Get CNC milling instant quote to help engineers and new product managers proceed with new products. When an engineer is developing a new item, they cannot afford to wait for the results of a typical CNC milling quote. Engineers may be frustrated by the slow response of an inquiry but concerned about if they will be able to afford the prices of the quote.

In searching for CNC milling manufacturing services, it is not only in the machinery itself where competitiveness resides, but also in the nimble response, cost transparency, and joint intelligence.

In this article, the logic of cnc milling instant quote will be dissected to show ways of effectively managing the CNC milling price while concurrently ensuring the quality of CNC milling parts.

Moreover, you will discover how leading Chinese manufacturers, such as JS Precision, integrate technology and digital processes to create a custom CNC milling services experience for their global clientele.

Key Answer Summary:

| Decision-Making Core | Common Misconceptions | JS Precision's Integrated Solution |

| Obtaining Instant Quotes | Believing Instant Quotes are Inaccurate, Sacrificing Transparency for Speed. | Using intelligent algorithms and our extensive knowledge database of processes, we are able to provide CNC milling price quotes in 60 seconds. |

| Cost Control Optimization | Focus only on unit price, ignoring design, batch size, and total cost of ownership. | Provide free in-depth DFM reports, optimize design from the source to improve material utilization, and significantly reduce CNC milling price through large-scale production. |

| Quality and Delivery Assurance | Worried that remote collaboration may not guarantee the accuracy and delivery time of "CNC milling parts". | We make use of a digital platform because of the end-to-end visualization, process quality control, and capacity management it provides to ensure delivery within time. |

Key Takeaways:

- True CNC milling instant quotes rely on mature digital pricing engines and standardized process libraries.

- Early Design for Manufacturing (DFM) has a much higher effect on the CNC milling price than negotiation skills.

- When considering custom CNC milling services, keep in mind factors such as engineering support and quality data clarity.

- China's leading CNC milling manufacturing service have established a comprehensive global advantage in terms of cost, technology, and response speed.

Why Believe In This Guide? JS Precision Real-Time CNC Milling Quotation

This guide is based on over 15 years of experience at JS Precision providing custom CNC milling services to clients worldwide, from startups to Fortune 500 companies.

We have processed more than 100,000 CNC milling quote, constantly refining our digital quotation engine to realize 98% accuracy to make sure the online cnc milling instant quote you get is just the same as your final contract price.

Our DFM optimization has helped clients to save between 30% to 60%, thanks to our team of over 50 certified engineers. We have also allowed the on-time delivery rate of CNC milling parts to stay high, at 99.2%. Unlike generic guides, we share real-world data:

For instance, we have observed that by reducing the complexity of tolerances or other design changes, the cost of CNC milling can be cut by as much as 40%, based on 5,000 projects. We are also ISO 9001 and AS9100 registered, and our quality program is supported by 100% first article inspection.

When you use our CNC milling instant quote tool, you rely on a system built on real success stories and strict standards.

Want personalized DFM optimization recommendations and an accurate CNC milling instant quote? Submit your 3D model and drawings today, and the team of JS Precision engineers will send you a free cost analysis and optimization plan for CNC milling within 24 hours.

How To Get a Transparent CNC Milling Instant Quote Online?

Obtaining a quick and correct online quote is the key to fruitful collaboration, enabled by data and standardization. Trustworthy partners for the services of CNC milling require proper information to provide correct CNC milling quote. This is how to achieve correctness:

Step 1: Assemble a "Perfect" Document Package

Include a precise 3D model (in the form of a STEP/IGES file) and 2D PDF technical drawings that include tolerances, surface finishes, and materials.

The more standard the documentation, the better the accuracy of the AI analysis and thus the CNC milling price quote, however, a sketch is enough for initial consultations, though complex documentation might avoid changes in pricing later.

Step 2:Understanding the Components of a Quotation

A professional CNC milling instant quote should include at least six major elements: material cost, programming preparation time, machining time, post-processing cost, quality inspection criteria, and packaging logistics. A supplier offering "package prices" could lead to a cost trap.

Step 3: Real-time Adjustments Using an Interactive Platform

On the JS Precision online platform, materials, surface treatments, or order quantities can be adjusted in real-time. The system recalculates CNC milling price and delivery times in real-time, making cost decisions more autonomous and eliminating the need for repeated communication.

