With a conventional machine tool, the several re-clampings and adjustments needed for an intricate aerospace part or a shaped medical implant take days and introduce cumulative errors.

Where once multiple clampings were necessary, now a single clamping is enough for one "all-around" machine tool to precisely complete all machining from every angle. This isn't futuristic technology, this is a reality being created by 5 axis CNC Machining.

This paper, by experts from JS Precision, will give an in-depth analysis of why 5 axis CNC machining is the inevitable choice for solving complex, high-precision manufacturing challenges and help you understand how to leverage this technology to empower your projects.

Using years of practical experience at JS Precision, we have compiled this comprehensive guide, from basic concepts to real-world examples, so as to give you a complete understanding of CNC 5 axis Machining.

Core Answer Summary

| Core Technical Advantages | Key Performance Indicators | Typical Application Scenarios | Service Provider Core Capabilities (JS Precision) |

| One-Stop Clamping, Five-Sided Machining | Eliminates cumulative errors from multiple clampings, achieving accuracy up to ±0.005mm. | Suitable for complex aerospace components, medical implants, and integrated UAV fuselages. | 12 years of industry experience, serving over 6000 clients, with end-to-end service capabilities from design optimization to quality inspection. |

| Complex Geometry Machining Capability | Reduces vibration using short tools, achieving surface roughness up to Ra 0.8μm. | High-precision parts with deep cavities, oblique holes, and continuous curved surfaces. | Equipped with multiple high-end 5-axis machining centers, capable of machining over 200 materials including titanium alloys and PEEK, and providing professional DFM analysis. |

| Efficiency and Cost Balance | Machining cycle time reduced by 30%-40% compared to traditional methods. | Rapid prototyping and small-batch production of complex parts. | Transparent pricing, allowing clients to enjoy top-tier 5 axis machining services without incurring high equipment investment and maintenance costs. |

Why Is This Guide Different? JS Precision Unveils Practical Techniques For 5 Axis CNC Machining

JS Precision has 12 years of professional experience in 5 axis CNC machining, having provided service to more than 6,000 clients across a wide variety of industries, including those in the fields of aerospace, medical devices, drones, and automotive parts.

For instance, we machined an artificial joint component for a medical company. This part has a complicated spherical structure with a requirement to be made from titanium alloy. It needs control within tolerance of ±0.005mm. We were able to achieve the desired precision by our 5 axis CNC machining technology and drastically reduced the production cycle from the industry average of 15 days to 8 days.

Other examples include our integrated fuselage support for a drone company, where we reduced the weight of the component by 35% while increasing rigidity by 50%.

This book is not a theoretical compilation, rather, it's an accumulation of practical experience from JS Precision over the last 12 years. That includes an overview of core techniques and common mistakes in the machining of different materials and dealing with complicated parts, in which you can absolutely have confidence in its practicality and professionalism.

JS Precision has 12 years of practical experience with CNC 5 axis machining that can solve many complex part machining problems in an efficient way.You can just submit your requirements about the parts, and our technical review and quotation will be issued within 24 hours to advance your project at the earliest.

What Is 5 Axis CNC Machining? Beyond Traditional Manufacturing

Understanding the very essence and structure will help you make informed decisions on whether 5 axis CNC machining is a good fit for your machining needs.

What does 5 axis CNC mean?

