5 axis CNC machining services have long been a core support for high-end manufacturing.

An impeller of a complex aero-engine, which used to be processed by five clampings and a few days, can now be finished in just one clamping operation with amazing precision and surface finish within hours. This is not an increase in efficiency but a revolution in design freedom.

5 axis CNC machining technology is the engine to this revolution. As a company deeply rooted for 15 years in the precision manufacturing field, JS Precision has watched countless clients accelerate product iteration and reduce production costs by choosing the right 5-axis machining services.

This guide will show why 5-axis machining has indeed become the cornerstone for producing complex, high-precision parts and how JS Precision masters this cutting-edge technology to be your most reliable partner, from concept through finished product.

Core Answer Table

| Comparison Dimensions | Benefits of 5-axis CNC Machining | Solutions Offered by JS Precision |

| Geometric Capabilities | Capable of machining complex surfaces, undercuts, deep cavities, and other features in a single operation. | Achieves truly integrated complex custom 5 axis CNC machining with advanced equipment and programming software. |

| Precision and Quality | It promises high positional accuracy in one setup, and the continuous toolpath improves surface finish. | As a professional aerospace 5 axis CNC machining company, we apply the most strict quality control system to every step. |

| Efficiency and Cost | Reduced setups shorten total machining time, suitable for small to medium batch production. | Optimized processes and localized rapid response ensure timely delivery of 5 axis CNC machining services near me. |

| Material Challenges | By orienting the tool appropriately, optimal cutting angles can be kept, thus improving stability. | We have a mature process database and dedicated tooling solutions for titanium 5 axis CNC machining. |

Key Takeaways:

- The core value of 5-axis machining lies in completing complex geometries in a single setup, thereby improving precision, surface finish, and shortening delivery time.

- When choosing a service provider, pay close attention to the technical team experience, equipment performance, quality control system, and localized service capabilities.

- Aerospace materials such as titanium alloys are only successfully processed with proper knowledge and stable equipment.

- Getting a transparent online quotation for 5-axis CNC machining is the first step toward the initiation of a project. Ensure that the quotation has a complete process analysis.

How To Optimize 5 Axis CNC Machining Services? JS Precision Practical Experience

With 5 axis CNC machining, JS Precision has accumulated pragmatic experience in the forefront of the industry. Our quality management system strictly follows the International Organization for Standardization (ISO) ISO 9001:2015 quality management system standard, which provides a framework guarantee for our process stability and continuous improvement.

During the past 15 years, we have been serving a wide range of customers worldwide through four major sectors: aerospace, medical, automotive, and high-end consumer goods. We serve scenarios ranging from single-piece prototypes to mass production.

We have reduced the weight of the machined lattice support in a titanium alloy for satellite manufacturers by 35% while maintaining strength, have maintained dimensional accuracy to within ±0.02mm for medical implants, and have enhanced hydrodynamic efficiency by 30% with 5-axis linkages in engine manifolds customized for supercars.

Our optimization experience permeates the whole process: CAM programming, toolpath simulation optimization, adjustment of cutting parameters with material properties, and reduction of positioning errors with single clamping.

This manual is the distillation of tens of thousands of our team's machining practices. Every suggestion has been validated in projects and is trustworthy.

Want to rapidly optimize your 5-axis machining projects? Please submit your part drawings and requirements, and our engineers will be able to offer a free customized process plan. Utilizing our experience in practice, we'll help you mitigate risks and maximize the value of your 5 axis CNC machining services.

5 Axis CNC Machining: Beyond 3D Manufacturing

5 axis CNC machining is well beyond adding two rotary axes, it is almost a concept change in manufacturing-thinking: it makes structures manufacturable, which were unimaginable because of their complexity.

What is 5-Axis CNC Machining?

