5 axis CNC machining services are an essential service for overcoming the limitations in traditional machining in premium sectors like the aerospace industry and medicine.

Three-axis machine tools tend to get jammed while dealing with deep cavities and curved surfaces, while multiple clamping is not only inefficient but also full of inaccuracies. 5 axis machining helps overcome these issues.

The market in many cases is very confusing, and engineering professionals usually encounter three kinds of dilemmas: What is basically the benefit of 5 axis machining? What is its technology limit? How to find qualified suppliers & get a quote?

This article uses data to explain the logic involved in cutting costs and increasing efficiency through 5-axis machining per clamping cycle, explain what distinguishes "True 5-Axis" versus "False 5-Axis," and offer a method for comparing precision 5 axis machining services bureaus.

At the end of the article, you will understand that the combination of a powerful online platform and deep engineering capabilities as a custom 5 axis CNC machining partner is the key to the success of the project.

Key Answers Overview

| Key Questions | Key Insights | Action Guide |

| Can 5 axis machining be a money-saver? | Saves machine fixture time per operation cycle, lowers production costs by as much as 30-40%, lowers rework by having great precision. | Consider overall investment costs and not merely per-unit costs. |

| What are the limitations of 5-axis machining? | Tool overhang is susceptible to vibration, ball end mills are balanced with efficiency requirements, and cooling is challenging for deep cavities. | Design considering tool accessibility and collaborating with suppliers to optimize processes. |

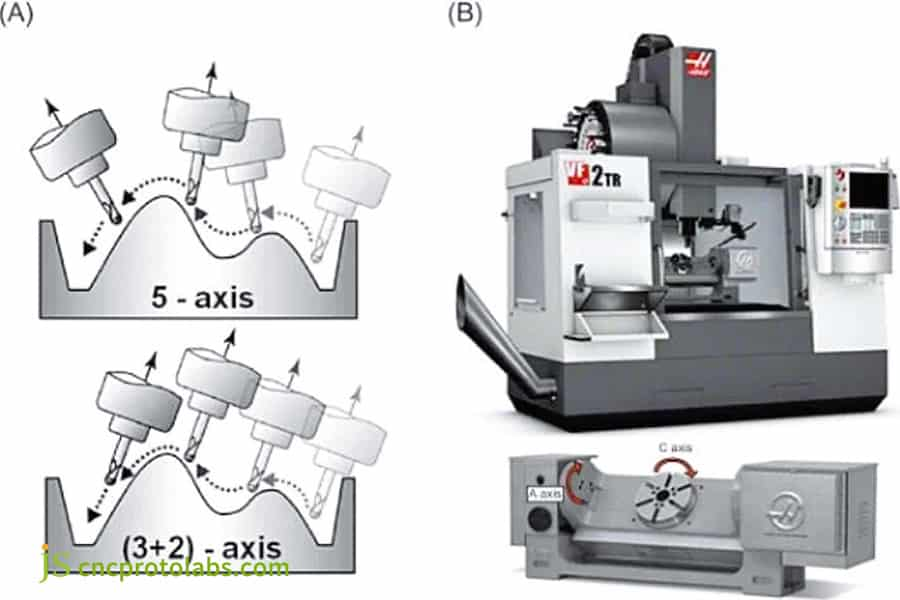

| Why prefer 5-axis techniques over 3+2? | Surface accuracy with 5-axis linkage is ensured, and with this technology, one-pass molding is possible for components such as impellers. | Complex surfaces call for specified continuous 5-axis machining. |

| How to select suppliers? | Verify quality of machine tool makers by checking their machines' accuracy, industry certifications, and ability to deliver against 98% or higher rates of on-time delivery. | Use a technical checklist for due diligence and request a typical component inspection report. |

| What is needed for a genuine quote? | Upload complete model drawings, specifying materials, tolerances, and processing requirements. | Enter specifications for a product into a smart system to generate a runnable quote. |

Key Takeaways:

5 axis CNC machining services lower overall production costs substantially for mass-produced components by reducing multi-position clamping procedures, implicit benefits are well beyond differences in individual costs.

Familiarity with physical constraints in 5 axis machining—like tool vibration and chip removal—is a basic prerequisite in effective design cooperation with skilled engineers from the outset.

