It is not a science fiction movie,but an actual medical revolution.3D printing technology is revolutionizing every aspect from surgical planning to rehabilitation therapy with unprecedented depth and dimension.

This manual will guide you through a comprehensive review of the remarkable uses of 3D printing in medicine,its limitations,and how it will change the future of precision medicine.

Summary Of Core Answers

| Definition | Integrating additive manufacturing and medicine, constructing personalized medical products based on image data, and achieving precise treatment |

| Key Applications | Including personalized implants, surgical tools, drug delivery systems, and bioprinted tissue repair, etc |

| Workflow | Divided into five steps: medical data acquisition, 3D modeling, material selection, printing and production, and clinical application |

| Pros and cons | Advantages: Personalized, efficient, and precise.Limitations: limited materials, high costs, and incomplete supervision |

| Common materials | Metals (titanium alloys, etc.), polymers (PEEK, etc.), biomaterials (alginates, etc.) |

| Future Trends | Intelligentization of materials, upgrading of equipment, expansion of applications to regenerative medicine, and popularization of cost reduction |

Mastering The Key To Winning In Medical 3D Printing!Practical Guide From JS Team

JS has been highly involved in medical 3D printing for decades,encompassing every possible scenario such as orthopedics,dentistry,and soft tissue repair,creating customized solutions for most cases.

Whether it is prototyping,small series production,or customized solutions,our skilled team can provide project specifications with rapid turnaround and competitive rates,enabling efficient completion of the project.

JS provides end-to-end process visualization on an online portal,and a professional team answers your queries at any time,providing you with accurate,safe,and efficient online 3D printing services.

What Is Medical 3D Printing?

Medical 3D printing is a comprehensive combination of additive manufacturing technology and medicine,and it is possible to precisely build up medical products or tissue engineering scaffolds with specific anatomical structure and function by layering up biocompatible materials or cell composites.

The foundation of it is patient CT,MRI and imaging data,which are modeled and digitally cut in three dimensions to drive the device to deposit material along a path,thereby making the conversion from digital models to physical devices.

Its intrinsic robustness is 'personalized manufacturing',transcending the limitations of traditional approaches on complex structures,accurately reproducing the patient anatomical features,and increasing treatment flexibility.

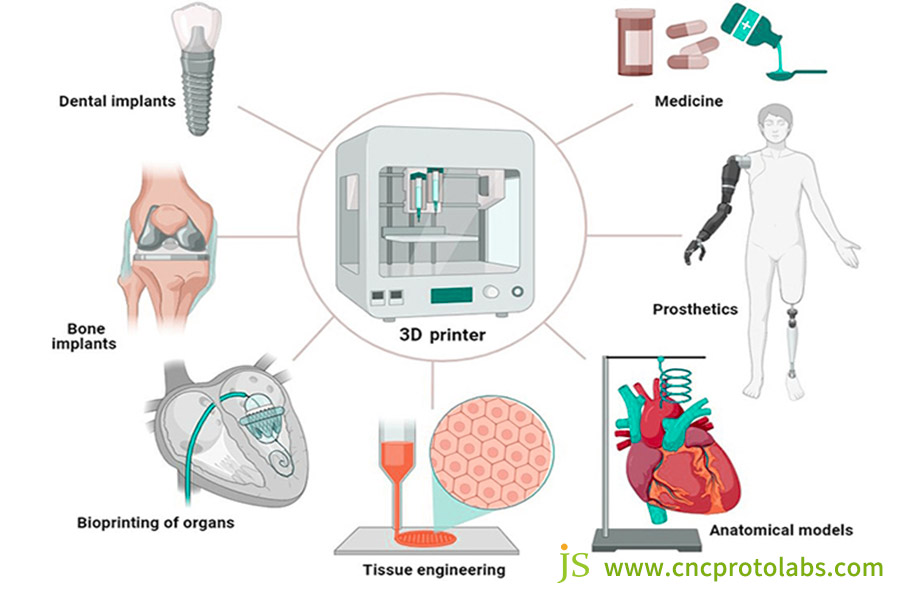

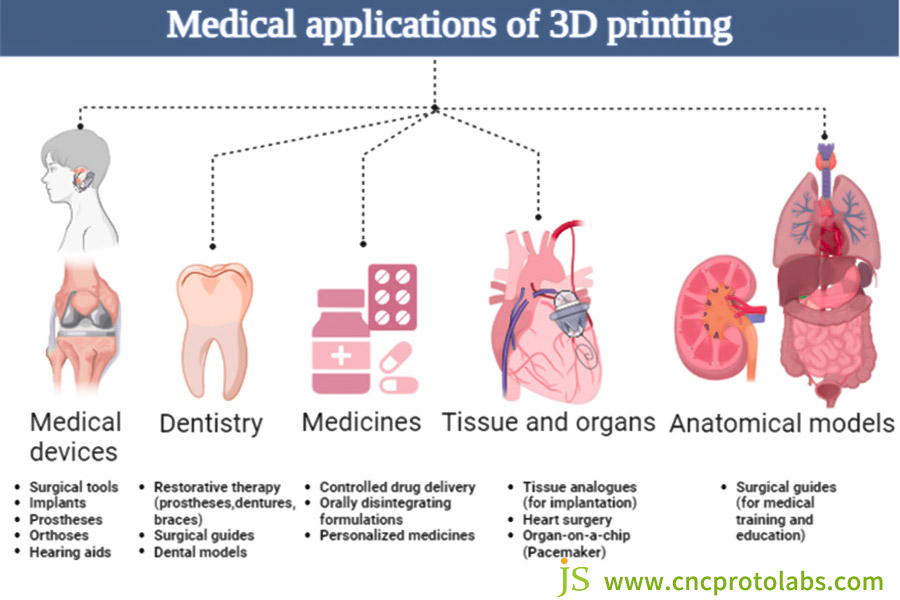

The following are the applications of mainstream 3D printing technology in the medical field:

