Engineers in a communications equipment firm were debugging the 5G base station casing assembly process. The originally designed connector interface, after completing sheet metal bending and anodizing, was found to not fit in at all.

Continued inspection revealed that the oxide film thickness increased, erasing the gap. This demonstrates the hidden action of surface treatment on the size of sheet metal after bending.

Whether it's an electroplated metal coating or a built-up powder coat, they both add an imperceptible but significant physical thickness to the part's surface. That micron-level fluctuation can have an "amplifying effect" on extremely precise bending geometry, potentially flipping over critical tolerances.

For personnel engaged in the design or production of sheet metal bending parts, the issues typically cause rework, additional costs, and in severe cases, delayed project completion. We thus created this guide to allow all to clearly understand how surface treatment affects sheet metal dimensions after bending, and scientifically how to minimize such risks to attain product precision standards.

Core Answer Summary

| Comparative Dimensions | Typical Impact on Dimensions | Critical Control Points |

| Powder Coating | Thickens uniformly (50-120μm), having significant effect on inner corner radius and outer dimensions. | Regulate film thickness, mounting point design, and mask methods. |

| Electroplating (e.g., galvanizing) | Thickens uniformly (5-25μm), potentially affecting fit clearance. | Regulate current density uniformity to avoid sharp corner effects. |

| Anodizing | Thickens slightly (5-25μm), having minor effect on macroscopic dimensions but altering internal stresses. | Sealing operations are sensitive to aluminum alloys. |

| Chemical Conversion Coatings (e.g., phosphating) | Thickening is minimal (1-5μm), but may alter the surface friction coefficient and affect springback. | Control film weight: Uniformity is critical. |

How To Reserve Processing Allowance In The Proper Way? JS Precision's Compensation Principles

JS Precision has over 15 years of hands-on working experience in sheet metal bending coordination and surface treatment. We have completed over 5,000 sheet metal bending parts orders for customers with various industries, including electronics, communications, and automobile. We have created surface treatment solutions for various substrates, from aluminum alloy, stainless steel, to mild steel.

The intelligent capability of JS Precision in the field of precision manufacturing mentioned in an article by TechPullion also provides solid technical support for precise size control in surface treatment and bending.

For instance, we used to manufacture a batch of bent pieces of mild steel 1.5mm thick for a automotive parts client. The client required a ±0.08mm tolerance on parts following powder coating (film thickness of 80-100μm).

Following our compensation algorithm, we incorporated an allowance of 1.8 times the film thickness in the design phase and subsequently optimized bending parameters. The batch manufactured had a 99.2% dimensional pass rate, which was much more than the client's desired 95%.

Apart from that, we have established a compensation database for over 20 materials for various surface treatments, such as anodizing and electroplating, which enables us to accurately compute the size changes of sheet metal of various thicknesses after treatment.

This guide has been developed based on extensive project experience and cumulative technical experience. All recommendations have been tested in production. You may rely on it completely to resolve the hassle of correlating surface treatment with sheet metal bending sizes.

For a precise surface treatment allowance, JS Precision's custom sheet metal bending manufacturing service can provide compensation-based products from a database. This complete control process, from design to manufacture, assures dimensional accuracy of your sheet metal bending parts. We welcome your inquiry and collaboration.

Why Is Surface Treatment Such a Crucial Detail In Sheet Metal Design?

Once you know JS Precision's compensation rules, you might be wondering why surface treatment itself matters so much in sheet metal design. We seem to care more about bending precision and material strength, after all.

Surface treatment not only makes sheet metal bending parts look more beautiful, enhances corrosion resistance, and optimizes functional properties. All these are the core elements for products to meet market demand.

However, while pursuing these important attributes, we must be acutely aware of the challenges they pose to the manufacturing cornerstone of 'size'.

For instance, a bent medical device case underwent electrophoresis treatment.Simply because no consideration was taken for coating thickness of 10-25μm, assembly clearance with internal circuit board decreased from 0.2mm to 0.12mm, and remaking of the bending tool was required.

