An unoptimized 3D printed model may cost you 70% more!When engineers complain about 'prototype exceeding budget',the problem often lies not in the printer,but in hidden design traps and pricing fog.

Whether it is an individual user's first attempt at 3D printing or a company's customized production, they may encounter difficulties: why do seemingly identical parts have vastly different quotes from different service providers? Why is the final cost still high despite choosing low-priced materials?

This article will break down the real cost structure of 3D printing,compare the prices of three major service providers,and reveal how to achieve zero compromise on quality through intelligent design adjustment and precise service selection,resulting in a sharp drop in costs.

Summary Of Core Content

| Aspect | Key Information |

| Drivers of Costs | Material cost,equipment cost,labor cost,post-processing cost,and service operation cost |

| Comparison of Material Prices | PLA: $2-7/kg (functional components). PETG: $5.5-14/kg (structural components). Resin: $14-70/kg (high-end field). |

| Design Optimization Guidelines | Minimize supports,minimize wall thickness,combine parts,and adjust fill density accordingly |

| Printing Hourly Cost | Desktop FDM (PLA: $0.7-3); Industrial grade SLS (nylon: $8-17). |

| Comparison of Suppliers | JS offers 0.1mm precision,2-5 day shipping,and 48-hour express shipping at a lower price,RapidDirect offers 0.2mm precision,3-7 day shipping,and Protolabs offers 0.15mm precision,with varying shipping times.JS offers more transparent and flexible costs. |

Why Is This Guide Reliable?

JS has been deeply involved in the field of additive manufacturing for over ten years,and its business involves a broad variety of high-accuracy industries such as aerospace,automobile,and medical devices.

In terms of pricing for 3D printing,we have set up a scientific and precise system.Each cost element is backed by immense data and case histories,and is based firmly on cost principles found in the industry,setting accurate and fair 3D printing prices.

Based on our expertise in the industry over several years and pricing experience,we have written this guide.New to online 3D printing services or need customized 3D manufacturing printing,you can take advantage of cost-cutting steps that actually work.

Require a precise 3D print estimate?JS,with the benefit of leading-edge technology and ISO 9001-certified processes,offers true solutions to 3D printing parts,so they're your best option.

What Determines The Cost Of 3D Printing?Five Key Cost Drivers

How do they manage to print the same 3D part so radically differently in price?3D printing prices aren't just determined on their own,they're impacted by a range of important cost drivers.

Material Cost:A Back-End and Necessity Spending

Materials are the back-end aspect of 3D printing,and their expense accounts for most of the total cost of 3D printing.All sorts of materials,such as plastics,metals,and resins,can vary significantly in terms of price.Prices even vary within a material by performance and quality.

For example,regular PLA plastic filament is inexpensive,but metal powders or premium engineering plastics are extremely expensive.The material cost directly affects the final pricing of 3D printed parts.

Equipment Cost:The Two Pressures of Purchase and Maintenance

The cost of purchasing 3D printing devices is an enormous one.Besides the cost of purchase,the maintenance expenses of the devices are equally high,including maintenance and replacement of the components.

Equipment depreciation is also borne by all those products printed by 3D printing,and equipment cost is thus one of the major costs of pricing,particularly for industrial 3D printing service providers.

Labor Cost:Professional Operation and Design Value

3D printing is not machine operation and needs to be operated professionally,monitored,and post-processed.It also entails human input ranging from model design and slicing,installation and operation of the printer,to post-printing processing such as support material removal and polishing.

Printing effectiveness and product quality can be optimized by skilled designers and operators but at the cost of labor,which is incurred and transferred in the 3D printing price.

Post-processing Cost:An Investment Worth Making towards Better Quality

Post-processing is executed for the majority of 3D printed items after they have been printed to allow them to carry out their respective function.Post processing methods include grinding,polishing,paint,and electroplating,with varying costs.Simple grinding,for example,does not cost anything at all,while complicated surface treatment or assembly is expensive.

Post processing cost is one of the important factors affecting final pricing,especially in custom 3D printing manufacturing,where tremendous expectation of product appearance and performance exists.

Service and Operating Cost:Underlying Expenses to Provide Service

Service and operating costs are also covered by online 3D printing service firms.They include website maintenance,customer support,order processing,and shipping.While these costs indirectly are not visible in the 3D printing process,they also become necessary to serve to perfection and finally subsidized in the service charge.

