The CNC machining cost is one of the core issues that every manufacturing enterprise is most concerned about in the production of precision parts. Imagine investing thousands of dollars in purchasing raw materials, going through multiple processes to produce a finished product, but due to the breakage of the tap in the last tapping process, hundreds of dollars worth of workpieces are directly scrapped.

At the same time, the production line stagnates, delivery time is delayed, and additional rework costs are also borne. This scenario is not uncommon in CNC machining shops, and traditional tapping processes are the main source of these hidden costs.

This guide will take you out of the simple misconception of process unit price and provide an in-depth analysis of how thread milling can systematically reduce CNC machining cost and improve machining reliability.

Whether you are facing high volume CNC machining pressure or need stainless steel CNC machining services or titanium CNC machining solutions, you can find practical and feasible cost optimization paths from it.

Summary of Core Answers

| Core Cost Challenges | Potential Pitfalls of Traditional Tapping | JS Precision's Thread Milling Solution |

| Reduce the Overall Cost of CNC Machining | Tap breakage leads to workpiece scrap, production line downtime, and high hidden costs. | Using stronger end mills avoids tap breakage, protects high-value workpieces, and eliminates the biggest risk source at its source. |

| Optimizing CNC Machining Price | Stockpiling large quantities of taps for different thread sizes results in high inventory and management costs, rapid wear is also a concern. | A single thread milling cutter can machine multiple pitches and internal diameters, significantly reducing tool inventory costs and extending tool life. |

| Ensuring High Volume CNC Machining Stability | Tap wear or breakage can cause consistency issues and downtime in large batches of parts. | Thread milling offers greater control, better thermal management and chip removal, ensuring consistent quality and delivery in long-term, high volume cnc machining. |

Key Answer Summary

- Thread milling is the most effective way to control CNC machining cost by avoiding cone breakage and directly protecting the workpiece.

- For stainless steel CNC machining services, thread milling can better control cutting force and heat, improving thread quality.

- In high volume CNC machining, the tool versatility and long lifespan of thread milling bring better long-term CNC machining prices.

- When evaluating how much does CNC machining cost, it is necessary to take into account the risk of cone breakage and the implicit costs brought by tool management.

Reducing CNC Machining Costs: JS Precision Thread Milling As An Alternative To Tapping

Based on more than ten years of experience in handling over 5000 high-precision orders, JS Precision deeply understands the pain points of traditional tapping in actual production: tap breakage, poor thread quality, and the resulting hidden cost increase.

Our solution is rooted in authoritative practices: In particular, for the stainless steel CNC machining services we offer, we have processed 304 and 316L parts with complex thread characteristics with a pass rate of 99.8%. In our high volume CNC machining, we have manufactured 100,000 threaded connections in 30 days without any pieces scrapped for thread machining.

Secondly, our process solutions fully conform to worldwide standards, such as following ASME B94.19, "End Mills and Cutters Standard," under which there is a strict requirement for tool accuracy and tolerance. This standard work provides an authoritative basis for reliability in the process of thread milling.

Our experiences provided us with clear insight into the areas of pain of conventional tapping processes in real-world production, including broken taps, poor thread quality, and increasing hidden costs.

This guide is an extraction of over tens of thousands of hours of onsite practice and technological research, and all our findings and recommendations stem from actual projects and customer feedback.

Regardless of whether you are a procurement manager worried about the expense of CNC machining or an engineer or entrepreneur trying to find the most reliable machining process, the professionalism and usefulness of the present guide can be counted on.

If you want to immediately verify how thread milling can reduce your CNC machining cost, please get in contact with our technical team. They will offer a complimentary process assessment report based on the part drawings provided.

Neglected Cost Black Hole: Is Your Threading Solution Eroding Profits?

Threading is a process that is generically included in the holistic cost of precision components. But the risk components associated with the conventional tapping methods include broken taps and thread damage. Just one incidence can result in the scrapped component and subsequently cause the CNC machining cost to escalate.