Does Batch Production Truly Lower Your CNC Milling Quote?

The cost-saving aspects of batch production are possible, although the trick is in spreading those fixed costs, rather than focusing on “low profit, high volume.” Instances where increased volume drives down fixed cost amortization-based cost savings are also possible.

Amortizing Fixed Costs:The Magic of Programming and Setup

The part quote contains costs for one-time programming. This is coupled with process development and fixture setup costs ranging from $200 to $500. This cost is amortized through mass production, thereby lowering the price to a substantial extent in actions like CNC milling.

Optimizing Production Cycle Time and Material Procurement

The mass production provides optimization for tool paths, increases the efficiency of cutting, and provides material savings through the mechanism of Centralized Nesting (which gives 15-25% lower material waste for 500 parts as compared to 10 parts). The higher volume procurement of materials also gives lower pricing, making the existing cost of the CNC milling quote lower.

Balance Point: Economic Order Quantity (EOQ)

"Bigger is better" does not apply in this case, as a balancing point regarding the inventory, capital invested, and demand forecast needs to be achieved. Reliable producers play an important role in shaping the calculation of the "economic order quantity" in regard to the CNC milling cost.

Do you want to know the optimal CNC milling price for your product after mass production? Discuss your anticipated order quantity and demand cycle with JS Precision, and our production consultants will determine the economic order quantity so you can fully reap the cost benefits of mass production.

Design For Economy: Practical Strategies To Optimize Your CNC Milling Price

Design contributes to the formation of costs by 70%, thus, careful attention to optimization before quoting can help to reduce costs to a considerably lower level. Many engineers overlook design details, which have a significant impact on CNC milling price and production efficiency.

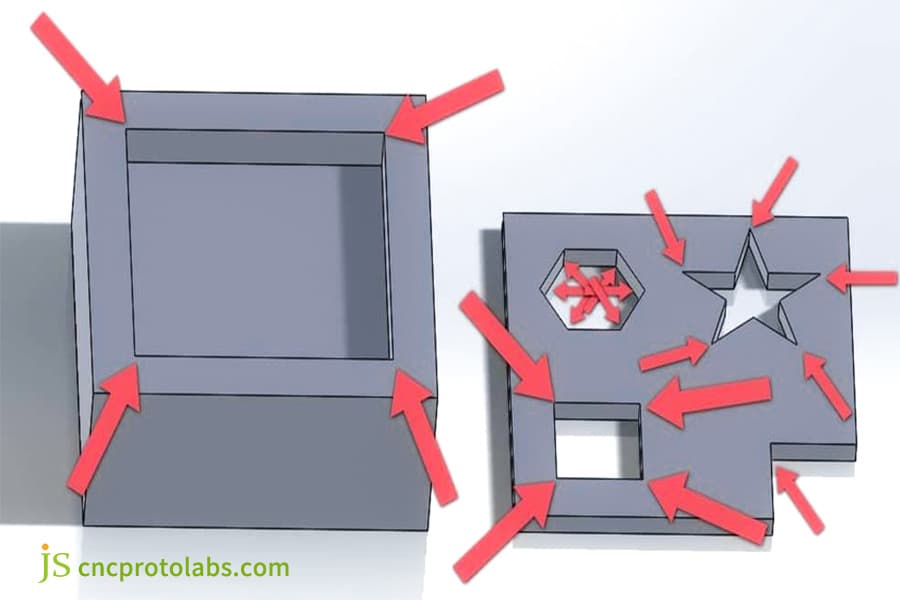

Rule 1: Use Fillets and Cavities

Care should be taken to avoid right angles and a standard radii value for milling cutters (like R3 and R5) should be adopted for internal corners to decrease machining time by up to 20-30%. Also, for deep cavity models, ratios of tool length to tool diameter beyond four times will enhance costs for CNC milling.

Rule 2: Simplify Complexity and Reduce Clamping Times

Minimize the number of part clamping times, too many clamping times multiply labor time and fixture expense. Complex assemblies may be broken down into machinable CNC milling parts or produced in one clamping operation by means of multi-axis machine tools.

