When aerospace companies must machine titanium alloy hangers featuring complex spatial curved surfaces, or medical device makers produce high-accuracy irregularly shaped parts, traditional three-axis machine tools are not accurate enough and suffer from extensive turnaround times due to repeated clamping operations.

Although the same part may be machined on all five sides at once in one clamping in 5 axis CNC machines, efficiency and precision are doubled. This is not tooling improvement, but a thinking revolution in manufacturing. In this article, let us see how 5-axis machining technology has become a single-stop solution for complex parts.

This is a guide to how the 5-axis CNC machining technology can be the one-stop-shop for complex parts, making it easy for you to acquire the necessary information in no time and have access to quality machining services.

Summary Of The Core Answer

| Comparison Dimensions | Three-axis CNC Machine Tools | Five-axis CNC Machine Tools |

| Machining Degrees of Freedom | 3 linear axes (X, Y, Z) | 5 axes (X, Y, Z + 2 rotary axes, e.g., A/B/C) |

| Common Applications | Prismatic parts, single-view features. | Parts with complex surfaces, deep holes, and tapering features. |

| Clamping Times | Requires multiple clampings to machine different surfaces. | One clamping completes most of the cutting. |

| Accuracy and Consistency | Prone to multiple clampings errors. | High accuracy, eliminates repetitive location errors. |

| Programming and Cost | Easy, low cost. | More complex, higher equipment and programming cost, but worthwhile in overall benefits. |

JS Precision Five-Axis Machining: One-Stop Complete Solution For Complex Parts

JS Precision is a 5-axis CNC machining business with over 15 years of experience and over 200 industry customers in the aerospace, medical, and automotive industries and has manufactured over 5000 complex parts.

For example, we machined titanium alloy hangers for an aerospace company, achieving a 15% weight reduction with no compromise on precision specifications, and became the preferred supplier; we machined surgical instrument core components for medical equipment manufacturers with ±0.003mm tolerance control.

This manual encapsulates our decade of hands-on experience in the most important areas like tooling selection, process refinement, and cost control. You can utilize it with total confidence to assist you in solving difficult parts machining problems.

JS Precision, having years of experience in 5-axis CNC machining, is best suited to manage parts that are intricate in nature with accuracy. Just send your part prints to us, and we'll quote and review right away, so you can go ahead worry-free with quality machining services. Our 5-axis CNC machining services are the way to go.

What Is A 5 Axis CNC Machine? Beyond The Basics

After learning about JS Precision's capacity, let us begin first by knowing the underlying question: What is a 5 axis CNC machine? This is the beginning of understanding why it can address demanding parts machining challenges.

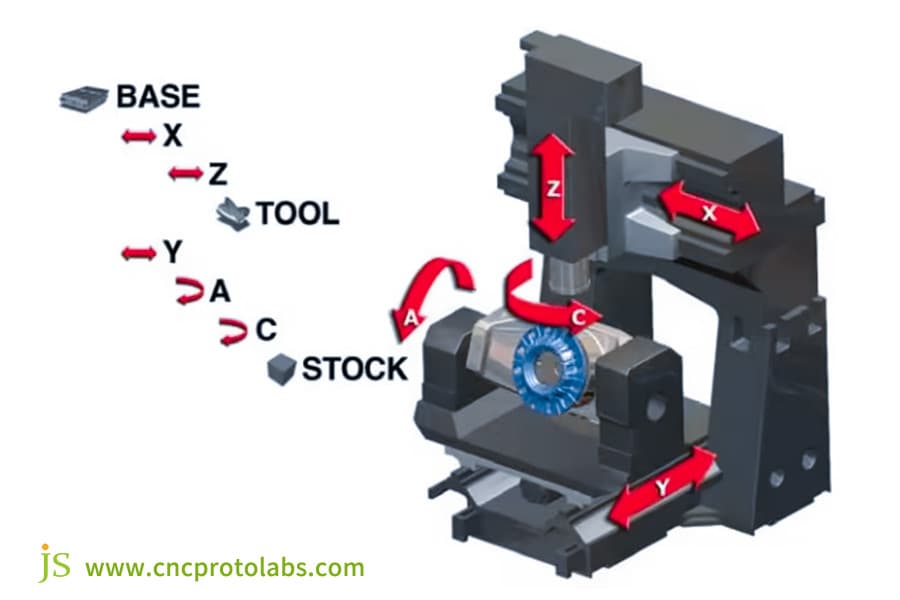

A 5-axis CNC machine is two rotary axes (A/B/C axes) in addition to X, Y, and Z axes, which are able to both rotate the work or tool and allow the tool to reposition itself to the workpiece from any angle, which removes the limitation of a three-axis system.

