CNC turning services are the core technology for achieving high-precision and complex rotary parts machining in modern manufacturing industry.

It is capable of handling the whole range of applications starting from prototype development to mass production with unmatched flexibility and consistency, hence, precision medical devices as well as automotive parts of a high level of durability can be manufactured and will be covered.

Even if you require sturdy metal parts or practical plastic parts, customized production has become the main instrument to accurately depict the design intent.

This article will delve into the core of CNC turning services and reveal how to open your projects transparently and quickly through an online CNC turning quote system.

Key Answers Overview

| Key Questions | Key Answers | Value for You |

| How to choose the right CNC turning service for my project? | Distinguish between metal CNC turning and plastic CNC turning characteristics, accordingly, match materials and processes based on strength, corrosion resistance, cost, and other factors. | Identify the material and process path to determine the best initial point for the project. |

| To what extent can customized parts be complex and precise? | Custom CNC turning parts services are capable of supporting complex geometries, whereas precision CNC turning services can achieve tolerances of 0.01mm or even tighter. | Know the boundaries of technical design freedom and precision, thereby unlocking your creative potential. |

| How to get instant transparent and trustworthy quotations? | Make full use of the online CNC turning quote system: upload files, select options, and get an accurate quote with real time process analysis within minutes. | Make the procurement process easier and gain predictability in cost and delivery time. |

Key Takeaways:

- Material determines process:

Aluminum alloys are ideal for high speed cutting performance, stainless steel necessitates tool wear consideration, and PEEK plastic demands temperature control for its shape retention.

- Precision is a systems engineering process:

To reach extremely tight tolerances (for instance, IT7), multiple contributing factors such as machine tool stiffness, cutting tool choice, and ambient temperature control must be united.

- DFM optimization significantly reduces costs:

By implementing minor changes to the design (e.g., using the same internal angle radius, omitting overly deep threads), the cost of a CNC turning service can be cut down by as much as 20%.

- Instant quotes are a hallmark of a mature supply chain:

Backed by a standardized process database and well, established precision CNC turning services abilities.

Why Choose Custom Services? JS Precision's CNC Turning Solutions

CNC turning is the main process of producing high precision rotating parts, and bespoke services are the key to meeting complex design requirements.

JS Precision has been offering CNC turning services for more than ten years and can manufacture parts with ultra high tolerances of 0.0005 inch. We cater to high end industries such as aerospace, medical, and automotive.

Our staff is well, experienced with hands, on work. We have made surgical tool components for medical customers with tolerances as tight as 0.0002 inch, thus precisely addressing their precision issues.

Our manufacturing operations try to meet the standards of the ISO 9001:2015 quality management system, a very well, known certification that highly contributes to product quality assurance.

In terms of equipment, we are equipped with advanced devices such as dual spindle dual turret turning and milling composite centers, 7-axis and 8-axis turning centers, which can achieve one-stop completion of multiple processes such as turning, milling, drilling, etc., reducing clamping errors.

Meanwhile, our lights out automated production mode can significantly increase production capacity and reduce unit costs.

Apart from high precision products, luxury buyers who opt for JS Precision's custom CNC turning parts may also expect the firm to be their total solution partner from design optimisation to mass production. We advise the most suitable materials and process by client needs, thus enabling them to attain the best cost without compromising the quality.

This CNC turning services guide is a reflection of more than ten years of industry experience, international standards, and numerous real, world client case studies. The professional content and the depth of the data ensure that the guidance is dependable and within reach of your projects.

Want to unlock high-precision solutions for custom CNC turning parts? Contact JS Precision engineers now and mention "customization needs" to receive a free customized process solution, easily overcoming complex parts machining challenges.

What Is CNC Turning Services And How Does It Adapt To Different Manufacturing Needs?

CNC turning is the main element of CNC turning services. Its flexible adaptability satisfies the production requirements of different industries.

