CNC turning parts are a challenge to most of the component manufacturers.In today's highly competitive manufacturing industry, the search for a CNC turning partner offering the best-in-class precision and cost-effectiveness simultaneously is crucial for a product's success. Searching "CNC Turning Parts Thailand" translates to seeking a global solution.

By drawing from our practical experience and industry insight, this guide will explain why top Chinese manufacturers like JS Precision are a wiser choice nowadays for customers from all over the world, such as Thailand.

Core Answer Summary

| Comparison Dimensions | CNC Turning Parts Thailand Service | China CNC Turning Service (Taking JS Precision as an Example) | Your Core Benefits |

| Core advantages | Geo proximity and communication convenience. | Full supply chain ecosystem, deep technology accumulation, scale economy leading to cost advantages, one-stop solution. | Lower total cost, higher efficiency, and higher quality. |

| Cost-Benefit Analysis | Competitive labor costs but possibly higher costs of raw material and supply chain. | Integrated local supply chain reduces raw material and consumable cost considerably, thus providing lower TCO. | Obtain more competitive prices for equal or even higher quality. |

| Quality Guarantee and Consistency | Widespread quality awareness. | Full-process digital control, advanced online inspection technology, strict ISO quality management system. | Excellent consistency and traceability of large batches of precision turned parts. |

| Technology and Equipment Capabilities | Gradually upgrading. | Generally investing in the latest generation of multi-axis turning centers with a highly automated capability. | Capable of handling more complex and high-precision Custom CNC Turning Parts requirements. |

| Quotation and Order Experience | Relying on traditional communication. | Efficient Online Quote for CNC Turning Platform, tracking the production process in real-time. | Rapid response, transparent process, without worries and effort. |

How To Get Accurate Online Quotes For CNC Turned Parts? JS Precision Explains For You

An accurate quotation constitutes the first step in any collaboration within the CNC turning industry.

The International Organization for Standardization (ISO) emphasizes that standardized processes are the cornerstone of ensuring consistency and accuracy of results (one of the core principles of ISO 9001 quality management system). Our JS Precision company has accumulated rich practical experience in the quotation process based on this principle.

Since the foundation, CNC turning services have been sold to more than 1200 clients around the world, including in Thailand for electronics and drones. Within these three years, more than 3000 online quotations have been dealt with, involving 15 commonly used materials, and the quotation and settlement price deviation rate is ≤3% constantly.

For example, last year, a Thai medical device company needed to machine precision connector parts for a new blood glucose meter. We gave a quotation within 10 minutes after they uploaded their CAD files through our online platform, pointing out two details that could increase machining costs in the original design.

Ultimately, the actual cost of the order perfectly matched the quoted price, and the parts qualification rate reached 99.9%.

Methods summarized from these real-world cases and data serve as the basis for the quotation contents in this guide. We know what factors affect quote accuracy and how to help clients avoid pricing pitfalls, so you can assuredly trust that this content will help you efficiently get an accurate CNC turning quote.

Need a custom CNC turning parts quote as soon as possible? Upload your part drawings to our online JS Precision platform now and get a precise, real-time quote based on materials, processes, and other parameters. Free design optimization analysis is also included.

Beyond Geography: Why Do Global Clients Choose Chinese CNC Turning Partners?

In today's globalized world, geography is no longer the top priority in the selection of the CNC turning partner. More Thai clients therefore proactively reach out to CNC Turned Parts Manufacturer China, with comprehensive consideration of supply chain, technological capability, and cost-effectiveness. JS Precision witnesses such a trend.

From "World Factory" to "Smart Manufacturing Hub": The Evolution of Precision Manufacturing in China

The manufacturing industry has gotten rid of the "labor-intensive" tag in China and has become more technology-driven, automated in nature, as seen in the field of CNC turning. In China, there exists a complete industrial supply chain in the world, and the relevant company can get the orders processed with efficiency by enjoying the following advantages:

- Fast response of the supply chain: 24-hour access to commonly used materials, 48-hour allocation of special alloys.

- High equipment precision: Using high-precision turning center from brands like FANUC in Japan and DMG MORI in Germany.

- High degree of automation: 70% of its production lines are automated to process orders of complex CNC turning parts efficiently.

Why are Thai manufacturers also turning to Chinese partners?

The Thai local manufacturing industry has several shortcomings, which Chinese manufacturers can precisely address for the following reasons:

- Limitations of the Thai supply chain: Special materials like aerospace-grade aluminum alloys take 2-3 weeks to deliver by local suppliers.