In the area of basic value, its primary mission is "single-step complex geometry machining," reducing settings and position errors to a minimum, and serving as the basis for the production of high-precision and complex components.

JS Precision has a diverse range of 5 axis CNC machines, from 5-axis CNC milling machines to 5-axis CNC turning machines. We will set up the proper equipment to perform the machining with the best efficiency once you provide us with your specifications. Choose our 5 axis CNC service for a hassle-free and smooth experience.

Figure 1: In a 5-axis milling machine, one configuration may include X, Y, Z, A, and B axes, while another machine might use X, Y, Z, B, and C axes. 5-axis cnc milling machine.

The Unmatched Advantages Of 5-Axis CNC Machines For Complex Parts

Having defined and described the nature of 5 axis CNC machines, let us now discuss their unsurpassable advantages in machining complex parts, which are the causes of their mainstreaming.

1. Leap in Accuracy: One clamping process can completely eliminate the accumulated errors caused by multiple repositioning. For example, while turning complex parts that consist of a hole system, tolerances on dimensions can be maintained to ±0.003mm, which provides a good fit while assembling.

2. Revolutionary Efficiency: Greater five-axis linkage length enables shorter cutters to machine deep cavities and sidewalls without deforming the workpiece. Greater cutting speed is also achievable, improving machining efficiency by 30%-50% over three-axis machine tools.

3. Design Freedom: They can machine components beyond the reach of three-axis machine tools, such as components with undercuts. It grants product designers design freedom without compromising machining limits, and leads to products with improved performance.

4. Surface quality: In machining, the relative tool-workpiece angle can be set freely in order to get the optimum cutting state. It removes tool marks on the surface of the workpiece and achieves a good surface smoothness with reduced follow-up polishing and other processings.

Navigating The Landscape Of 5-Axis Machine Types

Various complicated parts require various 5-axis machines types. The correct one can balance cost with quality. Let us explore some common 5-axis machine types.

1. 3+2 Axis Positioning Machining: Three-axis mill with constant tilt angle on the rotary axis. Easy programming and simple operation, suitable for components with multiple sloping surfaces (e.g., housings with sloping holes).

2. Continuous 5-Axis Linkage Machining: Five-axis simultaneous motion, real-time tool posture correction, for complex curved surface products such as impellers and propellers.

3. Desktop and Gantry Types: Desktop (stroke < 500mm) suitable for micro-medical devices; Gantry (stroke > 1000mm, load capacity > 500kg) suitable for heavy molds and structural components.

JS Precision has multiple 5-axis machine types that can match different part requirements. After you provide us with your part size, we will immediately recommend the best type of value for money machining. Choose our 5 axis CNC machining services for higher cost-effectiveness.

Understanding The Investment: 5-Axis CNC Machine Price Factors

After having a clear idea about what type of machines, the most important consideration is the 5 axis CNC machine price. Different configurations and pieces of equipment can differ significantly in terms of price. Below, we examine the cost drivers behind and see how JS Precision helps you to keep costs under control.

| Cost Drivers | Specific Details | Price Range (USD) |

| Brand and Origin | Imported (Germany/Japan): Good precision, good stability. Domestic: Good cost-performance. | Imported: 200,000-800,000+. Domestic: 80,000-250,000 |

| Machine Tool Structure and Configuration | Gantry Type > Cradle Type. CNC system, tool magazine, and speed effect on price. | Gantry Type: 150,000-700,000+. Cradle Type: 100,000-400,000 |

| Technical Complexity | Continuous 5-axis > 3+2-axis | Continuous 5-axis: 180,000-800,000+. 3+2-axis: 80,000-300,000 |

| Additional Functions | Automatic Tool Change / High-Pressure Cooling / Online Inspection. | Single Function: 15,000-50,000 |