The differences between 3+2 indexing and pure 5 axis CNC machining affect the performance and appearance of complex curved surfaces directly.

When evaluating suppliers, technological ability (accuracy/machine type) and quality management system ability (certifications) are valued more than price, and the ability to deliver under difficult conditions is the essential guarantee for long-term relationships.

A good online 5 axis CNC machining quote system will reflect the technical integration and responsiveness of the supplier, while a "design-manufacturing" closed loop will maximize the 5-axis machining capabilities.

Why Trust This Guide? JS Precision's 5 Axis CNC Machining Capabilities

As a firm that has experience in precision manufacture for 15 years, JS Precision boasts in excess of 20 state-of-the-art five axis CNC machine, incorporating essential machines such as the DMG MORI DMU 50 and Haas UMC-750 equipped with Heidenhain control and Renishaw in-machine probes, promoting a precise machining repeat accuracy of ±0.003mm.

Over 500 world-class clients have been served, including aerospace, medical, and automotive precision industries. More than 10,000 projects for complicated parts have been completed by our 5 axis CNC experts who consist of several chief engineers.

Over 1,200 sets of titanium alloy supports for turbine blades have been shipped to aerospace corporations in Europe and America, and minimally invasive instrument housings with a tolerance of ±0.005mm have been processed for our medical customers, of which 99.8% passed.

We are triple-certified (AS9100D/ISO 13485/ISO 9001) and have built a traceability quality system throughout our processes. A report detailing the inspection of each part by our CMM and a certificate of material traceability is supplied with every batch of components. Value-added services, such as NDT inspection for aerospace components, are also provided.

On the basis of our exclusive database of hard-to-machine materials, we have also maximized cutting parameters in high-temperature alloys like titanium alloys and Inconel, increasing our cutting efficiency by 25% compared to the industry average.

In the machining of components with deep cavity, we use the vibration-damping tool holder method, increasing the pass rate of 18 percentage points beyond that of our rivals.

Are you looking for full-cycle 5 axis CNC machining services from prototype to mass production? Submit basic part information (material, tolerances, batch size) to receive a free machining feasibility assessment and DFM optimization suggestions, avoiding trial-and-error costs.

What Are The Real Cost Savings With 5 Axis CNC Machining?

5 axis CNC is not necessarily expensive. This is due to the fact that the total expense lowered through process improvement is considerable in small to medium-series production.

A Revolution in Single-Setup: Reducing Fixture and Labor Costs

It is possible for 5 axis CNC machining services to perform multifaceted machining in one setup because it slashes dedicated fixture design and manufacturing cost by more than 60%, which is the case when using three-axis machining systems. On the other hand, manual operation time and machine downtime are cut by 40%.

Economies of Scale: The Cost Cliff of a Single Unit in Mass Production

The following is a cost comparison of machining 100 complex aluminum parts (including 3 undercut surfaces and 2 complex curved surfaces):

| Cost Breakdown | 5 axis CNC machining | 3-Axis Machining | Cost Difference Rate |

| Material Cost (USD) | 1200 | 1200 | 0% |

| Jig Cost (USD) | 800 | 2000 | -60% |

| Labor Cost (USD) | 3000 | 5000 | -40% |

| Rework Cost (USD) | 150 | 600 | -75% |

| Total Cost per Unit (USD) | 51.5 | 88 | -41.5% |

Precision Equals Profit: Reducing Rework and Material Waste

The repeatability is very high (e.g., ±0.003mm) for 5 axis CNC machining services. The statistics available at JS Precision indicate that there has been a considerable reduction in material wastage and rework rate after adopting five axis machining. The material wastage rate has come down from over 5% to less than 1% and rework rate has decreased from 8% to 1.2%.

Want to know how much you can save by switching your parts to a 5 axis CNC? Upload your part drawings now, and we'll calculate your costs for free, clarifying the potential for price reductions after scaling up production, ensuring every investment yields maximum return.

What Are The Untold Limitations Of 5 Axis CNC Machining Complex Surfaces?

Knowledge about 5 axis machining centers limitations is a prerequisite for efficient production. Preventing such difficulties in advance can eliminate delays in projects.

