CNC engine block machining is one of the most important parts of industries dealing in automotive and construction machinery. The central part of any high-performance engine-running steadily at thousands of revolutions per minute-is the engine block, which sees extreme thermal loads and mechanical stresses.

Such exceptional performance under such harsh conditions can be obtained through micron-level precision offered by the CNC engine block machining. Understanding every step from material selection to precision CNC machining, whether for mass production optimization or high-performance modification, is crucial to ensure reliability and performance in engines.

This tutorial will give insight into manufacturing secrets, from core engine component machining processes to cost control, with the aim of helping you efficiently accomplish the machining of an engine block.

Key Answers Summary

| Aspects | Core Information | Key Advantages | Application Value |

| Machining Accuracy | Cylinder bore tolerance control up to ±0.008mm, roundness ≤0.005mm. | Ensures high engine performance and reliability through precision CNC technology. | Meets the demanding requirements of high-performance sports cars, commercial vehicles, etc. |

| Material Selection | Aluminum alloy cylinder blocks are 30%-40% lighter than cast iron, with more than 3 times better thermal conductivity. | Achieves lightweighting, improving fuel economy and heat dissipation efficiency. | Suitable for lightweighting scenarios such as passenger cars and new energy vehicles. |

| Cost Control | Reduces unit cost by up to $35 through process optimization (such as merging processes). | Optimizes tool life management and automation, reducing hidden expenses. | Helps customers control total cost while ensuring quality. |

| Service Experience | JS Precision has 12 years of experience, serving 300+ industry clients. | Provides end-to-end digital services from design review to online tracking. | Ensures efficient project implementation, shortening delivery cycles to 5-15 days. |

JS Precision Manufacturing: The JS Precision Authoritative Guide To Precision Engine Block Machining

For the last 12 years, JS Precision has been deeply involved in the CNC engine block machining area, serving more than 300 clients across the automotive, marine, and construction machinery industries.

We have machined the aluminum alloy engine blocks for high-end sports car brands using Precision CNC Machining technology to control cylinder bore tolerances within ±0.008mm, way beyond the client's requirement of ±0.015mm.

This level of accuracy is in line with the in-depth research conclusions of the Society of Automotive Engineers (SAE International) on the relationship between the geometric accuracy of high-performance engine cylinder bore and friction loss in relevant technical papers, reflecting the direct impact of machining accuracy on engine performance.

In terms of improving efficiency, we have significantly increased our customers' production capacity by optimizing the rough machining process of cast iron cylinder bodies, reducing the single machining time from 45 minutes to 32 minutes.

Our CNC machining team consists of 15 certified engineers, averaging over 8 years of experience each, and can handle even complex machining needs. This guide summary was obtained from thousands of experience in machining projects, each point has been practically verified and can be used with confidence.

If you need high-precision CNC engine block machining services, JS Precision can offer a custom solution, following up on the entire process from drawing analysis to production delivery. Contact us now to receive a free process review to help you mitigate machining risks.

What Are The Core Processes In Precision CNC Engine Block Machining?

After understanding JS Precision's capability, let's look at the core processes of Precision CNC Engine Block Machining, each step influencing the final quality.

Basic Machining Process

- Blank Positioning: After allowance checking with 3D scanning, it is fixed with specialized tooling, having a positioning error ≤0.02mm.

- Rough Machining: Most of the allowance will be removed by high-speed steel tools, machining the outer contour and bottom surface while controlling the cutting speed to avoid overheating.

- Semi-Finish Machining: Replace with carbide tools to machine cylinder holes, etc., leaving a 0.1 - 0.2 mm finishing allowance.

- Finishing Machining: High precision tools with Precision CNC Machining technology provide the highest dimensional accuracy and surface finish.

Key Feature Machining

- Boring and Honing of Cylinder Bore: Adjustable boring tools ensure diameter tolerance, multi-oil honing heads achieve surface roughness with a Ra of 0.4-0.8μm and cross-hatching.

- Crankcase Machining: Horizontal CNC machine tools perform one-time machining of main bearing holes with coaxiality error ≤0.005mm.

- Water Jacket and Oil Passage Machining: Deep-hole drills are water-cooled to avoid any clogging in oil passages, and cavity milling cutters ensure smooth oil flow channels in water jackets.

Precision Control Core

- Thermal Deformation Compensation: with a temperature sensor, the machine tool automatically changes the tool path if the temperature difference exceeds ±2℃.

