Your patiently built part is finally taking shape on the printer, but suddenly, and without you doing anything, a corner begins to warp ever so slightly, trying to break free of the boundaries of the build platform.In a matter of minutes, warping creates a catastrophic mess not only of the print but also of possibly destroying your printer's nozzle.

It's not your fault, it's a characteristic of ABS material. But don't worry, we are not helpless in this war with thermodynamics.

This guide will be your bible. We will first introduce you to the cause of warping, and then propose solutions in various aspects, including parameter adjustments and multi-angled prevention. Finally, we will demonstrate the effectiveness of real-world examples to help you easily solve the problem of ABS printing warping.

Summary Of Core Answers

| Influencing Factors | Key Contributing Factors | Core Solutions | Applicable Scope |

| Root Cause | Thermal stress | Temperature control + closed environment + optimized first-layer parameters. | All ABS print scenarios. |

| Material Properties | ABS has a higher coefficient of thermal expansion and glass transition temperature. | Targeted temperature control + closed build volume. | Printing of ABS heat-resistant parts. |

| Part Size | Big parts experience high stress accumulation and big edge-to-center thermal gradients. | Increase chamber temperature + use 8mm-wide brim. | Big ABS structural parts. |

| Material Condition | Water inside ABS filament | Oven drying for 4 hours at 80°C. | Water inside ABS filament before usage. |

Why Should You Read This Guide? Core Tips From JS Experts

JS has years of experience with 3D printing and has printed hundreds of ABS 3D printing parts for auto, electronic, and industrial equipment customers.

Not only do we familiarize ourselves with various ABS filaments' properties, but we have also overcome warping issues for large ABS structural components for automotive customers and optimized drying process and printing conditions for accuracy ABS parts for electronics customers.

This guide is informed by actual project pain points, and each tip has been tried in actual printing conditions across various scenarios. From material pretreatment to environmental control, we guide you through all the printing process, so you can rely on it.

Need customized auto models or industrial-grade ABS 3D print parts? JS is able to provide sound solutions based on our extensive experience spanning decades. Simply send your part drawings, and we'll quickly review and quote for 3D printing to save you time and money.

What Is Print Warpage? Thermal Stress In ABS

Having learned the validity of this manual, let us now address the fundamental questions: What is print warpage? Why is ABS prone to this defect?

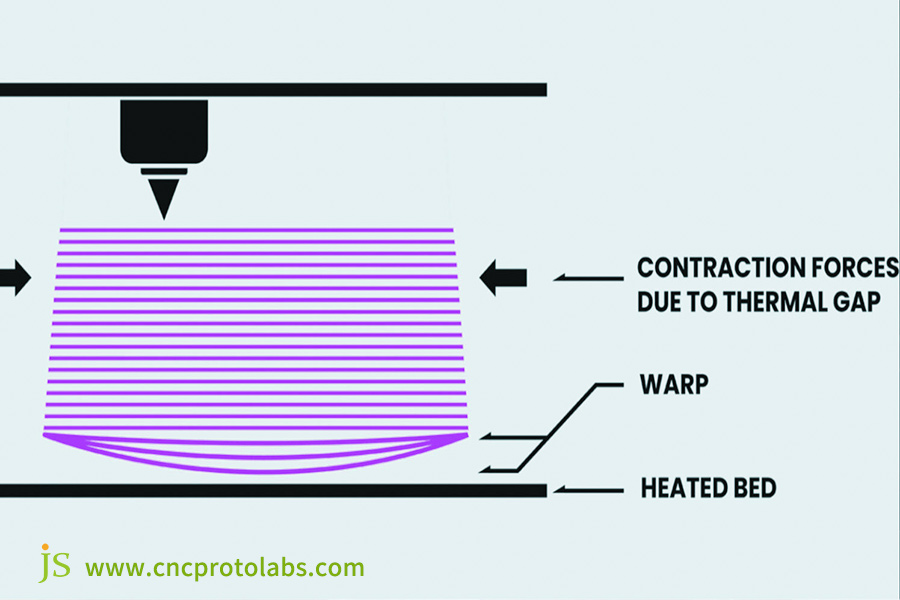

Root cause: thermal stress.During printing of ABS, the molten plastic solidifies and shrinks on the build plate. Due to temperature gradients in printed layers and within and outside the part, the material contracts. This confined shrinkage generates thermal stress. When the stress exceeds the material's inherent strength, the part warps.

In short, warping is not adhesion failure, but the result of stress release.