Therefore, incorporating surface treatment into sheet metal design initially, rather than as an afterthought, is crucial for avoiding issues with dimensions.

If you do need to make a trade-off between sheet metal bending dimensional accuracy and surface treatment quality, JS Precision's custom sheet metal bending manufacturing service delivers an integrated solution, from the initial consultation on design to production implementation, to have your product just the way you want it. Contact us and let us talk about working together.

Surface Treatment Option Library: An Initial Exploration Of Characteristics And Dimensional Impact

Since surface treatment is so critical, what are some generic surface treatment processes? What are their respective characteristics and first-order effects on dimensions? A detailed description is presented in the following table:

| Surface Treatment Type | Process | Typical Film Thickness Range |

| Additive Treatment (Build-up) | Spraying: Substrate Pretreatment → Electrostatic Spraying → Curing at High Temperature. Electroplating: Substrate Degreasing → Pickling → Electroplating → Drying. | Spraying: 80-120μm (one-side), Electroplating: 5-30μm (one-side). |

| Conversion Treatment | Anodizing: Substrate Degreasing → Pickling → Anodizing → Sealing. Phosphating: Substrate Degreasing → Pickling → Phosphating → Water Rinse. | Anodizing: 5-25μm (one-side), Phosphating: 1-5μm (one-side). |

| Aesthetic Treatment | Brushing: Substrate Fixing → Grinding Wheel/Cloth Wheel Brushing → Cleaning. Polishing: Rough Polishing → Fine Polishing → Waxing. | Almost no thickness gain (brushing reduces thickness by 0.01-0.03μm). |

As is clear from the table, the film thicknesses of different treatment processes are very different, i.e., their dimensional effect on sheet metal bending parts is also different.

For example, the maximum film thickness for additive processing needs to be carefully considered when reserving margin in the future, whereas the dimensional influence of decorative treatments is very low.

How Does Surface Treatment "Steal" Or "Amplify" Dimensional Accuracy?

Having gained an understanding of the inherent nature of different processes, let's discuss in more detail how these surface treatments specifically "steal" or "amplify" dimensional accuracy.

The "Cumulative Effect" of Coating Thickness

Every surface treatment contributes to the net thickness (or local height) of an article. For example, the normal powder coating thickness would be 80-120μm (approximately 160-240μm on each surface), or a dimensional increase of 0.16-0.24mm.

Electrophoretic coatings are typically 10-25μm (on one surface) in thickness, but may cause localized thickening in internal cavities or complex structures by fluid entrapment. Anodized thickness is 5-25μm (dependent on grade), thin as it is, and can affect fitting tolerances (e.g., bearing seat mounting holes).

Typical case: The coating thickness was ignored in the design of a portion of the equipment casing. The originally maintained 2mm assembly clearance was restricted to 0.8mm after coating, making the door panel hard to close.

Risk of "Local Thinning" due to Pretreatment Corrosion

Pretreatment operations such as pickling (for descaling) and alkaline cleaning (for degreasing) may cause minor corrosion on the plate surface, especially around sharp edges and corners.

For example, during pickling, hydrogen ions attack edges preferentially and cause localized thinning by 0.01-0.05mm, weakening the strength and dimensional stability of major stress-carrying areas.

"Reverse Deformation" While Heat Treatment

Thermal processing such as spray curing (180-220°C) and drying of electroplating (80-150°C) may cause thermal expansion (or contraction on cooling) of the material.

For example, low-carbon steel is beset by linear shrinkage of roughly 0.05-0.1mm/m on cooling after high-temperature spraying. For long sheet metal parts (such as guide rails over 1m in length), such shrinkage can generate dimensional offsets at the ends.

JS Precision’s sheet metal benders are equipped with advanced high-precision pressure and temperature control systems, which enable active pre-anticipation of the dimensional influence of surface treatments, ensuring stable accuracy for your products. Leave it to us to prevent the occurrence of dimensional defects.