- Unified Datum: The bottom surface of the cylinder block and two locating holes should be used as unified datums to prevent frequent datum changes and product errors.

- Online Measurement: Dimensions are checked with probes after key processes, such as checking diameter and roundness after cylinder bore machining.

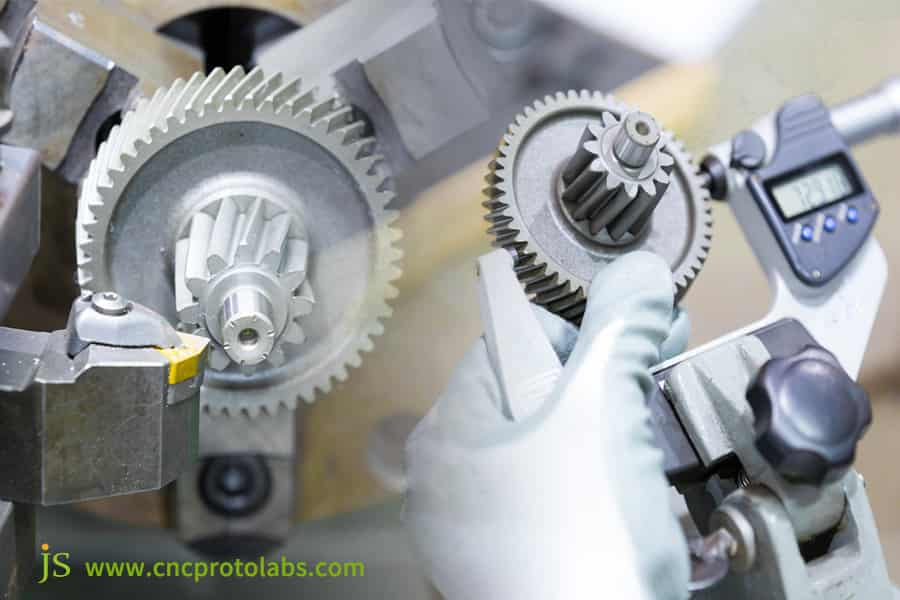

Figure 1 CNC-machining achieves tight tolerances of up to ±0.0025 mm for engine components. This precision guarantees better performance and durability of critical parts such as cylinder heads.

How To Select Optimal CNC Engine Block Machining Tooling For Different Materials?

After mastering the machining process, the selection of CNC engine block machining tooling is crucial, as it directly affects efficiency and accuracy. Every different material needs a different solution in tooling.

Tool Material Selection:

- PCD Tools: Hardness ≥ HV8000, wear resistance very good, machining of aluminum alloy, life 5-8 times as long as that of cemented carbide, keep surface roughness.

- Ceramic Tools: Suitable for cast iron machining, high temperature resistance ≥1200℃, cutting speed is 30%-50% higher than that of cemented carbide, improving roughing efficiency.

Specialized Tooling Solutions:

- Cylinder Bore Boring Tool: Modular design for easy insert replacement, insert selection based on material, with a 0.001mm precision fine-tuning mechanism.

- Face Milling Cutter: Multiple evenly spaced flutes reduce cutting force, suitable for cylinder block top and bottom surfaces, with a flatness error ≤0.01mm.

- Deep Hole Drill: Internal cooling design reduces cutting temperature, long guide section ensures drill hole straightness and prevents oil passage misalignment.

Machining Parameter Optimization:

- We optimize the database for cutting speed and feed rate of different CNC engine block materials: Gray cast iron cutting speed 80-120m/min, feed rate 0.15-0.2mm/r, Aluminum alloy cutting speed 300-500m/min, feed rate 0.2-0.3mm/r.

JS Precision has a professional CNC engine block machining tooling selection team that will recommend the best tooling solution for your cylinder block material and machining requirements. Besides, they can support parameter optimization. All these factors make choosing us worth consideration, saving your tooling cost while improving machining efficiency.

Which CNC Engine Block Materials Deliver The Best Performance And Durability?