There are five determinants of 3D printing and JS excellently controls them.Get a quick quote from us,with honest and clear 3D printing costs and helping you excel in controlling costs.

Material Prices Unscrambled:A Comprehensive Comparison From PLA To Titanium Alloy

Now that we've been careful to consider the basic cost drivers of 3D printing costs,let's now turn our attention to materials.Materials are the backbones of 3D printing,and price variation among them goes a long way in determining the final cost.

| Material | Price Range(per kg) | Advantages | Disadvantages | Applications |

| PLA | $2-7 | Easy to print,biodegradable and environmentally friendly,smaller shrinkage. | Weak tensile strength,poor heat resistance. | Simple model making and crafts,a starter material. |

| ABS | $4-11 | High strength,good impact resistance,and better heat resistance than PLA. | Emission of toxic fumes when printed,requires an enclosed environment,and high shrinkage. | Used for toys,electronic casing,and functional parts. |

| PETG | $5.5-14 | Combining the strength of ABS and PLA:high strength,good toughness,and chemical resistance,and moderate printability. | More costly. | Printable for food packaging,machine parts,and outer products. |

| Nylon | $11-28 | Strong,tough,and resistant to wear,and well-suited for SLS processing. | High cost of printing and high surface roughness. | Printable for gears,bearings,and structural components. |

| Resin | $14-70 per liter | High smoothness,high resolution,and high accuracy. | Brittle and impact-resistant resins and toxic resins can also be found. | Fine model jewelry,fine models,dental models |

| Titanium alloy | $280-700 | High strength-to-weight ratio,low weight,corrosion resistance,and good biocompatibility. | Due to their high cost,difficulty in printing,and the need for special equipment. | Aerospace,implants,and high-level production |

While choosing the material,it's best to consider the specific application environment as well as the price range,which goes a long way in making the 3D printing costly.

Plastic to metal,outstanding material range.Upload design files and we will help you choose suitable materials that balance performance and cost, making 3D printing more cost-effective.

Design Optimization=Cost Reduction:4 Rules For Instant Results

With the magnitude of differences in material costs,can design optimization reduce 3D printing costs?Yes,it can.Correct design,in addition to ensuring product performance,also reduces material usage as well as print time and hence costs.Following are four design optimization principles that will directly impact.

Reducing Support Structures:Reducing Material and Time Consumption

In 3D printing,when there are overhanging parts of a model,typically there would be a requirement for support structures to facilitate smooth printing.Support structures not only consume additional material but also waste time during the process as well as effort while removing later on.

Optimization of Design by Proper Setting of Model Orientation and Use of Self-Supporting Structures:It reduces or eliminates the need for support structures.

Optimization of Wall Thickness and Part Size:Prevention of Waste and Defects

Poor design of wall thickness and part size can lead to material loss and printing faults.Over-specifying part size increases material use and print time,and over-specifying wall thickness can cause internal bubbles and shrinkage,impacting quality and cost.

Specify part size and thickness as necessary based on actual product needs in design,but only if it doesn't compromise strength.Minimize part weight and material use to the absolute minimum.

Consolidation of Part Design:Reducing Print and Assembly Times

In traditional manufacturing,intricate products are normally made up of various parts that must be assembled.Integrated molding is one advantage of 3D printing.The molding of several parts as a single design for printing can potentially reduce the number of parts and thereby shorten the print times and assembly costs.

The total stability and strength of the product are also improved with the consolidated design.

