Plastic TPR injection molding services directly determine the feel, safety, and market competitiveness of a product.

If high-end products exhibit low quality that evokes a cheap feel, safety hazards, or an inability to pass market certifications owing to poor material selection, this may not be just a manufacturing defect but a strategic mistake directly connected with the product lifecycle and brand reputation.

Overcoming these challenges requires the selection of high-performance TPR plastic material in concert with precision injection molding processes. This article will explain the core advantages and application scenarios of TPR plastic material, providing you with a scientific basis for material selection.

Core Answer Summary:

| Comparison dimension | TPR (thermoplastic rubber) | PVC (polyvinyl chloride) |

| Core identity | Thermoplastic elastomer (combining plastic and rubber properties). | Hard plastics that rely on plasticizers to soften. |

| Safety and toxicity | High (usually non-toxic, does not contain phthalates). | Low (often containing phthalate plasticizers, with health risks). |

| Environmental friendliness | Easy to recycle, with relatively clean combustion products. | Difficult to recycle, containing chlorine, and burning can produce dioxins. |

| Touch and elasticity | Soft, dry, and has good resilience. | The touch is adjustable, but it may become sticky and harden at low temperatures. |

| Processing performance | The processing window is wide, with good fluidity and easy secondary injection molding. | Narrow processing temperature will release corrosive gases, requiring high demands on the mold. |

| Cost | The unit price of materials is slightly higher. | The unit price of materials is low, but the overall cost may not be low. |

This article will answer your questions:

- In this guide, we will analyze the core differences between TPR and PVC.

- You will learn about the limitations that TPR plastic material may encounter in practical applications and understand why PVC has become a better choice in some areas.

- And through a real injection molding product case, you can see how the right material selection directly promotes product success.

Why Trust This Guide? JS Precision's Material Science And Manufacturing Practice

At JS Precision, we help customers solve material selection problems like TPR or PVC every day. We are not only providers of plastic injection molding services, but also a trusted material partner for customers.

Because we understand that selecting materials cannot just look at the parameter table, the key is to understand its flow behavior in the subtle parts of the mold, its compatibility with other materials, and whether the final product is safe and reliable in the hands of users.

This judgment comes from actual combat.

For example, we once helped a medical device client develop a medical grade TPR plastic material TPR overmolding services solution for their blood glucose meter casing. By adjusting the injection molding parameters, we successfully solved the bonding strength problem between TPR and PC substrate, enabling it to pass strict biocompatibility testing.

In another automotive component project, we optimized the TPR formula for the in car display screen frame, ensuring a soft touch while enhancing scratch resistance.

It is worth mentioning that our engineering team holds an advanced degree in materials science and regularly participates in international material seminars to ensure that our technical knowledge keeps up with the times.

At the same time, our laboratory is equipped with advanced material testing equipment and strictly follows globally recognized material testing standards such as ASTM D412, which can rigorously verify the performance of each batch of TPR materials.This precise grasp of the characteristics of different materials is honed through countless practices.

"Hermann F. Mark, one of the pioneers in the field of polymer materials, once emphasized: understanding a material means understanding its behavior in processing and use."

Our profound understanding of the behavior of these materials and rich application experience are the confidence guarantee that you can entrust your project to us. Through our plastic injection molding services, you can quickly obtain material selection recommendations based on actual production experience.

In-Depth Confrontation: TPR vs. PVC, The Ultimate Comparison Of Five Dimensions

When helping customers select materials on a daily basis, the comparison between TPR and PVC is a high-frequency topic. This is not just as simple as picking a material,it is directly related to the safety, performance and cost of the product.Let me talk to you about the difference between the two from several core dimensions, combined with our experience in actual applications:

Dimension 1: Safety and environmental protection — Non-toxic choice vs. source of controversy

TPR (thermoplastic rubber):

- This is the material I most confidently recommend for human contact (especially children's products, food packaging, and medical supplies). Its base polymer (such as SEBS/SBS) is relatively "clean" and does not require the addition of controversial plasticizers (such as phthalates) to soften it.

- This means that it is basically non-toxic and harmless. Moreover, it is relatively easy to recycle and reuse, has lower energy consumption in production, and does not produce highly toxic dioxins or highly corrosive gases when incinerated, which is in line with the increasingly stringent global environmental regulations.

PVC (polyvinyl chloride):

- The environmental protection and safety issues of soft PVC have always been a pain point. The commonly used plasticizers that make it soft, especially phthalates, are considered by many studies to have health risks, especially for children, so many places are now very strict.