Coating Challenges For Sharp-Angle Bends: How To Avoid Powder Buildup And Edge Defects

For surface treatment effect on size, sharp bends are most prone to problems, mainly coating buildup and edge deficiency. How can these be corrected?

Why are sharp angles so vulnerable?

Acutet angles (≤30°) obtained through bending create three problems of highest priority in surface treatment:

- Coating buildup. The painting solution or plating solution easily accumulates at the internal corner, causing local size increase.

- Protection weakness. The coating is thinned at acute corners, lowering corrosion resistance.

- Stress concentration. Excessive stress at sharp corners when bending has a tendency to increase deformation on subsequent heat treatment.

Problem Description and Solution

Problem Description:

Sharp radii bending (e.g., <90°) will cause plating solution or powder coating abnormally build up at the inner radii and create a heavy coat. This will decrease the angle and even cause the two bent edges to "stick" to one another.

Solution:

- Design: Avoid too sharp bends and increase the inner corner radius (preferably specified at at least 1.5 times of the sheet thickness).

- Process: Use electrostatic shielding technology by utilizing high-temperature-resistant tape or a special shielding sleeve on the inside of the bend.

- Parameters: Control the spraying voltage (typically 60-80 kV) and powder flow (30-50 g/min), and utilize multiple thin spray passes instead of a single thick spray.

Process Sequence: Bend First Or Treat First?

After the sharp angle issue is addressed, the process sequence—bend first or treat first?—is the next crucial decision. It has significant bearing on dimensional accuracy as well as productivity.

Mainstream Process Path Comparison

| Process Path | Application | Advantages | Disadvantages |

| Bend First, Treat Later (Mainstream) | 90%+ Industrial use (equipment enclosures, appliance parts) | Good dimensional control, consistent stress relief, full coverage coating. | Treatment of complex internal cavities can potentially include blind spots (needs pre-designed flow paths). |

| Treat First, Bend Later (Special) | Applications with highly demanding substrate surface performance specifications (e.g., pre-sprayed anti-corrosion coating). | Shields substrate surface from bending scratches. | Treated layer prone to cracking, dimension controllability difficult to attain (impacts bend springback). |

Why is "Bend First, Treat Later" preferable?

- Dimensional controllability. The intrinsic size of the part is established upon bending, and the subsequent changes in surface treatment dimensions can be accurately calculated by reserving allowances.

- Correspondence of stress relief. Residual stresses in the sheet are induced in bending. Heat surface treatment processes such as spray curing can be applied for stress relaxation of such stresses as well as reduction of subsequent deformation.

- Coating flexibility is an issue. Bend first, treat second, so that the coating is over all of the surfaces following bending, including seams formed by the bend, offering complete protection.

Exceptions: If a specific functional layer must be on the substrate (e.g., conductive oxidation and then subsequent electroplating), or if some treatments cannot be done after bending (e.g., pre-clear flow channels for electrophoresis), then treat first.

JS Precision's online sheet metal bending services can easily identify the best process order based on your product needs, offering visibility from order entry to delivery, for peace of mind and efficiency.

The "Invisible" Role Of The Press Brake: How Pressure Settings Predict Coating Adhesion

After the sequence of the process is determined, press brake settings itself also become involved, especially pressure setting, which will affect adhesion of coating and generally gets overlooked.

Cause:

Overriding bending pressure or a poorly adjusted V-gap in the bottom die will create small indentations or scratches on the outer surface of the sheet (though not detectable by naked eyes).

Effect on Adhesion:

These micro-damages can also act as sites of stress concentration and continuity of the fracture surface. As a result of following processing thermal stress (mainly at spray curing), the coating would tend to delaminate easily from such defects, not only its appearance, but even corrosion resistance.

Best Practice:

Calculate and optimize bending pressure in terms of sheet thickness and material (e.g., bending pressure of 1.5mm aluminum alloy typically ranges from 120-150 tons) and use appropriate V-gap width in the lower die (recommended 6-8 times the sheet thickness) so that bending goes smoothly without overstress, with proper support for satisfactory adhesion of the coating.