- High equipment costs in Thailand: Most local manufacturers cannot afford investment in multi-axis turning center.

- Advantages of CNC Turned Parts Manufacturer China: Rapid material supply. For example, a Chinese manufacturer produced 50,000 CNC turning parts Thailand with a tolerance of ±0.01mm for a Thai customer in Thailand, with a delivery time of 12 days, significantly shorter than the local 25 days.

Would you like to explore the supply chain benefits from a CNC Turned Parts Manufacturer China? Reach out to JS Precision and share part specifications and your delivery requirement. We will design a tailor-made production schedule for you to ensure timely delivery.

Figure 1 CNC turning parts from China are widely used in Europe, North America, and Southeast Asia - both for high-end applications and as cost saving alternatives to domestically produced parts.

How To Choose the Ideal Material For Your CNC Turning Parts?

Choosing materials directly affects the performance and cost of your CNC Turning Parts.

The material standards developed by authoritative organizations such as the American Society for Testing and Materials (ASTM) provide scientific basis for engineering material selection. JS Precision will refer to these standards and recommend suitable materials according to customer application scenarios.

Common material core characteristics are as follows:

| Material Name | Strength Grade | Corrosion Resistance | Machinability | Cost (USD/kg) | Suitable Scenarios |

| Stainless Steel 316 | High | Excellent | Medium | 8.5-10.2 | Medical equipment, marine components. |

| 6061 Aluminum Alloy | Medium | Good | Excellent | 2.3-3.1 | Drone parts, electronic casings. |

| 4140 Steel | High | Average | Medium | 3.8-4.5 | Mechanical transmission components for automotive, mechanical parts. |

| 12L14 Free-machining Steel | Medium | Poor | Excellent | 1.9-2.5 | Common fasteners, low-precision parts. |

| Titanium Alloy Ti-6Al-4V | Extremely High | Excellent | Poor | 35-42 | Aerospace components, high-end medical. |

Pursuing Ultimate Strength: Which are the Best Performing Alloys?

If your CNC turning parts require high strength, the following three alloys are ideal choices:

- 4140 steel: tensile strength over 1000MPa after heat treatment, for heavy-duty auto parts.

- 316 stainless steel: This material grade shows high strength and is resistant to corrosion from seawater, thus finding its application in parts related to marine equipment.

- Titanium alloy Ti-6Al-4V: Strength near that of steel but at only 50% of its weight, for this reason, it is the alloy preferred in the aerospace industry.

Balancing Cost and Performance: What are the Cost-Effective Options?

The following two materials can be considered if you need to balance cost and performance.

- 6061 aluminum alloy: 30% more efficient in machining than steel, lighter mass reduces the cost of the Custom CNC turning parts. Suitable for electronic and drone applications.

- 12L14 free-cutting steel: Easily machined, has low tool wear, and therefore reduces labor costs. It is suitable for general fasteners and low-precision parts.

Figure 2 Chinese CNC turning parts manufacturers are capable of processing various materials, from metal to plastic, and optimizing processing techniques for each material.

Demystifying Pricing: How To Intelligently Compare CNC Turning Services Quotes?

Most customers just look at the overall price of a quotation for CNC turning services and could miss other hidden costs. JS Precision will identify the costing breakdown of its quotation. Here are some common costs of CNC turning services:

| Cost Breakdown | Percentage Range | Key Influencing Factors | Example (1000 aluminum alloy parts) |

| Materials | 30-50% | Material type, part weight, purchase quantity. | $600 - $1000 |

| Labor | 20%-35% | Machining difficulty, type of equipment, required tolerance. | $400-$700 |

| Surface Treatment | 5%-15% | Treatment process - anodizing, electroplating, etc., area. | $100-$300 |

| Administrative Fee | 5%-10% | Order size, service requirements. | $100-$200 |

| Quality Inspection and Packaging | 3%-8% | Quality inspection standards, packaging requirements. | $60-$160 |