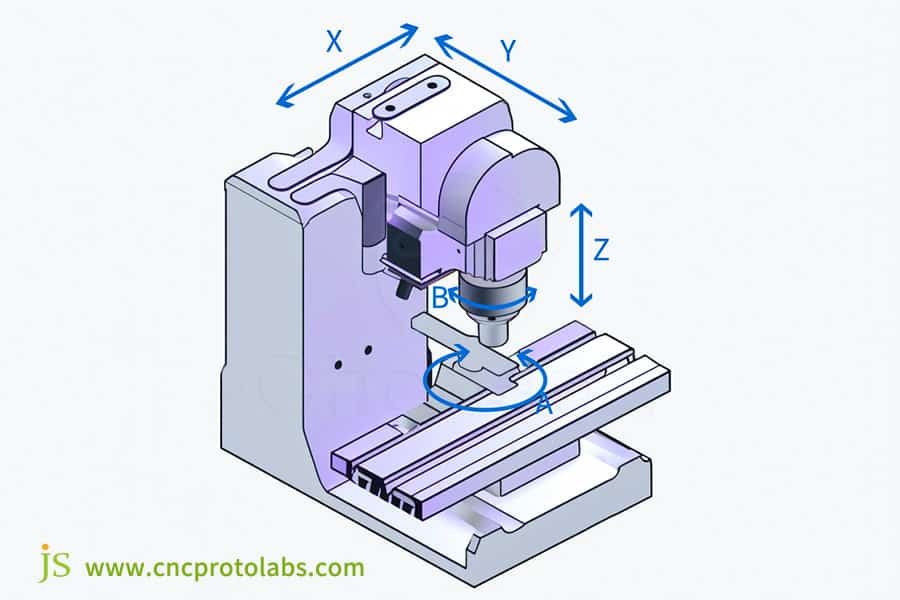

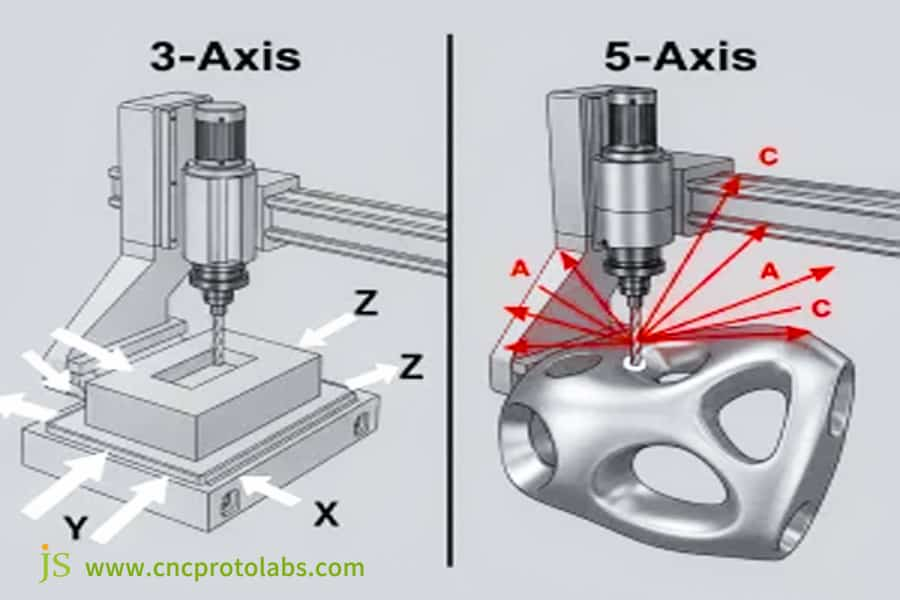

5 axis CNC machining represents state-of-the-art technology in manufacturing. It adds two rotary axes to the basic three linear axes of X, Y, and Z.

The structure can make the tool in any direction approach the workpiece, break through the limitations of the traditional 3-axis fixed-direction restrictions, and hence be highly suitable for highly complex curved surface machining and multi-angle feature machining.

What are the 5 axis on a CNC machine?

Each one of the five axes possesses different functions and motion modes, which all will clearly appear in the following table:

| Axis Name | Motion Mode | Core Function |

| X-axis | The linear motion along the X-axis | Provides left-right positioning of the workpiece and decides on the transverse machining position of the workpiece. |

| Y-axis | The linear motion along the Y-axis. | It accomplishes the front and back positioning of the workpiece, defining the longitudinal position of machining. |

| Z-axis | Linear movement along the Z-axis. | Z-axis Provides up and down positioning of the workpiece; this controls the cutting depth of the tool. |

| A-axis | Stands for Rotation around the X-axis. | This movement changes the workpiece's tilt angle, machining side, or sloped features. |

| B-axis / C-axis | B-axis rotates along Y-axis, C-axis rotates along Z-axis. | To drive the workpiece or tool to rotate for multi-angle machining, such as ring parts or inclined holes. |

A common type of 5-axis machine tool structure is the "rotary table + swivel head." The B-axis rotates the workpiece on the rotary table, and the A-axis performs a swiveling of the head, by which the tool can reach every surface of the workpiece.

