Under thousands of high-temperature and high-pressure cycles, the same mold keeps on "printing" the same plastic parts over and over again at a rate of several parts per minute. Modern life cannot be conceived of without this productive process, yet one basic question persists in the minds of all product developers: How many parts will my injection mold produce?

This is not a magician's promise but the true solution born from the synergy of material science, precision engineering, and economics.

This book responds to this critical question with mold design fundamentals and actual applications to provide you with a total understanding of the driving forces to mold life and to make informed decisions.

Key Answer Summary

| Mold Type | Expected Lifespan (Molds) | Typical Applications | Key Features and Cost Drivers |

| Prototype Molds | 1,000-5,000 cycles | Design verification, small-scale commercial testing | Aluminum or mild steel with low-cost cooling systems and light design for lowest cost and fastest delivery. |

| Mass Production Molds (Basic) | 50,000-100,000 cycles | For consumer electronics, home appliances, etc. | Medium-grade pre-hardened steel (e.g., P20), standard cooling channels, and conventional hot runner systems. |

| High-Production Molds (High-Performance) | 500,000-1,000,000+ cycles | For automotive parts and high-end medical devices. | High-grade stainless steel/hardened steel (e.g., H13), full quenching process, sophisticated cooling, high-quality hot nozzles, and coatings. |

| Extreme Life Molds | 1,000,000-2,000,000+ cycles | For high-volume items such as bottle caps and packaging. | Specialized wear-resistant steel (e.g., S136), bimetallic cavities, optimized cooling, and a full preventative maintenance program. |

Why Read This Manual? JS Uncovers The Secrets Of Mold Life

When selecting molds for items of varying production quantities, you would be wondering what guidance to heed. This is where having an experienced partner comes into play.

JS has acquired invaluable hands-on experience with injection molds, successful cases ranging from aluminum mold applications for prototyping, P20 steel molds for batch production to order, and the tricky custom injection molding manufacturing requirements of the medical and automotive sectors.

We have assisted customers in the electronics sector resolve issues with micro-wear in precision connector molds, designed gating systems for automotive component manufacturers with a production volume of 300,000 units, and special corrosion-resistant molds for corrosive food packaging materials.

This handbook is an abridged account of our experience on hundreds of projects, and every suggestion has been drawn from actual production. It's a reliable guide and can help prevent typical mold design errors.

JS offers industry-specific customized injection molds solutions according to various industries' needs. Right from the time of needs evaluation to follow-up after production, our professional team offers comprehensive support at every stage, helping you choose the right mold and avoid mistakes.

Anatomy Of The Mold: Discovering The "Longevity Gene" That Will Determine Lifespan

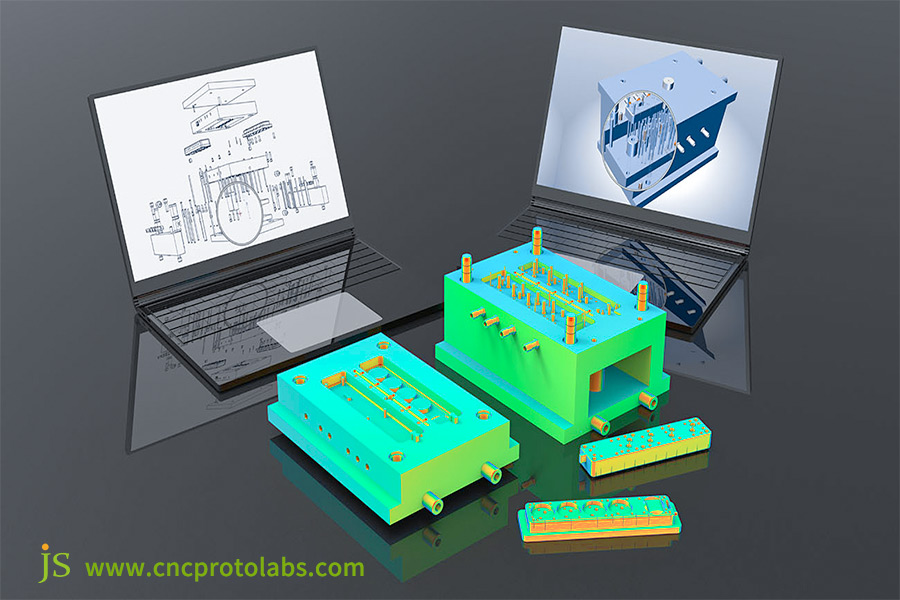

In order to understand how many pieces a mold will produce, you must first understand its anatomy. The performance of its numerous core systems is directly responsible for its lifespan.

