Rapid prototyping is an important bridge between product design and the market. Your prototype, on a product development track, represents not only the very first materialization of your idea, but also the first baton in the race against the market.

When design iterations are imminent, when budgets are running low, and performance requirements are near-obsessive, how do you find an optimal path through the complex maze of Rapid Prototyping processes?

This case study explores four real-world battlegrounds at JS Precision, illustrating how we use the precision of CNC rapid prototyping, the freedom of 3D printing for prototyping, the economy of rapid injection molding prototyping, and the performance innovation of metal 3D printing to provide our clients with the decisive competitive advantage.

Key Answer Summary

| Application Scenarios and Challenges | JS Precision's Process Choices | Core Value Created for Clients |

| High-Load Functional Test Parts | CNC Machining vs. Rapid Mold Making | CNC Machining: Delivery within 48 hours, material properties consistent with mass-produced parts, ensuring zero testing risk. |

| Complex Internal Flow Channel Fluid Testing | 3D Printing (SLS) vs. CNC Machining | 3D Printing: Iteration complete in 5 days, producing complex integrated flow channels that traditional processes cannot process. |

| 500-Piece Small Batch Terminal Shells | Rapid Injection Molding vs. Sheet Metal Machining | Rapid Injection Molding: unit cost reduced by 60%, appearance and texture can't be told from mass production. |

| High-Efficiency Thermal Management Metal Components | Metal 3D Printing vs. Traditional Processes | Metal 3D Printing: 40% improvement in heat dissipation efficiency, solving core technology bottlenecks. |

| Extremely Urgent Firefighting Projects | Full-Process Rapid Prototyping Service | 36-Hour Rapid Response from Drawings to Functional Samples, ensuring clients' critical business opportunities. |

Why Trust This Guide? JS Precision Rapid Prototyping Practical Case Analysis

Why should you trust this guide? That is because it is not a mere theorization, but a summary of experience from the thousands of real-world projects undertaken at JS Precision.

My team and I have operated Rapid Prototyping services for more than 8 years for upwards of 500 clients in all parts of the world, including four main sectors: automotive, medical, electronic, and aerospace.

Our rapid prototyping manufacturing process, especially in additive manufacturing, refers to the additive manufacturing technology standards developed by ASTM F42 Committee under ASTM International. This series of standards is the cornerstone of global 3D printing technology and material certification.

We used CNC rapid prototyping to deliver a high-speed load test-capable metal gearbox to an automotive parts supplier in 45 hours, saving them millions of dollars in mold losses. We have also utilized 3D printing for prototyping heatsinks with 200% improvement in thermal efficiency for a medical device company.

Additionally, we compared the costs of rapid injection molding prototyping versus rapid sheet metal prototyping for 500 housings for a consumer electronics client, saving them 30% in expenses.

The pitfalls and lessons learned from these projects are all distilled into this guide. Whether you need urgent prototype delivery or are struggling with process selection, this guide can provide you with practical assistance in such areas.

If you are new to Rapid Prototyping and wish to avoid common pitfalls, send for the "Practical Project Pitfall Avoidance Handbook." If you already have specific needs, submit your project information to receive one-on-one process advice, helping you avoid unnecessary detours.

What Are The 5 Key Factors In Choosing A Rapid Prototyping Service?

After understanding the credibility of this guide, the core question is: How to avoid waste when choosing rapid prototyping services? Blindly choosing processes wastes time and money, focus on these 3 core factors.

Project Objectives First: What to Validate?

Properly defining the prototype's purpose forms the basis for process selection:

- Proof of Concept: If only a visual demonstration is needed, use 3D printing (fast and low-cost).

- Functional Testing: If load-bearing, temperature resistance, or sealing is required, go for CNC machining or metal 3D printing for real material properties.

- Small-Batch Trial Production: If consistency with mass-produced parts is needed, select rapid injection molding to achieve mass-production-grade appearance and performance.

Material Properties: Not Just Appearance but Internal Factors

Properties of materials will affect the choice of the manufacturing process. Use CNC machining with PEEK/metal processes that have high temperature resistance of >200°C, for biocompatibility, choose specialized materials with aseptic processes to avoid rework because of poor performance.

Economy and Timeline: Balancing Cost and Speed

Attention should be paid to the "Unit Cost + Initial Setup Fee + Delivery Time" balance. A quick reference table is shown below:

| Process Type | Unit Cost Range (USD) | Initial Setup Fee (USD) | Typical Delivery Time |

| 3D Printing (SLS) | 50-200 | 0-100 | 1-3 days |

| CNC Machining (Metal) | 100-500 | 50-200 | 2-5 days |

| Rapid Injection Molding | 10-50 | 5000-15000 | 5-10 days |

Less than 10 pieces: 3D printing-no high set-up fee. More than 500 pieces: Rapid Injection Molding-lower total cost.Urgent project: 3D printing/CNC must be taken into consideration.