The biggest magic of 5-axis CNC machining lies in "one clamping, all done," reducing machining time by over 40% and fundamentally avoiding the cumulative errors of multiple clampings, thus improving part accuracy.

Whether you want to understand what are the 5 axis on a CNC machine or have complex parts to machine, JS Precision's 5 axis CNC machining services will be able to meet your needs. We will develop a customized machining plan according to the characteristics of the part to ensure the best machining result.

Figure 1: Unlike traditional machining processes that operate in three axes (X, Y, and Z), 5-axis machining adds two rotational axes to enhance flexibility and precision.

Why Is 5 axis CNC Machining Able To Achieve Such Amazing Precision?

Among the various factors, many companies choose 5 axis CNC machining. The reason for this lies in its very core: achieving high precision that is difficult to realize with traditional machining. This precision is not accidental, rather, it is determined by three key factors.

1. Fewer Errors: One Clamping Eliminates Cumulative Errors

Traditional 3-axis machining of complex parts requires 3-5 clampings. Each clamping introduces positioning errors that may be accumulated and exceed the tolerances. 5 axis CNC machining allows all feature machining to be completed in one setup.

Taking the machining of complex molds as an example, when traditional 3-axis machining has a cumulative error of ±0.1mm, 5-axis CNC machining can control the error within ±0.025mm, fully meeting high precision requirements.

2. Short Tool Advantages: Reduced Vibration, Improved Quality

5 axis CNC machining involves the use of short tools. The optimal machining angle can be maintained through the rotation of the workpiece or tool on the machine tool. This will significantly reduce short tool cutting vibration. As a result, the surface roughness was Ra≤0.8μm, and tool life is increased by more than 50%, reducing machining costs.

3. Professional-Grade Calibration and Compensation: Maintaining Micron-Level Accuracy

High-end 5 axis machining centers keep their accuracy with technology like dynamic accuracy compensation, real-time correction of minute errors, and thermal deformation compensation, counteracting temperature deformation.

JS Precision has strict requirements when it comes to 5 axis CNC machining center. Spindles and guideways are calibrated every six months while the workshop temperature is kept at 20±2℃ and humidity at 40%-60%. This, together with 100% full inspection using a coordinate measuring machine, has ensured stable part accuracy.

Figure 2: In 5-axis CNC machining, extended tool movement and workpiece accessibility are achieved through two additional rotation axes. This ability is crucial for reducing settings and achieving higher accuracy.

Which Materials Excel On A 5 Axis Machining Center?

One of the main advantages of the 5 axis machining center is its strong adaptability. Almost all kinds of materials which can be machined can show good performance on them. The processing characteristics and applicable industries for different materials are listed in the table below:

| Material Category | Specific Material | Applicable Industry | Processing Advantages |

| Metal Materials | Aluminum Alloy, Stainless Steel, Titanium Alloy, Chromium-Nickel Iron Alloy. | Aerospace, Medical, Automotive, Drones. | Handles the high strength and hardness of difficult-to-machine metals while maintaining processing accuracy. |

| Engineering Plastics | PEEK, ULTEM, Nylon, Polycarbonate. | Medical, Electronics, Automotive. | Precisely controls the temperature of processing to prevent plastic from melting or deforming and losing its strength. |

| Composite Materials and Wood | Carbon Fiber Composites, Glass Fiber Composites, Hardwood. | Model Making, Aerospace Interiors, Special Equipment. | Prevents composite material delamination, reduces wood chipping, ensures surface quality. |

Equipped with a library of over 200 material processing technologies, ranging from low-temperature cutting to temperature control of titanium alloy materials, and the adjustment of spindles to prevent the deformation of PEEK plastics, JS Precision has processed more than 50 types of materials to meet the needs of many industries.

