CNC Milling Machining solves many manufacturing challenges. Imagine how a solid block of aluminum can be transformed in days into a drone fuselage with hundreds of precision holes, complex surfaces, and tight tolerances?

The answer is in the "magic hand" of modern manufacturing: CNC Milling Machining. Besides changing digital blueprints into tangible parts, it forms one of the core engines fostering innovation in everything from aerospace to medical devices.

In this comprehensive guide led by the experts at JS Precision, gain insight into how CNC milling makes your ideas alive with the greatest precision, efficiency, and consistency.

Key Answers Summary

| Comparison Dimensions | Basics of CNC Milling | Challenges and Solutions | Core Value from JS Precision |

| Core Definition | Computer-controlled mechanical subtractive manufacturing process involving the removal of material by means of a rotating cutting tool. | Machining errors, complex geometry, hard material handling, and cost control. | High precision, design freedom, material versatility, and quick prototypes and mass production. |

| Key Components | CNC controller, milling machine, cutting tools, fixtures. | High precision machine tools, tool management strategies, process optimization, and professional engineers. | It is able to machine complex geometries that could not be achieved by a traditional method. |

| Process Capabilities | Milling, drilling, tapping, boring, contour machining. | Three-axis to five-axis simultaneous machining to handle parts of varying complexity. | Consistency and scalability from single prototype to mass production. |

| Material Applicability | Metals, plastics, composites. | Dedicated tools and parameters for different materials, such as titanium alloys and hardened steel. | One-stop solutions from aluminum to engineering plastics for a wide range of needs. |

| Selection Criteria | Part complexity, precision requirements, materials, budget, and lead time. | JS Precision uses professional consultation to match you with the best equipment and process. | Get the most cost-effective manufacturing by optimizing your design and process expertise. |

JS Precision: Your Source For Precision CNC Milling

JS Precision has been involved in precision CNC milling for 12 years and is ISO 9001- and AS9100-certified. The company provides services to more than 600 customers from 12 industries: aerospace, medical, automotive, drones, new energy, and more.

Every year, JS Precision manufactures more than 30,000 CNC milling machining parts. Its equipment matrix includes high-end models from DMG MORI and Haas.

We process titanium alloy bone nails for medical clients, with a stable accuracy of ± 0.005mm through customized hydraulic fixtures and parameter control. The processing parameters and biocompatibility verification refer to the ISO 5832-3 surgical implant standard.

We produce aluminum alloy brackets for aerospace companies, reaching a batch yield rate of 99.5%. We process battery tab clamps for new energy companies, reaching an accuracy of ±0.01mm.

This guide is a practical summary of over 3000 complex projects and is trustworthy.

Want to learn how JS Precision can tailor CNC milling solutions to your industry? Send in your industry and part requirements to receive a free personalized case study and grasp the key points in industry machining in record time.

How Does CNC Milling Machining Turn Digital Drawings Into Reality?

CNC Milling requires the collaboration of controllers, cutting tools, and fixtures to achieve the conversion of drawings into entities. Below is a breakdown of the core CNC milling machining process.

From Code to Motion: The Brain Role of the CNC Controller

The CNC controller is the "brain," while G-code is the "instruction language."

Following the importation of CAD drawings, the CAM software converts them into G-code, such as G01 for linear motion and M03 for spindle forward rotation. These are instructions which the controller uses to activate servo motors, driving the worktable and spindle trajectory so that its path precisely matches the drawing.

Tool Magazine and Tool Changer

Multi-stage automated machining can be done with the use of a tool magazine and tool changer.

JS Precision machining centers have a 20-40 tool magazine that will store milling cutters, drills, etc. The system automatically changes the tools according to the requirements of the CNC milling machining process, which negates the need for manual intervention, thus allowing milling, drilling, and tapping operations to be performed in one go.

Fixtures: Stable Clamping is the Basis of Precision

Workpiece fixing affects precision. JS Precision designs fixtures according to the type of part, such as hydraulic and vacuum chuck.