If you already have your project output and time requirements, you can submit a "Cost Calculation Sheet," and we will send over the detailed breakdown of the rapid prototyping cost in 1 hour. If you are not sure how to obtain the best result from the process, then our engineers can suggest the optimal solution according to your goals.

Demystifying Rapid Prototyping Applications: Material And Performance Boundaries

Having explained the selection factors, rapid prototyping applications will be discussed next: there are definitely limits to each of these rapid prototyping applications, and their advantages and disadvantages should be understood.

3D printing for prototyping: Beyond Plastic Trinkets

- Advantages: Complex designs like integral runners, rapid delivery, suited for urgent prototypes.

- Disadvantage: Generally low mechanical properties, low surface accuracy, unsuitable for high-load parts.

CNC Rapid Prototyping: The Benchmark for Precision and Strength

- Advantages: High precision ±0.01mm, high strength isotropic, wide material selection, suitable for high-requirement test parts.

- Disadvantages: In case of complex parts, the machining time is long, there is large waste of material, internal right angles cannot be machined.

The Niche Players: Rapid Injection Molding & Sheet Metal

- Rapid Injection Molding: Offering mass production performance, not economically viable for quantities less than 10 pieces due to high mold costs.

- Sheet Metal Machining: Suitable for chassis/fuselage, unsuitable for complex 3D parts.

| Process | Core advantages | Core limitations | Applicable scenarios |

| 3D Printing | Complicated designs+fast deliverables | Low performance/ precision | Complicated structure/ urgent prototyping |

| CNC machining | High precision+high strength | Complex components are time-consuming. | High load test /Metallic parts |

| High load test /Metallic parts | Low unit cost + mass production performance | Expensive molds + long lead times | Small batches of 50+ pieces |

| Sheet Metal Machining | No molds + flat part adaptation | Unsuitable for complex 3D parts. | Simple structures such as chassis/fuselage |

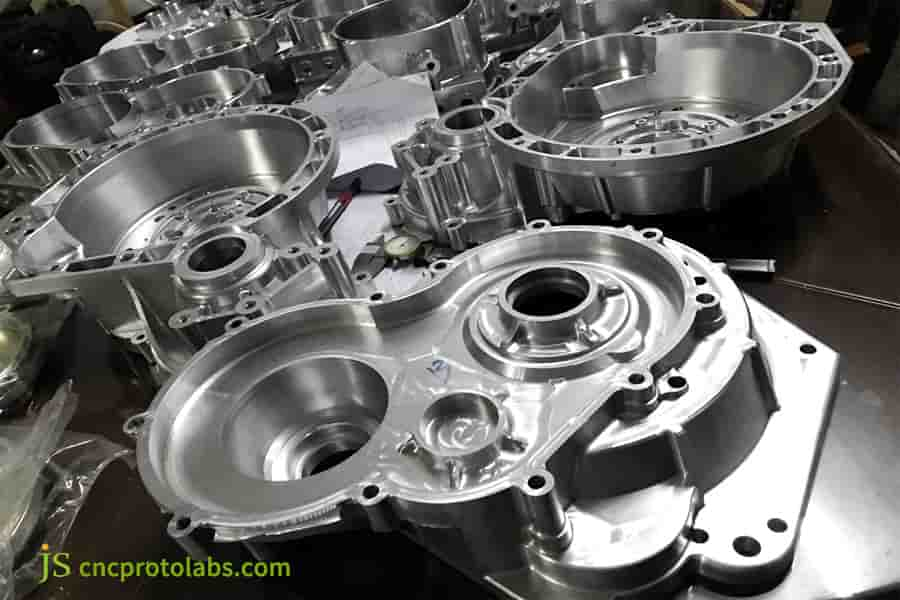

Practical Case 1: The 48-Hour Gearbox – CNC Machining Vs Rapid Tooling For High-Strength Validation

Now that the theoretical part has been covered, let's break it down into the first real case: an urgent project from an automotive transmission company last year, which underlines the benefits of CNC rapid prototyping.

The Client's Dilemma

The newly designed metal gearbox of the client needed high-speed load testing within 48 hours, failing which the mold for mass production would be scrapped entailing losses worth millions of dollars. Optional Processes:

- Option A: Rapid Tooling. Delivery in 7 days is not meeting the requirements.

- Option B: CNC Rapid Prototyping, and it is the only solution with delivery within 48 hours. However, the client had concerns about the precision and strength.