Basic Definition: Demolishing the Core Systems of the Mold

We divide injection molds into four core systems, and the health of each core system directly affects the overall mold lifespan:

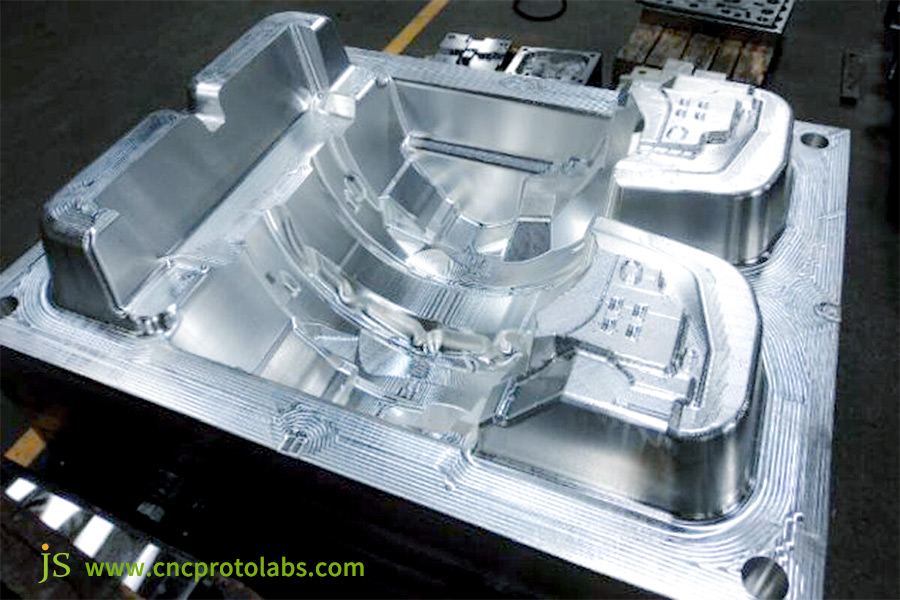

- Cavity System: This directly affects part shape and is the system most likely to be worn. For example, in producing fiberglass-reinforced parts, the cavity surface becomes scratched readily. Especially in multi-cavity molds, all cavities' wear must be even, or some of the parts are dimensionally out of tolerance. The design must be made such that runners transfer the melt evenly in order to avoid localized excessive wear.

- Gating System:It is used to transfer the plastic melt. Poor runner design may cause pressure increase and accelerate mold wear.

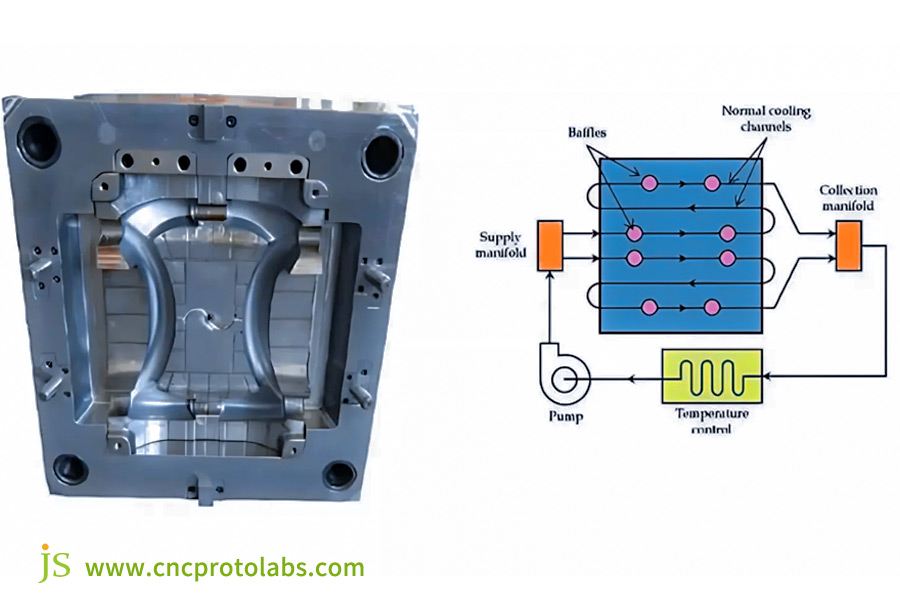

- Cooling System: It controls mold temperature. Inconsistent cooling may lead to thermal fatigue and decrease mold life.

