Have you seen it? A machine that cleanly cuts 10mm thick steel plates in our workshop in the morning to manufacture key parts of construction machinery. In the afternoon, it switches to the meticulous mode, cutting hollow patterns thinner than a hair for a batch of high-end wedding invitations. This is not magic, but thelaser cuttingtechnology we rely on every day.

Many people are curious about how it can switch freely between heavy metal and thin paper while ensuring strength and precision?The core of the answer lies in the precise control of the high-energy laser.By precisely controlling its power, speed and focus, we can instantly melt andcut metal, and gently vaporize and separate paper. The whole process is fast and clean, and there is no direct contact with the material, avoiding deformation or damage.

It is this unparalleled adaptability and precision that makes laser cutting a secret weapon that connects two seemingly different fields, heavy metal and paper art, and has become indispensable in modern manufacturing. This is why it is so important to understand its core principles.

Core Answer Summary:

| Features | Laser metal cutter |

Laser on paper

|

| Core principle | Brute force melting. | Controlled Vaporization. |

| Energy demand | High power (kilowatt level). | Extremely low power (watt level). |

| Assist gas | Nitrogen (protecting the incision), oxygen (accelerating cutting). | Compressed air (blows away heat and debris). |

| Key advantages | High precision, fast speed, and the ability to cut complex shapes. | No contact, no burrs, can achieve ultimate details. |

| Main challenges | Material reflectivity and heat affected zone control. | Prevent combustion and discoloration. |

This article will answer your questions:

- In this guide, we will take you to take a deep look at how laser beams interact with completely different materials such as steel plates and paper.

- You will learn the tricks to avoid burn marks when we use laser on paper.

- And through a real business case, we will see what surprising possibilities this technology can bring. After reading it, you will understand why everyone, from workshop engineers to designers, is increasingly inseparable from laser cutting.

Why Should You Trust This Guide? JS's Beam Control Philosophy

At our JS company, what we are best at is not simply cutting metal or engraving paper, but precisely controlling thelaser beam.

We are well aware that the quality of laser processing does not depend on the power of the laser itself, but on the precise coordinated control of the beam characteristics, motion trajectory, and auxiliary medium. This understanding stems from our team's over ten years of dedicated practice in the field of industrial laser applications.

The true experience is reflected in the precise adaptability to a wide range of materials. We have cut titanium alloylaser cutting parts with extremely high requirements for aerospace clients, and also produced meticulous paper micro carvings for top luxury brands.

This requires us not only to know how to choose fiber lasers for stainless steel to achieve mirror like smooth cutting surfaces, but also to know how to finely tune the parameters of CO ₂ laser for advanced paper to achieve perfect edges without focal marks. This practical experience spanning metal and non-metal enables us to recommend the most reliable technical path for any material.

Our methodology is consistent with the core philosophy advocated by the Laser Association of America (LIA): as a tool, the enormous potential of lasers comes from precise parameter setting and process control.

"As Theodore Maiman, one of the pioneers in the field of lasers, emphasized: The value of lasers lies in their controllability."

This is the core of our work every day. Focusing on precise control of each beam of light, rather than just treating it as a cutting tool, is the key to our ability to help you turn ideas into reliable products.

In-Depth Analysis: How Lasers Work In Two Worlds

As a front-line engineer at JS, let me tell you aboutthe core differences between laser cutting metal and paper, which seem to be "cross-border". As we often say, cutting metal requires the "hard work" of lasers, while cutting paper requires "skill".

Cutting metal: Melting, gasification and strong blowing

A trio of physical processes

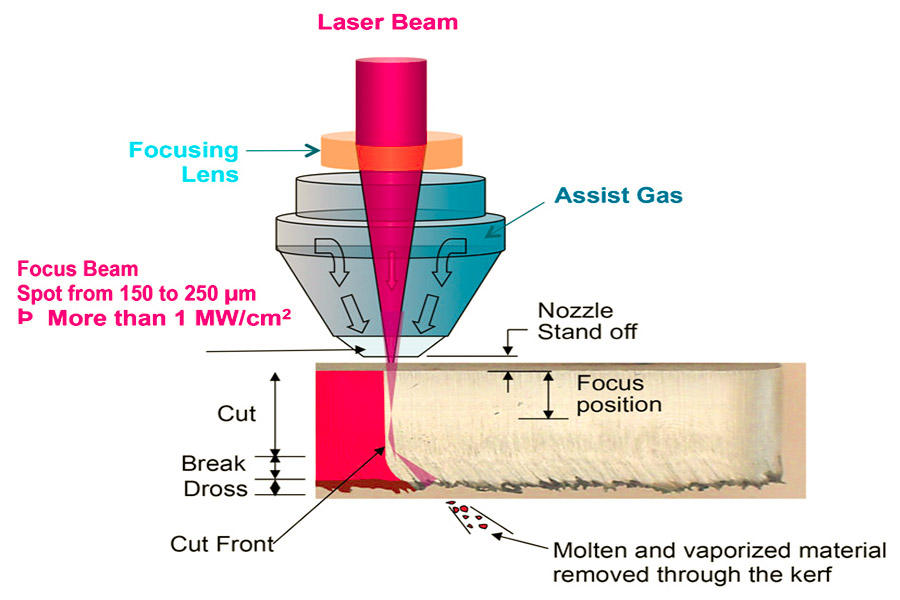

(1) Key is energy concentration:

Let's assume that we utilize afiber laser(power range 1-8kW) to emit strong light, and that it is finally concentrated into a light spot with 0.1mm in diameter by a precise optical path system. It produces an energy density of >10⁷ W/cm², and its power can be thousands or tens of thousands of watts!

(2) Molten metal:

These high energy bounces off the metal surface, and the metal can't stand it at all.The metal surface is heated to 1600°C in 0.01 seconds(we're assuming stainless steel), melts instantaneously, and forms a small pool of molten metal. We might say that we are "burning" a crack with light.

(3) High-pressure assist gas:

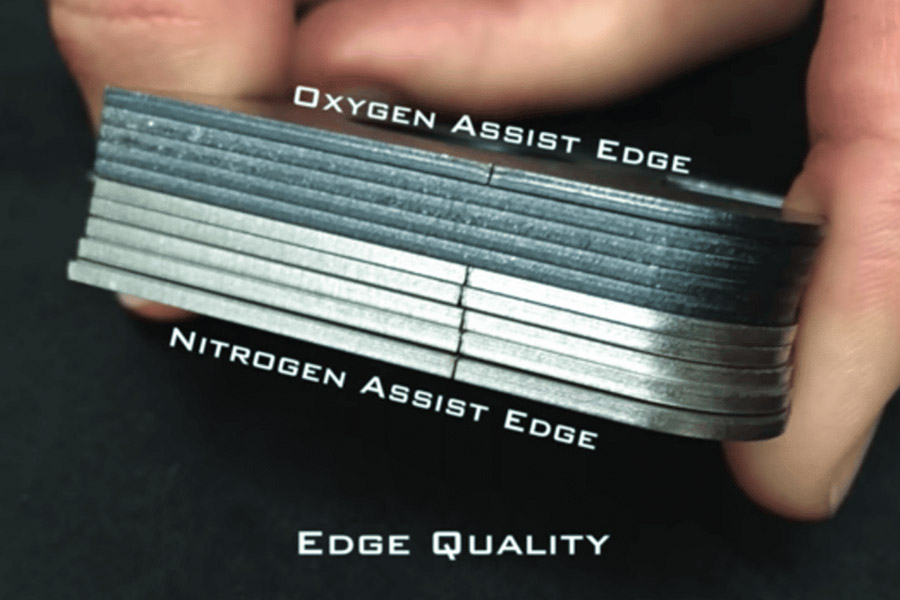

Melting light is insufficient alone, the molten metal must be "cleaned" to form an incision. During this time, 15-20Bar high-pressure nitrogen is blown coaxially with the laser beam to accurately blow off the molten metal from the cut.

Small details:We at times use oxygen in cutting carbon steel. Oxygen not only blows but also reacts with the molten steel and gets oxidized, giving an additional 10³ J/mm of heat, increasing the rate of cutting.

Why is this metal processing revolution?

(1) Precision and complexity:

Lasers can easily handle complex curves, sharp corners, and small holes that traditional tools cannot handle, and the accuracy can be controlled to a few tenths of a millimeter.

(2) Speed is efficiency:

When cutting thinsheet metal, the speed of laser is much faster than plasma cutting and flame cutting (400% faster than flame cutting), and the efficiency is significantly improved.

(3) Small heat-affected zone:

The laser acts quickly, and the heat does not have time to diffuse too much around the metal (controlled within 0.3mm), and the material deformation is much smaller, which saves a lot of trouble insubsequent processing.

Cutting paper: The art of instant vaporization and "zero contact"