JS Precision Solution

The moment we received the requirement, my team and I immediately kicked off an urgent CNC rapid prototyping protocol.

- First, we chose 6061 aluminum alloy blanks because their strength and resistance to impact can meet the load requirements of gearboxes.

- Then, we used a five-axis CNC machining center to complete the machining of all complex tooth profiles and structures in a single setup-that avoids precision errors caused by multiple setups.

- At the same time, we arranged engineers for 24-hour monitoring to ensure that the whole machining process is without any problems.

Our final results

Delivered a fully functional prototype in 45 hours. Gear interference issues were identified during customer testing that would have prevented significant losses. Although unit cost was $2000 - well above rapid prototyping cost of $500 - we were able to secure a small-batch prototype order prior to mass production.

Figure 1 Rapid prototyping of CNC machined aluminum gearbox

Practical Case 2: The Intricate Intake Manifold - When 3D Printing Outperforms CNC

The second case study: intake manifold project, showcases the benefits that arise from using 3D printing for prototyping in complex structural parts.

Client's Needs

A newly established energy vehicle company in need of a functional intake manifold prototype with complex internal flow channels that have to be optimized for engine efficiency. Core Requirements: Seamless internal flow channels, 0.8MPa pressure test without air leakage.

Process Dispute

CNC machining was the originally selected method by the customer. However, three parts needed to be disassembled and assembled, two seams were prone to leakage, and the flow channel shape was hard to optimize.

As opposed to this, 3D printing for prototyping utilizes integrated manufacturing, where a smooth, seamless internal flow channel can be made, replicating an optimal flow channel.

JS Precision Solution

Finally, after discussing with the client, printing was done with SLS nylon material, it had sufficient strength and temperature resistance to meet the working environment of the engine (maximum temperature resistance of 120 ° C).

In the process of printing, we also optimized the parameters of laser to ensure that the surface roughness of internal flow channel was controlled below Ra1.6μm, in order to avoid the influence on airflow. After printing, we also performed sandblasting on the surface to improve appearance and texture.

Our Success

The prototype passed an air pressure test up to 0.8 Mpa, improved the efficiency of an engine by 15%, while using the integrated structure to achieve light weighting reduced the weight by 30%.

The customer valued the disruptive value of 3D printing for prototyping and intended to shift priority to our rapid prototyping services when future needs for complex-structure prototypes arose.

Figure 2 Nylon Automobile Intake Manifold

Practical Case 3: The 500-Piece Enclosure – Cost Showdown Between Rapid Injection Molding And Rapid Sheet Metal Prototyping

The third case study is for the cost of 500 enclosures and is used for reference by clients who are troubled by the manufacturing process.

Client's Objective

The customer is from the consumer electronics field and requires 500 custom enclosures for marketing/early testing. Core requirements include cost control, smooth and flat enclosure, and compatibility with internal components.

Cost Analysis

- Rapid Sheet Metal Prototyping: No mold cost, $30 a piece, total price $15,000 for 500 pieces (welding seams require grinding, increasing lead time),

- Rapid Injection Molding Prototyping: $8,000 aluminum mold, $10 per piece, seamless and flat appearance, high precision total price is $13,000 for 500 pieces.

| Process | Mold Cost (USD) | Unit Cost (USD) | Total Cost for 500 Units (USD) | Appearance Quality | Delivery Time |

| Sheet Metal Fabrication | 0 | 30 | 15000 | With seams | 7 days |

| Rapid Injection Molding | 8000 | 10 | 13000 | Seamless | 10 days |

Precise JS Solution

Based on this cost accounting model and samples of both processes, we explained to the client that though rapid injection molding has initial mold costs, for 500 units of quantity, the total cost is already $2000 less than that of sheet metal processing, with better appearance and consistency, more suitable for market promotion.

We also promised that if production needs to be increased later, this mold can still be used without further mold costs.

Results

The rapid injection mold was chosen by the customer, and within 10 days, it provided 500 shells that were successfully put to use during marketing. Further production of molds resulted in 1000 pre-production parts with the benefit of further reducing the total cost due to optimal rapid prototyping cost efficiency.

If you need 50-1000 small batches of shell/accessories, please provide the quantity and appearance requirements, and we will provide free comparison of the total cost of sheet metal, injection molding, and 3D printing. And after the process is determined, sample production cycles and preferential quotations can be prepared.

Figure 3 The rapid prototyping tool options have lower costs in small batch production, but when it comes to large-scale production, injection molding can provide unparalleled single piece costs.