- Ejector System: It ejects the molded piece. Mold stability is based on the fit between the ejector pin and the mold plate.

Knowing these systems will allow you to identify potential injection mold issues in advance.

Design Decides The Future: Three Primary System Engineering Factors That Dominate Mold Lifetime

Most people believe that mold life span is delineated in the production phase, but in fact, the majority of it has been delineated in the design drawing. Good design is the foundation of extending mold life span, and the three major system engineering elements are particularly crucial.

Design Philosophy

Good design will meet part requirements and reduce wear and fatigue, forming the foundation for mold life span.

Venting System

Venting in the direction of deterioration may lead to gases getting trapped inside the mold cavity, causing temporary pressure build-up and increased wear. JS correctly calculates vent groove size based on the plastic material.

For thin-walled electronic housing injection molding parts, vent groove depth is controlled at 0.01-0.02 mm and vent groove width at 5-8 mm. It prevents the overflow of the melt and allows high-speed venting, reducing cavity shock. This maintains cavity pressure fluctuation at 5%, further minimizing the risk of wear.

Tolerance & Fit

Insufficient clearance between the ejector pin and mold plate, or between the core and cavity, will cause burrs or part seizure. We have tight tolerances of within 0.005 mm so that we can ensure precise fit, which is extremely critical in creating high-precision parts in custom injection molding manufacturing.

Standardization & Interchangeability

The use of standard components allows for simple replacement when they become worn out, without mold repair and extension of injection mold life.

Choosing JS's in-house custom injection molding manufacturing services ensures quality mold designs to industry standards. Our engineers will optimize each system from a lifespan perspective to make a more durable mold.

Decision Matrix: Five Factors Affecting Mold Life

Having gained knowledge on mold structure and design key points, it's critical to gain knowledge on the factors that directly affect mold life. The below decision matrix can lead you instinctively to identify the importance of each factor.

Factors Matrix Affecting Mold Life

| Influencing Factors | Impact Level | Specific Manifestations and Examples |

| Mold Material | ★★★★★ | Aluminum molds <10,000 pieces, P20 steel molds 100,000-500,000 pieces, H13 steel molds > 1,000,000 pieces, S136 steel for glass-fiber PPS. |

| Part Material | ★★★★☆ | Low wear for unreinforced plastic (PP), high wear for glass-fiber plastic (glass-fiber PA66), and cavity corrosion for PVC. |

| Production Process Parameters | ★★★☆☆ | Thermal fatigue from high temperatures, deformation from too much pressure, typical parameters lengthen mold life by 10%-20%. |

| Maintenance Frequency and Method | ★★★☆☆ | Reduced wear from weekly maintenance and monthly lubrication, neglect reduces mold life by over 30%. |

| Part Difficulty | ★★☆☆☆ | Multicavity and deep cavity parts are riddled with weak spots and possess a shorter mold life of 15%-25%. |

Five-Factor Prioritization In Real-World Injection Choice

When designing molds, prioritize high-impact factors in terms of production volume and nature of the part.

- When selecting aluminum molds for low-volume manufacturing (<10,000 units), prioritize using a non-corrosive and non-reinforced part material.

- For mass production of simple parts (10,000-100,000) and regular parts, employ hard-anodized aluminum molds, with hardness greater than HV300 and durability 50% longer than general aluminum molds and therefore best suited for mass production of standard injection molded parts.

- In the selection of steel molds for mass production of parts (>500,000), maintain a routine servicing routine.This allows for better optimization of mold life.

With a matrix and a prioritization program, it is simple to identify key factors based on part material and production volume.

JS provides transparent injection molding prices quotes with open costs, developing cost-effective solutions with five key factors and priorities in mind to allow openness on where each cost is being expended and eliminate waste.

Invisible Wear: How Molds Age Aside From Wear

When mold wear is discussed, the majority of people automatically consider surface wear, but there are other "invisible killers" that shorten the life of injection molds and are often overlooked.