Apart from choosing cutting tools, CNC engine block materials selection is imperative since it will decide upon the performance of the engine and its durability. The application scenario has to be the basis for making a selection.

| Material Type | Strength (MPa) | Wear Resistance | Vibration Damping Characteristics | Lightweighting Effect | Applicable Scenarios |

| Gray Cast Iron | 200-300 | Good | Excellent | Poor | Commercial trucks, agricultural machinery engines. |

| Ductile Cast Iron | 400-600 | Excellent | Good | Fair Poor | Heavy trucks, construction machinery engines. |

| Aluminum Alloy | 250-400 | Medium | Average | Good(30%-40% lighter than cast iron) | Passenger car, sports car engines. |

| Magnesium-Aluminum Alloy | 300-500 | Medium | Average | Excellent(15%-20% lighter than aluminum alloy) | High-end sports car, new energy vehicle engines. |

Cast Iron Material Characteristics:

Gray cast iron exhibits excellent vibration damping and noise reduction, and good wear resistance, making it suitable for commercial trucks, however, it has high weight that increases fuel consumption.

In ductile cast iron, there is a strength increase of more than 50% as compared to gray cast iron, along with better wear resistance, hence suitable for heavy loads, however, its weight is still higher than that for aluminum alloys.

Advantages of Aluminum Alloys:

It is lightweight (30%-40% lighter) with very good thermal conductivity (3+ times that of cast iron), helping to improve fuel economy and heat dissipation. We enhance the strength of aluminum alloys through T6 heat treatment or by adding silicon and magnesium reinforcement.

Composite Material Trends:

Magnesium-aluminum alloys are 15%-20% lighter compared to ordinary aluminum alloys and have similar strength, they are suitable for high-end sports cars and new energy vehicles.

Metal-based composite materials, such as aluminum-based silicon carbide, possess good wear resistance and high-temperature resistance and are suitable for cylinder bore liners. The application in high-end fields is on the increase.

What Are The Technical Keys To Success In CNC Machining Cylinder Heads?

After the engine cylinder block is machined, the CNC machining cylinder heads are also critical, and the machining quality affects the combustion efficiency and reliability of the engine.

Combustion Chamber Machining:

Shape error > 0.05mm easily leads to incomplete combustion, while Ra > 1.6μm easily leads to carbon buildup. 5-axis CNC milling + finish milling ensures Ra ≤ 0.8μm and shape accuracy.

Valve Seats and Guides:

The coaxiality error of the valve seat shall not be more than 0.01mm, otherwise, there will be a problem of poor sealing. Fit clearance between the guide and valve: 0.02-0.04mm. If improper, there is easily air leakage or jamming. We use special tooling for positioning. First, we machine the guide hole, press-fitting the seat, then reaming.

Water Jacket Machining Cooling:

The flow channel of the water jacket for cooling is complicated, burrs or chips can easily result in overheating of an engine. We use a custom cavity milling cutter to perform multistage milling to avoid deformation, and ≥5MPa high-pressure flushing + endoscopic check for cleanness.

With years of experience in CNC machining cylinder heads, JS Precision ensures the most precise machining of critical parts such as combustion chambers and valve seats. If you require a complete machining service for engine blocks and cylinder heads, choose us for precise matching and improved overall engine performance.

What Factors Truly Impact CNC Engine Block Machining Cost?

We discussed the technology, and a lot of factors influence the CNC engine block machining cost. Understanding these factors enables one to optimize them, thereby decreasing the cost while keeping the quality intact.

Cost Structure Analysis:

| Cost Composition | Percentage (%) | Explanation |

| Equipment Depreciation | 25-30 | Mainly depreciation of the CNC machine tool, high precision machine tool depreciation costs are higher. |

| Tool Consumption | 15-20 | Depending on material used, the tool consumption is in the order from higher to lowest, for example, cast iron machining, aluminum alloy machining. |

| Labor Costs | 20-25 | Includes wages for programmers, operators, and quality inspectors, complex machining requires highly skilled workers. |

| Energy Consumption | 5-10 | Mainly energy consumption for CNC machine tools and auxiliary equipment, the more time the machine is on, the higher the energy consumption. |

| Others | 10-15 | Includes losses of raw material, coolant, site rent etc. |

The main cost items include equipment depreciation, labor costs, and tool consumption. These account for an estimated proportion of over 60%. In the process of machining of the aluminum alloy cylinder block, for example, the total cost is about 230-330 dollars, and more than 70% is in the first three items.

Optimization Potential:

Process optimization: Combining processes can reduce the time used for machining. Tool life management: Replacing tools in time can avoid the wasting of workpieces. Automation: It reduces labor costs and improves equipment utilization.

Value Engineering:

Simplification of complicated structures in design and elimination of difficult-to-machine features, like deep holes or narrow slots. Example: After adjusting the deep hole of a certain customer's cylinder block, the machining process was reduced by 40%, resulting in a decrease of $35 in the CNC engine block machining cost.