For instance, for automotive engine prototype parts, a custom-built fixture controls the clamping force at 500-800N with minimal deformation to make sure that the dimensional error is within ±0.02mm, thus ensuring the precision of CNC milling machining parts.

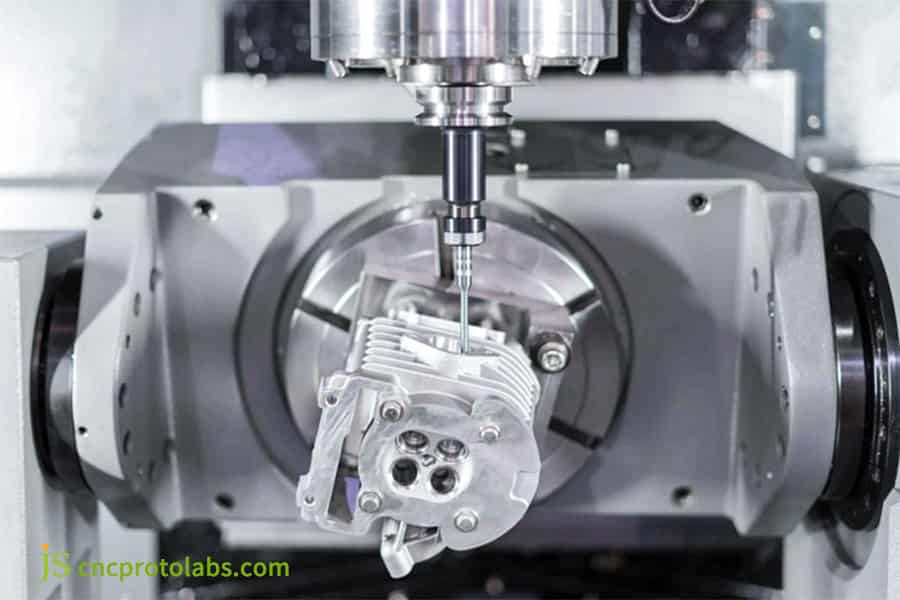

Figure 1 Numerical control milling machines convert three-dimensional computer-aided design (CAD) models into a series of computer instructions.

How To Master The CNC Milling Machining Process, Achieving Micron-Level Precision?

For micron level precision, the CNC milling machining process should be optimized, which includes identification of errors, control strategies, and measurement feedback.

Sources of Error Identification: Machine Tools, Cutting Tools, Thermal Deformation and Vibration

- Machine Tool Error: A machine tool, which has not been calibrated for 5 years, may have guideway error of 0.03mm,

- Cutting Tool Error: During the machining of aluminum alloys, high-speed steel cutting tools wear down 0.01mm per 100 pieces,

- Thermal Deformation Error: When operating at 8000rpm, a 5℃ rise in temperature may extend the spindle by 0.005mm,

- Vibration error: Deep cutting of deep-cavity parts can easily produce vibration, affecting the surface roughness.

JS Precision's Precision Control Strategy: From Prevention to Compensation

- Monthly machine tool calibration with a laser interferometer, controlling positioning errors within ±0.003mm,

- The infrared sensors on the machine tool will automatically signal for replacement if the wear has attained 0.008mm.

- The constant-temperature cooling system can maintain the cutting fluid at 20±1℃ to reduce thermal deformation.

- Antivibration pads on the base of the machine tool decrease vibration by 10% while machining steel parts.

Measurement and Feedback: Ensuring the Quality of Every Part with Data

JS Precision has established a full-process quality inspection system, sampling at each process. Using a coordinate measuring machine for full-dimensional inspection of finished products.

For example, for optical components, 15 key dimensions are measured, each dimension is measured 3 times and the average is taken, any deviation is used to adjust the parameters of CNC milling machining process.

Figure 2 CNC milling machining parts have incredible capabilities for accurate and precision machining.

Three-Axis Vs. Five-Axis: Choosing The Best CNC Milling Machining Center For Your Project

The selection of the correct CNC milling machining center holds the key to enhancing efficiency and cutting costs. Three-axis and five-axis machining centers each boast their sets of advantages.