Rule 3: Define Tolerances and Surface Finishes Carefully

For Specify strict tolerances only for critical function parts. Meanwhile, reduce tolerances for non-contact surfaces (e.g., change from ±0.1 mm to ±0.2 mm) for cost savings on finishing operations. High Ra values are unnecessary for non-appearance surfaces to avoid additional grinding costs and optimize CNC milling price.

| Design Optimization Measures | Expected Cost Savings | Applicable Scenarios |

| Use standard fillets | 15%-30% | for all internal corners of parts |

| Reduce clamping times | 25%-40% | for complex, multi-faceted parts |

| Reduce clamping times | 10%-25% | for non-mating, non-appearance surfaces |

Figure 1 Processing a 90 degree angle will increase processing time, resulting in an increase in total cost.

How Do Tolerances Impact Your CNC Milling Parts Quote?

Tolerance is the heart of quality for CNC milling parts, but it is also one aspect that contributes most to cost escalation. The majority of customers perceive tighter tolerance as quality without appreciating the cost escalation aspect.

Exponentially Increased Machining Time:

When the tolerance ranges are reduced from ±0.1mm to ±0.025mm, tool changes, lower feeds, and additional finishing passes result in twice or thrice the machining time, thereby directly impacting CNC milling quote.

This is because machining components with a tolerance of ±0.01mm increases machining time by 3 to 4 times compared to those machined with a tolerance of ±0.05mm.

Requirement for Specialized Equipment and Technicians:

The requirement for high-precision five-axis machine tools, temperature-controlled workshops, and specialized technicians increases with increased geometric tolerance values (IT7 and above).

The price for advanced equipment is taken into account when obtaining a quote. The price of machine tools when machining parts with an IT6 tolerance value is considerably higher compared to normal machine tools.

Pass Rate and Quality Costs:

The closer the tolerance, the higher the potential for scrap. Honest suppliers will factor the cost of quality control and scrap materials into their pricing to guarantee a 100% pass rate for CNC milling parts. For instance, a material scrap of 5-8% for components with a tolerance of ±0.005mm.

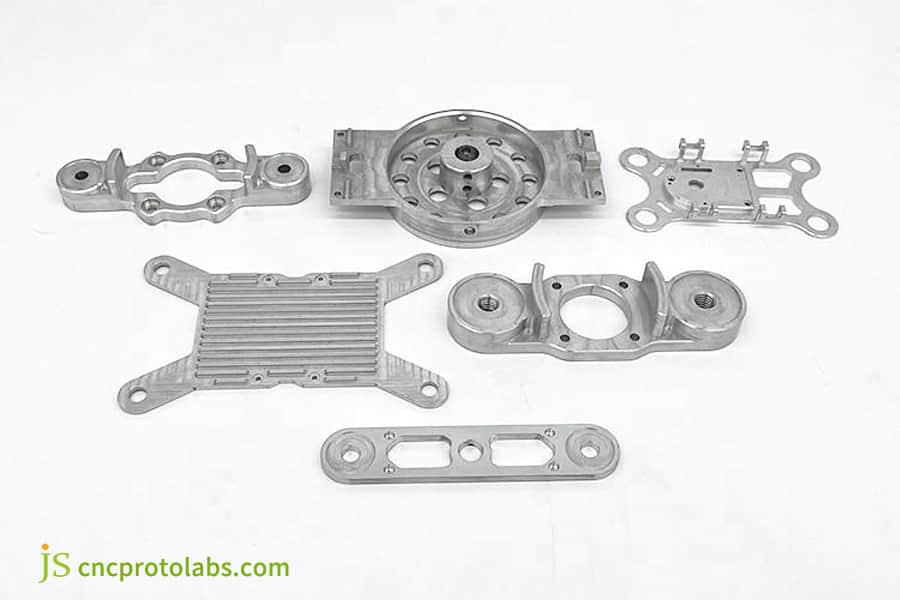

The Global Advantage: Why Choose a Chinese CNC Milling Manufacturing Service?

Choosing Chinese CNC milling manufacturing service has shifted from a cost oriented approach to a comprehensive value oriented approach. The China manufacturers possess advantages in cost as well as incore competitiveness in technology, value chains, and services.

