fuselage weight and aerodynamic loads of flight.

6xxx Series (Al-Mg-Si Alloys): such as 6061, are "universal" materials for a wide range of applications. Not only passenger aircraft fuselage reinforcements but also the fuselage frames of unmanned aircraft and internal brackets of satellites. Due to their high corrosion resistance, they are used in humid and high-altitude applications.

8xxx Series and Al-Li Alloys: such as 2099 and 2195, are new-generation advanced materials for aircraft and aerospace fuel tanks. SpaceX Falcon 9 rocket fuel tank uses 2195 aluminum-lithium alloy that is 8% lighter than traditional aluminum alloys to provide payload increase for the rocket.

JS Precision also knows about the characteristics of various aviation aluminum alloys and offers online sheet metal fabrication services that respond to processing requirements for various grades of aluminum alloys in real time and eliminating material compatibility issues.

Indomitable Link: The Technique Of Joining Aluminum Alloy Sheet Metal In Aerospace

The integrity of aluminum alloy sheet metal joints directly impacts aerospace component safety. Four methods of joining are used:

1. Riveting: A conventional depiction of the air transport industry, it is very reliable, easy to inspect, and could be replaced instantly even in event of minor defects. To date, approximately 80% of passenger aircrafts' fuselage joints are riveted. JS Precision uses precision rivet guns to manufacture rivet strength to specification.

2. Friction Stir Welding: A solid-state connection technology that does not generate a welding heat affected zone and avoids material performance degradation, commonly used for connecting 7075 aluminum alloy wing beams.

3. Adhesive Bonding: A method that is compatible with composite materials. Structural adhesives distribute stress and are often used in conjunction with riveting. For example, in the skin joint of the "Lingque" demonstrator aircraft, adhesive bonding in combination with riveting enhanced joint strength by 20%.

4. Fastener systems: High-lock bolts and ring-grooved rivets, with high precision (tolerance ±0.05mm) and loose-proof design, are applicable for parts exposed to repeated vibration, e.g., engine mounts.

The Wisdom Of Bending: Precision Forming Of Aviation-Grade Sheet Metal

Control of a number of key points is required to bend aviation-grade aluminum alloy sheet metal precisely:

1."K Factor" and "Bend Tolerance"

The K factor determines the location of the neutral layer in sheet metal bending, simply put, "where is the layer inside the material that does not deform during bending. Accurate calculation of the K factor ensures a bend angle deviation of less than 0.5°.

Specific software is used by JS Precision to automatically calculate the K factor for different aluminum alloys. "Bend tolerance" refers to the range of acceptable angular deviation. For aerospace-grade requirements, this is typically within ±0.3°.

2.The Golden Rule of Bend Radius

The R/T ratio of bend to sheet thickness should not be less than 1. For instance, a 7075 aluminum alloy that has a thickness of 1mm should have a bend radius no less than 1mm. The reason is that the material will have stress concentration with too small a radius, which beyond its tolerance level, can easily make it crack.

3.The Significance of Grain Direction

Roll sheet metal has a grain direction like the grain of wood. The bend line must be perpendicular to the direction of the grain. When, for example, 6061 aluminum alloy is bent in the grain direction, the likelihood of cracking increases from 5% to 30%.

4.Predicting and Compensating for Springback

This is a basic technology of sheet metal fabrication used in aviation. Finite element software simulation of springback, for example, 7075-T6 aluminum alloy experiences around 5° springback when bent to 90°. Molds are therefore created to bend 95°. Precision bending machine with a correction feature is used to make pressure corrections in real time to ensure the final angle to up to desired standards.

JS Precision focuses on precision forming of metal sheets, mastering core technologies for rebound prediction and compensation. We can attain contour accuracy levels of ±0.2mm and provide precision bending solutions for your aerospace applications.

