When making micro-heart pump impellers for medical device companies, stainless steel castings with over ±0.1mm tolerances can lead to unstable blood pumping.When making small engine components for aerospace companies, minute dimensional inconsistencies can influence the safe operation of the entire machine—such is the nature of high-precision requirement in stainless steel investment casting.

Whether they are joint implants that need to be biocompatible with the human skeleton or turbine blades that have a direct influence on aircraft engine efficiency, dimensional tolerances are frequently tightly regulated within ±0.1mm. This presents radical challenges for the stainless steel investment casting process.

This article categorizes the key solutions in achieving this micron-level precision, including systematic material science solutions, mold engineering, and process control solutions, to give you a sound way forward.

Core Answer Summary

| Comparative Dimensions | Challenge to Realize a ±0.1mm Tolerance | Solutions to Achieve a ±0.1mm Tolerance |

| Fundamental Conflict | Different Combinations of Shrinkage (Wax, Shell, Metal) and Process Variables. | Systematic Compensation and Precision Control. |

| Wax Pattern Stage | Uneven Wax Contraction and Distortion. | Use Low-Contraction, High-Stability Wax, Isothermal and Constant Pressure Injection. |

| Shell Stage | Expansion and Sintering Distortion of the Shell. | Use High-Stability, Nano-Fine Powder Surface Slurry to Enhance the Shell Manufacturing Process. |

| Melting and Pouring | Contraction of Metal and Thermal Stress Induce Distortion. | Contraction of Metal and Thermal Stress Induce Distortion. |

| Post-Processing | Cutting and Polishing Cause Secondary Errors. | Employ Precision Cutting and CNC Polishing to Maintain Tolerance Allowances. |

| Core of Quality | Rely on Seasoned Craftsmen's Experience. | Rely on a Data-Driven, Standardized Process Control System. |

Why Use This Guide? JS Precision Breaks ±0.1mm Tolerances In Investment Casting

JS Precision has over 15 years of practical experience in stainless steel investment casting. We have provided over 5,000 customized investment casting parts to the medical, aerospace, and marine engineering sectors, with over 200 multinational clients.

For example, we produced tens of thousands of surgical instrument parts from 316L stainless steel for a global medical device company, with tolerances within ±0.1mm and a scrap rate of less than 0.5%, lowering the client's post-processing cost by 30%.

Our team has optimized the entire process, from wax pattern production to mold shell handling, and established a dedicated process database that accurately predicts the shrinkage behavior of a range of stainless steel alloys.

This handbook, a distillation of our experience, combines international standards such as ISO 8062 and production data from actual production. You can trust its recommendations, based on customer verification and shop results. This guide will provide both theoretical knowledge and immediately applicable tactics for achieving your high-precision goals.

JS Precision focuses on custom investment casting manufacturing. Simply send us your 3D model and tolerance requirements, and our engineers will provide a feasibility report within 24 hours. Ordering is simple and efficient, so you can get your project underway quickly.

The King Of Precision: What Is The Tolerance Limit Of Investment Casting?

To find out if your part can achieve a tolerance of ±0.1mm, you first need to know the tolerance limit of investment casting. Investment casting is an important process for achieving high-precision parts, and its tolerance level directly affects part performance. Even a difference of 0.05mm will cause assembly delay or functional failure.

What are The Tolerances of Investment Casting?

Commercial tolerances tend to be around ±0.005 inch/inch (±0.127mm/25.4mm). This is sufficient for most industrial parts but far from sufficient for critical medical and aerospace applications, for instance.

±0.1mm is in the precision or even semi-precision range, which is comparable with an error within the diameter of a human hair (approx. 0.08-0.12mm) over a 25mm length. This is pushing the limits of stainless steel investment casting technology.

Understand Industry Standards

Standards such as ASTM A732 and ISO 8062 classify casting tolerances. ISO 8062-CT4 tolerances are close to ±0.1mm (e.g., ±0.12mm for lengths ≤100mm). These high tolerances are specified only for critical parts.

For example, the turbine blades in the aerospace industry and artificial joints in the medical field require CT4 or higher standards. CT5 tolerances (±0.18mm for lengths ≤100mm) would not meet the accuracy of ±0.1mm.

JS Precision has the ability to reproduce CT4-grade investment casting parts to global standards time and again. Once you inform us of your requirements, we will match you with a corresponding tolerance control solution to ensure part accuracy.