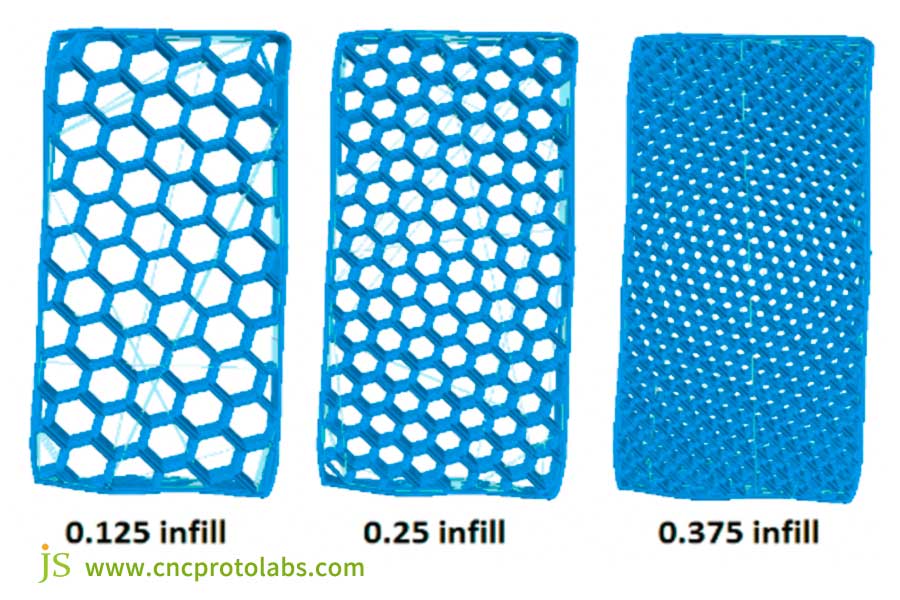

Proper Infill Density Use:Balance Strength and Cost

3D printing fill density is the proportion of fill material to a part.More fill density provides strength to a part but requires more material and is more costly.In the case of lightly loaded parts,a reduced fill density between 10%-30% may be used,for more loaded parts,a higher fill density between 50%-80% must be applied.

By properly defining the fill density at design,you can ensure product functionality while effectively reducing material costs,a valuable skill to maintain 3D printing costs in check.

Cost savings are possible in design optimization,and JS has practical guidelines.Send your CAD file,and we will optimize complex designs for you,ensuring quality while reducing material consumption and helping to maintain 3D printing costs in check.

Cost Truth:What Does a 1-Hour Print Cost?

Having learned that costs can be reduced by optimising design,the majority would need to know the cost of a one-hour 3D print.In fact,a one-hour print cost is not a fixed amount,it varies greatly depending on various factors such as the printer type,material,and labor.Let us uncover the cost of a one-hour print.

A one-hour print cost varies widely depending on the different types of 3D printing.Desktop FDM printers are everywhere,basic machines that cost very little to purchase.Industrial 3D printers,such as SLS,SLA,and metal 3D printers,are extremely expensive.They are extremely expensive to own and maintain,and their materials are also expensive.

Apart from this,the cost strategy of online 3D printing service providers can affect the cost of a one-hour print.

Some service providers are charged based on a mix of factors including print time,material consumption,and model complexity,and therefore get various quotes from different service providers.For choosing a 3D printing service,users need to consider the unit price as well as the cost-effectiveness overall.

| Printer Type | Material Type | 1-Hour Material Cost(Approximate) | 1-Hour Other Costs(Equipment Depreciation,Electricity,Labor,etc.) | 1-Hour Total Cost(Approximate) |

| Desktop FDM | PLA | $0.2-0.7 | $0.5-2 | $0.7-3 |

| Desktop FDM | ABS |

$0.5-1 |

$0.5-2.5 |

$1-3.5 |

| Industrial-Grade SLS | Nylon |

$1-3 |

$7-14 |

$8-17 |

| Industrial-Grade Metal Printer | Titanium Alloy |

$3-7 |

$28-70 |

$30-77 |

JS provides clear and affordable hourly rates for 3D printing.We leverage new equipment and efficient processes to realize greatest cost savings.Get a quote from us to reduce wasteful expenses.

3 Giant Services Comparison:JS vs.Rapiddirect vs.Protolabs

Within the business of 3D printing services,JS,RapidDirect and Protolabs all provide specializations.RapidDirect provides metal and plastic 3D printing,provides SLS and SLA process assistance,and provides shipping internationally.Protolabs leads in SLA rapid prototyping,SLS,and FDM processes with manufacturing automation focus.

JS leads in not just mass-market processes but also high-precision resin and metal printing,with 0.1mm-level control precision and with fine detail on intricate parts.

As far as quotation models are concerned,RapidDirect requires upload of the models to obtain quoted price.Protolabs offers immediate online quotes but demands strict model geometry.