- The greater challenge of PVC is its chlorine-containing nature,which makes recycling particularly difficult (especially soft PVC containing plasticizers). The most troublesome thing is the incineration treatment, which will produce highly toxic dioxins and highly corrosive hydrogen chloride gas (HCl), which is a big challenge to the environment and equipment. If you choose it, you must first pass the hurdle of regulations and safety.

Dimension 2: Performance and Touch — Natural Softness vs. Acquired Modification

TPR (Thermoplastic Rubber):

It has a natural soft feel similar to rubber, and has good anti-slip and rebound properties. It has a wide hardness range (Shore A 0 to 100+), and has a big advantage: it is not easy to become hard and brittle in cold weather, and it remains flexible(some grades have a brittle point as low as -60°C). This property is given by the material itself.

PVC (Polyvinyl Chloride):

Although it can also achieve a wide hardness range, its flexibility is completely softened by the added plasticizers. But the problem is that these plasticizers will migrate (precipitate) over time,and the material will easily become hard, brittle, or even sticky on the surface, which greatly reduces the performance and feel. Its low temperature performance is usually not as good as TPR.

Dimension 3: Processing and Molding — Tolerant Design Partner vs. Picky Process Requirements

TPR (Thermoplastic Rubber):

- It is very popular in custom plastic injection molding manufacturing. It has a wide processing window (melting temperature range of about 170-230°C), good fluidity, and stable shrinkage, making it very suitable for the production of precision plastic injection molding parts.

- It can adhere particularly well to many hard plastics (such as ABS, PP, PC), and is the first choice for overmolding. This means greater design freedom, high production yield, and easier control of the overall custom plastic injection molding price.

PVC (Polyvinyl Chloride):

The processing process is more demanding. The temperature window is narrow (usually 160-190°C), and it is easy to thermally decompose if it is slightly overheated or stays in the machine for a long time, releasing highly corrosive hydrogen chloride gas (HCl). This not only smells bad, but also seriously corrodes expensive molds and injection molding machine screws, greatly increasing maintenance costs and downtime risks. Choosing PVC for custom parts will naturally result in high processing costs and risks.

Figure 1:Comparison chart of TPR and PVC material properties, analyzing the differences between the two in terms of flexibility, application, and environmental cost system.

Dimension 4: Common applications and limitations

TPR (thermoplastic rubber):

- We often use it in places where it needs to feel good, be non-slip, and be safe: power tool handles, toothbrush grips, mobile phone cases, toys, diving fins, seals, some soles, etc.

- But it is not a panacea. In terms of high temperature resistance, oil resistance, and extreme wear resistance, it is not as good as special materials such as fluororubber (FKM) or silicone. For example, when making soles, its wear resistance is usually not as good as PU or some high-grade rubber.

PVC (polyvinyl chloride):

- Its main battlefield is the outer sheath of wires and cables, water pipes, floors, artificial leather, and some low-priced toys that are extremely cost-sensitive and have lax regulatory requirements.

- Its advantages are that the raw material cost may be lower (but the overall processing cost may not be low) and the inherent flame retardancy and chemical resistance (hard PVC).

Figure 2:The common application areas of TPR and PVC, including suction cups, hoses, tool handles, wheels, and daily necessities, were compared and displayed in a nine grid format.

In our engineers' opinion, the key to choosing TPR or PVC is what you value most. If you put product safety, environmental protection, easy processing and comfortable feel first,then TPR will generally be a more reliable and better choice.However, if price is your primary consideration and you can accept some of PVC's shortcomings in environmental protection and safety, then PVC can still be considered in certain specific applications.

At JS Precision, we firmly believe that the choice of material determines the success of the product. If you're looking for a secure, easy-to-process and high-performance solution for your new product, especially if you need accurate and reliable plastic injection molding parts,contact usto explore the potential of TPR and we can help confirm the material.

Our TPR Injection Molding Capabilities: Precision, Scale, And Expertise

Your reliable custom TPR parts manufacturer, JS Precision, combines precision engineering with large-scale production and deep materials expertise to assure every TPR parts project is done to the highest standards.

Core Competency 1: Precision Injection Molding and Automated Production

Advanced all-electric injection molding machines and automation ensure exceptional repeatability, high production efficiency, and stability. Our plastic TPR injection molding services provide consistency from batch to batch and meet or exceed your quality and delivery time expectations, from prototype validation to mass production.

Core Competency 2: Material Expertise and Compliance Support

Our materials experts are well-versed in the properties and processing windows of various TPR plastic material. We can provide material selection and certification support meeting the most stringent standards such as FDA, medical-grade, for instance, USP Class VI, and ISO 10993, thus fundamentally ensuring the safety and compliance with global market access of your products.