The Main Influencing Factors Of Investment Casting Tolerances

To achieve a ±0.1mm tolerance, it is essential to first understand the most significant variables in investment casting tolerances. Any process variation can be the cause of non-conforming tolerances. A 0.02mm deviation in the wax pattern can potentially result in a 0.1mm error in the casting.

Wax Pattern Stability

Shrinkage rate of the wax, injection molding process, and storage conditions are the key variables. Shrinkage percentage can vary by 0.5%-2% between different wax materials. Low-temperature waxes (50-60°C melting point) shrink around 0.8%-1.2%, and medium-temperature waxes (70-80°C melting point) shrink around 1.5%-2%. We prioritize using low-temperature waxes in order to minimize the shrinkage differences.

In the injection process, injection pressure must be kept within 5-8 MPa, and temperature fluctuations must be within ±2°C. Low pressure will cause the wax pattern to be incompletely filled, and high pressure will easily generate internal stress.

The surrounding environment during storage should be maintained at 22°C ± 1°C and humidity 50% ± 5%. Humidity above 60% will cause the wax pattern to absorb water and expand, with dimensional deviations of 0.03-0.06mm.

Mold Shell "Fidelity"

Its ability to maintain the original shape at high temperatures depends on the ceramic material's thermal expansion coefficient and the uniformity of the mold shell thickness.

Silica sol mold shells that are widely used have a thermal expansion coefficient of about 1.2 × 10^-6/°C, while water glass mold shells have an expansion coefficient of about 2.5 × 10^-6/°C. We use silica sol mold shells to decrease thermal deformation.

The thickness of the mold shell must be uniform with a tolerance of ±0.2mm. Thicker regions can lead to non-uniform heat transfer while firing and hence unequal shrinkage of the mold shell, resulting in dimensional variations of 0.05-0.1mm in the casting.

Metal Shrinkage

The shrinkage of all grades of stainless steel from liquid to solid is subject to a very significant factor that must be precisely compensated for. For example, the shrinkage of 304 stainless steel is approximately 1.8%, while that of 316 stainless steel is approximately 1.6%. We calculate compensation for each grade individually.

For example, in the production of 304 stainless steel parts, the size of the mold is enlarged by 1.8%-2% so that the part gets the wanted size after the metal has cooled and shrunk. A 0.1% deviation in compensation will result in a 0.2mm dimensional error for a 200mm long part.

Hidden Tolerance Killers: The Special Challenges Of Stainless Steel Casting

Stainless steel casting comes with its own share of issues. If these "tolerance killers" are not addressed, it is difficult to hold a ±0.1mm tolerance. These issues are ignored by most companies, and hence batches of castings are rejected due to dimensional inconsistencies.

Surface Pitting and Inclusions

The reason is that the chromium element within the stainless steel will react with the mold shell material or the oxygen in the air. The formed oxide inclusions (e.g., Cr2O3) adhere on the casting surface to create pitting. Inclusions with a diameter larger than 0.05mm can reduce the tensile strength of the part by 10%-15%.

Solution: Use a neutral or inert surface layer material (e.g., 120-mesh zircon sand or fused quartz) to reduce the reaction with chromium. Casting should also be carried out under argon protection (purity ≥99.99%) to prevent the molten metal from coming into contact with air.

Hot cracking and deformation

The cause is the high linear shrinkage of austenitic stainless steels (e.g., 304 and 316 stainless steel). 304 stainless steel experiences a linear shrinkage of approximately 2.1%, and 316 stainless steel experiences a linear shrinkage of approximately 1.9%. Thermal stress is easily generated during solidification. Cracking is sure to occur when the stress exceeds the material strength.

Solution: Enhance the gating and riser design using MAGMAsoft simulation software in such a manner that the casting freezes away from the gating and riser, thus achieving sequential solidification. Also, there was a flexible mold shell system with an inner layer of high elasticity ceramic fiber for stress accommodation during solidification and reducing deformation.

Dimensional "drift"

The reason lies in the summation effect of slight deviations of all the above factors. For example, 0.03mm deviation of wax pattern shrinkage, 0.04mm deviation of mold shell thermal deformation, and 0.03mm deviation of metal shrinkage compensation can result in 0.1mm deviation of casting dimension.

Solution: Establish a comprehensive statistical process control system, sampling every two hours and inspecting five key points each time. Whenever any point fluctuates more than ±0.05mm, process conditions are corrected immediately, e.g., increasing the wax pattern injection temperature by 0.5°C or increasing the mold shell firing time by 10 minutes, to ensure dimensional stability.

