5 axis vs 3 axis CNC machines are among the most important considerations that are difficult to escape when it comes to precision manufacturing.

Given the presence of complex curved surfaces, angled holes, and multi-faceted precision features within your design, you have to choose between performing the machining on the 3 Axis machine through multiple clamping setups or opting to do it on the 5 Axis machine through a single setting.

To provide the best cost-effectiveness and quality for engineers and buyers, the first step towards making the correct decision would be to comprehend the differences and variations between the 5 axis and 3-axis CNC machining. In the following article, a concrete analysis on the differences and variations between the two machineries would be presented.

Key Answer Summary

| Comparison Dimensions | 3-axis CNC Machining | 5 Axis CNC Machining | JS Precision's Perspective |

| Core Capabilities | The machine traverses in three linear axes (X, Y, and Z), machining one surface in one clamping setup. | In 3-axis machining, the inclusion of two rotary axes makes it possible to machine five surfaces and complex curved surfaces in one setup. Not all the components undergo 5 Axis machining. | We advise the cost-effective machining process according to your components. |

| Cost Breakdown | The costs of the machine tool and manpower are reduced, but additional processing of complex components increases the number of clamping processes and the cost of fixtures. | 5 axis lathe are expensive and programming is expensive too, but through reduced processing and fixtures, the cost of processing complex components can be brought down. | We provide transparent costing and break down the actual cost of 5 Axis CNC processing. |

| Best Applications | Parts requiring machining in multiple planes in addition to plate-like parts and prisms. | Aerospace parts, impellers, turbines, complex molds, medical implant parts, and other 5 axis machined parts involving continuous curved surfaces and angled elements. | We have an entire matrix of machines ranging from 3-axis to 5 Axis machining so that your job can be done by the appropriate machine. |

Key Takeaways

- The salient benefit of 5 axis CNC machining can be stated as machining complex geometries within a single clamping setting, thereby enhancing accuracy, surface finish, and reduced operations.

- For simple components, 3-Axis machining is more economical, while for complex components, 5 Axis machining can cut down the overall expenditure through enhancement in overall efficiency.

- In choosing a contract manufacturer, experience in implementing technologies, ability to integrate processes, and quality control processes are what should primarily be considered and not the brands of machine tools.

5-Axis vs. 3-Axis CNC: JS Precision Helps You Make The Right Decision

Precision manufacture, the professionalism of 5 axis CNC machines, becomes the decisive factor in the overall competitiveness of products, while the right choice between 5 axis vs 3 axis CNC machines is crucial for cost optimization.

The International Organization for Standardization standard ISO 10791-6:2014, “Machine tools - Test conditions - Part 6: Geometric accuracy of 5 Axis machining centers” specifies criteria for accuracy assessment and application limits for 5 axis machining centers in an accurate manner by emphasizing rational selection.

JS Precision claims more than 15 years of practical experience in both 5 axis and 3-axis machining. JS Precision has served more than 500 clients in high-end industries like aerospace, medical, and automotive. It has completed over 1000 customized machining projects for complex parts.

We not only have top-grade 5 axis and 3-axis machining equipment manufactured by German DMG MORI and Japanese Mazak, respectively, but also employ a group of engineers skilled in CAM programming, process optimization, and quality control.

With the use of our proprietary process database, we can immediately find an optimum solution in machining for various parts.

For example, the orthopedic implant project of a medical client had suffered from large accuracy fluctuations and long delivery cycles when using 3-axis machining. Optimized with 5 axis CNC machining, the form and position tolerances of the part eventually stabilized within ±0.02mm, the delivery cycle shortened by 40%, saving 25% of the total cost for the client.

Our success stories stretch from single-piece prototypes to mass production, all verifiable and traceable with every piece of data.

If you find yourself in a dilemma regarding the choice between the benefits offered by 5 axis vs 3 axis CNC machining, or if you have the same doubts regarding the cost and delivery risks associated with 5 Axis machining, do not hesitate to get in contact with the JS Precision technical team.

What Is The Core Difference Between 5-Axis And 3-Axis CNC?

