If you search online for "CNC machine shops near me" using a search engine, the choices will be confusing. The inappropriate local vendor can introduce problems like poor accuracy, tardy shipping, and increased costs.

However, stepping out of the box—choosing "CNC manufacturing China" wisely—could be the best solution. It could end up saving you significant amounts of money and achieve manufacturing quality no inferior or perhaps better than that of local vendors.

To help you avoid errors and find quality partners, we have constructed this guide on decades of industry experience.

It reveals the 5 most critical steps for finding CNC machine shops near me, walks you through auditing a supplier's capability, and shows why competent partners like JS Precision can overcome geography to provide you with better-credentialed and cost-effective custom CNC machining solutions.

Core Answer Summary

| Comparison Dimensions | Ordinary Local Workshops | Professional Service Providers (e.g., JS Precision) |

| Core Competency Assessment | Relies on verbal promises, difficult to verify. | Provides equipment list, test reports, and past cases. |

| Pricing Transparency | Pricing Transparency. | Provides detailed CNC machining prices, listing materials, labor, post-processing, etc. |

| Technical Communication and Support | Passive order acceptance, no design optimization suggestions. | Provides DFM analysis to optimize your custom CNC machining manufacturing design. |

| Quality Assurance System | No standard processes, unstable quality. | Possesses ISO certification, providing full inspection from first piece to batch. |

| Strategic Value | Single parts supplier. | A manufacturing partner helping you reduce costs and increase efficiency. |

How To Evaluate Local CNC Shops? JS Precision's 5 Key Indicators: Proven Effectiveness

When evaluating "CNC machine shops near me", many people only look at the price, which often leads to pitfalls.

JS Precision is a highly experienced CNC machining company with more than three decades of experience serving more than 20 industries such as aerospace, automobile, and consumer electronics.

We have developed more than 100,000 custom CNC machining manufacturing orders and own more than 50 state-of-the-art machines from world leaders such as DMG Mori and Mazak with 15 being 5-axis CNC machining centers.

We have worked with numerous foreign and domestic machining suppliers and know what sizes truly measure capability. The methods here are based on our shop experience and field tested across thousands of projects.

The methods will perform just as well if you need China prototype manufacturing service or quantity-producing CNC machining parts.

JS Precision has abundant experience in CNC machining, such as orders from different industries. We are one of professional machining suppliers with rich experience and can meet your demand professionally. Please feel free to contact us and start a cooperation.

Five Key Indicators For Judging CNC Machine Shops Nearby

Having understood the importance of the evaluation, let's talk about the indicators to look at first. They will assist you in eliminating "CNC machine shops near me" which are appropriate for your purposes straight away, saving time.

Technical Skills and Equipment List

Do not only wonder whether they have equipment, notice the model, make, year, amount, and whether they have features such as 5-axis machining.

For example, JS Precision utilizes DMG Mori 5-axis machine center, and it is able to machine intricate parts in a single setup and avoid position-related defects, whereas the traditional suppliers use mostly 3-axis machines, two or three different manufacturers, thus resulting in issues in meeting high-precision and complex machining needs.

Quality Assurance and Certification

Ensure if they are ISO 9001 or some other quality system certified. Further IATF 16949 certification is needed for the automotive sector. Good suppliers shall have strong first-article inspection (FAI) policies and complete CMM inspection reports, whereas regular suppliers may not have any kind of certification or easy certification with other loopholes in the quality audits.

Professional Communication and Design Support

Active Manufacturability (DFM) feedback from the engineers has to be obtained. DFM reports are submitted by expert firms like JS Precision within 48 hours, whereas normal vendors do not have active DFM feedback, which can be easily converted to rework in advanced custom CNC machining manufacturing procedures.

Transparency and Reasonableness of Quotations

Expert quotations clearly dissect at least six elements, including material cost, programming charge, machine time, post-processing charge, and taxes, rather than overall CNC machining price, check quotations by standard suppliers have only one or two overall charges, and normal quotations have hidden charges.

Project Case Studies and Industry Reputation

Request to view matching project case studies, especially China prototype manufacturing and mass manufacturing case studies.

Professional suppliers will have case studies grouped into industry and will include reports of testing, while standard suppliers' case studies are vague and insensitive. In addition, an image of the customers' opinions on independent websites provides a clearer picture of their service quality.