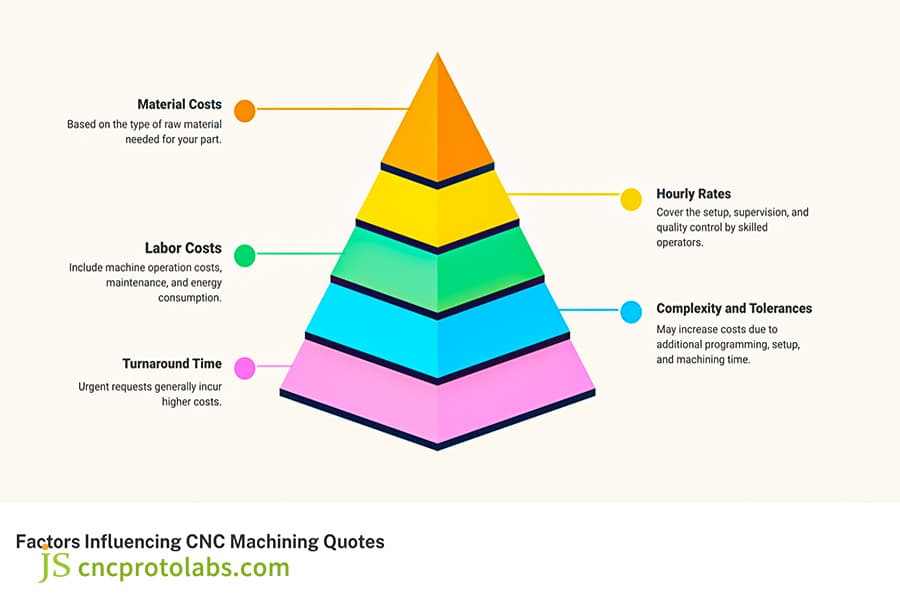

What's Hidden in the Quotation? Understanding Cost Drivers

A complete CNC turning services quote includes all of the above-mentioned cost items, the core drivers are as follows:

- Material Costs: Dependent upon material density, volume, and unit price. Parts made of titanium alloy are around 15 times more expensive compared to aluminum alloys.

- Labor Costs: According to the machining steps, complex grooved parts take 2-3 times longer than simple cylindrical ones. Therefore, the cost of labor is higher.

- Tolerance Requirements: Increasing tolerances from ±0.1mm to ±0.01mm can raise the labor cost by over 50%.

Beware of Low-Price Traps

Some suppliers quote prices far below market value. Here are some traps you should watch out for:

- Material Traps: The use of ordinary stainless steel to impersonate 316 stainless steel, thus making the parts have inadequate corrosion resistance.

- Quality Inspection Traps: Sampling only 10% of parts instead of 100% inspection increases defective product risks.

JS Precision reminds you, while comparing quotations, to ensure that the material certification, standard of quality inspection, and range of tolerance taken by the supplier are fully consistent. Only then does a price comparison have any meaning.

Figure 3 Composition of CNC machining cost. The cost depends on factors such as material selection, complexity, output, and required delivery time.

Cost Depth: A Cost-Effectiveness Showdown Between Chinese And Thai CNC Turning Parts

Many clients in Thailand are concerned about the unit price for Chinese and Thai CNC turning parts. However, the TCO is more important. JS Precision, a CNC turned parts manufacturer China, can help clients reduce costs from multiple dimensions.

Beyond Unit Price: How to Calculate the True "Total Cost of Ownership"?

Total cost of ownership (TCO) includes not only the unit price of parts but also the following key costs:

- Procurement management costs: the manpower and time costs incurred in liaising with suppliers and tracking orders.

- Quality failure costs: losses due to rework and production line downtime caused by defective parts. For example, a Thai customer once lost $20,000 annually due to defective local parts.

- Delivery delay costs: order penalties resulting from delivery delays. This customer once lost a $100,000 order because of delays from a local supplier.

After partnering with JS Precision, their cost of quality failure went down to $2,000 per year, delivery delay rate became 0%, and overall costs decreased by 12%.

Scale and Efficiency: How can the Chinese supply chain empower you?

The cluster effect of the CNC turning industry in China is considerable, and more than 200 raw material suppliers have been attracted by related industrial parks. This can enable clients by:

- Faster acquisition of raw materials: the 316 stainless steel will arrive on the same day, 5-7 days faster than in Thailand.

- Reduced testing costs: sharing testing equipment with surrounding companies eliminates the need for investments that are individually too expensive.

- Shorter lead times, cost reductions: In manufacturing Custom CNC Turning Parts, the lead times are reduced by 40%, while the cost is reduced by 15%.

Want to know how much you can reduce your overall cost by sourcing CNC Turning Parts Thailand? Just tell JS Precision what annual purchase volume you require, what quality you need, and your lead time needs. We will perform a TCO analysis in detail, which will clearly show the cost advantages of cooperation.

Quality Is Life: How To Ensure Consistency Of Millions Of Precision Turned Parts?