JS Precision possesses a skilled sheet metal bending technical staff that can refine the pressure of the sheet metal bender accurately according to your specifications of sheets and provide you with uniform adhesion of coating according to your specifications and offer repeated product quality to you.

Advanced Considerations: The Impact Of Material Selection And Stress Release

In addition to process and equipment, material selection and stress relieving affect dimensions after surface treatment, which are intrinsic issues in advanced design.

Different Material Responses:

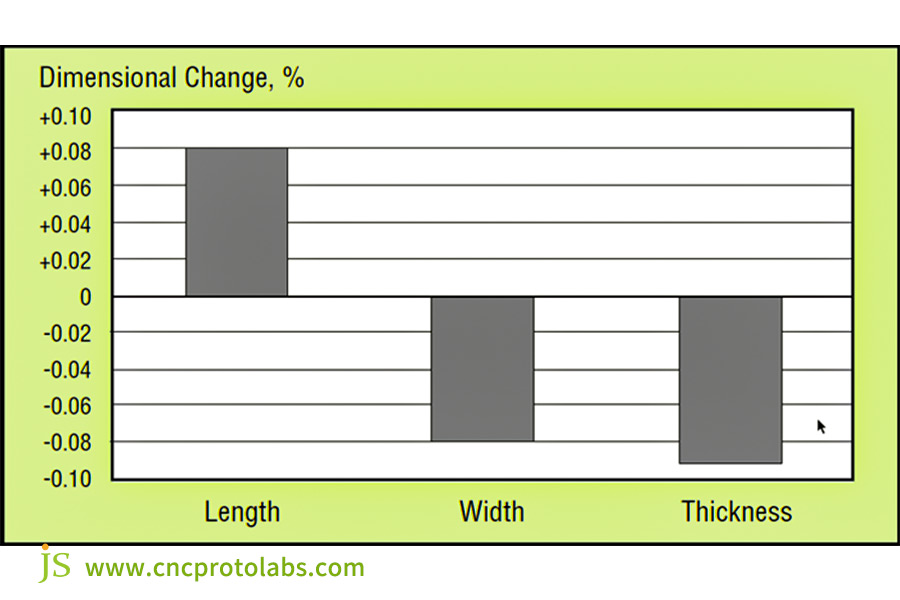

Aluminum alloy, mild steel, and stainless steel respond differently after bending with dissimilar springback behavior and react differently to stress relieving during the surface treatment heat process. This can introduce coating thickness effects.

For example, the rebound rate of aluminum alloy is about 1-3 °. During the sealing process at 120-150 ° C during anodizing, stress release may increase the rebound amount by 0.5-1 °, resulting in changes in angular dimensions. Minimum rate of springback (0.5-1.5°) will be for stainless steel and the heat operation will have no significant effect on dimensions.

Function of Prestressing:

For accurate parts (e.g., connector parts mating tolerance ±0.05mm), stress relief (e.g., low-temperature anneal, 150°C/2 hours) may be performed after bending but before surface treatment to reduce subsequent heat operation-induced deformation.

Coating Uniformity:

Recesses in complex sheet metal parts are liable to non-uniform coating. This is due to the "Faraday cage effect"—the electric field intensity in grooves is not high at the time of electrostatic spraying or electroplating, and therefore there is lesser deposition of coating, resulting in locally decreased film thickness and with size dimensional uniformity effect.

The solution is to optimize the component structure, not employ overly deep closed grooves, or modify the electrode position during processing.

JS Precision Case Study: The "Dimensional Redemption" Of A 5G Base Station Housing

Background

A 5G base station aluminum alloy shells (600×400×1.5mm) was manufactured by an equipment company for communications equipment. They required the surface anodized (thickness of anodized film 15μm) before assembly using precision connectors (mating tolerance ±0.1mm).