Core Technology Principles Overview

CNC turning through programming of the computer numerical control system manages the lathe to rotate the workpiece and change the position of the cutting tool, thus very accurately machining cylindrical, conical, and other revolving features. It is characterized by a high level of automation, thus significantly limiting human error.

Applicable Industries and Usage Scenarios

The usage of CNC turning services is very extensive.

- In the aerospace industry, they manufacture engine shaft parts.

- In the automotive industry, they make sensor housings and other similar parts.

- In the medical sector, they produce surgical instrument handles.

- In the consumer electronics field, they manufacture precision connectors.

Workflow Overview from Design to Finished Product

The standard CNC turning workflow is concise and efficient: CAD model creation → conversion to CAM program to generate G-code → raw material clamping → automated machine tool machining → post-processing → coordinate measuring machine quality inspection to ensure parts meet tolerance requirements.

Want to learn how CNC turning services can adapt to your industry needs? Click to get JS Precision's industry application white paper and view more practical cases of metal CNC turning and plastic CNC turning.

What Complex Part Designs Can Custom Plastic CNC Turning Services Achieve?

Custom plastic CNC turning services are all about precision plastic machining, delivering a very high degree of design freedom and being capable of producing parts with different requirements.

Design Freedom and Geometric Possibilities

With JS Precision's custom plastic CNC turning services, it is possible to incorporate a multitude of complex features, for instance, M1.2 micro-threads, deep holes with a depth-to-diameter ratio of 10:1, thin walled structures having a thickness of 0.5mm, and composite surfaces, thus responding to various special design needs.

From Prototype to Mass Production

JS Precision's custom plastic CNC turning services utilize standardized CAM programs, advanced fixtures, and SPC process control, thus being able to successfully transfer a prototype to mass production, all the while keeping the level of part precision at the highest standard.

Success Story Sharing

One of the customers required a PEEK insulating sleeve incorporating internal cooling channels to handle heat dissipation and insulation issues. Through its custom plastic CNC turning services, JS Precision was able to accurately machine the cooling channels, thereby achieving a perfect balance between insulation performance and dimensional accuracy, thus fully complying with the specifications.

Why Is Precision CNC Turning Services Crucial For High-Quality Parts?

Precision CNC turning services are at the heart of producing high, quality parts, and the level of accuracy during these processes essentially dictates the performance of the parts and the final results of the assemblies.

Precision Standards and Tolerance Control

Precision CNC turning services rigorously follow the ISO 2768 tolerance standard. IT7 tolerance level (0.015mm for a 25mm diameter) is the most commonly used tolerance, alongside very careful control of concentricity, roundness, and other geometric tolerances to ensure robust part assembly.

Different levels of precision in precision CNC turning services differ greatly in terms of the main machinery parameters and the scenarios in which they can be applied, and the table below illustrates that.

| Precision Grade | Screw Positioning Accuracy (mm) | Fixture Repeatability (mm) | Typical Tolerance Range (mm) | Applicable Scenarios Percentage (%) |

| IT6 Grade | ±0.002 | ≤0.003 | ±0.005-±0.010 | 12 |

| IT7 Grade | ±0.003 | ≤0.005 | ±0.010-±0.015 | 38 |

| IT8 Grade | ±0.005 | ≤0.008 | ±0.015-±0.025 | 35 |

| IT9 Grade | ±0.008 | ≤0.012 | ±0.025-±0.040 | 13 |

| IT10 Grade | ±0.012 | ≤0.015 | ±0.040-±0.060 | 2 |

Key Elements That Determine Precision

The precision of CNC turning is influenced by the four main factors as follow: the lead screw positioning of the machine tool must have an accuracy of 0.003mm, control the thermal deformation of the machining, replace the worn tools in time, and keep the fixture repeatability within 0.005mm.

Quality Inspection and Assurance Process

JS Precision's precision CNC turning services have a very thorough quality inspection process which includes the first-piece full dimensional inspection, the in-process sampling inspection, and the 100% final screening. Instruments such as coordinate measuring machines ensure that the rate of product qualification is up to standards.