There are many cases where companies consider only material costs, equipment depreciation, or labor costs while determining the final CNC machining price, ignoring the hidden costs involved in tapping operations.

Such hidden expenses add up with each passing day and greatly reduce the profits of a company. Thread milling, with stable near-zero tool breakage and high process flexibility, eradicated the risks at the root, which makes the CNC machining cost more controllable, ensuring that the long-term CNC machining cost is more competitive.

| Process Type | Common Hidden Cost Contributors | Cost Controllability Requirement |

| Conventional Tapping | Breaking and scrapping of taps, down time, multi-specification toolin | Low |

| Thread Milling | Tool Wear (Long Life) | High |

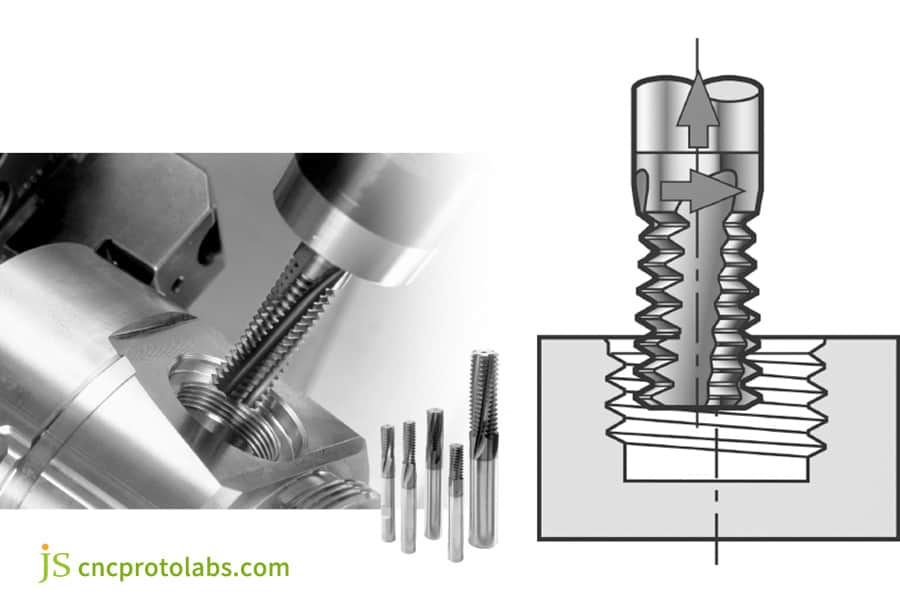

Figure 1 If you want to reduce the cost of single hole machining, thread milling is usually the preferred solution.

How Can Thread Milling Systematically Reduce Your CNC Machining Cost?

In order to understand the economic benefit of thread milling, it must be considered from beyond the cost of the process by looking at its effect from within a manufacturing process lifecycle perspective.

Thread milling isn't merely an alternative process for CNC machining but also an approach for risk control and process optimization that would answer the question: "How Much Does CNC Machining Cost" from various angles.

Directly avoid catastrophic losses and protect high-value artifacts

Avoid disassembling for scrap due to tap breakage:

In many production cases where high-value parts are being machined, as well as difficult materials, a tapped breakage can result in scrapping an almost completed part. This is where a higher robust design with a softer cutting motion of thread milling cutters plays a critical part in helping eliminate tapped tool breakage, thus safeguarding your key offering.

Less unexpected downtime and related processing costs:

It is time and labor-consuming to eliminate faulty taps. Therefore, thread milling guarantees a stable and trouble-free production process and saves money on unexpected production downtime.

Increased flexibility for processes and optimized long-term CNC machining price

| Dimensions of Optimization | Thread Milling Benefits | Effects on CNC Machining Prices |

| Tool Management | Multi-purpose tool, able to handle various diameter threads with similar pitch. | Lowered inventory acquisition cost. |

| Machining Quality | High surface finish, good dimensional accuracy. | Reduced rework, lower unit costs. |

- Multitasking tool, simplified inventory, and management: This contributes to a major saving in tool procurement, hence optimize the comprehensive CNC machining price.