Non-contact energy control

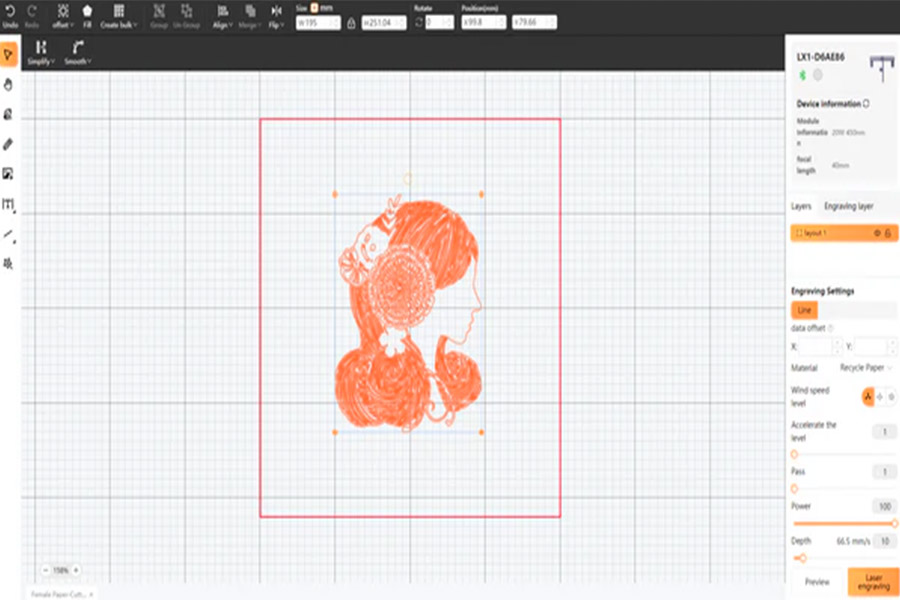

(1) Gentle power:

Non-metallic materials such as paper, acrylic, and fabric cannot withstand "burning". At this time, we mainly use CO2 lasers (30-150W) to scan at a high speed of 3m/s. Its wavelength is more easily absorbed by these materials, and the power is relatively mild (tens to hundreds of watts).

(2) Instant sublimation:

When the laser beam scans the surface of the paper, the paper fibers absorb the 10.6μm wavelength laser and directly vaporize. This process is so fast that the heat has no time to conduct to the surrounding paper.

(3) "Breeze" escort:

In order to prevent residual heat or vaporized fibers from causing the paper to turn yellow and burn, we will cooperate with alow-pressure airflow of 0.5Bar. This "breeze" blows away heat and debris in time to ensure that the cut is clean and there is no burn mark (the temperature is always <120°C). This is the core of achieving high-quality laser on paper.

Why is it particularly suitable for delicate work such as paper?

(1) Detail Maniac:

It can cut out fineness that is completely incomparable to die stamping, and achieve 50μm line width cutting, such as complex lace, lace effects, tiny text and patterns.

(2) Zero contact, zero damage:

The laser head does not touch the paper at all!It completely avoids the indentation, tearing, pulling and deformation that may be caused by traditional knife cutting, and is particularly suitable for processing 80g/m² ultra-thin rice paper.

(3) Flexibility is king:

It eliminates the link and cycle of making expensive physical die. Whether it is a single piece customization or a small batch production, once the design drawing changes, the cutting path can change immediately. This is why our onlinelaser cutting servicesare particularly popular with designers and start-up brands. Upload the design drawing and get the physical sample quickly.

"At JS, our engineers understand that the versatility of laser cutting relies on precise control of beam energy, motion trajectory, and auxiliary processes. Whether you want to make titanium alloy parts for aircraft, paper art for luxury packaging, or quickly test designs through online laser cutting services, we can help you with the most appropriate "light".

Practical Casestudy:Designing"Inside And Outside" Display Packaging For Premium Electronic Goods

When a client's project requires both hardcore durability and beauty like a work of art,laser technology becomes our trump card."This is what ourJS teamoften says. A recent high-end headphone flagship packaging project perfectly proves this point.

Case: Perfect puzzle from metal framework to paper interior support

Project background:The customer needed a packaging solution that would be an eye-level display stand in the store and a stunning packaging box when the headset was removed from the box at home.

The center was two things:A plain stainless steel framework and a black paper interior that could safely contain the headset and was full of brand artwork.

See how JS solves it:

Challenge 1: Metal base - a balance between firmness and refinement

Task:Use 2mm thick brushed stainless steel to cut out the precise outline of the customer's brand logo (with complex hollowing) and the headphone bracket.

Key point:Cut cleanly and neatly, do not destroy the brushedsurface texture, and the sharp corners of the logo must be clear.

Our operation:

- Directly use our main equipment - 1500W fiberlaser metal cutter.

- Key trick:Use nitrogen "blowing" to cut throughout the process. The cut edges are super smooth, without any burrs, and the high temperature has little effect, perfectly preserving the high-end feel of stainless steel brushing. No matter how complex the sharp corners of the logo are, the accuracy can be stably controlled within ±0.1mm.

Challenge 2: Paper art lining - "finely crafted" on thin paper

Task:Use 350g black special art paper to cut out two key points: one is to fit the shape of the earphone and the metal base tightly, and the other is to cut out the extremely fine sound wave diffusion pattern around the paper surface to symbolize the propagation of sound.

Our operation:

- This metal cutting machine can't do it, it's too fierce. We immediately switched to the process of precisionmaterials to laser cut- CO2 laser cutting service.