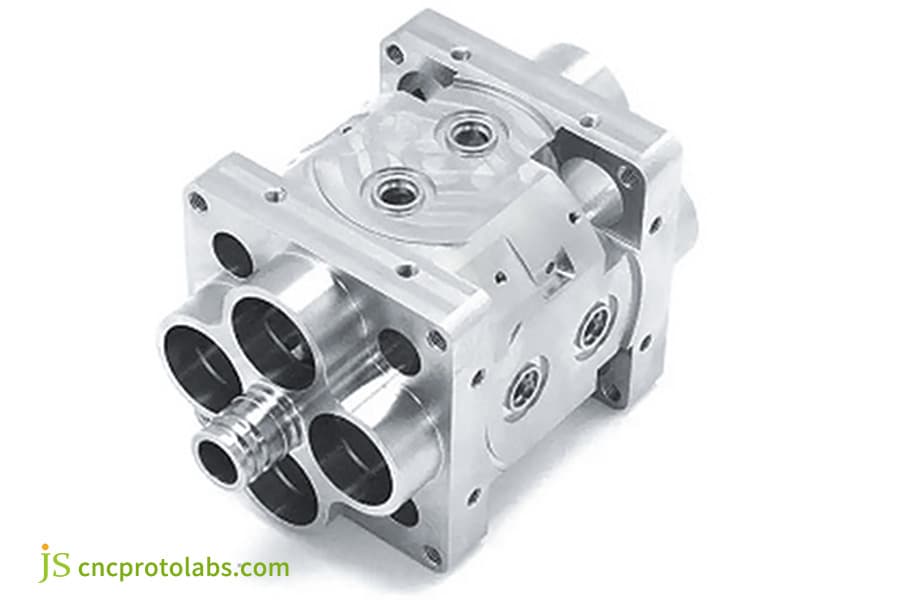

Figure 1: A shiny, intricate metal part with various holes and flat surfaces, isolated on a white background.

What Are The Key Differences And Considerations When Choosing Between Metal And Plastic CNC Turning?

Metal CNC turning and plastic CNC turning differ significantly in materials and processes. Choosing the right process can effectively reduce costs and improve quality.

Material and Process Characteristics of Metal Turning

The commonly used materials and process characteristics for metal CNC turning are shown in the table below:

| Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Tool Type | Tool Type |

| Aluminum Alloy 6061 | 200-300 | 0.2-0.5 | Carbide Tools | Anodizing, Sandblasting |

| Stainless Steel 304 | 50-100 | 0.1-0.3 | CBN Coated Tools | Passivation, Nickel Plating |

| Brass C360 | 150-200 | 0.3-0.6 | High-Speed Steel Tools | Polishing, Electroplating |

| Titanium Alloy TC4 | 30-60 | 0.05-0.2 | Diamond Coated Tools | Pickling, Passivation |

Metal CNC turning processes are characterized by extreme cutting forces and excessive heat generation, so the use of specialized tools together with ample coolant are key to successfully preventing tool wear and workpiece deformation.

Special Characteristics and Applicable Scenarios of Plastic Turning

Plastic CNC turning primarily works with POM, nylon and PEEK materials. In this operation, the use of sharp tools with big rake angles is necessary, and the process is usually done under high speed and low feed conditions while cold air cooling is used to control the temperature and avoid deforming the workpieces.

The technology is very common in the manufacturing of electronic and medical insulating parts.

How to Choose Materials Based on Project Requirements?

Picking a material is a matter of weighing up four parameters: Metals generally have greater strength than plastics. Plastics are more resistant to corrosion, they also cost less and weigh less.

Basically, the right material together with the process should be chosen by taking into account the operating environment and the performance requirements of the parts.