For high-volume orders, precision turned parts require consistency in quality. JS Precision ensures every part meets standards through a three-pronged approach: hardware, software, and management systems.

Our Arsenal: How advanced inspection technology guards every micrometer?

We have invested heavily in advanced inspection equipment, including:

- Coordinate Measuring Machine: Accuracy ±0.001mm, capable of measuring dimensions and geometric tolerances, 0.005g for drone rotor dynamic balancing.

- Optical Imaging Measuring Instrument: Non-contact inspection, suitable for thin-walled, easily deformable Precision Turned Parts.

- Roughness Tester: Controls surface roughness to make sure the Ra value of medical parts is controlled below 0.8μm.

From Digital to Reality: How does the end-to-end traceability system work?

We use ERP and MES systems for end-to-end data recording and traceability, starting from the warehousing of raw materials to the delivery of finished products. The specific process is as follows:

- Raw material warehousing: Record the material batch number and the material certificate number.

- Production Process: Transfer turning center parameters and operator information to the MES system.

- Quality Inspection: Associate part inspection data with the part number.

- Problem location: When a quality problem is detected, identify which batch, personnel, and equipment are involved in 10 minutes or less to enable immediate isolation.

Want to be assured of consistent quality for your millions of Precision Turned Parts? Then plan a visit to our factory to see JS Precision's physical testing equipment and traceability system for yourself. We'll also be happy to provide you with a "Quality Assurance Plan" so you can rest easy when placing your order.

How To Get An Instant Quote For Your Custom CNC Turning Parts Online?

Many customers worry that getting quotes for Custom CNC Turning Parts online will be cumbersome or inaccurate, but the online quotation platform of JS Precision easily solves these problems with its simple operation and accurate pricing.

Get Your Instant Online Quote for CNC Turning in Three Steps

Get a quote in just three easy steps:

- Upload CAD File: Upload a 3D model in STEP/IGES format, and the system will automatically recognize the dimensions and structure.

- Choose Parameters: Decide on material (for example, 6061 aluminum alloy, 316 stainless steel), production quantity (from 1 to 100,000 pieces), and surface treatment process.

- Get Quote: The system instantly generates a quote and estimated date of delivery within 10 seconds. A detailed quote can be downloaded.

Your Design Optimization Partner: More Than Just a Quote

Our online quoting platform offers more than just quotes, it also provides free DFM analysis by a professional engineering team. Specific services include:

- Problem identification in design: Identifying the excessively deep blind holes in Custom CNC Turning Parts designs.

- Optimization Suggestions: Offering solutions like converting blind holes to through holes without affecting performance.

- Cost Reduction: Helping customers reduce their cost of processing by 20% due to design optimization.

Case Study: How A Thai Drone Company Achieved 20% Cost Reduction And 100% On-Time Delivery Through JS Precision

A rapidly growing drone company in Thailand needed 100,000 aluminum alloy rotor parts for its core flight control system with a dynamic balance of ≤0.005g and weighing 15±0.5g.

Client Background and Core Challenges

This customer earlier worked with a local CNC turning parts Thailand supplier and faced two core challenges:

- Low product yield: As the local supplier used ordinary lathes, the proper dynamic balancing of parts was difficult to achieve, yielding only 80%, thus producing 20,000 defective products annually and wasting $30,000 in costs.

- Unstable delivery times: Material procurement cycles often pushed the deliveries 5-7 days behind schedule, which drastically reduced new product launches and led to a lost opportunity for the client amounting to $100,000 due to delays.

JS Precision Custom Solution

Upon receiving the client's request, JS Precision assembled a dedicated team to provide the following customized solution:

1. DFM Analysis and Optimization: the original design had a 2mm radius at the rotor edge, which is not favorable for machining. It was advised to change this to 3mm without affecting dynamic balance, optimizing the toolpath increased efficiency by 30%.

2. Material Upgrade: The aerospace grade 7075 aluminum alloy was chosen. Compared to the customer's original 6061 aluminum alloy, this was 25% stronger and lighter, meeting part requirements.

3. Machining and Service Guarantee: Adopted multi-axis turning center to realize one-time forming and avoid multiple clamping errors, opened the VIP production channel for priority scheduling of orders, and realized real-time synchronization in production and quality inspection progress through the customer's portal.

Exceptional Accomplishments and Long-term Value

In a year of collaboration, this customer reached the following three major outcomes:

- Cost Reduction: Processing costs went from $15/piece to $12, decreased annual procurement costs of $300,000, and an overall cost reduction of 20%.