Main Uses Of Aluminium Alloys: Engineering Solutions To Weight Saving And Strength In Aerospace

The application of aluminium alloys in various aerospace segments is a question of weight saving versus strength:

Passenger planes:

For example, Boeing 777 employs approximately 54 tons of aluminum alloy sheet metal components in fuselage and wing, 30% lighter than made of steel and conserving $200,000 value of fuel annually. Furthermore, the skin of the Airbus A350's fuselage is made of 2024 aluminum alloy. With proper sheet metal fabrication, splicing of intricate curved surfaces is perfect, reducing flight drag.

Aerospace:

Aluminum-lithium alloy satellite fuel tanks weigh 10% less than conventional aluminum alloys, can carry 5% more fuel, and extend the on-orbit life of a satellite. For example, the fuel tank of a geosynchronous satellite using 2195 aluminum-lithium alloy which was reduced by 12kg, extended its on-orbit life from 15 years to 18 years.

Drone field:

6061 aluminum alloy is used in the fuselage frame, meeting wind resistance requirements and keeping the unit weight under 20kg and improving endurance when flying. An assembly of a military reconnaissance drone using 6061-T6 aluminum alloy sheet metal weighs only 3.2kg but can withstand force 8 winds and last 40 hours of flying.

JS Precision understands the needs of numerous aerospace applications and offers custom sheet metal fabrication manufacturing solutions with competitive sheet metal fabrication prices to handle project costs.

The "Ultimate Challenge" In Materials: State-Of-The-Art Innovation In Aerospace Aluminum Alloys

Faced with increasingly stringent demands of aerospace, aluminum alloy technology is consistently advancing the frontiers:

1. Thermal Management Challenge: Supersonic aircraft have the potential to touch surface temperatures of up to 300°C on flight. High-thermal-conductivity aluminum alloys (thermal conductivity: 250 W/(m・K)) are capable of dissipating aerodynamic heat rapidly.

2. Corrosion-Resistant "Armor": Silicon carbide particle-reinforced aluminum alloys offer 50% higher corrosion resistance than standard aluminum alloys and 30% higher specific stiffness, and are thus available for deployment in carrier-based aircraft components exposed to marine environments.

3.Additive Manufacturing (3D Printing): Special aluminum alloy powders can be used to 3D printing topologically optimized structural components, e.g., engine turbine blades. These components are 25% lighter than traditional forgings and can support complex internal channels for improved heat dissipation.

Case Study: Precision Sheet Metal Assembly Of Highly Complex Scaled Down "Lingque" Demonstrator Wing

Project Challenges

A manufacturer of aerospace technology developed a mid-wing assembly for the scaled down "Lingque" demonstrator. The assembly consisted of five 7075-T651 aluminum alloy skins (maximum size 1200mm x 800mm) with varying curvatures and 12 6061-T6 aluminum alloy reinforcement ribs.

- Material Challenge: 7075-T651 aluminum alloy boasts an elongation of merely 11%, therefore being very susceptible to cracking upon bending and forming.

- Precision Challenge: Aerodynamic structure required that the surface of the skin be within ±0.2mm tolerance, twice the thickness of a human hair.

- Joining Challenge: Strength of 7075 aluminum alloy can be reduced by 15% by the weld heat-affected zone (HAZ), and traditional welding must be avoided.

JS Precision Solution

1.Digital Forming: A marriage of digital incremental forming and precision waterjet cutting is utilized to "knead" the aluminum sheet into a precise surface with over 1,000 incremental presses, without the use of traditional molds. Accuracy in waterjet cutting is up to ±0.05mm.

2.Bending Optimization: With the help of finite element software ABAQUS to model springback, bending compensation angles of 5°, 7°, and 9° were adjusted for sheet metal thickness of 1mm, 2mm, and 3mm, respectively. This was performed using a German TRUMPF precision bending machine to allow real-time angle correction.

3.Strong Connections: Friction stir welding was utilized on the ribs, having a weld strength of 90% parent material. Skin joining was done through a hybrid combination of 3mm diameter titanium alloy rivets and structural adhesive bonding to load-share.

Project Results

The successfully installed 2.8kg wing assembly was only 5% under the target design weight, 2.8kg. Contour accuracy in all positions was certified by coordinate measuring machine testing to ±0.15mm, meeting aerodynamic requirements in full.