It is very important to understand that knowledge about the disparities in dimensions of motion and flexibility in machining is essential to ensure a right purchase decision between a 5 axis vs 3 axis CNC.

5 Axis vs 3-Axis CNC: What are the Differences?

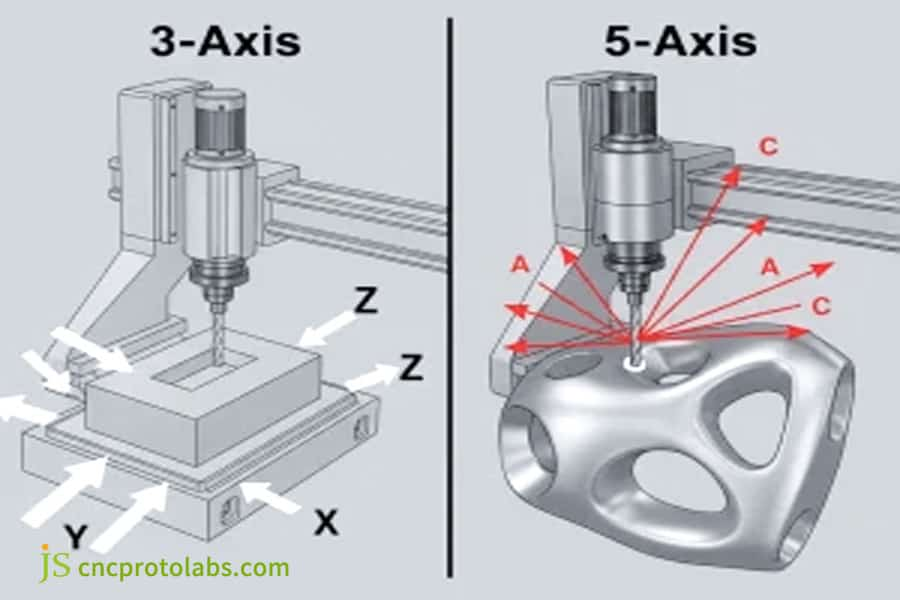

A 3-axis CNC machine is limited to movement based only on the X, Y, and Z axes, which enables it to perform machining operations on the top surface of the material in one setup.

A 5 axis CNC adds two additional rotary axes, A and C, enabling the tool to approach the workpiece from multiple angles, therefore enabling the machining of five surfaces and complex, curved surface areas in a single setup. This is a huge leap forward in quality, efficiency, and even design freedom, hence, complex parts have taken a liking with 5 axis CNC machining.

Why "reduce the number of setups"?

One of the key advantages of 5 axis vs 3 axis CNC is the reduction in setup numbers. Multiple clamping operations accrue positioning errors and affect the accuracy of parts. 5 Axis machining finishes multi-faceted machining within a single clamping and cuts this error right from its source, saving clamping time and labor costs and reducing part damage liability.

Figure 1 A three-axis machine tool runs along three linear axes, while a five axis machine tool adds rotational motion.

Decoding The Cost: 3-Axis Vs 5-Axis CNC Machining Price Factors

It is a common misconception that 5 axis CNC machining is always costly than 3-axis machining. This is not true. There is a lot that goes into determining the CNC 5 axis price. It is not a matter of calculating the cost per hour.

3-Axis vs. 5 Axis CNC Machining: Price Comparison

| Comparison Dimensions | 3-Axis CNC Machining | 5 Axis CNC Machining |

| Machine Tool Purchase Cost | 50,000 to 150,000 US dollars | 200,000 to 800,000 US dollars |

| Hourly Rate | 40-80 USD/hour | 80-150 USD/hour |

| Number of Clampings | Multiple, requires specialized fixtures | Single, no complex fixtures required |

The benefits associated with 3-axis CNC may include lower cost of purchasing and operating a machine tool and easy programming. However, complex parts demand numerous clampings, which may result in a loss of accuracy.

Although 5 Axis CNC may involve high cost of purchasing a machine tool and programming, the “single clamping” technique makes it less expensive compared to producing complex parts with 3-Axis CNC.