- The difficulty lies in that paper is too delicate. It will become fuzzy if the power is a little higher and it will become burnt if the speed is a little slower. Our team did hundreds of fine-tuning tests and finally figured out its "temper":extremely low power + ultra-high speed + precise airflow control.

What is the result?

The incision is as neat and tidy as a knife cut, and the paper is still the original deep black, without any burnt yellow, and even the most subtle sound wave pattern is clearly and sharply presented.

Key data breakthrough of art paper laser cutting

| Core parameters | Conventional processing scope (prone to problems) | This project breaks through the parameters | The achieved technical effect |

| Laser power (W) | 25-40W (easily carbonized edge). | 8-12W (precisely adjustable). | The energy is precisely controllable and only acts on the cutting line, eliminating thermal damage. |

| Cutting speed (mm/s) | 200-400 mm/s (high risk of thermal accumulation). | 800-1200 mm/s (millisecond pass). | The thermal action time is extremely short, and there is no time for heat to conduct and diffuse. |

| Auxiliary gas flow rate (L/min) | 10-15 (compressed air, oxygen assisted combustion). | 18-22 (Precision Inert Gas). | Powerful cooling+oxygen isolation, inhibits combustion, and blows away molten materials. |

| Focus position | Material surface (0 mm). | +0.3mm (micro lift defocusing). | Form a slightly wider light spot to reduce the energy density per unit area. |

| Core achievements | Edge yellowing/slight focus, slight shrinkage. | The edge is as sharp as a knife cut, the natural color is intact, and there is zero shrinkage deformation. | Realize true 'cold cutting' and perfectly preserve the original appearance of artistic paper. |

The result is satisfactory:The paper cut is as clean and neat as if it was cut by a knife, the most subtle sound wave texture is clearly visible, and the whole paper maintains its original pure black from beginning to end, without any trace of being "burned".

Key winning point: the value of one-stop precise matching

For this project to be successful, the customer values our ability to "solve the problem in one stop". The metal base and the pattern on the paper inner tray require 100% perfect matching, not even a little difference.

"This kind of precision unification across two completely different materials, metal and paper, is almost impossible to achieve if it is done separately by different suppliers. However, we can master this cross-material high-precisionlaser processingtechnology. This proves that JS not only knows how to operate the machine, but also knows how to make technology accurately serve the design."

FAQ - Your Last Question About Laser Cutting Materials

Why does laser cutting paper turn yellow? How to avoid it?

We found that the yellowing of paper after cutting isessentially a slight "burning" caused by the accumulation of heatin a certain area for a long time. The key is to prevent the heat from leaving before it can burn the paper.

The most effective way is "fast in and fast out":we will try to lower the laser power and increase the cutting speed as much as possible. In this way, the laser energy is just enough to cut through the paper instantly and move away before the heat diffuses and causes yellowing.

In addition, the powerful air blowing device on the equipment is very critical. It can immediately blow away the heat near the incision and the fine paper scraps generated, which is crucial to prevent the yellowing of the incision edge. Simply put, it is low power, high speed and strong air blowing.

How much laser power is needed to cut paper?

For cutting ordinary paper and cardboard, a10-watt to 40-watt CO2 laser is usually enough.

In fact, the key is not how much total power the machine has, but whether it can adjust the power steadily and finely. A professional device that is not top-notch in power but can be accurately controlled at a lower output level often has a much better effect than a machine with high power but rough adjustment, especially for work with high precision requirements.

Simply put, accurately controllable low power is more important than pure high power.

Can all paper be cut with a laser?

Not all paper is suitable for laser cutting. Natural fiber paper, such as cardboard, kraft paper or art paper, usually works best and cuts cleanly.

But be sure to avoid paper with PVC (polyvinyl chloride) coating, which produces toxic gases when cut, which is not only harmful to health, but also seriously corrodes and damages laser equipment. If you are not sure about the composition of the paper, the safest way is to cut a small corner first to see the effect, which can avoid big problems and is safe and worry-free.

Summary

The power of laser cutting lies in its ability to "smartly" adjust according to the characteristics of the material itself. It can cleanly process hard metals anddelicate materialslike paper. This powerful adaptability makes it an indispensable tool in modern manufacturing.

Take action! Whatever your project requires, JS can handle it:

- Material experts: We can handle a wide variety of materials to laser cut. Whether you need industrial-grade strength or artistic-grade fine effects, we have a matching solution.

- Full support: From optimizing your design drawings to the final delivery of the finished product, our team of engineers will provide professional advice to ensure that your ideas are perfectly implemented.

- Fast and transparent: Want to know the cost? Upload your CAD file now and we will provide you with a clearlaser cutting priceestimate immediately. Experience efficient and professionalcustom laser cuttingmanufacturing services.

Don't wait,upload your designand let us help you turn your ideas into reality with lasers!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com