Whether it be titanium alloy, PEEK plastics, or carbon fiber composite materials, our JS Precision 5 axis machining center has the capability to process these difficult-to-machine materials effectively. We optimize the whole process of machining according to material characteristics to ensure part quality and efficiency in delivery.

How To Choose The Best 5 Axis Machining Center Configuration For Your Project?

The right configuration of the 5 axis machining center will find the ultimate balance between machining efficiency and cost. Following are the steps that should be followed:

Define your needs

The key parameters of the part to be identified are:

- Dimensions: maximum length, width, and height.

- Complexity: each with continuous curved surfaces or oblique holes.

- Batch size: small batch of 10 pieces, large batch of 1000 pieces.

- Target accuracy: ±0.025mm or ±0.05mm.

- Material: metal or plastic. These parameters are determined in direct relation to machine configuration.

Key Configuration Considerations

Travel and Table Size: The travel decides the maximum part size that could be machined. For example, a machine tool of travel 600×500×400mm corresponds to a part size up to 500×400×300mm. Table size shall match the part weight and mounting requirements. Heavy parts need a table with large load-carrying capacity.

Rotary Axis Structure: The rotary table structure is suitable for heavy parts.Swivel head structures are suitable for parts with complex curved surfaces being processed. Hybrid (rotary table + swivel head) structure supports flexibility.

Tool Magazine Capacity and Tool Change Speed: 24 tools for small to medium batch production, 48+ tools for large batch and complex part manufacturing. Fast tool change speed reduces waiting time.

CNC System: Only the high-end systems can enable complicated 5-axis simultaneous programming, such as FANUC 31i and SIEMENS 840D.

Investment and Return Analysis

The 5 axis CNC machine price, in general, ranges from $100,000 to $500,000, with increased configurations translating to increased prices. However, high-configuration machine tools can save up to 30% on delivery time and boost yield by as much as 20%, which results in lesser overall costs in the long run. Most companies need not buy them on their own.

They simply need to opt for the services of a provider, like JS Precision, for access to top-tier 5-axis machining center configurations without having to incur equipment costs themselves.

The 5 Axis CNC Machine Price Revealed: Where Does Your Investment Go?

The 5 axis CNC machine price have a very big range-from $100,000 to $500,000. The major costs are focused on:

1. Core Component Costs

The main cost drivers are high-precision dual rotary axes, rigid mechanical structures, high-power electric spindles, and advanced CNC systems. For instance, a high-precision dual rotary axis costs $20,000-$50,000, a 15kW electric spindle costs $10,000-$30,000, and high-end CNC systems from FANUC and SIEMENS cost $20,000-$40,000.

These components directly determine the machine tool's accuracy and stability.

2. Technological Added Value

"Invisible" technologies such as dynamic compensation software (real-time error correction), vibration control technology, and thermal stabilization technology (reducing the impact of temperature) add to the high cost of machine tools.

For instance, dynamic compensation software can cost $5,000 to $10,000 and the thermal stabilization technology costs $4,000 to $9,000. Such technologies enable the machine tool to maintain high precision over long periods.

3. Brand and Reliability

First-tier brands, represented by DMG MORI and FANUC, are about 20%-30% more expensive than second-tier brands but, in return, their stability, precision retention, and after-sales service are more guaranteed.

For example, first-tier brand machine tools have an average MTBF of over 8000 hours while those in the second tier only have about 5000 hours, and their after-sales response is faster.

For most customers, buying an independent 5 axis machining center involves high expenses of purchase, upkeep, and personnel. Collaboration with JS Precision means these costs are eliminated and you reap the best of 5-axis CNC machining services at more economic and efficient levels.

A bit apprehensive regarding the 5 axis CNC machine price? Avail of JS Precision cost-effective 5 axis CNC machining services today to save on equipment purchase and maintenance, send over your part requirements, and we will provide you with transparent pricing and offer efficient machining services.