The Achilles Heel of Tool Vibration

While machining deep cavities or overhanging features, lack of tool rigidity may cause vibrations resulting in the Ra value increasing from 0.4 to above 1.2μm. JS Precision customarily minimizes this risk of vibration by an average of 80% either by reducing the tool overhang or employing damping tool holders.

Balancing Efficiency, Quality with Ball End Mills

For finishing with ball end mills, low surface finish with Ra of 0.4μm has been achieved using small step over distances that increase exponentially with time. This has been addressed using a high-speed milling cutter strategy or barrel tools with more than 30% increased efficiency.

Internal Challenges of Cooling and Chip Removal

During machining of complex channels in fluid flow systems, a deficiency in coolant reaching the machining area might result in tool overheating. The 5 axis machining centers manufactured by JS Precision feature a spindle center internal cooling system of more than 70 bar along with path programming for optimized removal of chips.

Why Does Your Design Irrevocably Require 5 Axis Over 3+2?

Where components require complex surfaces or dynamic accuracy, 5 axis CNC machining service can only support the process, and it differs entirely from 3+2 indexing machining.

When 3-Axis Machining Encounters Geometric Bottlenecks

For example, using an automotive headlight cover mold as a case study, the undercut surface prevents the 3-axis machine tool from reaching the machining region. Custom 5 axis CNC machining allows adjusting the machining direction freely. Thus, the machining is done in a single pass without grinding by hand.

3+2 Indexing vs. True 5-Axis Linkage: Fundamental Differences

| Comparison Dimensions | 3+2 Indexing Machining | True 5-Axis Linkage Machining |

| Motion Mode | Fixed Angle Post-Inclination 3-Axis Milling | Continuous Tool Direction Adjustment |

| Applicable Parts | Simple Polyhedral Features | Continuous Complex Curved Surface Parts |

| Surface Finish | Ra 1.0-1.6μm | Ra 0.4-0.8μm |

| Machining Efficiency | Medium | High (Reduces Path Overlap) |

| Typical Applications | Box-Type Parts | Impellers and Turbine Blades |

Case Study Insights: The Victory of Integrated Manufacturing

In aerospace applications, the introduction of 5 axis machining centers has allowed for integrated machining of turbine blades, thereby reducing several component welding steps to only one, enhancing strength by 40%, and adopting aerodynamics by 15%, which could not have been achieved through 3+2 machining.

How To Evaluate a 5 Axis Machining Provider For Critical Projects?

While choosing a precision 5 axis machining services supplier, it is more important to consider their capabilities and quality management system rather than the price tag.

Technical Capabilities List: An Exploration of "Hard Power"

- Machine Tool Configuration: Must have five-axis linkage capability, table travels commensurate with part size (usually 500-2000mm).

- Accuracy Indicators: Repeatability ≤ ±0.003mm, spindle speed.

- Auxiliary Systems: With in-machine measuring system, tool magazine capacity > 60 tools.

- Process Accumulation: Experience in processing similar complex parts, such as cases in the aerospace and medical fields.

Certifications: The "Cornerstone of Trust" for Quality Systems

- AS9100D: Essential for the aerospace industry, emphasizing traceability and process control.

- ISO 13485: Medical industry standard, strictly controlling cleanliness and process validation.

- ISO 9001: Basic threshold, ensuring basic quality control capabilities.

Delivery Resilience: Stability Beyond Promise

High quality suppliers need to meet on-time delivery rates>98%, urgent service capabilities (48 hour sampling), and contingency plans to cope with supply chain fluctuations. JS Precision has a flexible production line consisting of 20+ five axis CNC machines, achieving a on-time delivery rate of 99.2%.

Want to mitigate supplier selection risks? Contact us with the note "5-axis supplier evaluation" to receive a free "Precision 5 Axis Machining Services Supplier Due Diligence Checklist." Verify each item on the checklist to ensure you choose a reliable partner.

How To Get An Accurate Online 5 Axis CNC Machining Quote?

A precise online 5 axis CNC machining quote can provide reliable basis for project planning, and the key is to provide complete information.

Information Completeness: The Cornerstone of Accurate Quotes

- Upload a complete 3D model (STEP/IGES format) and 2D drawings (PDF/DWG).