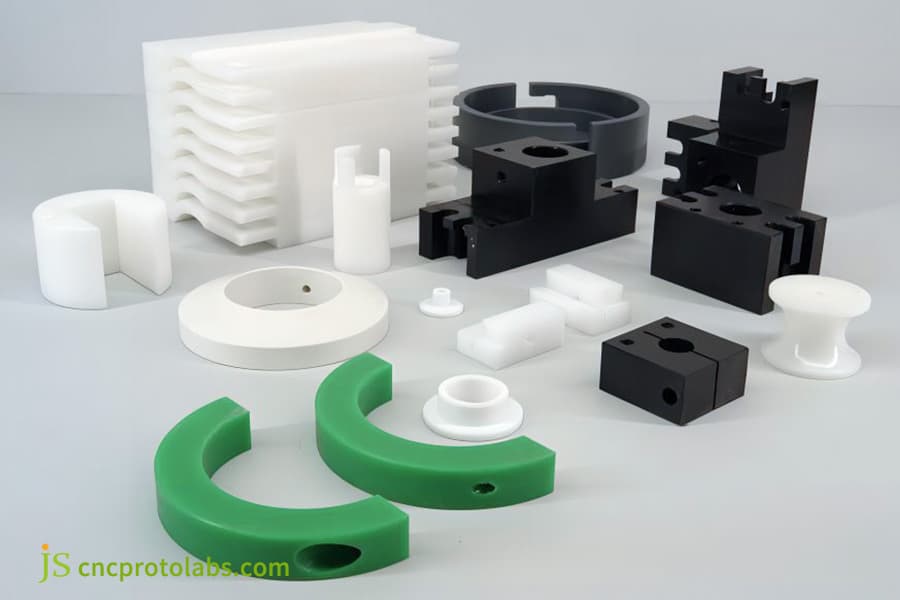

Figure 2: An assortment of white, black, and green plastic and metal industrial components arranged on a light grey background.

How To Choose Cutting Tools For Metal CNC Turning?

Tool selection is a core challenge in metal CNC turning, choosing the right tools can improve efficiency and reduce costs.

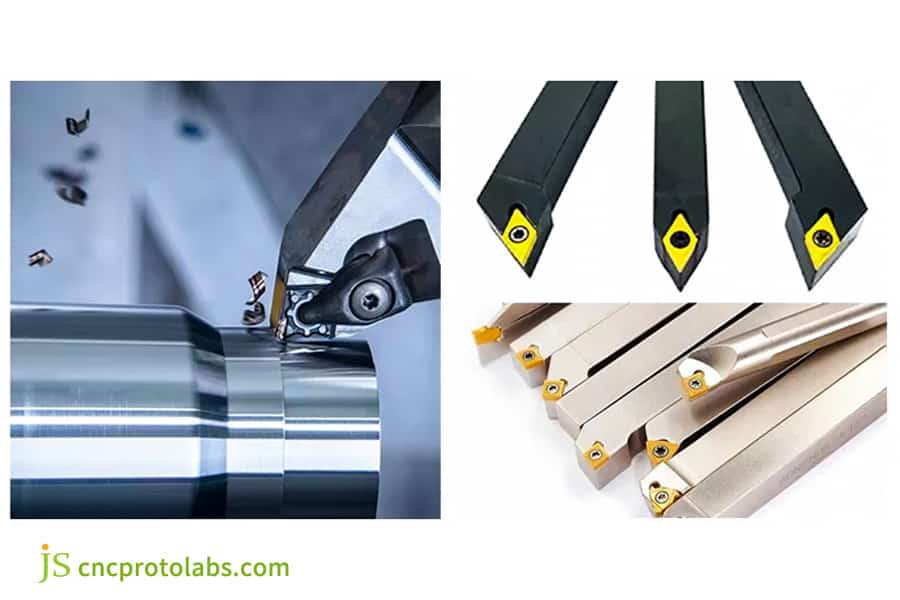

Tool Materials and Coating Technology

The choice of the tool material for metal CNC turning should be in line with the metal being machined:

- Carbide tools are generally used for working aluminum alloys and brass.

- CBN tools for the machining of hardened steel.

- PCD tools for the machining of non, ferrous metals.