Comparison Table of 5-Axis Machining Service Prices of Complex Parts in Different Batch Sizes

| Order Batch (units) Part Type | Part Type | Material | Machining Type | Unit Machining Price (USD) | Total Cost (USD) | Delivery Time (Days) |

| 10 (Small Batch) | Medical Surgical Instrument Parts | 316 Stainless Steel | 3+2 Axis Positioning Machining | 120-150 | 1200-1500 | 7-10 |

| 50 (Medium Batch) | Car Precision Gearbox Parts | 7075 Aluminum alloy | Uninterrupted 5-Axis Turning | 80-100 | 4000-5000 | 12-15 |

| 200 (Large Batch) | Aircraft Bracket Parts | TC4 Titanium alloy | Continuous 5-Axis Machining | 55-70 | 11000-14000 | 20-25 |

| 5 (Prototype) | Electronic Equipment Housing Parts | PEEK Engineering Plastic | 3+2 Axis Positioning Machining | 180-220 | 900-1100 | 5-8 |

JS Precision understands that the high cost of directly purchasing 5 axis CNC machines can put pressure on businesses.

Therefore, through combinations of scientific equipment and process improvements, we allow you to enjoy best-class 5 axis CNC machining services at a reasonable 5 axis CNC machine price without incurring depreciation and maintenance expenses, thus saving your production budget.

JS Precision allows you to enjoy quality services with a reasonable 5 axis CNC machine price. Simply share with us your budget and requirements, and we will optimize the solution, quickly start machining after your order. It is cost-effective to select us.

Figure 2: Aerospace components have extremely high requirements for material accuracy and lightweight, and are processed using five axis CNC machining.

3-Axis vs. 5-Axis CNC: A True Cost-Benefit Analysis

The majority of individuals are burdened with choosing between 3-axis vs 5-axis CNC, believing the higher cost of 5-axis CNC makes it unsuitable. However, following a cost-benefit analysis, what is truly worthwhile becomes evident. In the following, we do direct cost comparison and total benefits comparison.

Direct Cost Comparison

| Comparison Dimensions | 3-axis CNC | 5-axis CNC |

| Labor Cost (USD/hour) | 30-60 | 50-100 |

| Equipment Procurement Cost (USD) | 50,000-150,000 | 180,000-800,000+ |

| Single-piece Processing Price (for complex housing components, in USD) | 80-120 | 60-90 (due to reduced waste from single-clamping). |

Total Benefit Analysis

From the total benefit perspective, 3-axis CNC and 5-axis CNC differ substantially.

As far as time cost is concerned, initially, 3-axis CNC has several clamping cycles along with a special fixture design, which normally results in 4-6 weeks' cycle time for complex parts, while 5-axis CNC can do the job through one clamping cycle, reducing the cycle time by 30%-60%, and complex parts requiring only 1.5-3 weeks.

Next is the quality cost. 3-axis CNC machining is prone to errors by virtue of several positioning steps, with a scrap rate of approximately 5%-8%, and potentially having to undergo secondary processing. There are fewer errors in 5-axis CNC machining, with a scrap rate of only 1%-2%, considerably reducing secondary processing costs.

In terms of labor cost, 3-axis CNC machining requires 2-3 personnel to handle clamping and adjustment and involves more labor cost. 5-axis CNC machining is very automated and one operator is able to use several machines, which reduces labor cost further.

From the cost of design perspective, 3-axis CNC machining often entails dividing a complex part into 3-4 parts that complicate the assembly. 5-axis CNC machining can reduce multiple parts to one single part, simplifying the assembly and design process.

Furthermore, the yearly maintenance cost of 3-axis CNC machining is approximately $8,000-$15,000, with a lifespan of depreciation of 8-10 years. Due to its complex nature, the yearly maintenance cost of 5-axis CNC machining is approximately $15,000-$30,000, with a lifespan of depreciation of 7-9 years.

These analyses point out that yes, 3-axis CNC is economic and efficient in working with simple components, but when it comes to complex components, with the choice between 3-axis vs 5-axis CNC, the TCO of 5-axis CNC is generally lower, saving businesses more hidden expenses.