- Quality Improvement: Parts passed rate improved from 80% to 99.8%, annual losses from defective products were reduced by $27,000.

- Delivery Guarantee: Reduced delivery time from 25 days to 12 days, achieved 100% on-time delivery for 12 consecutive months, thus eliminating missed orders due to delivery delays.

Now, this customer has listed JS Precision as a core CNC Turned Parts Manufacturer China, and the volume of orders from this collaboration has continuously increased year by year.

Want to achieve cost reduction and on-time delivery for Custom CNC Turning Parts like this Thai drone company? Please share with us your pain points and needs in producing the parts, and JS Precision will tailor a specific solution for you to grow your business.

Figure 4 Alloy drone rotor turning parts

How To Track Your Order In Real Time After Obtaining The Online Quote For CNC Turning?

Many customers are concerned about the lack of transparency in order progress once the Online Quote for CNC Turning is available and an order is placed. With JS Precision, you have the ability to check the status of your order at any time with a customer portal and a dedicated project manager.

Your Dedicated Command Center: Introducing the Customer Portal

For each of our clients, we have a dedicated customer portal. We allow you to log in at any stage and view the status of your order:

- Raw Material Procurement Stage: The progress made in material procurement and the estimated time of delivery.

- Production Stage: The real-time video and photos of the turning center processing can be clearly viewed for understanding.

- Quality Inspection Stage: Download detailed quality inspection reports, including dimensional inspection data, surface roughness results, etc.

- Shipping Stage: Tracking number and estimated time of delivery will be provided. As easy as tracking a package!

Zero Distance Communication: The Value of a Dedicated Project Manager

In addition to the customer portal, a project manager is assigned to each customer for direct services including, but not limited to:

- After the order is confirmed: coordination of details, including production planning, standards for quality inspection, and shipping arrangements.

- In production: communicate problems promptly, and jointly find solutions.

- After the order is complete: After-sales follow-up to understand part satisfaction and collect improvement suggestions.

This one-on-one service smooths communication and there are no disparities in information.

FAQs

Q1: Is your online quotation system accurate?

Our Online Quote for CNC Turning system has high accuracy, it calculates intelligently based on the 3D model, materials, processes, and quantity you input. In fact, 98% of order quotations matched the final price in the past.

Q2: What is the minimum order quantity (MOQ)?

The minimum quantity we can offer is very flexible, from 1 prototype to over 100,000 pieces in mass production. Whatever the quantity, high-quality CNC turning parts can be offered.

Q3: What range of tolerance can be achieved?

The general tolerance is ±0.025mm. For the Precision Turned Parts requiring high precision, after properly adjusting the process based on the characteristics of the part, the tolerance can be up to ±0.005mm.

Q4: Normally, the production cycle is how much time?

The production cycle is related to the order size. The prototypes can be delivered within 3-5 days for 1-10 pieces. For batch orders from 1000-10000 pieces, usually it takes 1-3 weeks. We will provide the detailed schedule in advance.

Q5: Can you provide material certifications and quality inspection reports?

Yes, we will provide complete documentation along with the shipment, including material certificates like MTR reports, first article inspection reports, and final shipment inspection reports to ensure that the CNC Turning Parts meet the requirements.

Q6: Do you have a lead time advantage vs. local suppliers in Thailand?

Yes, a big advantage. Due to mainland China's well-established supply chain and efficient production management, our lead time normally is 30%-50% shorter than that of local suppliers in Thailand, and our lead time is more stable.

Q7: What brands of CNC equipment do you use?

We use high precision multi-axis turning center for most parts, which are made by Fanuc of Japan and DMG MORI of Germany. Those machines can ensure the highly accurate and efficient machining of CNC turning parts.

Q8: Is there a design review service at the beginning of a new project?

Yes, our engineers will do a free DFM (Design for Manufacturability) analysis for you and give some optimization suggestions for the design of Custom CNC Turning Parts in order to decrease cost and improve quality.

Summary

In precision manufacturing, the selection of suppliers is not just about the selection of one, it is about finding a strategic partner that can drive your business forward.

With profound technological foundational advantages, unparalleled supply chain advantages, and painstaking pursuit, JS Precision is becoming the manufacturing engine for elite global companies. We provide high-end CNC turning services that are accessible, transparent, and efficient.

Act now: Start your efficient precision manufacturing journey!

Do not let your ideas remain on paper any more. Just upload your CAD file on our website and experience the convenience of getting an instant quote in 30 seconds. Feel the speed and quality brought by China's top precision manufacturing!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com