What are the key factors influencing the final 5 Axis CNC quote?

The CNC 5 axis price is adjusted with the project, and the core influencing factors:

- The complexity of the part.

- The type of material to be worked (if it is a difficult-to-cut material such as a titanium alloy, it is more difficult. this raises the cost).

- The accuracy required.

- The lot size (small lots of complex workpieces).

When to Use 3+2 Axis Positioning Machining?:

There is a coupling between 3 axis vs 5 axis CNC machining. 3+2 axis positioning machining is appropriate for rectangular parts with various discrete inclined surfaces.

Inclined surfaces can be machined by fixing the workpiece to a constant angle to rotate it and performing 3-axis machining to allow 3+2 axis positioning machining to reap the primary benefit of smaller clamping. This is a feasible approach for determining the price of a 5 axis CNC machine.

Interested in understanding which machining technique and cost to budget for your component? Please feel free to contact JS Precision to obtain a precise machining price for your 5 axis machining or 3-axis machining requirements along with a suitable CNC machining plan. Schedule a consultation to receive a free detailed cost analysis report.

Figure 2 Considering the complexity of five axis machining, its programming difficulty will also be greater, and the programming cost will be higher.

How To Choose: 5-Axis Or 3-Axis For Your Project?

When it’s time to choose between 5 axis vs 3-axis CNC machining, there’s no need to simply look for the best possible option. The important thing to bear in mind here is to consider the needs of the project. This can all be done by asking these few straightforward questions:

- Are there multiple accurately interconnected machining surfaces in the part? Yes → Prefer 5 axis.

- Does it have deep cavities, inclined surfaces, and curved surfaces? Yes → Better for 5 axis machining.

- Is the part a simple plate or prism? Yes → 3-axis is the more economic choice.

- For small prototypes/complex components – 5 axis machining offers high flexibility. For large-scale simple components – 3-axis machining or specialized machines would be appropriate.

Collaborative Engineering Recommendations from JS Precision:

JS Precision engineers make their entry during the process of quoting with manufacturability analysis. By optimizing the design parameters, for instance, the value of the angle of inclination for the inclined plane, complex components can also be manufactured by 3-axis machining, thus resulting in savings.

Evaluating 5-Axis CNC Machining Center Manufacturers

The selection of good 5 axis cnc machining center manufacturers is very important for ensuring the quality and speed of 5 axis machining. It is insufficient to concentrate only on the 5 axis machining center model. The users and abilities of the equipment also have to be considered.

Capabilities to be considered while short-listing 5 Axis CNC Machining Center vendors:

- Technical experience and software capabilities: Evaluate the experience of the CAM programming team with respect to complex toolpath planning,

- Process chain integration: Are they in a position to offer services for the entire process range, such as machining, measurement, and surface treatment

- Quality control testing and certification: Do they offer online testing equipment and ISO 9001, AS 9100, certification systems?

- Communication and Transparency: Can they explain their process in detail and share DFM reports?

Important Details to Focus On during the Factory Tour

While visiting 5 axis cnc machining center manufacturers, the important areas to focus on include:

- The workshop environment and maintenance.

- The quality of inspection equipment, such as coordinate measuring machines.

- The work in progress, including work-in-progress management of the machine-tool side.

The Value of "One-Stop" Capability and Objectivity

Companies with the capability to offer high-end 5 Axis machining as well as effective 3-axis machining (e.g. JS Precision) can then offer optimal process choice from an integrated project perspective, with due regard for customer interests.

JS Precision is a professional 5 axis CNC machining center manufacturer, possessing top-class machinery, technical staff, and a comprehensive quality control system. Looking for a reputable 5 Axis machining solutions provider? Let’s schedule a factory tour today, and we’ll arrange an assigned account manager for your service needs.

Must-Machine Parts: The Domain Of 5-Axis CNC

Certain complicated components involve 5 axis CNC machining for sophisticated production. The main categories under typical 5 axis machined parts are premium industries, which include aerospace structural parts, impellers, turbines, complex molds, complex mold cores, precision medical devices, and premium auto parts.