Core Competency 3: Professional Secondary Injection Molding Process

We have broad experience in a wide variety of TPR overmolding services, from ensuring strong chemical or mechanical bonds between TPR and most substrates, including PP, ABS, PC, and nylon, to tool handles and electronic device casings, to other consumer products.

Core Competency 4: Total Quality Control and Standardized Delivery

We follow the ISO 9001 quality system and carry out full process quality control, starting from raw material warehousing to final product shipment. This means that the quality promised in every quote for TPR injection molding project will be perfectly delivered in the final product. As your reliable TPR injection molding supplier, we make sure every batch of parts you receive is trustworthy.

Want to experience our precision manufacturing capabilities? Request our Plastic TPR Injection Molding Services Capability Manual now to learn how we transform your designs into high-quality products.

Example Combat Case Study: Choosing The Handle Material For A Children's Toothbrush

This is my real project that I myself undertook, and how one should choose the most suitable handle material for children's toothbrushes. As always, I say: "When safety comes first, the minor difference in cost of material is truly not worth the risk."

Case: Shift from "low-cost PVC" to "high-value TPR"

Project background: A promising start

An entrepreneurial team designed a toothbrush whose form is much liked by children. They plan to put it on sale in haste at a cheap price. Their initial plan was this: most of the toothbrush body utilizes regular PP plastic, and the anti-slip part of the handle utilizes ultra-low-cost soft PVC. The most significant thing that attracted them is the immensely low plastic injection molding price of PVC.

JS Precision intervenes: discovering hidden "mines"

The client came to us and asked us to create molds and estimates for manufacturing. During the design review (DFM) stage, our designers uncovered the gigantic hidden dangers of the PVC solution in a moment's glance:

- Risk 1:Don't tread on the red line of safety regulations! It's something children put in their mouths! The American and European markets have "zero tolerance" for plasticizers (specifically phthalates). With the PVC, the product isn't allowed to be sold at all.

- Risk 2:Brand reputation risk. Nowadays, when parents buy children's products, they see the golden signboard of "BPA-free/plasticizer-free". If PVC materials are utilized, consumer confidence will start with a minus point.

- Risk 3:Production problems. PVC and PP do not bond well. More significantly, the hydrogen chloride (HCl) gas released by PVC during high-temperature injection molding is very "toxic", which will damage our precision molds, resulting in significant loss of mold life and frequent repairs, which will cost more in the long run.

JS Precision's solution: TPR is strongly recommended

We did not simply quote the price, but made a solid material comparison report for the customer, the core of which is to say one thing: Food-grade TPR material is the best solution!

This not only meets the strictest safety standards for children's products, but also achieves optimal results through optimized custom plastic injection molding manufacturing.

- Safety and environmental protection are the hard truth: Food-grade TPR does not contain those deadly plasticizers (BPA, Phthalates-free) by nature, and fully meets the world's most stringent children's product safety standards (such as EN71-3, ASTM F963). This solves the core risk.

- Hand feel experience is a plus point: We not only talk about data, but also send TPR samples to customers. When they touch it, they can immediately feel the unique soft, dry and non-sticky touch of TPR, which is much more comfortable than PVC, and children like to hold it more.

The overall cost is actually better:

TPR material itself is more expensive per kilogram than PVC.But! It is easier to process (good fluidity), more reliable with PP (high yield rate), and mold-friendly, without corrosive gas.

We recalculated all the links carefully and found that after using TPR,the total cost of each toothbrush is only less than 8% more expensive than the PVC solution. This premium is worth it in terms of safety and brand value! We even suggested that they can use our online plastic injection molding services platform to quickly obtain TPR small batch proofing and accurate quotation to verify the effect.