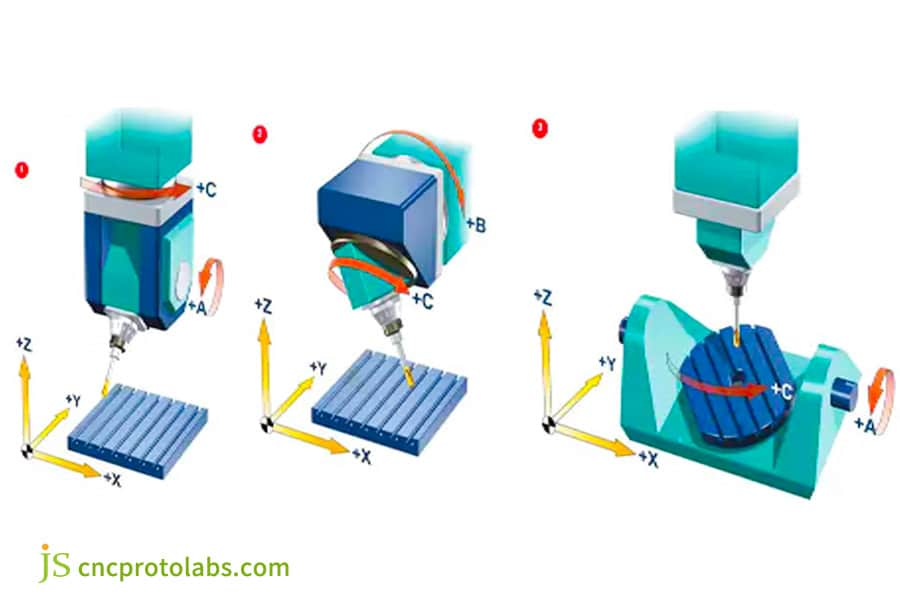

At its core, 5-axis CNC machining integrates three linear axes-which are X, Y, and Z-with two rotary axes, A/B or A/C-to achieve five-axis linkage.

The tool can approach the workpiece from any angle, completing complex feature machining without multiple clamping operations, reducing clamping errors, improving efficiency, and breaking the limitations of traditional 3-axis machining.

Two Core Types: 3+2 Fixed-Axis Machining vs 5-Axis Simultaneous Machining

| Machining Type | Core Principle | Application Scenarios | Core Advantages | Applicable Parts |

| 3+2 Fixed-Axis Machining | Fix the rotation axis angle first, then machine using the X/Y/Z axes, requires more switching. | Polyhedrals, multi-angle holes, batch production of simple yet complex feature parts. | Easy programming, high efficiency, low cost. | Boxes, brackets, multi-faceted drilled parts. |

| 5-Axis Simultaneous Machining | Five axes moving in a simultaneous way, the tool and workpiece are relatively adjusting their position in real time. | Complex curved surfaces, spatial curves, deep cavity undercut parts. | No need for multiple clampings, high precision, integrated processing. | Impellers, turbines, implants, aerospace irregular parts. |

Figure 1:Five axis machining is an advanced subtractive manufacturing technology that allows cutting tools to move on five different axes, achieving unparalleled versatility and precision.

Why Does Your Project Require True 5 Axis CNC Machining Services?

For high-end manufacturing, "true 5 axis CNC machining services" have become a must-have – addressing pain points from three dimensions: design, precision, and cost, thus becoming a core competitive advantage in the high-end field.

Removing Design Constraints: From Design for Manufacturability to Design for Performance

Compared with traditional 3-axis machining, designers have to make compromises in the process requirements. 5 axis CNC machining services break these chains entirely.

The designs can focus on optimum performance by enabling the integrated manufacture of complex structures, reducing assembly steps, and enhancing core performance. Topology-optimized part machining can precisely present lattice structures, balance weight reduction, and rigidity.

There are three major benefits to choosing this service: designing freedom increased, which enables the realization of complicated structures, enhancement of precision integration capability, which improves the critical dimension accuracy by over 50%, a 30%-60% reduction in machining cycle time can be accomplished with scrap rates controlled below 0.5%.