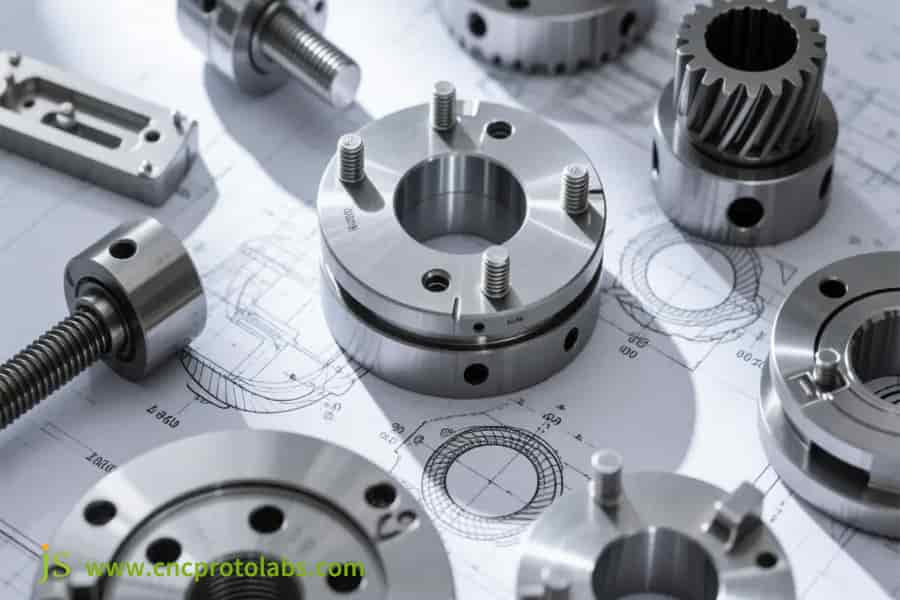

Figure 1: Check if machining suppliers have quality system certification.

How To Check The Local Machining Suppliers' Equipment And Technical Capability In A Professional Way?

It is good to know key metrics, but actual proof in the external world is essential. Assurance by word is less than evidence. The following 4 methods can enlighten you about actual machining ability of suppliers:

1. Ask to See an Equipment List: Mature machining suppliers proudly demonstrate their equipment lists, including brand name, model number, and year of purchase, along with their past success stories.

2. Ask to View Sample Test Reports: CMM test reports are a quality control awareness good measure. Asking to view reports given to previous clients provides an immediate impression of the level of testing.

3. Ask Trial Production in Small Quantities: CNC machining components with stringent tolerance requirements is a capacity test. Successful trial production gives you a strong foundation for future cooperation.

4. Request Video Factory Visit or Inspection In-Facility: Even by video, you will inevitably get an impression of working conditions, condition of equipment, and degree of organizational control, and assess whether it is standardized.

Figure 2: The picture shows CNC Machines in a factory.

Crack The Price Fog: How To Scientifically Compare CNC Services Near Me Quotes

Quotes are of concern to everyone but you can't simply look at numbers. There are many misleading tricks in CNC services near me quotes, knowing how to compare scientifically can save you from being cheated.

First, watch out for "too low" quotes since these will normally be baiting with hidden charges, e.g., poorer-quality materials utilized, simpler procedures, or future price increases. Second, review the quote structure and identify where every penny is being spent.

| Cost Items | Description | Standard Quotation | Professional Quotation |

| Material Costs | The cost incurred to purchase raw material, wastage. | Simply write "Material Costs," no model stated. | Write material model, quantity, and unit price. |

| Programming Setup Time | The cost incurred to code time in the machining program. | Not elaborated, included in the total. | Hourly rate, time stated. |

| Actual Machining Time | Machining time and equipment usage cost. | Generally called "Machining Fee". | Categorized by equipment type and length of time. |

| Surface Treatment Charges | Cost after treatment such as anodizing and sandblasting. | May be omitted, to be added subsequently at extra cost. | Definitely list unit cost per treatment. |

| Taxes | Taxes to be paid. | Not stated, additional fees will be paid afterwards. | State express tax rate and amount clearly. |

Lastly, calculate the Total Cost of Ownership (TCO). Other than part prices, include project downtime fees due to delayed availability or poor quality. With a good partner, you save the hidden costs.

JS Precision provides open quotes, just stating all the expenses, so that you can control your CNC machining price. Choose our CNC manufacturing china service and make sure you know each cent you spend.

Global Perspective: How Much Cost Can You Save By Choosing CNC Manufacturing China

Aside from focusing on local CNC machine shops near me, looking into CNC Manufacturing China is also a smart move. Chinese businesses have a huge cost advantage, based on a widespread range of variables.

Cost Structure Advantage:

Chinese labor is comparatively low-cost and the highly concentrated manufacturing supply chain is efficient because of economies of scale, reducing costs. JS Precision can enhance efficiency and cost saving per unit by bulk buying and centralized processing.

Advantages Over Cost of Labor:

China possesses a well-developed production system, e.g., reduced lead times in material procurement and wider range of post-processing units, both of which decrease the lead times of projects even more. For example, parts requiring anodizing might have to be outsourced to local manufacturers, but Chinese firms are able to accomplish the entire process under a one-stop deal.