The part was subjected to 1,000 simulated takeoff and landing pressure tests without deformation or cracking, providing key support to the first flight success of the "Spirit Sparrow" demonstrator aircraft and being a powerful affirmation of JS Precision's sheet metal fabrication capabilities.

Aluminum Alloy: Why It Is An Affordable "Pillar Of The Blue Sky"

Aluminum alloys became the pillar of aerospace due to cost-effectiveness:

| Cost Type | Aluminum Alloy Skin (USD) | Carbon Fiber Composite Skin (USD) |

| Raw Material Cost | 20,000 | 80,000 |

| Processing Fee | 15,000 | 40,000 |

| Service Life (Years) | 30 | 25 |

| Repair Cost | 5,000 | 20,000 |

| Recycling Value | 8,000 | 2,000 |

| Total Lifecycle Cost | 32,000 | 138,000 |

Mature Industry Chain

Over 500 aviation-grade aluminum alloy manufacturers exist worldwide, ranging from Alcoa's 7075 aluminum alloy sheet to China's 2024 aluminum alloy coil. The supply chain is good and lead times are typically only 7-10 days, with plenty of raw material in hand.

Unparalleled Cost-Effectiveness

In broad aerospace uses, aluminum alloys meet performance requirements at one-third the cost of titanium alloys and one-fifth the cost of carbon fiber. Having a very mature process and more than 98% rate of processing yield, today it is the "best solution."

JS Precision relies on a mature aluminum alloy supply chain to control costs and provide cost-effective services in the production of sheet metal fabrication parts. After placing an order, customers can enjoy raw material traceability services to ensure stable quality of each batch of parts.

FAQs

Q1: How do we control bend springback when machining aviation aluminum alloys?

We initially simulate springback of various aluminum alloys at various thicknesses and bend angles with finite element software (e.g., ANSYS). Later, during mold design, we then use proper angle compensation based on the simulation. Finally, using actual pressure feedback of the CNC press brake, we trim two to three times to eliminate errors, with a final bend angle error of below 0.5°.

Q2: How does aerospace aluminum alloy differ from common aluminum that is used in building?

First, in terms of purity, aerospace aluminum alloys have more than 99.7% aluminum, whereas common construction aluminum has just 95% purity. Second, in terms of composition of the alloy, aerospace aluminum alloys have strict limits for copper, zinc, and magnesium content, whereas construction aluminum provides a less limited composition. Finally, in case of quality testing, aerospace aluminum alloys are required to be tested for internal porosity, while construction aluminum is not.

Q3: Why aren't all aircraft lighter carbon fiber composites?

Carbon fiber composites are so expensive, over five times as expensive as aluminum alloys. Also,they has poor resistance to impact damage. When struck by a bird, carbon fiber components will shatter on the spot, while aluminum alloys will only deform. Repair is also complicated, broken carbon fiber components must be replaced in their entirety, three times the expense of aluminum alloys.

Q4: In design, how do I choose the appropriate aluminum alloy grade for my aerospace project?

This includes a balance of four considerations:

- Strength requirements. If high strength is required (such as for wing spars), choose 7xxx series.

- Processing technology requirements. If welding is required, choose 6xxx series.

- Consider weight needs. In case extreme weight loss is desired, use aluminum-lithium alloy.

- Consider cost. If it is a cost issue, 6xxx series is ideal.

Summary

From commercial passenger aircraft to deep space exploration craft, aluminum alloys, with their improved performance and proven economics, have given us the platform for today's aerospace. Not only is it a materials science classic, but also a statement of human ingenuity striking the ideal balance between "lightness" and "strength."

JS Precision provides total-process online sheet metal fabrication service,from material sourcing and design optimization to processing and shipping. With open sheet metal fabrication prices and rapid delivery cycles, we can precisely fulfill your needs, whether you require simple sheet metal components or complex sheet metal fabrication parts.

Contact us today for a personalized quote from your 3D model, plus process and material recommendations. Let's build your designs with precision!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com