JS does both,offering quick online quotes within 10 minutes,using engineers to offer free optimization suggestions,and offering over 95% quote transparency,no surprise fees,and more competitive 3D print costs.

| Company | JS | RapidDirect | Protolabs |

| Normal delivery time | 2-5 days | 3-7 days | depending on availability |

| Expedited service | 48 hours, 60% of the industry average | No express expedited service information | Fastest delivery time: 1 day (for simple prototypes) |

| Precision control | 0.1mm | 0.2mm | 0.15mm |

| Processes covered | Mainstream processes, with specialized optimizations for high-precision resin and metal printing. | Metal and plastic 3D printing, including SLS and SLA. | Metal and plastic 3D printing, including SLS, SLA, and FDM, is focused on rapid prototyping. |

| Quotation model | A combination of custom quotes upon uploading a model and online instant quotes. | A custom quote is required after uploading a model. | Online instant quotes are available. |

| Quotation features | Fast online quotes within 10 minutes, free optimization suggestions from engineers, over 95% transparency, no hidden costs. | No relevant description. | Strict requirements for model format. |

JS,with its distributed manufacturing setup,offers standard delivery guarantee and rapid response to emergency orders.Its straightforward simple online 3D print stores and special abilities in custom 3d printing manufacturing distinguish it with higher accuracy,variable costs,and reasonable quick service.

JS's strengths are shown here,as accuracy extends to±0.1mm and processing entails FDM and SLS.Upload your designs and receive a quote within 24 hours for a better online 3D printing service experience.

Case Study:74% Cost Reduction For High-Pressure Globe Valve Bodies

Customer Pain Points

A 316L stainless steel high-pressure globe valve body producer had to produce 500 of them.Conventional casting and CNC possessed a three-challenge problem:Up to $280 per unit at best.An 8-week business cycle kept production line upgrades lagging.The leakage rate for a sealing surface was 12% in a 550-bar pressure test.

JS's Solution

- Material and Process Innovation: Industrial grade metal 3D printing (LPBF) is used instead of casting, and high-purity gas atomized 316L powder (cost $60/kg) is selected. Combined with a self-developed argon gas circulation system, the consumption of protective gas is reduced from 30% in traditional processes to 12%.

- Structural Optimization: Reconstruct internal flow channels through topology optimization algorithms, reducing weight by 35% while ensuring pressure resistance; Integrated sealing ring groove structure, directly eliminating 2 CNC precision machining processes; Design honeycomb shaped lightweight support to reduce powder consumption by 22%.

- Batch Smart Manufacturing Accelerated: Dispatch 4 devices for parallel printing, using intelligent splicing technology to increase single batch printing volume by 40%, and equipment utilization rate jumped from the industry average of 65% to 92%.

Final Result

The cost per part fell substantially from $255 to $66(a 74% reduction),and the cycle time was decreased from 8 weeks to 11 days(a 78% reduction).The product also passed a 650 bar overpressure test(18% above the specification),with a leak rate reduced from 12% to 0%,95% powder recovery,and zero scrap compared to the 15% scrap from traditional casting.

JS has saved customers great amounts of cost in the field.Send design documents,and our professional team will contact you in a timely manner.Our custom 3D printing manufacturing service will efficiently troubleshoot and save your money.

FAQs

Q1: Is there a significant difference in post-processing time between different 3D printing processes?

The difference is significant. FDM post-processing accounts for 15% of the total working hours.SLA resin printing accounts for 25%. Metal printing requires removal of support and heat treatment, accounting for up to 40%.

Q2:How is JS's metal printing 40% lower in price than its rivals?

The core advantage comes from dual cost control: the closed-loop argon gas circulation system reduces the loss of protective gas from 20% to 8%; The mass production scale of over 5000 pieces per month dilutes the depreciation cost of a single equipment by 30%.

Q3:Why is there extra charge for surface sandblasting?

Sandblasting needs to be done by hand and includes a dust removing system.Nevertheless,JS provides free sandblasting for orders over $280(competitors usually charge $20-55).

Summary

In practice,for private use and custom 3D printing manufacturing,you can sequence material selection,design optimization,printer acquisition,and service acquisition to effectively manage costs and achieve more efficient and economic manufacturing of 3D printing parts without compromising quality.

Looking to save on the expense of 3D printing?Choose JS Precision Manufacturing.Upload a sketch to begin the process and we will provide you with one-stop support from material to delivery,assuring cost-effective and effective 3D printing parts manufacturing that meets your specifications.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com