Three-Axis Machining Center: King of Economical and Efficient Planar Machining

Only movement on X, Y, and Z axes allows it to be used with planar parts such as plates and bases, it is low-cost and of high efficiency. For example, an aluminum alloy plate 200×300 mm could be machined for 1 hour for about $50. In contrast, a part with complex curved surfaces requires many clamping operations, which may increase errors.

Five-Axis Machining Center: A Powerful Tool for Complex Curved Surfaces and One-time Forming

Including X, Y, Z axes+A, C rotation axes, multi angle machining, complex parts can be clamped in one go with high precision, suitable for aviation and medical parts, but the cost is relatively high.

How JS Precision Helps You Make an Intelligent Choice?

JS Precision has 10 three-axis and 5 five-axis machining centers. Engineers suggest based on part size, complexity, accuracy, and budget: while choosing three-axis for simple aluminum bases to reduce costs for instance, five-axis should be chosen for complex impellers of titanium alloy.

Comparison of Three-Axis and Five-Axis CNC Milling Machining Center

| Comparison Dimensions | Three-Axis Machining Center | Three-Axis Machining Center |

| Axes of Motion | X, Y, Z (Linear Axes) | X, Y, Z + A, C (Rotary Axes) |

| Applicable Parts | Flat parts, simple housings | Complex curved parts, impellers, medical devices |

| Clamping Frequency | Several (complex parts) | Single (most complex parts) |

| Machining Accuracy | ±0.02-0.05mm | ±0.005-0.02mm |

| Machining Cost (per hour) | $40-80 | $100-200 |

Figure 3 5 axis cnc milling. Continuous five axis machining can produce highly complex three-dimensional shapes with intricate surfaces.

Deciphering The Pricing Logic Of Complex CNC Milling Services

Costs of the CNC milling services include machine time, materials, and post-processing costs. Knowing this logic helps to control the budget.

Machine Time Costs: Material and Geometric Complexity

The machine time cost is connected with the difficulty and time of machining.

Because the machining speed of the titanium alloy is 1/3 that of the aluminum alloy, with the same time its machine time cost is higher. Complex deep-cavity parts take five times longer to process when compared with simple cubes. In such a case, it costs $50 per hour for an aluminum cube, while a complicated titanium alloy part costs US$300 for 5 hours.

Material Costs: From Common Aluminum to High-Priced Special Alloys

The prices of different CNC milling materials vary: 6061 aluminum is ~$10/kg, whereas that of TC4 titanium alloy is ~$100/kg. The material loss is included and estimated as 20% for a complex part and 5% for a simple one.

Post-processing and Finishing: The Overlooked Cost Components

Price will be influenced by the post-processing treatment: anodizing for aluminum alloy costs $20/m², nickel-plating for stainless steel is $50/m², whereas high-precision polishing has to be done manually, which would raise the cost accordingly.

Common Material and Post-processing Cost Reference

| Material Type | Material Cost (USD/kg) | Common Post-processing | Post-processing Cost (USD/m²) |

| 6061 Aluminum Alloy | 10-15 | Anodizing | 15-25 |

| 304 Stainless Steel | 20-30 | Sandblasting | 10-20 |

| TC4 Titanium Alloy | 90-110 | Pickling and Passivation | 30-40 |

Do you want to have a clear understanding of the composition of your CNC milling services quotation? Fill in your part requirements of materials, dimensions, and post-processing, and let JS Precision give you a detailed cost breakdown while optimizing your design for cost reduction.

What Designs Are Considered The Perfect Match For CNC Milling Machining Parts?

CNC milling is most suitable for the following three types of designs to maximize its advantages.

High-Precision and Tight-Tolerance Mating Parts

CNC milling excels in machining mating parts down to ±0.01-0.05mm tolerance, including various aerospace brackets and optical lens mounts requiring a ±0.005mm tolerance. JS Precision achieves more than 99% of yield rate for those kinds of CNC milling machining parts.