On the other hand, coatings like TiAlN and TiN not only extend tool life but also minimize wear.

Geometric Parameter and Cutting Parameter Optimization

The rake angle, clearance angle, and tip radius of the tool have an immediate impact on the cutting result: tools with a large rake angle produce lower cutting forces and are thus better for machining soft metals, tools with a small rake angle possess greater rigidity and are therefore better for the machining of hard metals.

Cutting parameters need to be adjusted according to the material, such as using high speed and large feed for aluminum alloy and low speed and small feed for stainless steel.

Want to optimize tool selection and cutting parameters for metal CNC turning? Contact JS Precision's process engineers for a customized tool selection guide to improve machining efficiency.

Figure 3: A collection of different cutting tool inserts and bars used in CNC turning processes.

How To Obtain Accurate And Real-Time Online CNC Turning Quote?

Online CNC turning quote is an effective way to quickly obtain cost information; mastering the correct methods is essential to ensure accurate quotes.

The Logic Behind the Quotation System

The price structure of online CNC turning quote is clear and transparent, as detailed in the table below:

| Price Structure | Calculation Basis | Percentage Range | Reference Unit Price (USD) |

| Material Cost | Real-time Market Price × Material Usage | 30%-50% | 0.8-5.2/piece |

| Processing Time Cost | CAM Simulation Processing Time × Machine Tool Rate | 20%-40% | 5.5-22/piece |

| Post-Processing Cost | Process Unit Price × Quantity | 5%-15% | 0.3-3.8/piece |

| Administrative Expenses | Total Cost of the First Three Items × 10%-15% | 10%-15% | 1.8-7.5/piece |

Step by Step Guide: Using Online Quotation Tools

The steps of using the quote tool are simple and straightforward:

- Upload your 3D model file in STEP or IGES format.

- Choose the material (e.g., aluminum 6061, POM, etc.), production quantity (1-10000+), and surface finishing method.

- The platform will evaluate the part's manufacturability and provide a quotation as well as the delivery time instantly.

What are the best ways to encrypt your design to save money?

One of the most effective ways to reduce costs is to follow the DFM rules:

- Use uniform hole diameters to reduce tool changes.

- Avoid excessively deep blind holes, by controlling the depth to less than 4 times the diameter.

- Increase the inner corner radius to R0.5mm or more.

- Use standardized thread specifications.

Want to quickly get an accurate online CNC turning quote? Upload your 3D design file now, and JS Precision's online quote system will generate a quote within minutes, plus free DFM optimization suggestions.

Case Analysis: Automotive Sensor Housings Are Produced Locally From Overseas, Reducing Costs By 35%!

Challenge:

An automotive parts manufacturer in Europe had their engine aluminum alloy (6082) sensor housings produced in their own European factories for a long time. This solution has 3 major pain points:

- The unit part price is as high as $25.

- The lead time could be up to 8 weeks.

- The 4 week response cycle for design changes of small, batch production severely lowers product iteration efficiency.

Solutions:

1. Process Restructuring and Optimization:

The original multi step setup process is replaced by utilizing a milling and turning composite center to complete all machining in a single setup, which effectively reduces setup errors and saves machining time by 25%, thus improving machining efficiency.

2. Supply Chain Localization and DFM Optimization:

- Raw material procurement costs are decreased by replacing high, performance imported materials with domestically produced high, quality aluminum.

- Changing the thickness of the two internal ribs from 1.2mm to 1.5mm retains the structural strength and at the same time significantly lessens the scrap rate caused by deformation during the thin, wall machining.

3.Intelligent Production and Quality Inspection:

With the introduction of automated production lines, production continuity and stability are greatly improved; for example, online measurement probes are used for 100% online inspection of key dimensions such as the flatness of the sealing surface (0.01mm), making sure product precision is up to standard.

Results

The solution was able to achieve a very remarkable set of works.

- Unit part procurement cost went down by 35% i.e., a cost of $16.25 per part.