Figure 2 CNC Automatic Vertical Honing Machine with Hole-to-Hole Automation

What Are The Essential Design Guidelines For Engine CNC Machining Parts?

Early design to reduce machining cost is very important, therefore, in designing the engine CNC machining parts, the following must be followed to ensure manufacturability and economy.

Structural Design Guidelines

- Uniformity of Wall Thickness: The wall thickness ranges from 2 to 5mm. The maximum difference should be ≤3mm to avoid machining deformation.

- Rounded Corner Transition: The radius of corners should not be less than 2 mm to avoid machining difficulties at right angles and stress concentration.

- Rigidity Guarantee: Ribs reinforce weak areas to prevent machining vibration problems that can affect accuracy.

Manufacturability Considerations

- Accessibility of Machinability: The tool must reach all machined surfaces. Whenever possible, avoid closed cavities or deep grooves having a depth to diameter ratio greater than 5, because these might require special tools and higher costs.

- Datum Design: Clearly define the positioning datum and fix it stably, try not to change the datums frequently, for example, two positioning holes with a bottom face.

- Tool Interference Check: Simulate the toolpath after design and modify any structures that could interfere in advance.

Tolerance design

- Based on function, appropriate tolerance is assigned. For example, the tolerance of the cylinder bore should be controlled within ±0.01mm, while for the side, it can be relaxed to ±0.1mm. We will give reasonable tolerance suggestions.

JS Precision offers you consultation in design for your engine CNC machining parts, which helps you optimize the structure and improve manufacturability. If you have design drawings, our engineers will do a free process review to ensure that the design is suitable for machining and reduce subsequent costs.

Figure 3 Avoid sharp inside corners whenever possible.Since all CNC drill bits are circular, it’s difficult to achieve sharp internal corners.

How To Implement CNC Machining Online For Engine Blocks Efficiently?

Since the widespread digitalization in recent years, CNC machining online, if put into practice effectively, will contribute much to improving efficiency. JS Precision has realized full-process digitalization and offers convenient online services.

Digital Process:

You only need to upload your drawings and technical requirements through the online platform, the system will auto-quote a preliminary quotation. The detailed plan and quotation will be provided by the engineers within 24 hours. After confirmation, track the production process in real time.

Remote collaboration:

The process modification is confirmed through real-time communication among the engineers when some problems appear in machining. For example, the cylinder block water jacket machining problem for an overseas customer was resolved within 3 days.

Intelligent Monitoring:

Sensors are installed on every CNC machine tool to monitor the cutting force, temperature, and tool wear. Warnings are issued automatically when any anomaly occurs. Data collection, analysis, and optimization have been implemented. For example, the adjustment of parameters increased efficiency in a certain machine tool by 15%.

Case Study: Achieving 25% Weight Reduction And 15% Power Increase With Precision CNC Machining

Having discussed the theory, we will now demonstrate with a practical case study the value that Precision CNC Machining can bring. Below is a case study on how we solved a weight reduction and performance improvement problem for a high-performance engine manufacturer.

Customer Challenge

The customer manufactures high-performance sports car engines. For this reason, the customer needs a lightweight cylinder block with increased power while still maintaining reliability in the engine.

They are targeting more than a 20% weight reduction for the cylinder block, benchmarking off an original cast iron design weighing 45kg that produces 350 horsepower, while achieving power increases of more than 10%, passing 500 hours of bench testing-the current industry standard is 400 hours.

Our Solution

First of all, we recommend changing the material from cast iron to high-strength aluminum alloy-Al-Si-Mg alloy, whose strength is 350MPa, 20% higher than ordinary aluminum alloy and 35% lighter than cast iron.

Then, we are to optimize the structure of the cylinder block: eliminate the unnecessary wall thickness, reduce the 8mm wall thickness to 5mm, set reinforcing ribs on weak points to ensure rigidity.

The precision CNC machining technology is used, with a 5-axis CNC machine tool for machining the combustion chamber to maintain shape accuracy, PCD tools for machining cylinder bores with a tolerance of ±0.008mm to reduce friction, the cylinder block is subjected to T6 heat treatment to improve the strength and resistance to wear.

Successful performances

- The weight of the cylinder was eventually brought down from 45kg to 33.75kg, representing a 25% reduction.

- The engine power was increased to 392.5 horsepower, a 15% increase.