Functional Prototypes with Complex 3D Geometry

Complex prototypes, such as the car engine block and the wearable device housing, are directly machined from CAD without any mold requirements. This allows fast design verification and reduces the R&D cycle time.

High-Value End-Parts in Small to Medium Batch Sizes

It can produce high-value parts in small and medium batch sizes, ranging from 1-1,000 pieces, without requiring molds to reduce costs. Examples include, but are not limited to, medical surgical instruments in batches of 50-200 pieces per batch and industrial sensor housings in 100-500 pieces per batch. The production will be efficient, and the quality ensured by JS Precision.

Need CNC milling machining parts? Specify the application, batch size, and precision requirements for a free feasibility assessment and DFM recommendations.

Optimizing CNC Milling Machining Process Parameters: Beyond Basic Skills

The reason for optimizing the parameters is to ensure accuracy, efficiency, and tool life. The following are some of the core techniques:

The Golden Balance between Cut Speed and Feed Rate

Efficiency, tool life, and surface finish are all interconnected with the cutting speed-feed rate. JS Precision finds an optimum based on the CNC milling materials and tools.

In the case of the 6061 aluminum alloy, carbide tools shall be used at 1500 rpm, feed 200 mm/min, while maintaining Ra0.8μm surface finish and tool life of over 500 pieces. In the case of 304 stainless steel, the speed is cut back to 800 rpm and feed to 100 mm/min to avoid severe tool wear.

Coolant and Lubrication: More Than Cooling

Coolant lubricates, removes chips, and reduces heat deformation. Different materials require different cooling methods: Oil cooling for aluminum alloys to reduce built-up edge, high-pressure air cooling for magnesium alloys to avoid combustion, air cooling for engineering plastics to avoid deformation.

CNC Milling Machining Process Parameter Reference for Common Materials

| Material Type | Tool Type | Cutting Speed (rpm) | Feed Rate (mm/min) | Cooling Method |

| 6061 Aluminum Alloy | Carbide End Mill | 1200-1800 | 150-250 | Oil Cooling |

| 304 Stainless Steel | Coated Carbide End Mill | 600-1000 | 80-120 | Oil Cooling |

| TC4 Titanium Alloy | Dedicated Titanium End Mill | 300-500 | 30-50 | Oil Cooling + High-Pressure Flushing |

Pushing The Limits: Strategies For Overcoming Difficult-To-Machine CNC Milling Materials

Difficult-to-machine materials, including high hardness and poor thermal conductivity, easily lead to tool wear and low precision. JS Precision has customized solutions.

Machining of Titanium Alloys and High-Temperature Alloys

Difficulties: Hardness in the range of HRC 30-45, thermal conductivity is poor, susceptible to work hardening. Solution: Application of dedicated carbide cutters, lower speed-higher feed rates- 300-500 rpm, High-pressure cooling-10-20 MPa

Lightweight yet strong, Challenges in Machining of Stainless Steel and Mold Steel

Stainless steel sticks to the cutter, use TiAlN coated cutters plus optimized feed rate. Mold steel (HRC 50 plus): anneal to reduce hardness, rough machining with carbide plus finish machining with CBN.

Precision Milling of Non-Metallic Materials: Composite Materials and Engineering Plastics

Due to the possibility of easy delamination in composite materials, use the spiral end mills with high speed and low feed, together with the buffer pad. In engineering plastics, melting may easily occur, hence, high speed steel cutters should be used with air cooling to prevent the generation of burrs and deformation.