Full-Fledged Supply Chain Ecosystem

The supply chain from material to machine tool, or from cutter to machine tool, provides the possibility to minimize the purchase cycle periods and the cost of the raw material (such as reducing 6061 aluminum alloy purchase costs by 15%-20%). The technical support system in the country forms the basis for the custom CNC milling services required.

Advancements in Technological Competence and Mindset

JS Precision competes with other leaders that have exceptional equipment and software engineering capabilities, which promote their engineering culture engaged in Design for Manufacturing. We provide Constructive Cost Optimization, with an average engineer experience of over 8 years and has already performed cost optimizations for over 10,000 projects.

Agile Collaboration Driven by Digitalization

Geographical distance will no longer be a problem. China's top CNC milling manufacturing service leverages online portals, real-time dashboards, and structured delivery to provide a more transparent and efficient collaboration experience than local workshops, with smooth multilingual communication.

Interested in benefiting from the overall advantages provided by China’s CNC milling manufacturing service? Please enter your project requirements, and JS Precision will offer you a tailored solution with exact pricing, tech support, and delivery, helping you benefit from world-class production services.

Figure 2 Chinese CNC enterprises rely on advanced technology and a comprehensive manufacturing system to produce customized parts and prototype products for the global market.

How Reliable CNC Milling Manufacturing Services Guarantee On-Time Delivery?

Timely delivery is the essence of the credibility of the manufacture process, which requires organized management and does not trust the word of the person but the process. This is because the lack of timeliness leads to the halting of projects or increased expenditure. The selection of the delivery service provider is vital.

Smart Scheduling and Capacity Analysis Using ERP

A modern system takes actual machine tool utilization, order status, and material status on a constant basis. The delivery date for CNC milling parts would be properly analyzed by a scientific system assessment including appropriate buffers. JS Precision's system can warn about potential bottlenecks at least 7-10 days prior through their own ERP system.

Standardized Process Flow and Critical Path Management

Modularity in timing has been implemented throughout the entire process of the CNC milling manufacturing service.

Project managers are specially concerned with managing the critical path, which involves sending out early warnings should any delay be foreseen, and marshaling resources towards such resolution, including switching to alternative post-processing suppliers to ensure timely delivery.

Flexible Capacity and Supply Chain Contingency Plans

Reliable suppliers prepare flexible capacity for urgent orders. Identify a backup list for the purchase of raw materials. JS Precision prepares 12 alternative material suppliers and 8 post-processing partners to ensure the stability of the supply chain.

Concerned about on-time order delivery? Choose JS Precision's CNC milling manufacturing service, and we will provide crystal-clear delivery time commitments and real-time progress tracking. From quotation to delivery, a dedicated project manager will follow up to make sure your CNC milling parts arrive on time.

How To Evaluate The True Quality Of Custom CNC Milling Services?

This means the quality of a supplier cannot be evaluated based only on machine tool brands, it lies in processes, data, and communication culture. The focus on just the end product increases the chances of receiving poor parts.

Request specific quality data and process documents

Analyze entire First Article Inspection (FAIR) sample reports, focusing on the measurement parameters, machine tool, and form of data generated. Ask if the IPQC frequency and recording are according to ISO 9001 requirements. A quality custom CNC milling services will not hesitate to provide this extensive documentation.

Understand their engineering review and DFM process

A better quality supplier is the one that suggests design optimizations before giving quotes. A good supplier for CNC milling parts has expert views in terms of manufacturability, cost, and performance, prior involvement is essential for a quality supplier.

Analyze the structure and transparency of communication

Communicative details should be attended to, such as: The use of numbered document lists. Steps followed when making requests for changes. Accompanying physical evidence when giving progress reports. A structured method of communications generally indicates organizational diligence and avoids potential errors.

Case Study: 52% Cost Reduction, 65% Faster Delivery: The DFM Miracle Of a Drone Onboard Frame

Case Background:

To address the issue, a European firm that produces drones developed a basic gimbal camera bracket using a core structural part made of 6061 aluminum alloy and designed it specifically for an industrial drone. Its original integral design featured several strong ribs and irregular curvilinear areas.

This is not onl<y prone to deformation during machining of the strong ribs, but the removal rate of material is over 85%. Furthermore, the cost of machining via CNC milling is quite expensive, taking an estimated 4 weeks to deliver, and the total cost is likely to be higher by 40%.