- Improved surface finish and dimensional accuracy: Lower rates of rework and scrap, which translated to lower overall cost of units processed by CNC machining over time.

Want to achieve long-term cost reduction for your CNC machining project? Upload your part drawings immediately, and we will tailor a thread milling process plan for you, clearly informing you of each cost saving point, so that you have a clearer answer to how much does CNC machining cost.

Figure 3 In thread milling, a tool can produce threads of various sizes.

Why Should Stainless Steel CNC Machining Services Shift Towards Thread Milling?

When faced with high-strength, high viscosity materials or large-scale production, the limitations of traditional tapping are magnified.

There would be no doubt regarding the economic and reliability benefits offered by thread milling, making it ideal for stainless steel CNC machining, titanium CNC machining, and high volume CNC machining.

The definitive tool for mastering the machining of hard-to-machine materials

Handling difficulties posed by stainless steel alloys and titanium alloys:

In stainless steel CNC machining services and titanium CNC machining, materials are prone to sticking to the cutting edge, severe work hardening, and traditional tapping is prone to cone breakage and thread quality problems.

This problem is dealt with by the SAE International ARP1331C document stating that the machining of difficult-to-cut alloys needs machining methods that ensure the removal of heat and facilitate chip removal. This is precisely taken care of by the intermittent cutting action present in the thread mill process.

Reduction of cutting forces helps to preserve thin walls and details:

The milling Radial Force is low compared to tapping and helps in operations such as cutting threads on thin-walled components without causing deformations.

Realize predictable costs and delivery times in high volume CNC machining

- Improved process stability and consistency: This ensures consistent high-quality thread quality from part number one to part number ten-thousand, thereby reducing sampling for inspections of quality.

- Reduced tool change time: When tool change time is reduced in manufacturing, it leads to more efficient use of equipment, faster production cycles, and controllable production cost in mass manufacturing.

Engaging in stainless steel or titanium CNC machining. Please specify your material type and production volume, and we will provide you with a customized thread milling process parameter package that will help optimize cost and efficiency in high volume CNC machining jobs.

Technical Practice: Crisis Of Thousands Of Titanium Alloy Joint Threads: 72 Hours From Near Scrap To Perfect Delivery

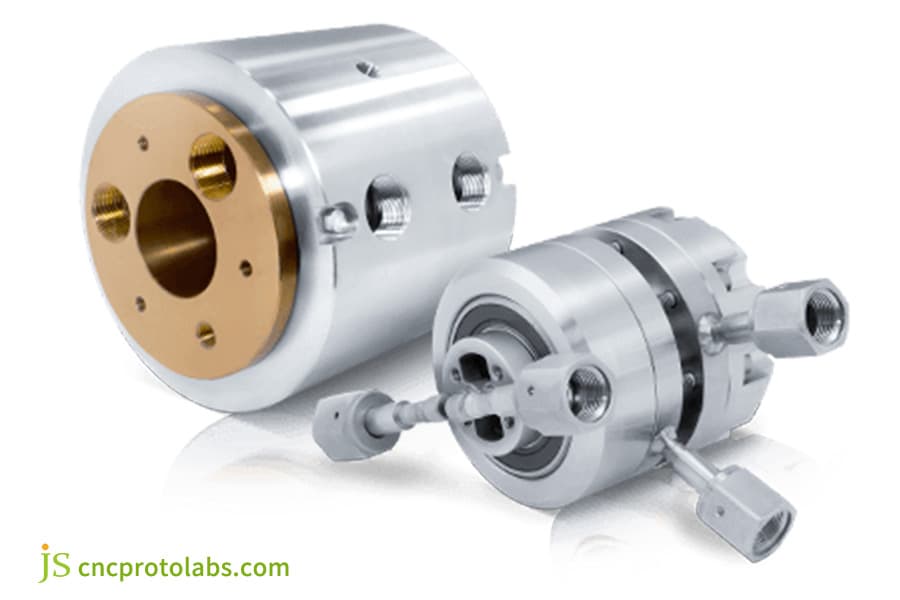

The long-established customer from the aerospace sector faced the urgent need to manufacture and supply 1000 TC4 titanium alloy fluid connectors. The product, being utilized in aircraft hydraulic systems, boasts stringent requirements for both thread accuracy and reliability.