- Specify dimensional tolerances (e.g., ±0.05mm) and geometric tolerances (e.g., flatness 0.02mm).

- Specify surface roughness requirements (e.g., Ra 0.8μm).

Process Selection Transparency: An Integral Variable in Costs

It is necessary to clarify the material type (such as 6061-T6 aluminum alloy, 17-4PH stainless steel), surface treatment (anodizing, sandblasting), post-treatment requirements, and whether a first article inspection report (FAI) is required.

Intelligent Engine: Automation from Data to Price

There is an online 5 axis CNC machining quote system in JS Precision that, through AI, analyzes features in a model, determines corresponding machining methods, and automatically quotes the processing procedure in 3 minutes. The data shows that after the information specification is submitted, the accuracy of the quotation reaches over 98%.

Want a quick and accurate quote? Organize the 3D models and drawing information of the parts as required, submit them to the JS Precision quotation system, and you will receive a free executable price plan, with a clear understanding of the cost composition of each link.

JS Precision's Success Story: How 5 Axis CNC Integrated Machining Reshapes Aerospace Brackets

Challenge: The Burden and Risk of Multi-Part Assembly

The landing gear bracket project of a certain drone enterprise originally adopted a 3-axis machining+assembly mode, with 8 7075 aluminum alloy parts connected by 32 M5 screws. The blank weight of a single set of brackets is 1.8 kilograms, with a processing cycle of 12 days per set and an assembly time of 2.5 hours per set.

The assembly errors were generally over ±0.15mm. After a high-frequency vibration test for 1000 hours, 30% of the samples showed stress cracking in the joints, while the overall price of each set reached $3200.

JS's Solution: Three Steps to Integrated Precision Manufacturing

Upon receiving the requirements, JS Precision optimized a custom 5 axis CNC machining solution.

Step 1: Topology Optimization and DFM Collaborative Design:

On the basis of ANSYS load simulation topoptimization, it was ensured that tensile strength ≥ 540MPa & yield strength ≥ 480MPa. Integration of eight parts into a combined component resulted in an optimum blank mass of 1.3 kg.

Step 2: Five-Axis Process Planning and Simulation:

The five-axis linkage tool path was planned, verified in Vericut simulation, avoided three possible tool interferences, and the spindle speed and feed rate were set to 8500 rpm and 3800 mm/min, respectively.

Step 3: High-Precision Five-Axis Execution and In-Machine Inspection:

We employed a five-axis machine tool, namely, the DMG MORI DMU 50, which was coupled with a vacuum fixture, facilitating one-time clamping and machining. Tolerances regarding key hole diameters were maintained within ±0.013 mm, and geometric tolerances within ≤ 0.02 mm, thus decreasing the machining cycle to 5 days per set.

Results: Triple Breakthroughs in Performance, Weight, and Cost

- The weight of the finished bracket has decreased from 1.2 kilograms to 0.9 kilograms (a 25% reduction in weight).

- The utilization rate of raw materials has increased from 66.7% to 69.2%.

- The manufacturing cost has been reduced to $2080 per set (a 35% decrease).

- The vibration fatigue life has been increased from 800 hours to over 8500 hours (a tenfold increase).

- Batch production of 100 sets with zero defect rate, with a delivery cycle shortened by 58.3% compared to the original plan.

If you have integrated manufacturing needs for complex parts, immediately view our complete case library or submit your part design concept, and we will customize a dedicated 5 axis CNC machining services solution for you.

How Does JS Precision Redefine The Standard Of Complex Surface Machining?

With its technology ecosystem, closed loop approach, and iron-clad quality principles in place, JS Precision has set a new benchmark in custom 5 axis CNC machining solutions.

Technology Ecosystem: High-End Equipment and Process Think Tank

We have superior 5 axis machining centers, such as the DMG MORI DMU 50 and Haas UMC-750, and have prepared unique cutting condition data sets for hard-to-cut materials like Ti alloys and Inconel, so that we can tackle various challenging machining problems.