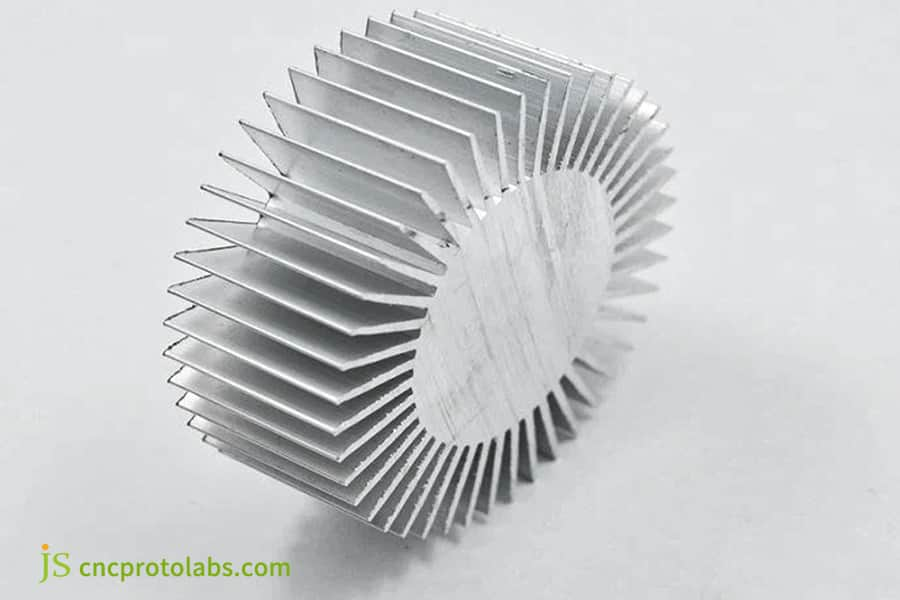

Practical Case 4: Radiator Performance Surges By 200% – Metal 3D Printing Vs. Traditional Fabrication

Fourth case: Breakthrough in radiator performance, proving the value of 3D printing metals in high-end rapid prototyping applications.

Technical Problems of Client

The medical device companies need very powerful laser equipment radiators, large amounts of heat need to be released, or else it will affect equipment lifespan.

Limitation of traditional process: Machining is only able to provide straight channel, small heat dissipation area, sheet metal welding has a seam and is easy to leak or flow in a turbulent way, its heat dissipating efficiency is only 20W/(m・K), which doesn't meet the requirements.

JS Precision Solution

According to the analysis result, we suggest Metal 3D Printing technology-SLM. First, we chose AlSi10Mg aluminum alloy whose thermal conductivity is very good and was suitable for the heat sink.

Then, on the basis of this, in the optimization design of the flow channel for customers, a heat exchanger with a conformal flow channel is created, the channel closely follows the heat-generating component and contains numerous internal protrusions, increasing the heat dissipation area a great deal.

Finally, SLM technology is applied to print the whole heat sink in one step, and it gets a smooth and seamless flow channel.

Our Final Result

The 3D metal printed heat sink achieved a heat dissipation efficiency of 60W/(m·K), which was over 200% higher than the one made in the traditional process, and fully satisfied the demands. Later, clients used this design in mass-produced products, revealing the value of a performance breakthrough with advanced technology.

Figure 4 3D Printing Aluminum Heat Sink

When Time Is Critical: How Our Rapid Prototyping Services Saved A Product Launch

Many clients have contacted us due to time constraints to discuss how JS Precision applies rapid prototyping services when handling urgent projects and saves product launches.

Our "Red Line" Protocol: Seamless Emergency Process

Our exclusive "Red Line Protocol": orders reviewed within 1 hour, equipment scheduled within 2 hours, progress is updated every 8 hours during processing, finished products get priority quality inspection and logistics. Thanks to this, a 48-hour gearbox case has been delivered ahead of schedule.

Transparent Communication: You are Always Informed of the Project Progress

To avoid information gaps in urgent projects: Set up a special group after kick-off, update the details, including relevant engineers in production and logistics, progress is updated every 4-8 hours. If any problem happens, offer 2-3 solutions directly to reassure you during the whole process.

Anticipatory Problem Solving: Experienced Engineers to Assist You

The design for manufacturability thus involves DFM analysis of the pre-production design flow to predict design flaws that might include insufficiently thick walls or hard-to-machine internal holes and to suggest modifications, including adjusting key parameters, which can be made in order not to waste time on production rework.

In the case of an urgent need for prototyping within 24-72 hours, emergency hotlines will be activated for immediate response. In urgent projects that require preparation in advance, please submit the "Pre-registration Request Form" so we can prioritize your desired equipment.