However, in the last step of M8x1 deep blind hole tapping, a problem occurred unexpectedly because of the-high viscosity of TC4 titanium alloy material and challenges encountered while removing chips of deep blind holes. Tap breakage rates reached 15%, and 150 semi-finished products could not be machined because of tap breakage within two days.

Crisis: Defective Batch of Taper Cuts Leads to Suspension of Project

With only 72 hours left for the customer's delivery deadline, any failure would attract a late delivery penalty of up to $50,000. The procure cost for this particular titanium alloy raw material had already gone over $30,000 for this particular project and was thus heading for failure.

It was with this backdrop that the customer hastened their plea for a remedy with JS Precision with the aim of salvaging this particular project that was heading for the dump.

The Rapid Analysis & Process Switchover

When JS Precision received the request for aid, our company initiated its system to deal with the emergency. After examining the part specifications, material, machining conditions, process engineers concluded that the major problem with the damaged taper cutters was the presence of the built-up edge due to material viscosity and improper chip removal during deep blind holes.

Within 2 hours, our engineers rewrote the spiral interpolation thread milling program, using TiAlN coated thread milling cutters specifically designed for titanium CNC machining, and adjusted the cutting speed, feed rate, and cooling method to optimize chip removal and heat dissipation effects.

Resulting in: Zero scrap and Cost savings

Our production team spent the night adjusting equipment and tuning parameters. All ten trial-processed components passed tests for thread precision, with a result of no tool breakage and no scrap.

Subsequent processing of a constant 1000 components for the next 48 hours culminated in the ideal outcome of zero tool breakage and zero scrap. The processed component threads exceeded required industry standards for the aerospace industry.

This process switch not only helped the customer deliver the order on time and avoid high breach of contract compensation, but also saved the implicit costs of raw material repurchase and project delay for the customer. Its value far exceeds the initial CNC machining cost adjustment caused by the process change.

Having troubles machining thread on difficult-to-cut materials? Got a part problem? Simply call our technical hotline and describe your part problem thoroughly. JS Precision will then give you an emergency rescue plan to save you from losing CNC machining cost.

Figure 3 Aircraft hydraulic system fluid joints

How To Compare And Interpret CNC Machining Price Quotes From Different Suppliers?

When you are given quotes by several suppliers, just comparing the total cost of the quotes may not be appropriate. A responsible quotation should reflect the risks and values behind the process selection, helping you to more clearly determine the true how much does CNC machining cost.

Unraveling Hidden Processes in Quotes

- Process Description Details: One must be aware of whether direct tap or thread mill quote is mentioned. Thread mill is normally less risky and more capital-intensive, depending on the supplier's technical capacity.

- Request Hidden Cost of Guarantees: Directly ask the supplier, "What happens if a taper should break during a machining procedure, resulting in a scrap workpiece? How are the parties divided in their responsibility and cost obligations?" Reliable partners will have confidence in adopting robust processes such as thread milling and can provide clear quality assurance terms.

Analyze & Calculate Total Cost of Ownership – TCO

- Compute the Potential Risk Cost: It includes the part value and the probability of tap breakage. The potential risk cost for the two processes can be compared. For illustration, when the value of the $100 part is considered and the probability of tap breakage in tapping is assumed to be 5%, the risk cost amount alone is $5. Therefore, the actual CNC machining cost can be comprehensively estimated.

- Valuing Partnership Over Time: When determining if you should partner with a supplier of this kind, their ability to offer improved processes and mitigate risk in your business is worth far more than if they were to simply low-ball you on a contract.

Why Is JS Precision Your Ideal Partner For Optimizing High Volume CNC Machining Costs?

We can offer not just machining services but also provide manufacturing solutions with extensive process knowledge. At JS Precision, thread milling remains our prime choice of process for all materials and difficult-to-machine materials too so that your project gets straightaway onto the fast track for controlling costs and risks.