JS Precision has the proven solutions for the specific issues of stainless steel investment casting, effectively preventing defects and ensuring dimensional stability in castings. Feel free to contact us if you have any such requirement.

Material Selection: Which Grades Of Stainless Steel Are Most Suitable To Achieve These Tolerances?

The use of a suitable stainless steel grade simplifies the attainment of ±0.1mm tolerances considerably.

In general, it is easier for alloys with a narrow crystallization temperature range, good fluidity, and normal shrinkage tendency to achieve high tolerances. Other than 316 and 304 stainless steels, low-carbon stainless steels such as 316L and 304L are commonly used in the manufacture of high-precision castings. The comparison of common stainless steel grades is as follows:

| Stainless Steel Grade | Principal Characteristics | Tolerance Performance | Applications | Casting Process Compatibility |

| 316 Stainless Steel | Molybdenum-containing, with good corrosion resistance and high-temperature strength, crystallization temperature 1400-1450°C. | Can reach ±0.08mm with strict processing. | Can be applied to high-level medical and marine engineering applications. | Good fluidity, uniform shrinkage, and easy control. |

| 304 Stainless Steel | Universal, nice castability, and low cost. Crystallization temperature range 1420-1460°C. | Suitable for general precision parts with tolerance ±0.1mm. | Suitable for general precision instruments and industrial fittings. | Steady shrinkage, suitable for mass production. |

| 316L Stainless Steel | Low carbon content, good weldability, and biocompatibility. Crystallization temperature range 1390-1440°C. | Suitable for precision medical parts with ±0.09mm tolerance. | Suitable for implantable medical devices and food processing. | Slightly less shrinkage than 316, suitable for complex cavity parts. |

| 304L Stainless Steel | Low carbon, excellent intergranular corrosion resistance, crystallization temperature range 1410-1450°C. | Conventional precision parts can reach ±0.11mm. | Chemical equipment, low-temperature pipeline fittings. | The casting performance is similar to 304, but the cost is slightly higher. |

The result is that 316, 316L, 304, and 304L all can meet ±0.1mm tolerance requirements.

The choice between 316 and 316L is based on extreme corrosive environments or biocompatibility requirements. The choice between 304 and 304L is an economy choice with no sacrifice in performance. 304 suits traditional parts with large quantities, and 304L fits applications that are intergranular corrosion demanding.

Breakthrough Casting: A Clash With Other Precision Processes

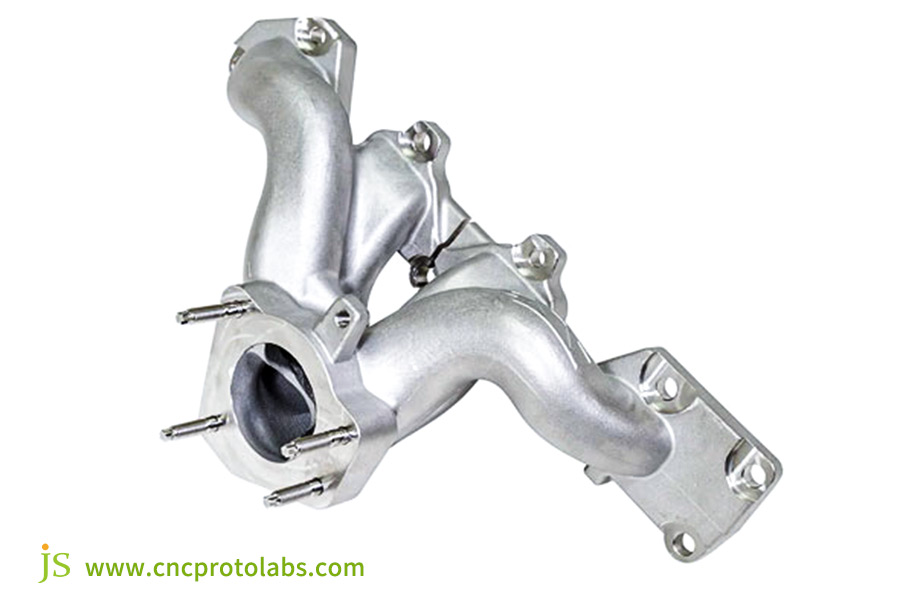

A comparison of investment casting with other precision processes clearly shows its superiority in manufacturing parts with ±0.1mm tolerances.