To further assist you in differentiating for yourself, we've summarized the difference between warping and adhesion failure:

| Traits | Warping (result of stress release) | Adhesion failure |

| Where it occurs | Edges and corners of the part (where the heat dissipates quickly). | The whole first layer or localized areas. |

| Expressions | Upward curling and curling. | Separation and relocation of the first layer from the platform. |

| Root cause | Thermal stress is greater than the material's own strength. | The first layer adhesion is less than the material shrinkage force. |

| Solution | Reduced thermal stress (sealing, temperature control). | Increase adhesion (glue stick, cleaning the build plate). |

Root Cause Understanding: Why Is ABS "Capricious"?

Now that we know that warpage is due to thermal stress, why on earth would ABS be more susceptible to thermal stress than other plastics? There are three main reasons as follows:

1. High Coefficient of Thermal Expansion: ABS has a coefficient of thermal expansion of approximately 100-130 ppm/°C, while PLA(Polylactic Acid) has the coefficient of thermal expansion as low as 50-70 ppm/°C. This means that ABS will contract more in volume with the temperature change and therefore is more likely to be under stress.

2. High Glass Transition Temperature: ABS possesses a glass transition temperature of about 95-105°C. When the part's temperature is lowered to this temperature, the material shifts from being extremely elastic to becoming a glass state and shrinking suddenly. Sudden stress accumulation takes place when cooling is non-uniform.

3. Prone to Cooling Rate: ABS is highly prone to cooling rate. When a small section cools too quickly (for example, with wind and open air), it contracts first and tugs on surrounding regions, leading to warping.

We've compiled the most important properties of ABS and PLA into a table below to allow you to better appreciate:

| Material Properties | ABS | PLA |

| Coefficient of Thermal Expansion (ppm/°C) | 100-130 | 50-70 |

| Glass Transition Temperature (°C) | 95-105 | 55-60 |

| Build Platform Temperature (°C) | 90-110 | 50-60 |

| Susceptibility to Warping | High | Low |

| Applications | High-strength, heat-resistant parts (e.g., car parts) | Low-strength, cosmetic parts |

JS knows how various materials behave, like ABS and PLA, and can tell you about suitable materials for your application. If cost-effective PLA parts or heat-resistant ABS 3D printing parts are what you need, we can fulfill your order in a timely manner utilizing our online 3d printing services.

The Foundation: Master Manual On Defining Optimal First Layer Parameters

ABS is cooling- and temperature-sensitive, and initializing the first layer is therefore an important step to prevent warping. The first layer, naturally, lays down the foundation for the interface of the part to the build platform, and a bad setup can quickly lead to trouble.

We have brewed a table of recommended first-layer parameter settings. The important parameters and their role are summarized below:

| Parameter Type | Range Recommendation | Function | Applicable scenarios |

| Platform Temperature | 90-110°C | Delays cooling of the first layer and reduces shrinkage. | 90-100°C for small models, 105-110°C for large models. |

| First-layer Speed | 20-30mm/s | Enhances adhesion and reduces interlayer stress. | All parts printed in ABS. |

| First-layer Thickness | 0.25-0.3mm | Maximizes contact area and accounts for build surface roughness. | Printers with typical build surface flatness. |

| Adhesion Material | Glue Stick / PEI Film | Enhances adhesion of the first layer to the build surface. | Glue sticks are not permanent, but PEI is. |

JS strictly controls first-layer parameters in custom 3D printing manufacturing. From platform temperature to desired adhesion material, we meticulously pair up to the characteristics of ABS filaments. Simply send us your specs, and we will optimize parameters step by step to supply part quality.

All-Around Protection: Multi-Dimensional Anti-Warp Techniques

Once you have created the first layer, you need to build a multi-dimensional "defense system." ABS warping has a multiplicity of causes, and only relying on the configuration of the first layer alone will not suffice. Here are critical techniques from three perspectives:

Platform Preparation ("Chemistry")

The critical step is to create the platform level and clean. Scrape the remaining material gently with a scraper after cleaning the platform with isopropyl alcohol to degrease and clean before printing. Level the platform, ensuring all the corners are equidistant from the nozzle (approximately the same as the A4 sheet thickness).

Model Design ("Architecture")

Reduce stress concentration by optimizing the structure. Add a 5-10mm wide brim to the model (suitable for large flat areas), replace right-angle corners with chamfers or fillets, and orient the part wide flat surface downwards to reduce lateral shrinkage and warping.