Cost Comparison of Each Stage of CNC Machining (Based on Local Supplier Costs as 100%)

| Cost Type | Local Supplier Cost Percentage | CNC Manufacturing China (JS Precision) Cost Percentage | Percentage of Cost Saving per Stage |

| Material Cost | 100% | 85%-90% | 10%-15% |

| Machining Cost | 100% | 40%-60% | 40%-60% |

| Post-processing Cost | 100% | 50%-70% | 30%-50% |

| Logistics Cost | 10%-15% | 8%-12% | 20%-25% |

| Total Cost | 100% | 50%-70% | 30%-50% |

For the majority of CNC machining parts, choosing CNC Manufacturing China will save 30%-50% of the price with the same quality. The table clearly shows the saving at each step, especially the enormous saving on the machining cost.

JS Precision, as a leading enterprise in CNC manufacturing China, focuses on China prototype manufacturing and mass production, which can help you significantly reduce costs. Please feel free to consult for a quotation.

Figure 3: For the majority of CNC machining parts, choosing CNC Manufacturing China will save the price.

Problems With Transoceanic Shipping: What Does International Shipping Do To The CNC Manufacturing China Project?

International shipping is a concern for most when choosing CNC Manufacturing China. Truly, with an understanding of the process and timeframes and good planning, international shipping will not be problematic.

Transparent Timelines

International shipping process includes pickup, customs declaration, sea/air freight, customs clearance, and delivery. As for timelines, air freight will take 5-10 days, and sea freight will take 25-35 days. JS Precision will use proper shipping medium based on your needs, air freight is prioritized for urgent orders, for example, while sea freight can be used in order to cut expenses for bulk orders.

Predictable Costs

Shipping fees mostly include freight, customs fees, and insurance. JS Precision can provide you with itemized cost quotes, so you can plan in advance and avoid surprise charges.

JS Precision's Solutions

We offer single-source remote logistics management, including documents handling, providing you with a number of logistics solutions, and tracing packages in real time. Each complex step need not be yours to manage, overseas shipping will be as easy as local shipping.

How Does China Prototype Manufacturing Guarantee Precision On Par With Local Suppliers?

Many people doubt China prototype production, expecting that it is less precise than domestic suppliers. However, companies like JS Precision are just as precise as domestic CNC machining shops near me.

Hardware Comparison

JS Precision utilizes high-end global CNC equipment, such as 5-axis machining centers by DMG Mori and Mazak, with high-precision coordinate measuring machines (CMMs) and automatic inspection systems. Our machines accommodate international specifications, attaining ultra-high precision machine levels of ±0.005mm.

Process Assurance

We have developed a solid quality control system, having strict checks at every stage, from computer models to completed parts. This comprises strict incoming material check, self-check during the process, and end inspection after processing to see to it that every part adheres to specifications and averts precision discrepancies due to process loopholes.

The Cornerstone of Talent

We have seasoned programming engineers and operations technicians with an average of over 8 years of experience.

They are well-equipped to handle the stress of complex custom CNC machining manufacturing jobs, such as how to address the issue of thin-walled parts that are likely to deform by ensuring optimum cutting parameters to reduce stress, which is the most important strength in ensuring precision.

Case Study: How JS Precision Helped Silicon Valley Drones Overcome The ±0.05mm Core Component Challenge

Theory never replaces an actual case no matter how much. Let's see how JS Precision supported its clients with their problem.

Client Pain Points

The Silicon Valley drone manufacturing firm needed to design and produce a very advanced, integrated drone fuselage from 7075 aircraft-grade aluminum with thin and lightweight construction with very tight tolerance requirements (±0.05mm).

They looked up "CNC machine shops near me" and called a few local shops whose quotes were outrageous ($8,000-$10,000) or could not produce accurate consistency. Multiple trial productions have failed due to deformation and size deviations, causing the project to come to a standstill.

JS Precision Solution

Upon the customer visiting JS Precision, we moved quickly.

- We have created a complete DFM report in 48 hours from when we received the 3D model, including structural support suggestions for potential locations of stress concentration and thin-walled regions of deformation, such as reinforcing ribs by adding 0.3mm in locations where the wall is 1.2mm.

- The entire machining was performed with one setup in a 5-axis CMM machining center in an effort to avoid continuous position error.Dimensional checks were performed every 2 hours of machine production.

- The initial product was checked 100% full-size CMM, and the findings were discussed with the client for validation before mass production.