JS Precision is able to provide you with a simple evaluation of whether 3-axis vs 5-axis CNC is cost-effective for you. As soon as you provide us with the part details, we shall recommend the optimal solution, and we shall expedite the process upon your order. Our 5 axis CNC machining services are less of a headache.

Selecting The Right Partner For Your 5 Axis CNC Machining Services

It is important to select the right partner for your 5 axis CNC machining services. A suitable partner can help avoid risk and ensure quality. Below is a checklist to assess partners that can help you quickly screen out stable partners.

- Technical Capability: Does the organization have real 5-axis machinery and skilled staff (not third-party 3-axis machining)? JS Precision has the full suite of 5-axis machinery and 100+ technical personnel to address technical problems.

- Process Know-How: Does the organization have industry case studies (e.g., aerospace, medical)? Can it perform DFM analysis? JS Precision has a number of industry case studies, enabling early design optimization.

- Quality Control: How does the company ensure spatial accuracy? Does it own advanced testing equipment? JS Precision has complete quality control and owns a coordinate measuring machine (accuracy ±0.001mm).

- Software and Programming: Does the company use high-end CAM software? What is the level of experience of its programming engineers? JS Precision uses UG and Mastercam, and its programming engineers have an average experience of 8+ years.

- Integrated Services: Do you desire to provide a one-stop service covering material, machining, and post-processing? JS Precision offers door-to-door services, saving your communication cost.

Figure 3: The cutting tool on a 5 axis CNC machine can approach the workpiece from any of five sides.

Overcoming Common Challenges In 5 Axis CNC Service

5 axis CNC service encounters lots of problems in actual operation. When these problems are not effectively controlled, they can impact machining quality and cycle time. Below we introduce typical problems and JS Precision's solutions.

Challenge 1: Tool Center Point Programming and Control

Tool center point programming is time-consuming and prone to errors. JS Precision uses advanced CAM software and machine tool TCP/RP functionality to minimize programming and maintain tool position in real-time control, ensuring accurate path precision.

Challenge 2: Machining Collision Interference

Tools, workpieces, and fixtures are prone to collision. JS Precision tools mimic and verify toolpaths in virtual conditions and sense and compensate for hazards in advance in order to avoid collisions.

Challenge 3: Complex Workpiece Coordinate System Setting

Manually setting the coordinate systems of complex parts is prone to errors. JS Precision uses a 3D probe automatic alignment (scanning < 5 minutes), quickly and accurately setting up the coordinate system.

Challenge 4: Extremely High Requirements for CAM Software and Operators

Strong software and operator skills are required for 5-axis machining. JS Precision gives employees annual employee training (≥40 hours/person) and constructs a standardized process library to ensure stable machining.

JS Precision Case Study: 5-Axis Machining Saves 15% Weight and Integrated Molding for Aviation Engine Mounts

With a case study, see how JS Precision's 5 axis CNC machining solves difficult part challenges:

Customer Needs

An airline needs to machine a titanium alloy engine bracket support, with complex spatial curved surfaces, a 50mm cavity depth, and a number of high-precision mounting holes (tolerance ±0.002mm). The requirements are for maximum weight reduction, high strength and fatigue life (10,000 cycles), and obtain a cycle time of ≤2 weeks.

Limitations of Traditional Solutions

Three-axis machine tool requires 5-6 sets of tooling and 5-6 clamping operations, which are more than the 4-week timeline. Position errors total ±0.01mm (difficult to achieve), with a top weight saving of 8%, which is unable to realize the goal.

JS Precision's 5-Axis Solution

JS Precision engineers collaborate proactively with customers on Design-Focused Modeling (DFM) to optimize the deep cavity transition fillets (from R2mm to R5mm) and weight-reduction groove shapes for 5-axis machining characteristics. Right-angle transitions are substituted with curved transitions, providing an extra 2% weight reduction without compromising structural integrity.

On the 15000rpm spindle, ±0.003mm positioning accuracy 5-axis gantry machining center, the workpiece is clamped just once in one setup using special fixtures. Through continuous 5-axis linkage, all the outside contour surfaces, heavy cavities, weight-reduction grooves, and high-precision mounting holes are machined simultaneously without secondary clamping requirements.