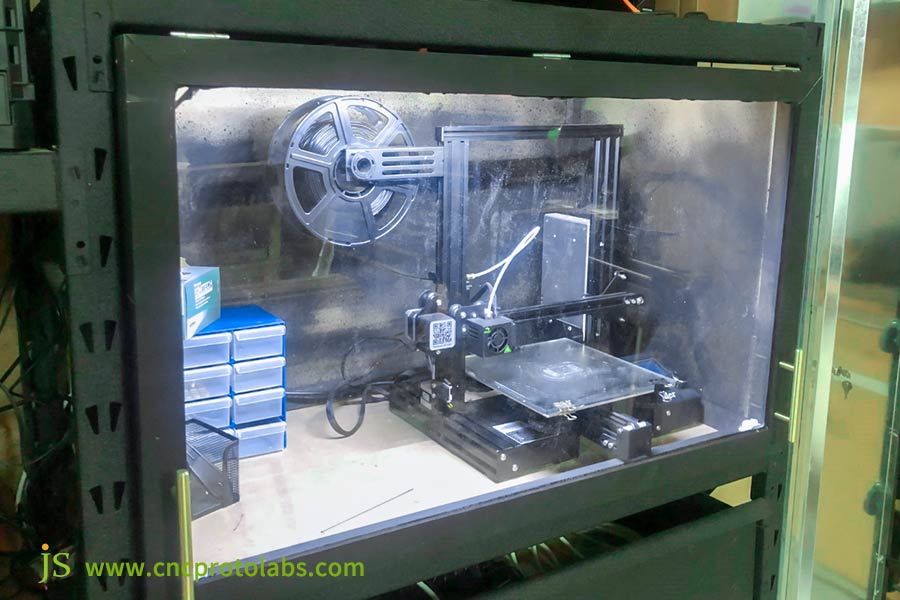

Printing Environment ("Weather Bureau")

Control airflow and temperature. Use a closed printer or build a covered cabin (e.g., a cardboard box) to allow constant temperature for the printing environment. The ambient temperature should be 25-30°C. Avoid putting the printer close to windows, air conditioner vents, or other places with temperature variance in airflow.

The table below describes multi-dimensional warp avoidance methods:

| Defense Dimension | Specific Measures | Effect | Implementation Difficulty |

| Platform Preparation | Level calibrate and clean with isopropyl alcohol. | Enhance adhesion and prevent warped first layer. | Low |

| Model Design | 5-10mm brim add, chamfer/radius corners, and reposition. | Relief stress and reduce stress concentration. | Medium |

| Printing Environment | No airflow, enclosed area, and 25-30°C environment. | Stable temperature and reduce cooling oscillations. | Low |

JS Precision Manufacturing provides customers with ABS 3D printing parts services, maximizing solutions from the three dimensions to create useful warp prevention for all parts.

If optimizing model geometry or adjusting the printing environment is required, JS can provide professional aid. Our online 3D printing services encompass the entire process from design to print and we are capable of designing multi-dimensional warp prevention systems based on the characteristics of ABS filaments.

Advanced Techniques For Preventing ABS Warpage

Aside from the primitive ways, some advanced technologies have a better ability to handle ABS warpage, especially in industrial use with intensive demand for print quality and efficiency.

1. Heated Chamber Printers: The printing chamber has an inbuilt heating mechanism that maintains a temperature level of 60-80°C, which is slightly less than ABS glass transition temperature. It facilitates slow part cooling and reduces warpage by over 80%, albeit at a relatively higher equipment cost (approximately $3,000-10,000).

2. Active Heated Bed Technology: This is an active zoned heating design that changes the temperature according to the dissipation of heat of different areas of the part. An example is increasing the edge temperature by 5-10°C so that it will be able to offer an uniform cooling rate. The cost of the machine ranges from $500-1,500.

3. Stress Relief Slicing Software: Some commercial slice software (e.g., Simplify3D) includes a stress relief feature that checks the model topology and adjusts the print speed and temperature where stress vulnerability is high. The cost of the software varies from $100-500.

We compare some particular approaches with recent technology in this table:

| Technology Type | Specific Method | Warpage Improvement | Cost (USD) | Applicable Scenarios |

| Conventional Techniques | Sealed Chamber, Brim, First Layer Optimization. | Reduce by 60% -70% | 50-200 | Individual consumers, small projects. |

| Heated Chamber Printer | Consistent temperature 60-80°C. | Reduce by over 80% | 3,000-10,000 | Mass production in industry. |

| Active Heated Bed | Zoned heating to offset part heat loss. | Reduce by 75% -85% | 500-1,500 | Medium-sized parts, high precision required. |

| Stress Relief Software | Structure analysis to control speed and temperature. | Reduce by 65% -75% | 100-500 | Complex parts. |

JS can offer industrial-grade custom 3D printing manufacturing needs. Do you want to successfully address ABS warpage issues? Select us for quality assurance without keeping an eye on the 3D printing price.