A 5 axis lathe is a type of 5 axis turning and milling machine that surpasses others in the category of 5 axis machining, focusing on rotating parts with eccentric or radial surfaces (like shafts and flanges), accomplishing one-time setup, all-inclusive machining.

Need to machine the above-mentioned 5 axis machined parts or are unsure about part compatibility? Contact JS Precision for a one-stop service based on their extensive experience in 5 Axis machining of complex parts. Submit your requirements to receive a free machining feasibility assessment.

Figure 3 Five axis CNC machining has particular advantages in high-precision industries, such as producing complex components such as turbine blades and engine parts for the aerospace industry.

Case Study: From 3-Axis Struggle To 5-Axis Success – A Turbine Housing Redesign

Regarding a comparison between the advantages of 3 axis vs 5 axis CNC in practical work, it is more effectively conveyed in example form. Here is a case study of JS Precision helping a customer overcome the difficulties of 3-axis machining with 5 Axis machining:

Client Motivations

A small turbine stainless steel housing from a certain energy equipment manufacturer was originally machined using 3-axis CNC with 4 clamping processes.

This part contains 8 inclined fluid channels and irregular flanges, and there are obvious bottlenecks in 3-axis machining: the processing time for a single piece is as long as 28 hours, and the delivery time is severely delayed.

The perpendicularity and hole position accuracy of different surfaces are difficult to ensure stably, with a defect rate of up to 8%. Repeated clamping results in poor consistency of parts, affecting subsequent assembly efficiency.

JS Precision Solution

After getting the requirement, JS Precision performed a comprehensive analysis for the part structure and the original processing method. Our understanding is that the complexity in part structure is where the benefits of 3 axis vs 5 axis CNC machining are obvious. 5 axis CNC machining can basically address the problem of errors in clamping and efficiency.

Our solution is as follows:

- Process Reassessment: A reassessment of the part machining process revealed the inclined fluid passages and irregular flanges as the major machining difficulties with resulting strategies tailored accordingly.

- Equipment Selection: For our project, we chose a German-made DMG MORI 5 Axis CNC machining center. The selected equipment can precisely machine complicated parts.

- Clamping Optimization: Specific tooling was developed for single clamping of the part to eliminate the problem of multiple clamping mistakes.

- Programming: It was achieved by optimizing the toolpath with CAM programming software. Side milling was carried out to cut the inclined surfaces. The drilling and milling stages of cooling channels were combined in a single program to decrease the process changeover time.

Data Comparison

| Indicators | Original 3-axis Machining Solution | JS Precision 5 Axis Machining Solution |

| Machining Time | 28 hours/piece | 10 hours/piece |

| Number of Clamping Attempts | 4 times | 1 time |

| Key Accuracy (Surface Perpendicularity) | ±0.1mm | ±0.025mm |

| Defect Rate | 8% | Below 0.5% |

| Total Cost (including materials, labor, and equipment depreciation) | $1200/piece | $936/piece |

Results

Using the 5 axis CNC machining solutions, the customer was able to increase the quality of the parts that were assembled while also improving the ability to meet the production requirements annually without having to make any investments.

The customer was able to reduce the production costs by 22%, the cycle of delivery by 64%, and the competitiveness of the markets by a significant margin.

If you too are struggling with similar machining issues and would like to enhance the quality, lead time, and lowering costs with 5 axis machining, please do not hesitate to contact JS Precision. We will create a tailored 5 Axis machining solution based entirely on your project requirements. Please share your project information to get free process optimization recommendations and 5 Axis machining cost estimates.

Figure 4 Small turbine stainless steel shell

Can You Customize a 5-Axis CNC Machining Solution For Us?

JS Precision specializes in catering to tailored 5 axis machining requirements. The main strength here is the holistic technical support offered through extensive engineering know-how. Starting from uploading 3D drawings, follow up throughout the process to transform design requirements into efficient and low-cost implementation solutions.

Main responsibilities of the project team:

- Analysis for manufacturability to detect difficult-to-machine parts and cost waste points in advance.