The initial process was anodizing before bending. The oxide film, however, fractured in the bent area, making it difficult to insert the connector. The oxide layer (approximately 15μm) reduced assembly clearance in the unbent area by 0.03-0.05mm, impacting overall assembly accuracy. The yield of sheet metal bending parts was only 65%.

Problem Diagnosis

1. Incorrect sequence of processes: Bending of the anodizing caused cracking of the oxide film on bending stress (oxide films of aluminum alloys are brittle but hard, cannot withstand deformation caused by bending).

2. Failure of incompensation of dimensions: Thickness of the oxide layer was not considered during design, resulting in actual clearances being less than the theoretical value, which causes interference during assembly of the connector.

3. Poor tool conformity: The press brake pressure was excessive (200 tons), far more than the 150 tons required for 1.5mm aluminum sheet. This resulted in local sheet thinning of the aluminum sheet to 1.2mm, worsening oxide film damage even more.

JS Precision's Solution

1. Reversing process step sequence: Adopting the globally accepted bending-then-processing practice, optimizing bending pressure to 150 tons and making sure the bending radius R = 3mm (preventing sharp corners).

2. Dimensional compensation design: Oxide layer thickness subtraction in the CAD model (7.5μm/side, introducing 0.015mm to the overall gap) to introduce assembly space.

3. Mold and parameter optimization: Using a polyurethane bending mold (to reduce sharp corner indentations), and follow-up stress relief annealing (150℃ x 2h) after bending to reduce internal stress in material.

4. Coating adaptation: After-anodizing addition of a nickel salt sealing treatment improves corrosion resistance and film flexibility, preventing cracking when flexed.

Results

The finished product incorporated no oxide film cracking on bends, and the pass rate of connector assembly was increased from 65% to 98%. Tolerances in dimensions overall were kept at ±0.08mm as needed for precision assembly. Moreover, with reduced rework and scrap, savings in production costs were realized at $12 per unit, generating high customer visibility.

FAQs

Q1: What tolerance should I provide for coating thickness?

Normally, for single-side coating, the tolerance margin of 1.5 to 2 times nominal film thickness can be allowed in both sides' dimensions. For example, if single-side 80μm powder coating is opted for, the tolerance margin of 120-160μm can be allowed for each side. The precise values ought to be checked with your supplier based on their process capabilities.

Q2: Are there processes of surface treatment that do not affect the dimensions?

Conversion coatings (such as conductive oxidation) produce minimal or no size change, typically only 1-3μm thick film, and significantly less than additive treatment. They contribute negligible size impact to sheet metal bending parts. They offer limited corrosion protection but only for short-term use indoors.

Q3: How do I calibrate the actual bend angle of a coated part?

The most effective method is by using an optical projector or 3D scanner. An optical projector can accurately measure the angle by amplifying the part image, and a 3D scanner can acquire three-dimensional data of the part for multi-angle inspection. The traditional contact protractors spoil the coating, causing faulty reading. This is especially for highly coated parts, in which an error of up to 1-2° can be made, hiding the true angle.

Q4: The bend angle sometimes changes after anodizing. Why?

This is generally related to stress in the material. Aluminum alloys develop internal stress during bending sheet metal. The heat treatment of anodizing relieves this internal stress, producing slight distortion in the part and then altering the bend angle. In addition, the shrinkage of the oxide film itself can also slightly affect the angle, tending to change by 0.5-1°.

Summary

The surface treatment influence on dimensions of sheet metal after bending is rather complex, but the effects can be fully controlled by scientifically planned allowances, the natural order of logic (e.g., treatment after bending), correct adjustment of equipment (e.g., pressure of the press brake), and respective material characteristics.

JS Precision, with many years of custom sheet metal bending manufacturing experience, has incorporated these methods into every project, keeping customers from slipping into dimensional pitfalls and reaching a win-win state in both product accuracy and surface performance.

Our clear sheet metal bending prices, skilled sheet metal bender machinery, and thorough project experience guarantee your product's surface treatment and dimensional precision needs are met. Contact us now to have a solution tailored to your needs and start your efficient production journey.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com