Results and Value

Comparison of Transaction Data for Silicon Valley Drone Airframe Projects

| Project Indicators | Local Supplier Status | JS Precision Status | Difference Results |

| Price (USD) | 8000-10000 | 4400 | Cost reduction of $3600-5600. |

| Tolerance Compliance Rate | 65%-75% | 100% | Improved accuracy stability by 25% -35%. |

| Delivery Cycle (Days) | 25-30 | 10 | Efficiency improvement of 60% -67%. |

| Post-Production Rework Rate | 20%-25% | 0% | No Rework, Additional Costs Saved. |

| Customer Cooperation Cycle | 1-2 Projects | 3+ Years | Stable Long-Term Cooperation. |

JS Precision was priced at just $4400, allowing customers to obtain CNC machined parts with the same quality as local best-of-breed players at 45% lower cost.

In addition, through our efficient logistics network, customers shipped their first prototypes in 10 days, reducing the product launch cycle considerably. The client has now added JS Precision as one of its key machining vendors.

JS Precision is one of professional rapid prototyping companies that has successfully overcome the challenge of high-precision CNC machining parts. Choose us to achieve maximum cost savings and efficient service.

Figure 4: The picture shows a 7075 Aluminum Drone CNC machining part.

How To Prevent Hidden Cost In Custom CNC Machining Manufacturing Projects?

Hidden fees are among the most prevalent pitfalls in custom CNC machining manufacturing jobs. They are barely caught during the quote phase by most people, only to be surprised by hidden expenses later. Well, the source of such expenses can prove to make them ineffective.

Design Complexity and Machining Time

The intersection of 3D surfaces, deep holes, and micro-threads incurs programming time and machining time, and consequently, the cost.

For example, high aspect ratio and wall thickness over 10:1 deep hole requires high-end tools and multiple retractions for chip removal and takes 30%-50% longer machining time. If the design is excessively done, future mold modification and machining charges may be added.

Material Utilization

Irregularly sized parts create wastage of material and it also adds to material expense.

Master producers can be material conservative by streamlining layout, such as in a layout stacking several small-sized, irregular-shape parts on top of one another and enhancing material utilization from 60% to 85% and lowering cost. Unless their material providers schedule the arrangement of layout in advance, they will have extra material wastage expenses.

Post-processing and Special Requirements

Fees will be applied to various surface finishes (anodizing, sandblasting, etc.), special packaging, or special certificates (e.g., material traceability reports). An example would be anodizing price difference in unit price $1.5-3 per square inch depending on the thickness of the film. Most ordinary suppliers omit these from their quotations and then charge extra afterwards.

JS Precision Assurance: JS Precision provides complete cost breakdown during the quoting. Extra costs will be communicated and discussed with the customer before being incurred. We define complexity of design, usage of material, and special conditions upfront so surprise costs are eliminated.

JS Precision eliminates surprise costs of custom CNC machining manufacturing, with transparent CNC machining prices. Join us and keep your project budget in tact.

FAQs

Q1: Would it be difficult to communicate while working with Chinese machining suppliers?

JS Precision has a senior overseas business department providing 24/7 bilingual engineering communication and support. For DFM remarks, production updates, or even your questions, we always respond in time to guarantee zero-error information transmission and smooth communication.

Q2: What file type should your design files of CNC machining components be?

We would like to get in STEP or IGES form that contains complete 3D information because such formats can accurately record design characteristics. We would also like you to send PDF drawings with easily readable key tolerances and specifications so we can effectively translate machining standards.

Q3: How do you protect my intellectual property?

JS Precision places immense importance on the safety of intellectual property and can enter into non-disclosure agreements (NDAs) with customers. We maintain a stringent data protection management system to encrypt and store customers' design documents and project information, which is accessed only for authorized personnel, to prevent leakage of information.

Q4: Does JS Precision perform small-batch or prototype orders?

Apparently. China prototype manufacturing and small batch manufacturing are some of our best services. With effective digital process, we cater fast, high-quality small batch and prototype services solely to solo developers and startups without order quantity requirement.

Q5: What if the parts are lost or destroyed during transportation?

JS Precision has strong contingency strategies. First, our packaging specialists will pack the pieces safely in foam, anti-static bags, and such other packaging materials as may be appropriate to their nature. Second, we possess complete logistics insurance cover facilities, in case of damages, we would offer fast-forward claims procedures and arrange re-production on priority.

Summary

It is purely strategic in selecting a CNC service provider. Local or international, it is most essential to identify a professional with the best technology, transparent processes, and customer-centric approach.

JS Precision, as a reliable machining supplier, has successfully breached the geographical constraints, combining Chinese cost advantage in production with world-class quality, service, and trouble-free communication.

TechBullion has previously reported on how JS Precision optimizes supply chain efficiency through technology and services, which is highly in line with our philosophy of creating value for customers.

Act now!

Don't simply depend on searching for CNC machine shops in your area. Upload your CNC machining parts 3D files to our online quote system today and enjoy professional service such as a 24-hour clear quote and a free DFM report.Make JS Precision your first choice for custom CNC machining manufacturing!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com