What critical factors must be considered when selecting premium 5-axis CNC machining services?

There are numerous 5 axis CNC machining service providers in the market. Herein, we recommend evaluating them from three dimensions:

- Capabilities: More than 5 years of experience in engineers and programmers for the most complicated parts involves the highest-end CAM software and full-process simulation collision avoidance. The collision avoidance simulation pass rate within the JS Precision programming team is 100%.

- Quality System: Equipped with online testing equipment and a high-precision metrology lab, authorized with certifications like AS9100 and ISO13485. Full inspection reports for every batch of parts are provided.

- Service Ecosystem: From special material procurement to post-processing support, all under one roof, and dedicated project managers.

What Are The Main Technical Challenges Faced By 5 Axis CNC Machining?

The 5 axis CNC machining is far above the technical threshold of traditional machining. A professional 5-axis CNC machining service provider has to provide mature solutions.

Programming Complexity and Collision Risk

5-axis simultaneous programming is very complicated, as five-axis coordination must be taken into account. We use HyperMill high-end CAM software matched with more-than-10-year-experienced programming engineers to generate the best toolpath and assure no collision by virtual machining simulation.

Tool Length/Workpiece Interference

Rotary axis motion can easily lead to interference between the tool holder, spindle head, and workpiece/fixture. We avoid this risk 100% by performing accurate tool length calculations, optimizing fixture design, adjusting rotation angles, and combining simulation interference checks.

Precision Maintenance and Machine Tool Dynamics

Rotary axis accuracy and machine tool rigidity are the most significant factors influencing machining accuracy directly. Equipped with state-of-the-art machine tools from DMG MORI and Haas, positioning accuracy is up to ±0.005mm, besides optimal cutting parameter and tool rigidity optimization for stable dynamic machining accuracy.

How Can Custom 5 Axis CNC Machining Turn Imaginative Designs Into Reality?

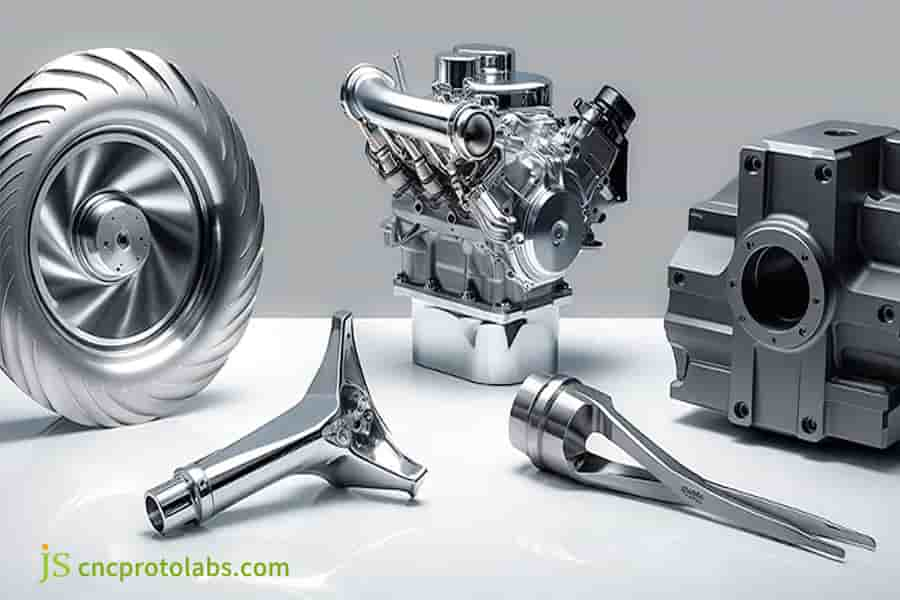

The greatest value of custom 5 axis CNC machining lies in bringing seemingly unmanufacturable complex designs to life, be it aerospace impellers, medical implants, or complex manifolds-all can be integrated and machined with precision.