Three Often Overlooked Loss Factors

1.Corrosion:

In the process of manufacturing corrosion products such as PVC and PPS, or through the use of plastics with chlorine additives, hot temperatures create corrosion-causing gases which corrode and expand the surface of the mold cavity. For example, in the production of PVC injection-molded parts, the mold life is halved if anti-corrosion treatment is not conducted.

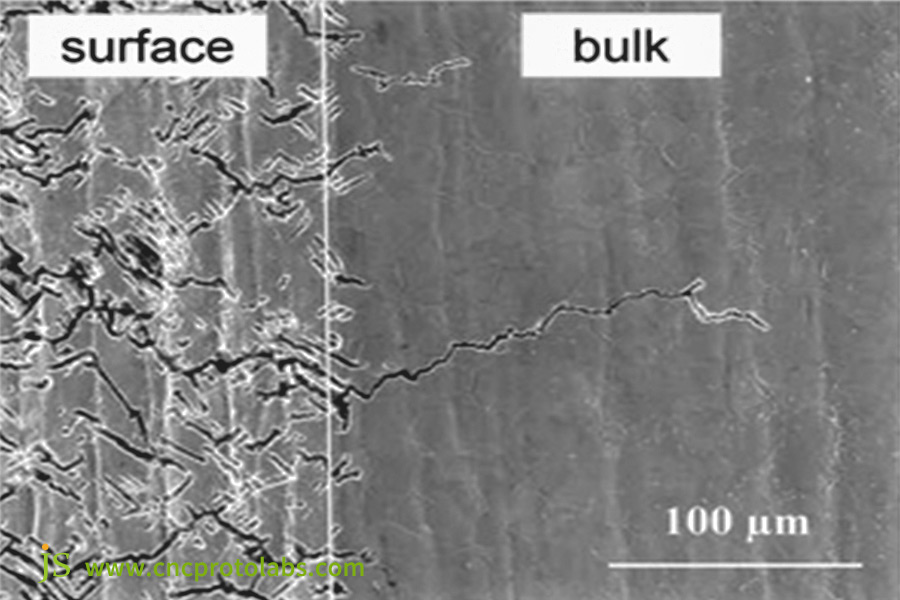

2.Thermal Fatigue:

Repeated heating and cooling of the mold can generate internal stress, and if this situation persists for a long time, "thermal fatigue cracks" may occur.During production of high-temperature material such as PC and PA66, the cavity of the mold changes between 220-280°C and room temperature. Microcracks can appear after 50,000 parts. If untreated, cracks extend to more than 0.1 mm, creating scratches on the product.

3.Plastic Deformation:

Mold temperatures greater than optimal or pressures greater than the yield strength of the steel result in permanent deformation of the cavity. For example, poor cooling during the production of thick-walled parts may cause the cavity to bulge.

For online injection molding services, JS is your go-to. We accurately test the underlying wear and tear of part materials before they're produced and apply corrosion and thermal fatigue treatments ahead of time to ensure that the molds last.

The Lifespan Struggle: How To Find The Optimal Balance Between Mold Investment And Unit Cost

When choosing a mold, people struggle with the question of having a cheaper or more durable one. The trick is finding the ideal balance between mold expense and unit cost.

Creating a Total Cost of Ownership (TCO) Mathematical Model

We recommend that customers use the following formula to calculate the Total Cost of Ownership (TCO):

- TCO = (mold amortization cost / total production volume) + unit material cost + unit processing cost + (maintenance cost / total production volume).

The formula is a good picture of long-term expenditures. For example, an $10,000 P20 steel mold yields 100,000 pieces, amortizing at a cost of $0.10 per piece, with a maintenance cost of $800 per 20,000 pieces. An $18,000 S136 steel mold yields 1.5 million pieces, amortizing at a cost of $0.012 per piece, and with a maintenance cost of just $1,200 per 100,000 pieces.

It is necessary for injection molding price calculation.

Mold Selection Recommendations for Various Production Volumes

| Expected Total Production Volume | Recommended Mold Type | Benefits |

| <10,000 pieces | Prototype Mold (Aluminum Mold) | Low cost (approximately $3,000-5,000 USD), fast cycle time, and best suited for prototyping or trial manufacturing in small lots. |

| 100,000-500,000 pieces | Production Mold (P20 Steel) | Moderate cost (approximately $8,000-15,000 USD), durable life supports mass production requirements, and high cost-performance. |

| >1,000,000 pieces | High-Performance Mold (H13/S136 Steel) | Durable life (more than 1,000,000 pieces), low maintenance cost, and lowest long-term unit cost. |

When calculating, do not just look at the initial cost, maintenance and downtime fees must also be factored in, especially in selecting high-precision molds for custom injection molding manufacturing.