JS Precision Solution:

The JS Precision engineering team performed a thorough DFM analysis. We suggested an optimized solution.

Firstly, to work within its functional limits, it was divided into two parts: a ‘main base’ and a ‘removable reinforcing rib plate,’ which eased the shape of the main base considerably.

Secondly, process and material technologies were employed in the following way: the base design changed to a two-and-a-half axis strategy for rapid removal of the bulk of the material, and the use of thin plate machining for the ribs, replacing the material in certain areas with the easier to machine cast aluminum 'MIC6' plates.

At last, assembly optimization was done. This was done through the provision of locking grooves and pin holes that ensured that when these two components were put together, they were no different from one unit.

Results:

Significant optimization results:

- The overall cost lowered by 52%, the CNC milling cost per set of parts decreased from $280 to $134.

- The delivery period reduced by 65%, compared with an initial period of 4 weeks (28 working days), now only taking 10 working days, parallel machining of two components hastening the progress of the project considerably.

- Precision of flatness tolerance values of major mounting surfaces is enhanced from 0.05mm to 0.03mm, along with the modular design reducing future production costs.

Do you want your product to achieve a dual breakthrough in cost and efficiency? Upload your part design file, and JS Precision's DFM engineers will analyze and optimize the space for you free of charge, providing customized machining solutions and accurate CNC milling quote.

Figure 3 Aluminum alloy drone camera gimbal bracket

FAQs

Q1: What type of documents must be provided for a CNC milling online quote?

Preferably, a 3D model in the format of STEP/IGES + PDF with tolerance, or no files, sketches will be acceptable, and our engineers will help fill in the necessary information.

Q2: Would there be any discrepancy between the online quote and the eventual final price of the contract?

The accuracy level of the online quote created from the specs is very high. The final cost for the contract is the cost if there are no design changes. We ensure that the cost is clear, there are no hidden charges, and we have complete control over your budget.

Q3: What is the typical difference between the cost per unit of small-batch prototypes and mass production cost?

The cost saving here is quite large. The cost per mass production of 1000 or more units is 30-60% lower compared to the cost for 1-10 prototypes. The amount of saving depends on the complexity of the product and the manufacturing process. The saving effect will be more when the product complexity is higher and the product volume will be larger.

Q4: Which design parameters have the biggest effect on the cost of CNC milling?

The three elements that impact designs to a large extent are: total size (directly affecting material costs), complexity of designs involving features, and tolerance criteria (affecting accuracy levels). Improving these three elements can lower the cost of CNC milling.

Q5: How do Chinese makers address problems of time zone and language communications?

We assign you dedicated bilingual project managers, and their response time is 24 hours. Through the online collaboration platform, you can place your messages any time, and immediate responses will be given within work hours, overcoming the challenges posed by time zones and languages.

Q6: What is the best way to protect my design intellectual property?

We offer internationally binding NDAs. We store your design files on encrypted independent servers, thus ensuring data access control within our company to fully protect your intellectual property security.

Q7: Is the surface treatment cost in the quote?

You are able to freely select the types of required surface treatments. The respective costs will be calculated and added to the total price automatically. Each cost is stated clearly, making it easy for you to see the components of the cost with no room for misunderstanding.

Q8: What would you do when encountering possible issues that may arise during the production stage?

We shall immediately contact you through the platform, explain the problem, impact, and provide at least two optimization solutions. After receiving your written confirmation, continue production to eliminate the risks caused by unauthorized handling.

Summary

In the cutthroat competition in the market, the speed and accuracy of production decisions matter a lot. Transparent CNC milling instant quote is the key to smooth partnerships. Reliable partners with the ability to optimize CNC milling price from the design stage and the ability to deliver the quality of CNC milling parts are key factors.

JS Precision takes advantage of China's CNC milling manufacturing service industry value chain to deliver controllable and optimizable integrated solutions for custom CNC milling services.

The time has come to experience the future of collaboration for manufacturing.

Now is your chance to visit JS Precision’s website and upload your files.Within 60 seconds, you'll receive an instant price quote and a reliable delivery time, and within 24 hours, we may offer you a free detailed report on engineering DFM Optimization Suggestions. Let your ideas be represented just right, with optimal efficiency and cost.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com