The customer required aerospace engine turbine blades with complex spatial curved surface and internal cooling channels, something impossible for traditional methods to achieve.

We efficiently completed the job with customized 5 axis CNC machining: design model optimization by engineers based on tool reachability, a 5-axis simultaneous CAM strategy to plan the precise toolpath, using specialized fixtures for one-time clamping, online monitoring for real-time deviation compensation-a combination leading to high-precision delivery.

Custom 5 axis CNC machining is a full-process customized service from design consultation to machining and inspection. If you have a creative design that requires implementation, please upload your 3D drawing for a one-stop solution from design optimization to finished product delivery.

Figure 2:Five axis CNC machining is widely adopted by many industries due to its multifunctionality and high precision.

How an Aerospace 5 Axis CNC Company Meets Stringent Quality Standards?

Most of the components in aerospace require extreme stringency: materials must resist high and low temperatures, high pressures, with tolerance as small as micrometers. For flight safety, each component is critical, hence, aerospace 5 axis CNC machining company face extremely high demands.

The core quality requirements are special materials such as titanium alloys, high-temperature alloys, and complete traceability certificates. Critical dimensional tolerances have to be ±0.01mm, geometric tolerance in accordance with AS9100 standard. Traceability has to be done for the whole process, recording all the parameters.

As a professional aerospace 5 axis CNC machining company, JS Precision is committed to delivering the promise of "full-process control" with:

- Process qualification certification: First article verification for critical components, including dimensional inspection material, and fatigue testing to ensure process feasibility.

- Full-process traceability: in a digital way, record the raw material batches, machining parameters, and inspection data to form a complete traceability chain.

- Advanced inspection technology: Equipped with CMM, blue light scanning, and X-ray flaw detectors, comprehensively inspecting dimensions, geometric tolerances, and internal defects.

Does your aerospace project require reliable quality assurance? JS Precision, as a senior aerospace 5 axis CNC machining company, strictly adheres to the AS9100D aerospace quality management system standard. Submit your requirements to obtain a detailed quality control manual!

Figure 3:Five axis CNC machining can produce complex, high-quality parts that meet the stringent requirements of the aerospace industry.

What Are The Unique Challenges And Solutions For Titanium 5 Axis CNC Machining?

Materials like Ti-6Al-4V alloy are core in many aerospace and medical fields for their high strength and excellent resistance to corrosion. However, titanium5 axis CNC machining poses considerable challenges that have to be addressed with appropriate solutions.

Unique Challenges

The low thermal conductivity of the titanium alloy is a core problem: cutting heat is hard to dissipate and easily leads to high temperatures, work hardening, tool wear, and part deformation. The high strength and chemical affinity increase the cutting forces and make it prone to sticking to the tool, affecting surface quality.

Targeted Solutions:

We have developed a mature process system:

- Optimization of thermal management: high-pressure coolant at 70bar is sprayed directly to the cutting zone, with control over the speed of the cut to reduce heat.

- Cutting parameter adjustment: Under "low speed, high feed," the contact time of cutting forces with the workpiece is reduced.

- Tool selection: To employ PCD or carbide-coated special tools, anti-sticking and wearable.

- Taking advantage of the 5 axes: Rotating the rotary axis angle optimizes the entry angle and improves chip removal channels.

We have done more than 500 items of titanium 5 axis CNC machining projects, with a pass rate of over 99.8%. For any complex titanium alloy parts, please provide your requirement for the structure and precision, and we will try to offer you a customized process solution.

What Is The Value Of Your Parts? Analysis Of Key Factors Affecting Online Quote 5 Axis CNC Machining

In most cases, customers find it confusing when seeking online quote 5 axis CNC machining because of the huge differences in prices. Quotes regarding 5-axis machining depend on several variables. Understanding these will help optimize design for cost control.

Core Influencing Factors

- Material Cost and Machinability: Special materials, like titanium alloys, are more expensive than aluminum alloys. Their machining difficulty is 3-5 times higher, thus leading to quotation marks.