Real Case: A Million-Dollar Decision For Life - Medical Connectors Life Decision

Original Customer Requirements

A medical startup developed a disposable infusion line connector. The part should meet the biocompatibility certification and smoothness requirement of Ra≤0.8μm in the inner wall. It was a custom injection molding high-precision production piece with a first order yield of approximately 500,000 pieces.

The customer believed that P20 steel molds (approximately $12,000) would be able to save $6,000 compared to S136 steel molds (approximately $18,000), and that 500,000 pieces was not a high output, and therefore they asked to use P20 steel.

JS's Analysis and Risk Alert

JS Precision Manufacturing analyzed that the part material was 30% glass fiber reinforced PPS. Glass fiber would cut the cavity at hot temperature and was corrosive. Through testing, we found that the life of P20 steel in this working condition can be less than 100,000 pieces, but S136 steel can be as high as 1.5 million pieces after chrome plating.

We warned the customer countless times that P20 steel would lead to low-quality products, yet the customer stubbornly refused to make changes.

Customer persistence and its result:

The quality of the mold was acceptable up to 50,000 pieces before it was mass-produced. Corrosion scratches on the cavity when 80,000 pieces were being produced. The product burrs were out of tolerance and the inner wall smoothness was sub-standard, resulting in the customer having to halt production.

The customer paid $8,000 for the repair of mold and $80,000 for liquidated damages and temporary production costs of delayed orders. Loss was much greater than cost savings, and product launch was delayed by 2 months.

Final solution

Customer accepted the JS solution and invested $18,000 to produce an S136 steel chrome-plated mold. The new mold has produced more than 1.5 million quality injection molding parts consistently, with the pass rate improved from 92% to 99.5%, and maintenance cost reduced by 60%.

This case became a typical lesson of "false savings" and simultaneously helped the customer understand that selection of the mold should take into account long-term needs.

In the case of custom injection molding manufacturing needs in the medical sector, JS can provide professional material selection expertise to avert losses from incorrect mold choice and ensure more efficient manufacturing.

FAQs

Q1: How can I know whether my mold is reaching the end of its life?

There are four main indications:

- Recurring flash on the part, even when parameters of the injection molding machine are reset, indicates excessive clearance.

- Decreased dimensional stability and repeated out-of-tolerance measurements indicate cavity wear.

- Persistent surface cracking that cannot be polished.

- Repeated maintenance to return to production indicates core component aging.

Q2: Can aluminum molds really produce only a few hundred parts?

Not necessarily. If a well-designed aluminum mold with an effective cooling and exhaust system is employed to produce non-reinforced, non-corrosive plastics and well-processed, it will easily produce tens of thousands or hundreds of thousands of quality injection molded parts. Its only restriction is in soft metal wear and thermal fatigue life.

Q3: Is mold life indefinitely extendable by follow-up maintenance?

No. Repairs to increase service life are temporary. Welding and polishing can alter internal stress.The life of a mold depends on the weakest component's fatigue cycle. Each component theoretically has a limit. When multiple components approach their limits, repairs cannot revive performance. A mold replacement will have to be considered based on the needs of custom injection molding manufacturing.

Q4: What do I need to supply to get a proper mold recommendation and quote?

Three items of data are required:

- A 3D model of the part (STEP or IGS file) to assess part shape and complexity.

- Target part material, different materials influence mold selection.

- Estimated annual and total production volume. JS will calculate total cost of ownership (TCO), send an injection molding price quote, and recommend a solution.

Summary

The existence of an injection mold is a delicate equilibrium between precision, durability, and cost. An understanding of the science behind it will make all your choices smarter, with your products being extremely competitive in the market.

Let not your dream of a million-unit product be ruined by a ten-thousand-unit mold selection. JS has years of experience in online injection molding services. Pilot production in small batches or large-scale production, we offer professional solutions and open injection molding prices to help you save your total cost of ownership and improve the stability of production.

Call JS's mold experts today to get a mold life and cost optimization plan according to your product's production volume, material, and quality demands. Let us apply our professional calculations to guarantee your successful mass production.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com