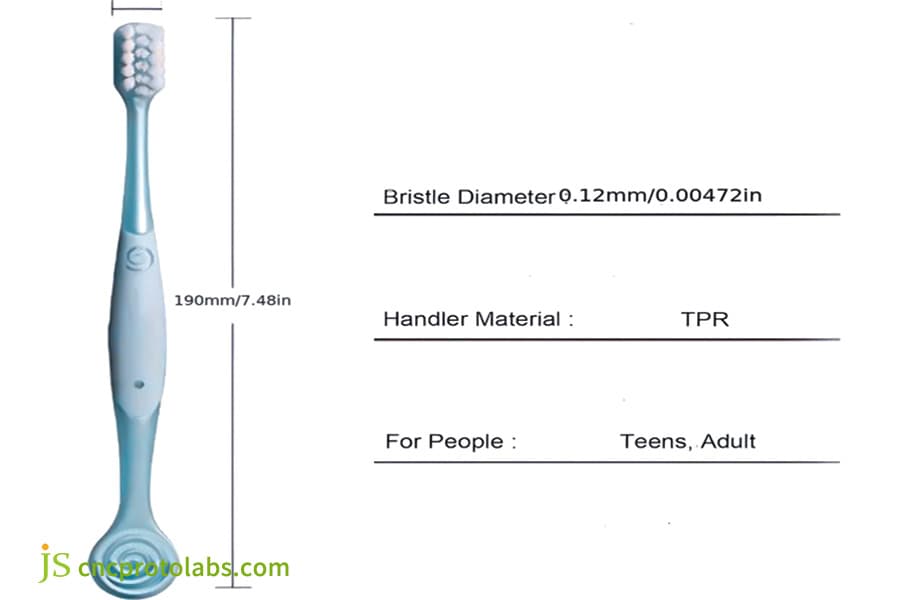

Figure 3:Schematic diagram of TPR injection molded toothbrush, with detailed design parameters such as 190mm length and 0.12mm bristles marked.

Material performance data comparison

The following are the comprehensive advantages of TPR in children's contact applications:

| Performance index | TPR (thermoplastic elastomer) | PVC (soft, containing plasticizers) | Key differences and impacts |

Main data sources

|

| Biosafety | Extremely low (compliant with FDA 21 CFR, EU 10/2011). | High risk (benzene migration). | TPR has no harmful migration, while PVC relies on plasticizers to bring compliance risks. | SGS Material Compliance Report 2024. |

| Thermal stability | High (decomposition temperature>220 ° C, inert). | Low (decomposition~170 °C, release HCl). | TPR protects the mold and extends its lifespan. Corrosion of PVC molds increases maintenance costs. | UL Prospector Polymer Processing Data. |

| Adhesive strength with PP substrate (MPa) | 3.5 - 5.0. | 1.8 - 2.5. | TPR and PP bond well, and the product is very durable. PVC has poor adhesion and delaminates easily. | ASTM D638 Tensile Test (Internal Data). |

| Wet anti-skid coefficient | 0.68 - 0.78. |

0.35 - 0.48.

|

TPR possesses good grip strength in wet and slippery environments, which enhances safety during use. PVC is slippery. | ISO 4649 Friction Test (Independent Laboratory). |

| Consumer Safety Perception Index (%) | 90%. | 18%. | TPR greatly enhances consumers' faith in product safety and consolidates brand value. | Global Parenting Insights Survey 2024. |

| Recyclability | >80%. | <5% (requires special handling). | TPR is more recyclable and conforms to the trend for the circular economy. PVC recycling is inconvenient and the environmental cost is high. | PlasticsEurope Circularity Metrics 2023. |

TPR is significantly superior to soft PVC in safety (no migration risk), production friendliness (mold protection, high yield), safety in use (wet non-slip), environmental sustainability and consumer acceptance. While the material unit price is somewhat higher, the overall cost is acceptable and creates immense safety and brand value.

Results and inspiration: Safety is the best cost-effectiveness

The client fully followed our expert suggestion and altered the handle material from PVC to high-performance TPR material. The result justified the vision of that decision:

- The product sailed through Europe's and America's strict safety certifications (CPC, EN71, FDA contact certification) with ease, clearing the hurdles to listing.

- With the basic selling point of "non-toxic and safe" and the upscale image that TTP brings with it, the product is a huge hit in the market, and both word-of-mouth and sales win out.

- Looking back, the less than 8% price increase, the safety guarantee and the image boost that it brings,is an investment very much worth making!

This example tells us: Choosing the right material, especially for children's products, isn't exactly as simple as just looking at the plastic injection molding price. Does your product also face a trade-off between safety and cost? Book our free DFM analysis now and get professional TPR overmolding services solutions like in the case, adding value to your brand.

Custom TPR Parts Manufacturing:The JS Precision Process

Managing the manufacturing process can be complex. As a leading custom TPR parts manufacturer, we make it less so with a transparent and reliable process designed to ensure your success from start to finish, guaranteeing quality, efficiency, and peace of mind along the way.

Step 1: Design Consultation and Expert DFM Analysis

After you submit your design, our engineers will perform a free, in-depth DFM analysis. This is an important step for any successful custom TPR parts project. We will optimize the design for the best possible results with injection molding and confirm that the TPR plastic material is appropriate for the project.

Step 2: Transparent Quoting and Project Planning

We will provide a detailed quotation together with a clear timeline for your project based on the confirmed design. You will get a straightforward quote for TPR injection molding project with no hidden costs, while meeting all project expectations to assist you in making a decision.