- Geometric Complexity and Programming Time: The programming and simulation time for complex surfaces and deep cavities is 2-3 times longer when compared with simple parts.

- Precision and Surface Finish: Stricter tolerances with higher surface finish requirements increase the process and inspection costs,

- Batch Size and Clamping Strategy: The cost of dedicated fixtures must be amortized in single-piece/small-batch production, mass production can reduce the unit price.

Cost Optimization Suggestions:

Prices can be reduced by relaxing the tolerances for non-critical dimensions, simplifying surface curvature, and selecting alternative materials which are easy to machine - provided performance allows.

Case Study: How JS Precision Processes Complex Titanium Alloy Brackets To Reduce Satellite Weight By 35%

Customer Requirements

An aerospace technology company requires a critical load-bearing bracket for its satellite: Ti-6Al-4V titanium alloy, tensile strength ≥900MPa, extreme lightweight design, lattice plus curved surface fusion design, tolerance ±0.02mm, 8-week cycle, vibration test needed.

JS Precision Solution

Coupled with this challenging requirement, we have set up a dedicated technical team to develop a comprehensive solution:

Design and Process Collaboration:

The engineers were involved right from the start with extensive collaboration with the client's design team to refine the manufacturability of the topology optimization model. This involved appropriately upsizing overly intricate lattice structures for tool accessibility without compromising strength while maintaining core features of the surfaces.

Dedicated Tooling and Programming:

A dedicated vacuum fixture was designed to complete all features in a single setup, thus avoiding positioning errors caused by multiple setups. HyperMill CAM software was used for planning a 5-axis linkage toolpath, utilizing a helical finish milling strategy in order to ensure the accuracy of the surface. Simulation software was harnessed for 100% collision checks.

Specialized Processes in Titanium Alloy:

The technology of 70bar high pressure cooling was adopted, matched with PCD-coated special tools. The cutting parameters were "low speed and high feed" (800rpm, 0.2mm/rev). The purpose is to strictly control the heat generated during cutting to avoid part distortion.

Full-Process Quality Monitoring:

We would get the whole material certificate in the process of raw material purchasing. Then every 2. Every hour, critical dimension checks are conducted, after completion, full-dimensional checks are performed using a coordinate measuring machine. A complete PPAP package is submitted with dimensional reports, material certificates, fatigue test data, etc.

Final Results

This batch of titanium alloy brackets passed the first-time processing qualification, with a 35% reduction in weight and meeting the requirements for strength. It successfully passed the vibration test, shortening the project cycle to 6 weeks, which is 40% ahead of schedule.

We have established a long-term relationship with the customer and have subsequently provided 5 axis CNC machining services for the core components of multiple satellite models.

If your project also faces some challenges such as complex structures, high precision, and lightweighting, please consider this case study. Please submit your particular needs and let us tailor for you a similar custom 5 axis CNC machining solution with mature technology and rich experience to help you get through the difficulties.

Figure 4:Ti-6Al-4V titanium alloy satellite key load-bearing bracket

5 Axis CNC Machining Services Near Me: How JS Precision Delivers Localization Efficiency in China

While looking for 5 axis CNC machining services near me, geographical distance is not an obstacle, the core is “localized” response and collaborative efficiency. Based on three major advantages, JS Precision builds “virtual proximity” services for clients from all over the world.

- 24/7 Agile collaboration: The communication window is adjusted by the customer time zone, with highly overlapping working hours. Tech inquiries are responded to within 2 hours, and progress is communicated remotely in real time, just like a local team.

- Rapid iteration and verification: Based on the Chinese manufacturing ecosystem, raw material procurement, fixture fabrication, sample processing, and testing are completed rapidly, prototypes can be delivered in as little as 3 days, speeding up design verification.