A Deep Materials Science-Based Process Database

Parameter Library for Parameterized Processes:

We have established a parameter library for parameterized machining processes like thread milling for stainless steel machinable materials and other materials like titanium alloys. This is to ensure that all machining processes are done using effective startup practices for rapid startup and startup cost reduction.

Proactive Recommendations in DFM:

Even in the design review stage, proactive design for manufacturability recommendations, in terms of suggested tooth profiles andtolerances for milling, can be made by our engineers for threads in order to reduce expenditure and improve productivity in your high volume cnc machining task.

A Production System for Stability

Advanced Tool Management & Monitoring:

To ensure that every thread milling cutter achieves its optimum state, we adhere to strict tool life management and on-machine monitoring, ensuring absolute stability during mass production, thereby preventing additional expenses related to tooling.

End to End Quality Traceability:

All critical machining information from materials to finished threads is traceable, ensuring a strong quality and on-time delivery assurance for your high volume cnc machining order.

Are you gearing up to start a high volume CNC machining project? Please share your production requirements and part drawings. Then, JS Precision can offer you a full solution for manufacturing, such as thread milling. This enables more stability in stainless steel CNC machining services.

FAQs

Q1: Is thread milling less efficient than tapping?

In single-hole processing, while thread milling may be slightly less efficient than tapping, it is free from problems like tap breakage and multiple tool changes. However, its efficiency is superior in deep hole processing of difficult-to-cut materials and machining of threads with multiple specifications.

Q2: Can the thread milling machine mill blind holes?

Absolutely. The advantage of thread milling is more substantial for making blind holes. It helps control the thread length precisely and chip removal by means of intermittent cutting. This helps overcome difficulties of chip removal while tapping a blind hole.

Q3: Is milling required for thread machining operations for aluminum components?

For general aluminum components and simple thread-cutting, tapping is more economical. But for high-cost aluminum alloys, deep hole threads, or thin wall aluminum components, thread milling is still advised against tap breakage and scrapping.

Q4: How can I determine if my part is eligible for thread milling?

Please contact a JS Precision engineer for a professional evaluation. Thread milling is beneficial when working with difficult-to-cut material, large-diameter threads, valuable material, blind holes, and thin-walled holes.

Q5: Could I get a analysis of existing parts for a conversion process?

Of course. If you provide us with your part drawings and your current tapping process data, then we can evaluate the cost-effectiveness of tapping vs. thread milling without charge.

Q6: What minimum diameter of a threaded component can be produced through machining?

Yes, JS Precision is generally able to machine threads larger than an M2 thread. But this truly depends on your machine part design and precision requirements. We will be able to give you a better solution for this problem.

Q7: Do you default to thread milling when pricing?

When it comes to difficult-to-machine materials like stainless steel and titanium alloys, for important thread characteristics or valuable components, we will put more emphasis on thread milling in the DFM assessment and quote.

Q8: What unique certifications or experience does JS Precision possess regarding machining of titanium alloys?

We have an advanced machining line of titanium alloys, which serves the aerospace and medical industries. We are quality system-certified for ISO 9001 and AS9100, and we have substantial knowledge and successful examples of the entire process of titanium alloys, which include thread milling.

Summary

In fact, trying to control the CNC machining cost is by no means a pursuit of low cost but a preventive measure against unknown risks. Thread milling, because of its zero tool breakage risk, flexibility, and material versatility, is considered the key to effectively controlling the CNC machining price and securing stable prices of CNC machining.

JS Precision can be that strong link in your supply chain, turning potential machining risks into definite quality and cost advantages.

Take the following steps right away to optimize your next project:

→ 【Get Your Personalized Cost Analysis Report】Please submit your part drawings, and our engineers will send you a process comparison analysis (tapping vs. thread milling) for free, illustrating the potential savings.

→ 【Schedule a Thread Machining Technology Seminar】 Have one-on-one communication with our experts to work on your best possible plan for your project.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com