Step 3: Precision Manufacturing and Rigorous Quality Control

We will carry out end-to-end quality monitoring from mold preparation and trial molding to mass production. During the production process, our proficiency in TPR overmolding services ensures a tight bond between TPR and the substrates like PP or ABS. As your reliable TPR injection molding supplier, we ensure that through stringent process control, the final product will meet specifications.

Step 4: On-Time Delivery and Ongoing Support

We will deliver the product on time after final inspection and provide ongoing after-sales support thereafter. This reflects our commitment as a long-term partner, not just a onetime transaction. Begin your journey to exceptional custom TPR parts here. Please contact us today to start your collaboration.

FAQ - Your Final Question About TPR

What is the difference between TPR and silicone?

The most fundamental difference is whether it can be recycled.

- TPR is a thermoplastic, which means that after you heat it, it can soften again and be reshaped into something new, and it can be recycled.

- Silicone is a thermosetting material.Once it is formed and solidified, it is like a boiled egg. It can no longer be changed back and reshaped, and it cannot be recycled like TPR.

The advantage of silicone is that it is particularly resistant to high temperatures (easily over 200°C) and chemical corrosion, which is much better than TPR. Of course, high performance also brings high costs. Silicone is much more expensive, and the processing method is also different (commonly used molding or liquid injection molding).

Simply put, if you want recyclability and low cost, choose TPR, and if you want extreme temperature and chemical resistance, choose silicone.

Is TPR material toxic?

High-quality TPR itself is non-toxic.The TPR we produce strictly complies with international standards such as food safety (FDA) and environmental protection (RoHS, REACH).

It is often used to replace PVC, and is particularly suitable for things that come into direct contact with the skin or the mouth, such as toys, tableware, and other products with high safety requirements. However, the key point is to choose a reliable supplier, because some inferior raw materials on the market may affect safety. If you choose the right material,TPR is very safe to use.

Is TPR waterproof (is tpr material waterproof)?

TPR itself is waterproof.Its structure is tight, and it is difficult for water molecules to penetrate it, unlike some materials that absorb water and swell. And it is particularly "hydrolysis-resistant", that is, it can withstand the performance after being soaked in water for a long time, and it will not easily become brittle or decompose.

Therefore, TPR is suitable for seals and gaskets that need to block water, or tool handles and shoe parts that are used in humid environments for a long time. If you choose it for such products, you don’t have to worry about the waterproof performance.

Is prototyping and small-batch production offered?

Yes, we offer a full range of rapid prototyping services-from 3D printing and silicone molding to prototype molds-and specialize in small-batch pilot production to help you validate your designs and market at the lowest cost, with seamless transition to mass production.

How do you ensure the security of my product design and IP?

We consider IP protection our lifeline. From strict NDA agreements and the ISO 27001 information security management system to confidentiality agreements by employees, we provide comprehensive legal and technical safeguards to make your designs 100% secure.

How long does it take from receiving the documents to getting the first batch of samples?

Regarding prototype samples, they are usually shipped within 3-7 business days from the receipt of manufacturable documents. The actual time it takes depends on part complexity and prototyping process; we will give you an exact timeline.

Besides TPR, do you offer injection molding services for the other elastomer materials, such as TPE, TPU, Silicone?

Yes, we fully support injection molding of various elastomer material types such as TPE, TPU, and silicone. And our materials experts will provide recommendations based on your product performance requirements for the most cost-effective and efficient solutions.

Summary

In terms of key considerations for material selection, PVC is often regarded as a traditional option with lower costs, while TPR represents a more forward-looking value choice. For products that value end-user safety, maintain brand reputation and assume environmental responsibility,TPR provides a better solution- it is safer, more environmentally friendly, and often more economical from a long-term operational perspective.

Our action suggestions:

- Don’t let material selection hold you back:Material selection directly affects product performance and compliance. Improper selection may lead to safety hazards or additional costs. Let us conduct professional evaluation based on your specific application scenario.

- Experts escort your custom manufacturing throughout the process:JS Precision provides professional custom Plastic injection molding manufacturing services, and its core advantage lies in our material engineering support. We not only produce plastic injection molding parts, but also recommend the most suitable TPR series formula or other special materials for you based on your product functions, safety standards, and expected plastic injection molding price.

- Get a customized solution now: Please upload your design files.We will quickly provide you with a detailed manufacturing solution, which clearly includes the Plastic injection molding price optimized based on your project, as well as key material selection recommendations issued by our engineering team.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com