To achieve titanium alloys' challenging machining characteristics, ultra-fine grain carbide cutting tools with 30% increased tool life were employed, along with 200bar high-pressure cool technology and optimal cutting parameters with the cutting speed being kept constant at 80-120m/min to handle temperature and stress well and prevent part deformation.

Results and Value

Lastly, JS Precision reduced the production cycle of this part to 1.6 weeks, 60% better than traditional solutions, meeting the cycle requirement of the customer; reduced the weight of the part by 15% (from 5kg to 4.25kg), meeting the customer's specification for weight reduction; and CMM inspection showed that all the geometric tolerances were ≤±0.005mm, meeting the norms.

On the basis of this project performance, JS Precision attained this aerospace company's core-supplier certification, securing further long-term orders, with a total cooperation value above US$2 million.

Figure 4: The aviation bracket 5-axis CNC parts, meeting the intricate needs of the aviation industry.

Why JS Precision Is Your Ideal Partner For Custom 5-Axis CNC Parts

Having discussed the case studies, why JS Precision is your best partner for custom 5-axis CNC parts? Our intrinsic strengths are as follows:

- Technology-Driven: We possess multiple 5-axis CNC milling machines and 5-axis CNC turning machines, and our engineers possess an average experience of 10+ years, providing full-process technical support.

- Quality Commitment: We embrace whole-process quality inspection, from raw material inspection to finished product inspection, with each process handled by specialized personnel to ensure parts to be delivered meet the standards.

- Project Guarantee: A unique project manager and progress system allow you to track progress in real time and firmly adhere to delivery schedules.

- Value Co-creation: Supplementing your production capabilities, our 5-axis CNC machining services allow you to max out your solutions and create highly competitive products.

FAQs

Q1: What is the true accuracy of 5-axis machining?

JS Precision's state-of-the-art 5-axis machines achieve a positioning accuracy of ±0.003mm and a repeatability of ±0.0015mm. Custom precision will be ensured after inspection with consideration of part size and configuration.

Q2: Can 5-axis services be used in small-batch prototyping?

Yes. 5-axis machining is well suited for both small-batch and rapid prototyping. It eliminates tooling cost, quickly transforming complex designs into tangible objects and allowing iterative testing.

Q3: Is 5-axis machining suitable with all materials?

Yes, it can machine materials ranging from aluminum alloys, stainless steel, and titanium alloys to engineering plastics such as PEEK. JS Precision will adjust equipment and processing parameters depending on the properties of different materials.

Q4: Is 5-axis machining suitable for small-batch or prototyping?

Yes. It does not have to undergo any special tooling and can effectively perform complex prototype machining in a single setup, cutting the R&D cycle considerably and making it most appropriate for small-run test production.

Q5: Will my design require full 5-axis machining or may 3+2 axis be used?

Varies depending on part geometry. Continuous 5-axis is ideal for complex surfaces, while 3+2 axis is ideal for features with more than one fixed angle. JS Precision experts will explore and recommend the most economical solution.

Q6: If my model file is faulty, can you help me alter it?

Yes. JS Precision provides expert DFM analysis services, visually checking the model and making adjustment suggestions to make it cost-effective, manufacturable, and reasonable.

Q7: What is your typical lead time?

Lead time depends upon part complexity and order quantity. Standard complexity prototypes are typically shipped in 1-2 weeks. Mass production will be carefully scheduled and rigorously adhered to.

Q8: What industries do you have extensive experience with 5-axis machining?

JS Precision has experience in the aerospace, medical device, automotive, and precision electronics industries. Those industries' high standards have defined our superior process solution capability.

Summary

Faced with the machining difficulties of intricate parts and not being able to maintain a compromise among precision, efficiency, and cost, 5-axis CNC machining is the answer. Choosing a technically skilled and experienced partner is the answer to master the technology successfully and achieve your business goals.

JS Precision, being a competent 5-Axis CNC machining services provider, is committed to becoming your most reliable 5-axis CNC machining services partner.

Upload your 3D model file today and get an instant quote based on professional DFM analysis. Work with us to make your most difficult design concepts a reality.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com