Figure 4: The picture shows a high-end five axis CNC horizontal machine tool, which can easily exceed a price of 250000 US dollars.

What Are The Key Points To Ensure The Successful Use Of 5 axis CNC Machining Services?

By focusing on the following four key aspects, you will be able to truly leverage the services of 5 axis CNC machining for your project:

1. Design Phase Manufacturability Analysis

Early in the design process, communicate with the service provider to optimize a design from the machining perspective. For instance, ensure the wall thickness of a part is no less than 1mm and the cavity depth does not exceed 10 times the diameter of the tool. This will reduce the difficulty and cost in machining.

Our professional advice from engineers at JS Precision contributes to reducing machining costs by an average of 30%.

2. Professional Programming and Simulation

Compared with the 3-axis, 5 axis machining programming is much more complicated and demands higher software (like UG and Mastercam) and experienced programmers. The simulation of the toolpath is very important so the risks of collision may appear as early as possible.

By simulating the toolpath with RoboDK for over 10 years, our programming team has attained a success rate of 100% with no collisions.

3. The Art of Fixture Design

5 axis machining fixtures need to firmly hold the workpiece with a clamping force not less than 500N and not interfere with the tool. Custom-designed fixtures better adapt to part shapes, ensuring accuracy.

JS Precision has a professional fixture design team that customizes fixtures according to the characteristics of parts to make sure the machines are stably machined.

4. Comprehensive Quality Control

Quality control is performed at every stage: during raw material inspection, spectral analysis to confirm the composition of metals, during online measurement, through machine tool probes detecting critical dimensions in real time, and during final inspection, comprehensive inspection using a coordinate measuring machine.

JS Precision will provide a complete quality inspection report for each part to ensure requirements are met.

JS Precision provides 5 axis CNC machining services, from design optimization to quality control. You only need to submit the drawing and requirement for the part, and we will take care of the rest, with professional capability, for successful machining that gives you peace of mind.

Case Study: How JS Precision Overcame The Complexity Of Drone/Model Aircraft Parts With 5 Axis CNC

The lightweight and precision requirements of drone/model aircraft parts are very high. JS Precision solved the challenge in machining an integrated fuselage support for a high-end drone racing team. The specific process is as follows:

Customer Challenge

The integrated fuselage support, made from 7075 aluminum alloy, has a weight requirement of less than 100g. The part had complex aerodynamic surfaces with surface errors ≤0.03mm, while it also needed to integrate three mounting brackets at different angles, with positional tolerance ≤0.02mm.

Conventional component assembly weighed 150g, over the specification requirement, the fracture strength turned out to be only 200MPa, which could not stand up to the racing demand either.

Solution by JS Precision

1. Design Optimization: The design of the lightweight topology was further optimized in collaboration with the customer by removing redundant materials. The wall thickness had been modified from 2mm to 1.2mm, keeping all key stress points intact. The fine-tuning of mounting bracket angles enhanced machining feasibility.

2. Process Planning: DMG MORI 5 axis machining center was adopted with a strategy combining "3+2" fixed-axis roughing, which raised the efficiency by 40%, and 5-axis simultaneous finishing.

3. Precision Execution: All machining was completed in a single setup. Machine tool probes were used during processing for online measurement and error correction, the final positional accuracy reached ±0.025mm and the surface roughness Ra was 0.4μm.

Results and Value

The completed bracket weighed only 92g (reduced by 38.7%), with increased breaking strength of 280MPa (up by 40%) and a 15% decrease in air resistance. This part gave the team the second prize in the National Speed Machining Competition.

Until then, the client solved every design and manufacturing problem at one stop, JS Precision, reducing the R&D cycle from 45 days to 20 days.

Figure 4: high precision aluminum alloy drone frame

How To Work Effectively With Your 5 axis CNC Machining Services Provider?