JS's Hands-On Review: From Failure To Success - The Genesis Of An Automotive Prototype

Background of the Project

One of the prints they asked for was to make a big, flat engine compartment prototype bracket (300mm x 200mm x 20mm). The part has to endure certain temperature conditions in the engine compartment, so they used ABS filament in order to meet the heat resistance requirement.

The company first wanted to use a mold to make the prototype, but the mold cost was up to $5,000 and the production cycle was four weeks. Therefore, they used 3D printing in order to cut costs and reduce the production cycle.

Problem Analysis

After analysis, the JS engineering team determined that there was too much thermal stress.

- The open environment caused airflow in the print region, which cooled more than 30% quicker from the edges and corners of the piece in comparison to the center, resulting in drastic uneven cooling.

- Secondly, the large size of the part (300mm long) produced high overall shrinkage, and the level of adhesion strength provided by the glue stick was not sufficient enough to handle the stress induced due to shrinkage, which finally led to warping.

Solution

JS team developed a four-component solution for the problem:

- Environment: The printer was moved to a wind-proof corner and a temporary shield constructed using cardboard boxes and tape. The temperature of the enclosure was maintained constant at 28°C in order to prevent airflow interference.

- Material: ABS filament easily takes up atmospheric humidity (which may exacerbate printing defects). The group dried new ABS filament in an oven at 80°C for four hours to drive off moisture.

- Parameters: The platform temperature was reduced from 110°C to 105°C (temperatures over this will cause excessive shrinkage in the first layer), the cooling fan was turned off (the fan will accelerate part cooling), and the first layer speed was reduced to 20mm/s to improve adhesion.

- Design: An 8mm wide brim was incorporated to the part in slicing software to augment the contact surface area between the platform and part and to improve the distribution of shrinkage stress.

Final Result

Solution optimization consumed the entire printing duration of 28 hours, and warpage was not observed. After printing, the part was allowed to cool under natural conditions to room temperature inside a covered chamber (approximately two hours) to avoid stress due to flash cooling.

When cooled down, the Brim could be removed easily, revealing a flat and even bottom with tolerances of dimensions to ±0.1mm, fully meeting assembly requirements.This 3D printing service only cost $800, saving $4,200 compared to mold making, and the cycle time has also been shortened to 3 days.

FAQs

Q1: I've already applied glue, but edge warping is still occurring?

Glue improves only the adhesive bond between the part and the build plate but can't repair the fundamental reason for warping in ABS prints—thermal stress. After thermal stress exceeds the adhesive adhesion or the part's internal strength, warping will occur anyway. You need to implement measures such as a closed printing environment and controlling cooling speed (such as turning off fans) to reduce stress at the root.

Q2: Besides ABS, what other materials warp?

Nylon, PC, and high-performance materials like PEEK/PEKK are all more prone to warping than ABS. They require higher print temperatures and higher thermal shrinkage, and basic anti-warping precautions will not suffice. An active heat print chamber is usually required for stable printing.

Q3: I have no problem printing small models, but large models keep on warping. Why?

The larger the part, the greater the thermal stress accumulated during printing, and the greater the temperature difference (thermal gradient) between edge and middle. Adhesion will suppress stress in small parts, but large parts require stress reduction, e.g., increasing the print chamber temperature and optimizing the part's orientation.

Q4: How can I tell if my ABS filament is humid?

You can tell it by the printing process and appearance of the material: crackling noise coming from the nozzle, uneven extrusion with bubbles, or loss of gloss and brittleness in the surface of the ABS filament. These are typical indications of dampness and need to dry out first before use.

Summary

Beating ABS warpage is a journey from understanding materials science to optimizing process parameters. It's no longer a frustrating problem, but instead a chance to be dealt with entirely with a systematic method. Remember that thermal stress control is the key, not solely relying on glue.

Whether you are a beginner working on your first ABS print or a professional looking to print large functional prototypes, mastering these techniques will double your printing success rate.

JS has a complete bespoke 3D printing manufacturing facility, from material choice and parameter tuning to printed finished product. Simply give us your part details, and we will immediately provide you with a price and technical solution for 3D printing. With online 3D printing services, we effectively provide certified products in order to assist you with easily fixing warping problems in ABS printing.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com