Maximizing Your ROI: How JS Precision Optimizes Your Rapid Prototyping Cost

Besides time, the cost is also one of the important considerations by the client. The majority of clients think that rapid prototyping is costly, however, it can be significantly optimized with the right approach. JS Precision has rich experience in this area and can help maximize your ROI.

Technology-Agnostic Advice: We Recommend the Most Cost-Effective Solution for You

Many companies have equipment for certain processes they suggest, but we do not. We offer several processes, and our recommendations are fully based on your interests:

- When you need 10 prototypes, we recommend 3D printing because there are no mold costs.

- For 500 prototypes, rapid injection moulding is advised because it will be less expensive overall,

It means we won't just recommend having unsuitable parts CNC machined because your CNC equipment is standing idle. Instead, we will help you choose the most cost-effective process.

Design for manufacturability (DFM) analysis: Free Cost-Saving Service

We offer free DFM analysis that helps you reduce your cost, starting from the design stage.

- For instance, if some part has too thick walls, we'll recommend its thinning in order to save the material and thus money,

- If it contains complicated curved surfaces, we advise simplifying them to reduce the time and labor for processing.

By using our DFM analysis, many clients have reduced rapid prototyping cost by 20%-30%.

Intelligent Sourcing & Logistics: The Hidden Cost Saver

We have a mature supply chain, as well as a logistics system, to help you save on hidden costs:

- In materials, we work with a number of international material suppliers to lower prices, which we then pass on to you,

- In terms of logistics, we have logistics partners optimized in such a way that we avail fast and cheap transportation services to projects, with discounts on air freight for urgent projects and sea freight for bulk projects.

These surreptitious cost savings will, in turn, help you further reduce your total expenses.

Cost-saving steps from the design stage: send your drawings for a free DFM analysis report, for long-term bulk needs, you can fill in a "Cooperation Intent Form" to customize tiered pricing that will help you reduce the rapid prototyping cost even further.

FAQs

Q1: What is the main difference between 3D printing, CNC machining, and rapid injection molding?

Complex geometry and speed make 3D printing ideal for urgent complex structural prototyping. Material performance and precision are the advantages of CNC, thus suitable for high-load testing. And with rapid injection molding, unit cost can be the lowest with quality in small batches.

Q2: My prototype requires resistance to high temperatures (>200°C). What process would be suitable?

The best options are CNC machining of high-temperature engineering plastics like PEEK, or metal 3D printing/CNC metal machining. This will be able to achieve high-temperature resistance requirements that ordinary 3D printing resins and plastics cannot sustain.

Q3: Why select you over and above a local rapid prototyping service provider?

JS Precision offers one-stop multi-process solutions, professional DFM analysis, and global logistics support to ensure you have the best technology match and cost-effectiveness without the limitations of a single process.

Q4: How can I further reduce my rapid prototyping costs?

The cost of rapid prototyping will also be minimized by optimizing the design for reduced material use and processing time, by relaxing tolerance requirements when appropriate for non-critical parts, and by selecting processes compatible with production volume.

Q5: How long does it take from placing the order to receiving the prototype?

For simple and urgent orders, like some small plastic parts, we can deliver within 24-48 hours. For example, we have delivered a gearbox within 48 hours on one occasion.

Q6: Do you offer any post-processing services, such as painting or sandblasting?

Yes, we offer comprehensive post-processing services, including sandblasting, anodizing, spraying, screen printing, etc., to meet your various requirements for prototype appearance and make them more suitable for actual use.

Q7: Which of the following processes provides the most accurate for very small prototypes, say micro gears?

Material requirements permitting, high-precision SLA 3D printing or micron level CNC machining is best. Apply SLA for plastic micro gears and micron level CNC for metal micro gears.

Q8: I do not know yet which process to select, what should I do?

Please provide us with your 3D files and requirements (application, production volume, time, etc.), our professional team will provide a detailed solution with process comparisons and quotations to help you with final decisions.

Summary

In the race for innovation, the determinant factors are speed and precision. Four case studies conducted by JS Precision vividly illustrate how an appropriately selected process can lead not only to cost and time savings but also to performance breakthroughs.

Whether urgent delivery, cost control, or complicated design, if you currently have a Rapid Prototyping project, don't hesitate to contact us: based on our 8 years of practical experience, we'll help you choose the right process and work out high-quality prototypes to save time and effort for your project.

Do not let the selection of processes be the bottleneck to your innovation. Act now!

Build your instant quote now at JS Precision and get a clear, transparent quote comparing multiple processes and a professional DFM analysis report in 60 seconds. Let our expert team help you make the smartest decisions and accelerate your ideas to market!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com

Resource