By working effectively with your 5 axis CNC machining services provider, you stand to reduce project cycles, thus improving the quality of machining substantially. In fact, this can be achieved specifically by:

1. Preparing Your Data Package

Please provide a complete 3D CAD model in STEP format for better compatibility. Also, please provide 2D engineering drawings. Major dimensional tolerances, surface treatment, and material specifications should be clearly depicted in 2D drawings. A complete data package will enable the service provider to quickly understand your needs, thus reducing communication costs.

2. Clearly Define Technical Requirements

Give the service provider exact specifications of materials, such as 7075-T6 aluminum alloy or PEEK 450G, surface treatments like anodizing or painting, critical dimensional tolerances including ±0.02mm, and what kind of operational environment the parts will face, such as heat-resistant or corrosion-resistant, in order to help the service provider build an accurate solution.

3. Communicate Expectations and Budget

Clearly state the project objectives, whether prototype verification or mass production, quantity-for instance, 50 units or 500 units-and budget range-for instance, $10,000 or $50,000. In this case, the service provider will adjust the process accordingly, offer a cost-effective solution, and avoid adjustment due to discrepancies in budget.

The cooperation process of JS Precision goes smoothly: You send data package → Confirmation by engineers within 24 hours → Process, quotation, and delivery schedule solution → Your confirmation of order → Production and delivery with quality inspection report. The whole process is open and efficient, you can track it at any time.

FAQs

Q1: Is 5-axis CNC machining only for mass production?

No. Though it's suitable for mass production, the big advantage will be in rapid prototyping and in manufacturing small batches of complex parts due to saving on tooling and fixture costs and set-up time.

Q2: What are the typical minimum tolerances in 5-axis machining?

Generally speaking, it reaches ±0.025mm according to different materials and the size of a part. For some precision parts, it reaches up to ±0.005mm. For a certain tolerance, it needs to be evaluated and determined by the engineer.

Q3: Can 5-axis machining completely replace 3+2-axis machining?

No, it cannot replace it entirely. Here is where the 5-axis simultaneous is being used for continuous complex surface features, while for making multi-angle features, 3+2 axes are used. High-end 5-axis machine tools can do both modes, and this provides a lot of operational freedom.

Q4: What are the advantages of 5 axis machining for difficult-to-machine materials like titanium alloys?

The process of 5 axis machining maintains the best cutting angles and keeps the cutting speeds constant, which effectively controls the heat generated by the cutting, prolongs the service life of tools, and improves the quality and efficiency in machining titanium alloy parts.

Q5: Is 5 axis programming extremely difficult and more costly?

It's indeed more complicated than the 3-axis and requires specialized software and experience. However, JS Precision has a professional programming team and software, and has optimized this cost in the service, thus, customers can have no worries about it.

Q6: My part requires machining on five sides, though without many curved surfaces. Do I need 5 axis machining?

Yes. In this case, the "3+2" fixed-axis machining mode is particularly effective, one of the functions of a 5-axis machine tool that can help avert errors resulting from several clamping operations.

Q7: What is the general price of a 5-axis machining center?

That is a very broad price range of $100,000 to $500,000, depending on specifications, brand, and configuration. Most companies are wiser to choose professional 5-axis machining services.

Q8: What size 5-axis parts can JS Precision handle?

JS Precision's equipment can handle parts ranging from tiny, such as 2mm in diameter, to large structural components such as 1000×800×600mm. Precise dimensional matching resources are needed.

Summary

5 axis CNC machining propels the manufacturing industry from "being able to manufacture" into a higher level of "intelligent manufacturing." It is far more than five moving axes but a philosophy of breaking geometric limitations, integrating production steps, and unleashing design potential.

If there's a lot of trouble with the machining of complex parts, please don't bother about equipment configuration and price. JS Precision, dedicated to high-level requirements with 12 years of practical experience and top-of-the-line 5 axis machining centers, offers services that range from design optimization to final delivery, solving customers' manufacturing problems and accelerating project implementation.

Send us your CAD files now and experience top-of-the-line precision, efficiency, and value in CNC 5 axis machining services with JS Precision's expert team. We will provide you with a professional manufacturing feasibility analysis and a competitive quote within 6 hours.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com