- Fuel consumption was reduced by 8%, from 12L/100km down to 11.04L/100km.

- Bench tests revealed 500 hours of continuous operation with no failure, while cylinder wear reached only 0.002mm, far below the industry standard of 0.005mm.

- The customer was satisfied and thus placed an order for 300 cylinder blocks.

At JS Precision, we go above and beyond in solving complex customer needs with Precision CNC Machining technology. Be it weight reduction or improved performance, we can offer a tailor-made solution for you. This is one among the many successful projects taken up by us. Choose us, and your engine project could also achieve a breakthrough.

Figure 4 CNC aluminum engine cylinder block

How To Start Your Engine Project With Our CNC Machining Online Services?

If you want to start the engine project, don't fuss-the process of using our CNC machining online service is pretty straightforward, follow it to get going.

Step 1: Technical Requirements - Detailed drawing information should be provided in CAD, STEP, or whatever format is supported and should include technical specifications such as dimensional tolerances, surface roughness, material, and target cost. Please feel free to contact us for design suggestions if your drawings are incomplete.

Step 2: Process Scheme Review - Your requirements will be received and analyzed professionally and manufactured by our engineering team within 24 hours, including process evaluation, tooling recommendations, and cost estimation. We will provide a proposed solution and confirm any modification with you if necessary through your feedback.

Step 3: Confirmation of Project Plan - after confirming the solution, we will develop a detailed plan which will clearly define timelines of raw material procurement, processing, quality inspection, delivery time, quality standards include testing items and acceptance methods, and delivery requirements like packaging and transportation ways. We will sign the contract with you to protect your rights.

Step 4: Production and Delivery - Production will be done accordingly, with quality inspection at every stage. A quality inspection report shall be provided upon completion. The product shall be delivered to your desired location based on the agreed method, ensuring timely delivery.

FAQs

Q1: What are the advantages of aluminum engine blocks over cast iron?

Aluminum alloy cylinder blocks are lighter compared to cast iron cylinder blocks, thus contributing towards better fuel economy and vehicle dynamics. Besides that, they have better thermal conductivity, which is very useful for engine cooling and reduces localized overheating issues.

Q2: Which tolerances can be achievable in cylinder bore machining?

Cylinder bore diameter tolerances controlled within ±0.01mm by Precision CNC Machining technology, roundness and cylindricity can be less than 0.005mm to fulfill high precision requirements.

Q3: How do you prevent deformation during engine block machining?

We minimize cylinder block machining deformation by optimizing its clamping scheme for avoidance of over-clamping, controlling the cutting parameters for reduction of cutting temperature, adopting a symmetrical machining strategy, and performing any necessary stress relief processes.

Q4: What surface finish is required for cylinder walls?

After honing, cylinder walls generally require surface roughness Ra of 0.4-0.8μm to form a consistent cross-hatch pattern. A pattern that would keep the oil film and reduce friction between piston and cylinder wall effectively.

Q5: What is the typical lead time for engine block machining?

Usually, the lead time for engine block machining is within 5-15 working days. The exact time will be determined by the complexity of the cylinder block, process requirements, and the current schedule of production. We will notify you of the exact time in advance.

Q6: How do you ensure the alignment of main bearing bores?

We use special tooling to fix the cylinder block and can machine all main bearing bores in one go using a horizontal CNC machine tool. In this way, we avoid all kinds of errors due to multiple clamping and ensure coaxiality of the main bearing bores.

Q7: How do you handle heat treatment of engine blocks?

We use the right treatment corresponding to the material of the cylinder block, such as T6 heat treatment for aluminum alloy. Meanwhile, we strictly control the heating, holding, and cooling rates during heat treatment to minimize the deformation after treatment.

Q8: Can you provide complete engine assembly services?

Yes, we provide a complete solution from parts manufacturing to assembly. During the assembly, several rounds of testing ensure that the assembly of engines meets technical requirements and performance standards.

Summary

From the very beginning, CNC engine block machining acts as the essential guarantee for performance and reliability, taking the entire process into consideration and including concept design down to performance verification.

Choose JS Precision for your lightweighting or high-precision needs, and together we will work out a solution to help implement your projects efficiently. Let's work together and make your design into a highly competitive CNC machining parts.

Begin your high-performance engine project today!

→ Click to upload your cylinder block design and get professional process analysis and a quote.

→ For more detailed discussions about technical solutions and the possibilities of co-operation, please contact our team of engine experts.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com