- Simulation for several process paths (simulator for pure 3-axis, 3+2-axis, and 5 Axis linked processes).

- Offering transparent solutions.

- Integration of other value-added services such as coordinate measurement and non-destructive testing.

Our Customization Process

- Alignment in understanding about performance, budget, and application.

- Competitive optimization of process solutions.

- Clear execution process and real-time sharing of execution progress.

- Optimization of continuous parameters to reduce costs through efficiency improvement after mass production.

Begin Your Project Today

Need custom work? Just send in your part drawings and basic information, and we'll get back to you with a professional recommendation in 24 hours or less, including a 5 axis machining manufacturability study, 5 axis vs 3 axis CNC recommendation, and price quote.

FAQs

Q1: Can a 5 Axis CNC machine always produce a better surface finish than a 3-axis one?

Yes. In case of surface machining, for example, 5 axis CNC machining enables the cutting tool to remain in an optimum cutting position, thereby preventing defects in machining in the low linear velocity range around the center of the ball end mill and achieving a superior finish. This is among the most notable differences for machining quality when compared to 3-axis CNC machining.

Q2: My project involves complex work, but I have limited funds. Are there any options in between?

Yes. The best economical compromise would be 3+2 axis positioning machining (also known as indexing machining). It involves rotating the work piece to a certain angle and machining it by fixing it, later it carries out machining in 3 axis mode. It may not be continuous cutting but helps to a great extent in cutting down the CNC 5 axis price.

Q3: What is the smallest batch size for a 5 Axis machine?

There is no limit on the minimum batch size in 5 axis machining. Even for single-piece prototype production, if the geometry is complicated enough, 5 Axis machining can often be the best choice because it eliminates tool design and manufacturing time and is thus favored in rapid prototype manufacturing and small batch trial production.

Q4: How to determine whether a supplier truly has 5 Axis machining capability?

This can be determined by three dimensions: First, ask whether they have physical samples or videos that can prove typical 5 axis machined parts they have machined, second, what methods and equipment do they use to measure the accuracy of their items, third, what is the cycle of their machine tool's accuracy calibration, how does the quality control process run.

Q5: What is the difference between a 5 Axis turning-milling lathe and a vertical 5 Axis machining center?

The core use scenarios are different. 5 axis lathe main use for turning, and good at processing rotary parts, five-axis vertical machining center mainly used for milling, good at box-type parts and mold type parts processing, should be determined according to the main characteristics of the part.

Q6: Is delivery time and communication guaranteed when performing 5 Axis CNC machining in China?

Guaranteed. This is made possible through project management and communications teams of global suppliers like JS Precision. The processes are more or less transparent with the use of standardized online platforms for project tracking. The lead time and communications process will be the same as those of global suppliers with more benefits related to costs.

Q7: What formats of design files do you accept?

We support many common designs file formats, but for 2D and 3D designs, we support only STEP, IGES, SLDPRT, or X_T format designs. We also accept designs in DXF or DWG format for 2D designs. The most common neutral format for designs is STEP.

Q8: Can 5-axis CNC machine process composite materials or plastics besides metals?

Yes. The machining of high-performance composites like carbon fibers, engineering plastics like PEEK, and resin blocks in prototype manufacturing is also exercised in 5 axis CNC machining. This also includes high-precision molding of complex shapes.

Summary

The decision to choose between 5 axis vs 3-axis CNC machining involves much more than simply "high-end" versus "low-end" quality. Although 3-axis machining may still be an economically irreplaceable option when it comes to making simple components, the strong point of 5 axis machining, "completing complex machining in a single setup," gives it the optimal price to performance ratio.

While selecting a 5 axis machining center, it is always important to know the complexity level of the part that has to be machined. Selecting good 5 axis cnc machining center manufacturers is always important.

JS Precision, with full capability on 3-axis, 5 axis, and mill-turn jobs, remains dedicated to serving you with an objective analysis of process performance as well as manufacture with no limitations imposed by our machines. We can bring your designs to usher you into precision with performance as well as economy.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com