| Comparison Dimensions | Investment Casting | CNC Machining | Metal 3D Printing (SLM) |

| Material Utilization | Near-net shape, minimal waste, and material cost savings. | High stock removal, low utilization, and high material waste. | High material utilization, but high equipment costs. |

| Suitability for Complex Parts | Suitable for complex cavities and thin walls, with single-piece molding possibility. | Very complex parts are impossible to machine and must be assembled in multiple parts. | High design freedom, but poor surface quality requires post-processing. |

| Batch Cost | Extremely low piece cost in mass production, typically $10-50 per part. | High, $20-100 per part, with small variations depending on batch size. | Moderate cost for small series, high cost for large series, $30-150 per part. |

| Material Mechanical Properties | Isotropic, identical to traditional casting, with reproducible mechanical properties. | Reproducible performance but batch quality dependent. | Anisotropy present, with post-processing required to attain optimum performance. |

The main advantage of investment casting is that it provides an optimum balance between complexity, mass production cost, and mechanical material properties, which makes it particularly suitable for mass production of complex, high-precision stainless steel parts.

JS Precision provides online investment casting services with significant cost advantages for mass production. After you submit your requirements online, we will quickly provide process solutions and cost analysis to help you reduce production expenses.

The Price Tag Of Precision: Cost-Benefit Analysis Of Investing In A ±0.1mm Tolerance

To chase a ±0.1mm tolerance is more expensive, yet over the overall lifecycle, it is generally well worth the expense. Customers are always concerned about more expense at the beginning, yet after actual cooperation, they will discover that the cost is overall lower.

Cost Analysis

The precision of ±0.1mm entails increased explicit costs, such as more expensive raw materials, longer process cycles, more sophisticated testing equipment, and better quality human resources.

Hidden Cost Savings

Machining cost can be saved or even eliminated.Scrap rates can be significantly reduced, and high yield rates can avoid batch scrap losses.Time to market of the product can be accelerated by reducing processing steps and shortening the manufacturing chain.Product performance and reliability can be improved, and future maintenance cost can be reduced.

Decision Guide: The investment in casting precision pays off highest when the component is high-value, assembly-critical, difficult or impossible to post-process, or requires extreme performance.

JS Precision can help your investment casting price cost structure be lower and realize fewer lifecycle costs. A detailed cost-benefit analysis will be presented at the time of your consultation to shed light on your return on investment.

JS Precision Case Review: How ±0.1mm Ensures The Rhythm Of Life

Customer Requirements

A top-5 global medical device company needed to design a stainless steel impeller, the heart of a micro heart pump. The impeller had a diameter of 25mm with three twisted blades, each 0.8mm thick. The blade pitch error needed to be ±0.05mm, and the overall tolerance was ±0.1mm. Biocompatibility was also required to ensure there was no risk of hemolysis.

JS's Solution

1.In terms of material selection, 316L stainless steel with a good biocompatibility was selected. Composition tests were also conducted to ensure chromium content of 16%-18% and molybdenum content of 2%-3%, as per ISO 10993 standards.

2.Computer simulation was carried out using MAGMAsoft software to compute separately the shrinkage of 12 key locations of the impeller (e.g., blade tip and root transition), which resulted in a customized, non-uniform mold magnification factor of 0.8%-1.2%.

3.Wax mold by Germany low-temperature wax was made. In a 22°C ±1°C temperature and 50% ±5% humidity constant temperature and humidity workshop, a full-automatic wax press (accuracy: ±0.02mm) was used to achieve a repeatability of ±0.03mm.

4.The mold shell was constructed with seven layers of special ceramic, with 150-mesh zircon sand being the surface layer and the fourth layer reinforced with a 0.3mm thickness layer to prevent deformation.

5.Vacuum (vacuum <5Pa) melting and pouring was conducted, with the gating system optimized (gate diameter 2mm) for smooth mold filling,