Solutions to tough-to-machine CNC milling materials

| Material Type | Machining Challenges | JS Precision Solution |

| TC4 Titanium Alloy | Hard, poor thermal conductivity, prone to hardening. | Dedicated cutting tool + low speed, high feed + high pressure cooling. |

| 304 Stainless Steel | Sticking to the tool, chip entanglement. | TiAlN coated cutting tool + optimized feed + air blowing chip removal. |

| Carbon Fiber Composite Material | Prone to delamination and fiber breakage. | Spiral end mill + high speed, low feed + buffer pad. |

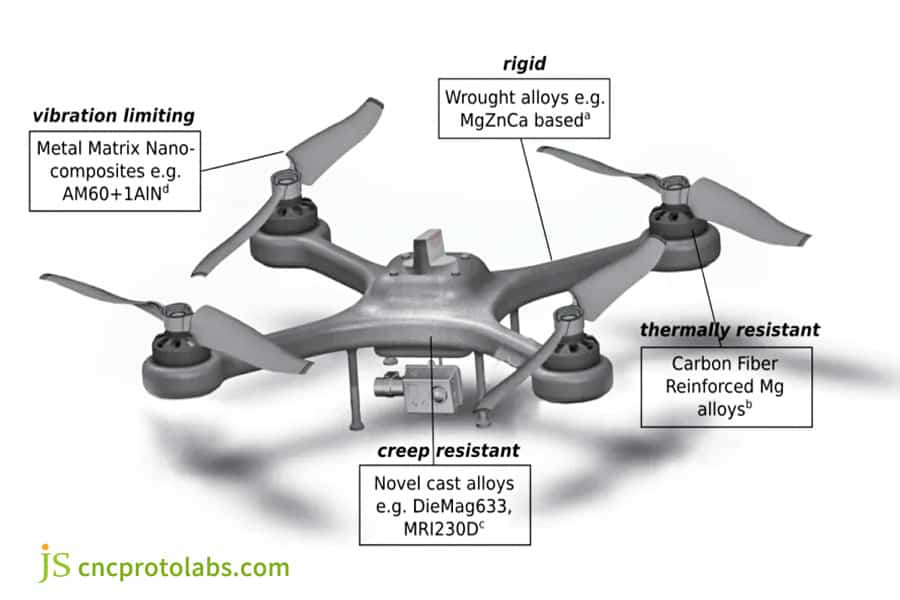

Case Study: From 48 Hours To 8 Hours – How 5-Axis CNC Speeds Up Drone Projects By 83%

Customer Pain Points

A drone startup had an urgent problem. It needed to make a 300×200×150mm magnesium alloy fuselage with a complex streamlined outer shell and internal reinforcing ribs.

The original process required six clamping operations on three 3-axis CNC machines and took up to 48 hours. Although the precision of the single machine was very high, due to the recalibration of the machine after every clamping operation, it had a 0.1mm cumulative error, which resulted in the yield rate only reaching 70%, severely affecting the product launch schedule.

JS Precision Solution

1. Equipment Selection:

We use a five-axis machining center (model DMG MORI NTX2000). This machine supports X, Y, Z, A, and C axes linkage, thus enabling the machining of all surfaces of the machine body in one setup and completely eliminating the cumulative errors caused by multiple setups.

2. Material-Specific Solution:

Magnesium alloy is a flammable material. We customized specific cutting parameters-spindle speed: 5000 r/min, feed rate: 800 mm/min-and in the process used high-pressure air cooling-pressure of 0.8 MPa-in combination with an oil mist collector to guarantee effective cooling while avoiding the combustion of magnesium alloy debris.

3. Toolpath Optimization:

We applied Mastercam software's dynamic milling strategy to optimize the toolpath and reduce idle travel. For instance, we changed the original linear infeed/retract toolpath to a circular infeed/retract toolpath and combined some adjacent machining operations, which decreased the time of idle travel from 8 hours to 2 hours.

Results

By applying the above solution, the machining time for a single magnesium alloy fuselage was shortened from 48 hours to 8 hours, which improved overall efficiency by 83%.

At the same time, one-time molding avoided cumulative errors and controlled the dimensional accuracy of parts within ±0.02mm, increasing the yield rate to 99.5%. Further, the decrease in the number of clamping operations saved costs from manufacturing three sets of special toolings-about $3,000.

Eventually, the customer's drone product was launched two weeks in advance, gaining an advantageous position in the market. Later, they signed a long-term cooperation agreement with us, placing all the orders of CNC milling services with JS Precision.