- Supply chain resilience: In cooperation with the best material suppliers around the world, special materials are acquired in a very short time. A mature local supply chain flexibly copes with changes, and efficient logistics reduces the risks during delivery.

Why Is JS Precision Your Best Partner For Complex Parts Manufacturing?

In the manufacturing of complex parts, JS Precision has become the choice of a large number of customers owing to four core advantages.

We possess strong technical capabilities: Equipped with a matrix of high-end 5-axis machining centers from multiple brands, our engineering team has possessed an average 8-year working experience in the industry and is proficient in a variety of material and structural machining processes.

We have specialized expertise: a lot of successful cases within high-profile industries like aerospace and medical, knowledge of quality standards and compliance requirements within these industries, and a quick way to match the exact needs of specific customers.

Guaranteeing quality is our principle: We stick to the zero-defect notion in the whole process, establishing a complete quality control system with several international certificates. Every batch of parts will be provided with a full inspection report.

We pursue deep collaboration: We are not just suppliers, but the extension of our customers' manufacturing capability, participating in problem-solving down the value chain to create win-win outcomes.

FAQs

Q1: What is the minimum tolerance in 5-axis machining?

In high-precision 5-axis machine tools, the tolerance of medium-sized metal parts can reach ±0.025mm and, for small precision parts, it is possible to optimize further to ±0.01mm depending on the material and structure.

Q2: How do you ensure collision safety during 5-axis machining?

Advanced CAM software, including HyperMill, is used to simulate toolpath and perform a full collision check, thus accurately simulating all the motion trajectories of the machine tool, fixture, cutting tool, and workpiece. Engineers will go through it again manually for absolute safety in the machining process.

Q3: Do you provide a first-article inspection report?

Yes, we provide complete first-article inspection for every new project with full-dimensional inspection data, material certificates, process parameter records, and other key information to ensure the first piece will meet customer requirements before mass production.

Q4: What are the differences in strategies for 5-axis machining of aluminum alloys and titanium alloys?

In the machining of aluminum alloys, high speed, 3000-5000 rpm, and a high-feed strategy are used to leverage their excellent machinability and further improve efficiency. In the machining of titanium alloys, it focuses on temperature and force control with low speed, medium feed, and high-pressure cooling to minimize tool wear and part deformation.

Q5: Will it be possible to machine deep cavities or undercut features on parts?

This is the most essential benefit of 5-axis machining. Simply put, adjustment of the rotary axis angle optimizes the posture of the tool when it approaches the machining surface, which enables machining deep cavities up to 200mm with shorter tools, together with undercut features without dissembling the part or using special processes.

Q6: What is the typical lead time from quotation to delivery?

For parts of moderate complexity, the typical lead time ranges from 2 to 4 weeks, depending on the current production schedule, material procurement cycle, and part complexity. Expedited service is available for urgent customer needs, with prototypes delivered in as little as 3 days.

Q7: If my design has minor issues, will you offer suggestions?

Of course. Free manufacturability analysis by engineers in the drawing review step, with specific optimization suggestions to the probable machining difficulties or excessive cost or precision limits in design, helps the client refine their design.

Q8: Besides machining, do you also provide post-processing and assembly services?

Yes, we are providing integrated one-stop services, including post-processing processes: sand blasting, anodizing, painting, and heat treatment. What's more, we can assemble components for simple products based on customer requirements to save supply chain management expenses and enhance project efficiency.

Summary

5 axis CNC machining services are no longer a "luxury" in high-end manufacturing but a "necessity" for breaking design bottlenecks and enhancing product competitiveness.

Here at JS Precision, we are devoted to being the most reliable partner you have for your manufacturing needs, taking your cutting-edge designs and building them into a higher level of performance in precision parts.

Take action now and make your ideas a reality! Just upload your part drawings or CAD models to our online quote 5 axis CNC machining platform, and you will receive a detailed quote and preliminary process suggestions reviewed by professional engineers in a short time. Let's work together to challenge the limits of manufacturing.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com