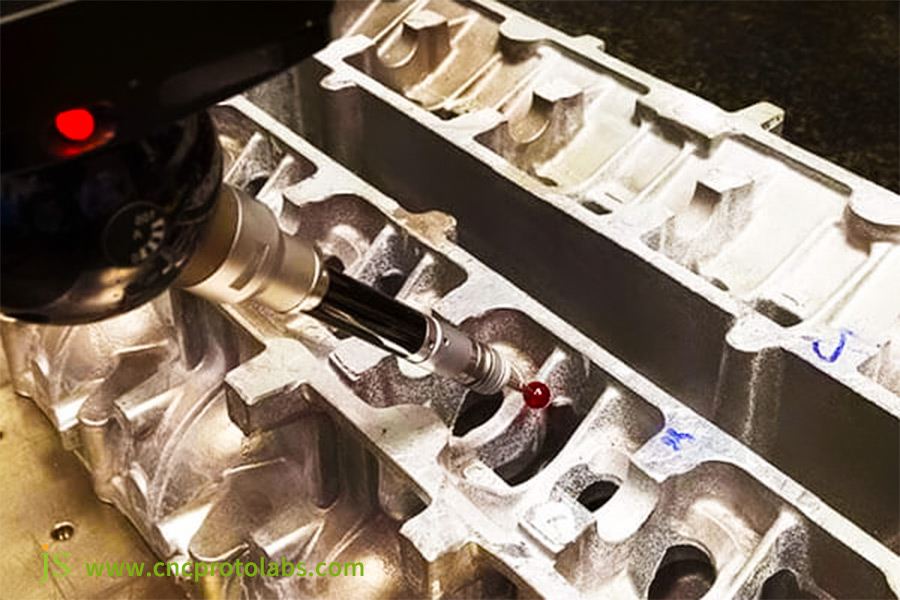

6.Three-dimensional coordinate measuring machine (accuracy: 0.001mm) carries out 100% inspection in 20 points of each impeller.

Final Result

These 100 impellers were finished with a 98% pass rate, and all the critical dimensions within ±0.08mm and Ra <3.2μm surface finish. The customer was able to skip polishing and post-processing altogether, and they were able to deliver this life-saving product to market ahead of schedule.

Eventually, the company obtained sole supply rights to this series of impellers and has sold over 5,000 units since.

Why Is JS Precision The Best Partner To Assist You In Overcoming The ±0.1mm Tolerance Problem?

Choose JS Precision because we can help you achieve a ±0.1mm tolerance as a standard every time.

- It's not the machine, it's the system: In addition to cleanrooms and leading-edge equipment, we have a data-based precision casting system for control at every step.

- Process database within: We have created a proprietary shrinkage rate and process parameter database for different materials and structures based on the experience of thousands of successful jobs, enabling "predictive manufacturing."

- "Microscopic" control of the entire process: Over 50 points of quality control from raw material receipt to product shipment ensure process reliability and zero dimensional deviations.

- Collaboration led by engineers: We are an extension of your R&D team, involved in the product design phase, providing manufacturability analysis to ensure high tolerances from the source.

FAQs

Q1: For a tolerance of ±0.1mm, what is the suitable part size for investment casting?

This tolerance is more suitable for small- and medium-sized components, typically with a maximum outline size of less than 300mm. As component size increases, the amount of compounded error from sources such as wax pattern shrinkage and shell deformation increases exponentially. Whether or not this tolerance can be achieved relies upon a professional team to determine based on the part structure.

Q2: Is ±0.1mm feasible for all stainless steel components?

Unfortunately, no. Components with extremely thick section and thin walls, or components with large flat areas, tend to be difficult to control due to uneven cooling rates and stress concentration. A skilled person's critical review of your own design is needed to establish if this tolerance is achievable.

Q3: What is most crucial in the achievement of this tolerance?

Most important is controlled stability of the whole process, instability at any stage can lead to failure. Stability of dimension of the wax pattern is critical. If the wax pattern itself is grossly incorrect, it will be difficult to correct in subsequent processing. Accurate shrinkage compensation design is also necessary, compensating ahead of time for the dimensional change resulting from metal shrinkage.

Q4: What do I need to provide for a quote and feasibility study?

Please provide us with your 3D CAD data in STEP or IGS file format, material type (e.g., 304 or 316 stainless steel), tolerance type (e.g., ±0.1mm), and volume required yearly. This allows us to effectively determine process feasibility, production cost, and provide you with a proper quote and professional feasibility study.

Summary

±0.1mm in stainless steel investment casting is not only a figure, it is art, patience, and data at its best. It is the conversion of high variable art into reproducible, accurate, and predictable science.

JS Precision, with its extensive history of custom investment casting manufacturing, turnkey systems, and experienced staff, can help you take high-precision components from the drawing board to production.

Drop your order with us online and we will return to you quickly, keeping quality and accuracy at every step, from process inspection through to production delivery. We are your reliable business partner for fulfilling the need of ±0.1mm tolerances.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com