- Lead time which was 8 weeks initially, is now a stable 3 weeks.

- Product qualification rate was boosted to 99.8% from 98.5%, the product successfully passing bench vibration testing.

- The introduction of design change prototype delivery cycle to 1 week has greatly helped the customer's product iteration efficiency.

Want to replicate a similar 35% cost reduction case? Contact us and mention "automotive parts" to obtain a customized localized production solution to reduce your procurement costs.

Figure 4: A silver aluminum EV motor housing with a complex internal structure and a green flange, isolated on a white background.

What Are The Key Points To Consider When Choosing a CNC Turning Service Provider?

Choosing the right CNC turning services supplier is crucial for project success.

Equipment Capability and Technical Support

You should look at the supplier's brand of machine tools, spindle precision, and whether they are working with a mill, turn center and automated loading/unloading system. Also, if the engineering team is competent, they could offer DFM feedback to significantly improve the design.

Industry Certifications and Quality Standards

The suppliers should hold standard certifications like ISO 9001, ISO 13485 for the medical industry, and AS9100D for aerospace. These certifications are a major sign of a company's quality system.

Delivery Time and Customer Service Support

You need to check how flexible a stock supplier's production capacity is and their supply chain management skills. Besides this, they must be willing to offer dual language communication support (Chinese and English) for project management that is geared toward delivering the right and timely information.

FAQs

Q1: What are the maximum and minimum part sizes that CNC turning can process?

JS Precision's machines are capable of handling the turning of rotary components with diameters ranging from 1mm to 300mm and lengths up to 500mm. Micro, turning techniques are capable of producing extraordinarily small precision parts.

Q2: What are the main differences between CNC turning of aluminum and stainless steel?

Aluminum features high cutting speed, long tool life, and lower machining cost, while stainless steel requires high cutting force and generates high heat, thus necessitating specialized tools and cooling strategies. Besides, stainless steel generally takes a longer time to machine.

Q3: Plastic parts are prone to deformation during turning. How can this be addressed?

The use of sharp, specially designed plastic tools, speed at high levels but feed at low ones, sufficient air cooling, and proper clamping forces can go a long way in controlling deformation of plastic components.

Q4: What is mill-turn machining, and what are its advantages?

Mill, turn machining is a method of finishing turning and milling in a unitary machine tool, whereby the number of clamping operations is considerably cut, the accuracy and machining efficiency of complex parts are also increased. And, shaft parts with eccentric holes can be the most suitable cases of using this technology.

Q5: What tolerance grades do you typically guarantee?

For standard precision CNC turning services, JS Precision can guarantee ISO IT7-IT8 level tolerances, and key features can achieve up to IT6 level tolerances.

Q6: What is the typical lead time from order placement to delivery?

Samples first pieces of standard parts can be supplied within 3-5 days, the lead time for small to medium batch production (100-1000 pieces) is generally within 2-4 weeks, which depends on the complexity of the process.

Q7: Can you help if I don't have 3D drawings, only sketches or ideas?

Absolutely. JS Precision's engineering department is on hand to help you completely from concept design through to manufacturing. They take your sketches or ideas and turn them into 3D production drawings.

Q8: Do you support small-batch or single-piece prototyping?

Totally supported. JS Precision gives you the choice of custom plastic CNC turning services and metal prototyping services. So, they are the perfect helping hand during the product development phase.

Summary

CNC turning services have made a meteoric rise being from a simple manufacturing method to a strategic capability for the production of highly complex and precise custom CNC turning parts. Since the demand for faster plastic CNC turning prototypes and tougher metal CNC turning mass production, choosing the right partner has become a must.

JS Precision synergizes state, of, the, art precision CNC turning services with a simple online CNC turning quote system, thus offering a complete concept-to-shelf solution.

Take Action Now: No more waiting. Just upload your 3D design files, use our smart instant quote system, and get DFM optimization suggestions by professional engineers within 24 hours. Make your next custom parts project not only smooth but also accurate right from the beginning.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com