To further improve data support, the following is a comparison table of core parameters and efficiency for five axis machining of different materials, all of which are from JS Precision's actual production verification:

| Material Type | Spindle Speed (rpm) | Feed Rate (mm/min) | Depth of Cut (mm) | Tool Coating | Machining Efficiency per Hour (cm³/h) | Pass Rate (%) |

| 6061-T6 Aluminum Alloy | 12000 | 5000 | 0.5-1.2 | Hard Anodized | 850 | 99.8 |

| 7075-T6 Aluminum Alloy | 10000 | 4200 | 0.3-0.8 | TiAlN | 680 | 99.5 |

| 17-4PH Stainless Steel | 6000 | 2800 | 0.2-0.5 | CrN | 320 | 99.2 |

| Titanium Alloy Ti-6Al-4V | 3500 | 1500 | 0.1-0.3 | AlTiN | 180 | 98.8 |

| Inconel 718 | 2800 | 1200 | 0.08-0.2 | HfN | 120 | 98.5 |

| PEEK Engineering Plastics | 8000 | 3500 | 0.4-1.0 | Uncoated | 720 | 99.6 |

"Design-Manufacturing" Collaborative

In this case, JS Precision engineers make their presence felt during the design stages with DFM analysis to maximize functions like thin-wall and corner radius design, thereby ensuring increased efficiency by more than 30% and reduced costs by about 20%.

Quality Ironclad Rule: Data Driven Verification Throughout the Entire Process

From raw material inspection upon arrival at the factory, to on machine testing during processing, and finally to coordinate measuring machine (CMM), complete data is recorded at every stage to ensure the traceability of parts and meet the requirements of high-end industries.

FAQs

Q1: What is the minimum batch size for five axis machining?

One-off or limited production with 1-10 pieces may use 5 axis CNC machining as it saves on tooling cost as there is no need for fixtures in this precision technique of cutting and machining materials.

Q2: What surface roughness can be achieved?

The precision machining of 5 axis CNC machining services can reach Ra 0.4 μm or even lower, depending on the material, tool, and process. Among them, aluminum alloy is easier to obtain a smooth surface than steel.

Q3: What is the maximum size of parts which can be machined?

The maximum machinable size is machine travel dependent. For example, JS Precision’s 5 axis machining centers are supplied with tables ranging from 500mm to over 2000mm, and there is machine capability to match whatever size is necessary for the job.

Q4: Are there additional challenges in machining difficult-to-machine materials such as titanium alloys?

While machining difficult-to-machine materials like titanium alloys involves some challenges with low speeds required for machining, specialized coatings for machining tools, and high-pressure cooling systems, machining time and costs tend to be relatively high.

Q5: Is 5-axis machining of plastic parts feasible?

A 5 axis cnc machine is capable of complete machining of a plastic part, particularly suited for high-performance engineering plastic prototypes with materials like PEEK and ULTEM. Nevertheless, a proper clamping force is required to avoid deformation of the part.

Q6: How do you guarantee machining accuracy?

At JS Precision, it is ensured by the use of a high-precision five axis cnc machine, machine calibration, in-machine measurement, and the use of a CMM machine after the process of machining.

Q7: What is the typical lead time?

The lead time for simple aluminum parts is generally 2-5 days. For complex steel parts and/or a high quantity order, the lead time is 2-4 weeks. The lead time can be confirmed with our customer service depending on how complex the process is and which projects are running on our production schedule.

Q8: Will there be a difference between the online quote and the final price?

In most instances, if part details are provided correctly by the individual submitting them as well as exact online 5 axis CNC machining quote for those details, differences are minimal. They are normally due to unsaid special requirements for post-processing and inspection.

Summary

The decision on 5 axis CNC machining services is the decision on a manufacturing philosophy of “integration, precision, and economy." Not only does it solve the problem of machining complicated parts, but it also adds a hidden value by optimizing the process.

JS Precision, having strong technical abilities, a complete quality management system, and efficient response to service inquiry, is a trusted partner for engineers.

Now is the time to turn your complex design into a competitive advantage. Upload your 3D model immediately and experience the speed and transparency of the online 5 axis CNC machining quote system. Or directly contact our engineering team to initiate a technical conversation.

Let JS Precision's precision 5 axis machining services be a solid starting point for your product's outstanding performance.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com