Want to speed up and lower costs for projects like drone fuselage machining? Call the JS Precision hotline and set up a time to see a machining demonstration at our 5-axis CNC milling machining center. We offer efficient and high-precision machining services that will help your products capture the market quickly.

Figure 4 CNC milling magnesium alloy drone body

Partner With JS Precision: Best Practices For Launching Your Next CNC Milling Machining Project

It is not complicated to start a CNC Milling Machining project. Here, JS Precision outlines three best practices to help you reduce communication costs and time waste.

Step 1: Standardized CAD files shall be provided in either IGES or STEP format. Dimensions are to be specified, along with tolerances and reference datums. The critical dimensions shall be in ±0.02mm. If unreasonable design structures-such as fillets that are too small or cavities that are too deep-are proposed, optimization shall be performed later.

Step 2: Clearly state the CNC milling materials used, such as 6061 aluminum alloy and TC4 titanium alloy. Specify the accuracy requirements with the key dimensions ±0.01mm and clearly state the required surface treatment-anodizing-to avoid rework due to unclear requirements.

Step 3: Free DFM consultation-Our Engineers will further optimize the design from the received documents and requirements. This may involve standardization of fillets for the purpose of adjusting cavity depth. We have helped clients optimize shell designs for up to 30% in machining time and 25% in cost.

Are you ready to start your CNC Milling Machining project? Provide a specification and CAD file here, and get a free DFM consultation right now to optimize your design for cost and time savings.

FAQs

Q1: What is the maximum precision that can be achieved using a CNC milling?

Precision depends on the class of machine tool and part size. Using its high-end five-axis machine tools, JS Precision can repeatedly realize ±0.01mm precision. Specific precision depends upon your assessment of part size and material.

Q2: How should I choose between CNC milling and 3D printing?

When the part requires high strength, high precision, and excellent surface quality, CNC milling machining is a better choice. When the part needs to have a complex internal structure, rapid prototyping, or lower strength, 3D printing can be selected.

Q3: What is the largest size of parts you can handle?

The travel strokes of JS Precision machining centers vary, and the diameter of workpieces can be over 1500mm, too. Please provide drawings so that we can give an exact answer on dimensional fit.

Q4: How long does it typically take from quotation to delivery?

Simple parts, like aluminum blocks, are delivered within 2-3 days after quotation. Relatively complicated projects, impellers of titanium alloy for example, take 1-2 weeks. The exact date of delivery will be included in the quotation.

Q5: Which material, between the two, is best suited for CNC milling: aluminum or steel?

Aluminum is easy to machine and low in cost, suitable for parts with low strength requirements. Steel is high in strength, but it is slower to machine and the tooling is more costly. Your application scenario decides which one is suitable.

Q6: Do you provide assembly services?

Yes, JS Precision provides a "one-stop" service from machining to surface treatment to the final assembly of your parts. It can ensure that the overall quality after assembly can meet your requirements.

Q7: How do I lower my CNC Machining costs?

Our DFM service will help you effectively reduce cost by optimizing design through depth cavity reduction and unifying fillet radius, selecting appropriate materials, and relaxing non-critical tolerances.

Q8: Other than milling, what other machining services do you provide?

Other than CNC milling, the service range in JS Precision's portfolio includes turning, wire cutting, and laser cutting, which can fulfill most of your precision manufacturing needs.

Summary

CNC Milling Machining is a kind of "magic hand" in precision manufacturing, which transforms virtual digital drawings into high-precision and high-quality cnc milling machining parts. Whether processing complicated curved surfaces or fittings in tight tolerances, it can do it all with ease.

Backed by 12 years of experience, a complete equipment matrix, and tailor-made solutions, JS Precision is helping customers to overcome the challenges of machining, speed up production, and cut costs.

Your design deserves to be manufactured perfectly.

Upload your 3D model file now to JS Precision's online quotation platform and get a detailed quote with free DFM advice in a few hours. Let precision empower your creativity!

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com