| Principle |

3D printing technology

|

Printing process | Materials | Advantage | Limitation |

| Extrusion printing | Fused deposition modeling (FDM) | Squeeze heated plastic filaments through a nozzle and construct the parts layer by layer. | Polymers and composite materials. | Widely applicable and affordable, capable of producing sturdy components suitable for prototypes, anatomical models, and surgical guides. | There are obvious layer lines, which are not suitable for medical applications with high surface smoothness or complex details, and the material selection is limited. |

| Vat-polymerization | Stereolithography (SLA) | Using ultraviolet laser to cure liquid photopolymer resin and constructing objects layer by layer. | Using ultraviolet laser to cure liquid photopolymer resin and constructing objects layer by layer. | Can produce high-resolution, smooth surface components suitable for fine anatomical models, surgical guides, implants, and can manufacture complex geometric shapes. | Post treatment is required to remove excess resin and fully cure it, as the resin has limitations in terms of biocompatibility and mechanical properties. |

| Powder bed fusion | Selective Laser Sintering (SLS) | High power laser selectively fuses powder materials layer by layer into solid structures. | Nylon, metal powder, etc. | There is a wide range of material options, including biocompatible polymers and metal alloys for implantation, which can produce components with excellent mechanical properties and complex geometric shapes without the need for supporting structures. | The equipment is expensive and requires post-processing, and the surface finish is not as good as SLA. |

JS can create complex structures with high precision,fast delivery,and high cost-effectiveness,helping you achieve personalized solutions in the medical field.Choose us for both quality and efficiency.

Key Applications:How Is 3D Printing Used In Healthcare?

3D printing,benefiting from 'layer by layer stacking and on-demand customization',has turned into a significant tool for"precision and personalized"medical treatment,and its scopes of application continue to expand.

Personalized implants:tailored to individual anatomy

Traditional implants are difficult to fit with the patient's bones or tissues,and 3D printing makes implants personalized by accurately replicating anatomical data.

- Orthopedics

Titanium alloy hip and knee prostheses were printed following CT scanning using a xyz 3D printer.The porous structure(50%-70% porosity)supports bone cell growth.In one instance,the rate of bone integration was 90% following 6 months of surgery,higher than 75% of conventional prostheses.

- Dentistry

Based on oral scanning statistics,xyz 3D printer prints 3D printing parts such as implant abutments and crowns with precision(error≤0.1mm)to enable compatibility,reducing the cycle from 7-10 days to 1-2 days.

- Skull and Maxillofacial Reconstruction

The bone curvature and thickness are replaced using 3D printed implants.Implants made with xyz 3D printer's PEEK material are 40% lighter than normal titanium mesh,with an elastic modulus close to that of human bones,reducing postoperative pain.

Surgical planning and auxiliary tools:improving accuracy

The success of complex surgery is based on preoperative planning,and 3D printing translates images into tangible models to facilitate the process of developing plans.

- Anatomical Model

With patient CT/MRI images,xyz 3D printer prints 1:1 organ models(e.g.,heart and liver tumor models)specifically exhibiting the interaction between tumors and blood vessels and can easily simulate surgical courses.Model of heart printed by children's hospital for pediatric patients with congenital heart disease saved 30% of surgery time and 50% of blood loss.

- Surgical guide plate

In spinal nail fixation and other surgical procedures,3D-printed guide plate is able to 'search' and fit exactly on the bone surface,so the screw implantation error≤1mm.The resin guide plate printed by 3D printer costs only 1/5 of the price of traditional metal guide plates and is disposable to prevent cross infection.

Drug delivery system:with exact drug delivery

- Custom-made tablets

- Localized drug delivery stent

Drug-loaded antibacterial stents are implanted within the infected site with 10-20 times local drug concentration than oral delivery,but with no systemic toxicity.The pore structure of 3D printed parts can also promote healing.

Bioprinting:Towards 'Artificial Tissues and Organs'

Bioprinting constructs functional tissue through cell and biomaterial extrusion,an envisioned future to organ transplantation:

- Human Skin Repair

xyz 3D printer mixes patient skin cells with collagen,prints and sculpts skin tissue with the same properties as the wound.More than 90% success rate of transplant and decreased scar.

- Cartilage repair

culture chondrocytes and hyaluronic acid hydrogel in the shape of cartilage,and form functional cartilage after being implanted for 6 months in a bid to improve mobility within joints.

JS complete the customized needs of orthopedic implants,dental restorations,etc.with high-quality 3D printing services,rely on latest technology for copy of difficult-to-replicate anatomical structures,provide diverse biocompatible materials,and increase the precision and efficiency of medical fixings.

The Workflow:From Digital Scan To Physical Part

Medical 3D printing has to be controlled stringently in order to be accurate and safe,and is divided into five broad steps:

1.Medical data acquisition:obtaining anatomy data

2.3D Model Design:Digital Restoration and Optimization

Convert image data to printable models with professional software and optimize:Mimics converts DICOM data to 3D models and trimming.Geomagic refinement processing.Include functional structure in CAD software.STL file format to export model to xyz 3D printer.

3.Material choice:Balance clinical needs

Metal material(titanium alloy,cobalt chromium alloy)may be used for permanent implants.For polymer material,PEEK is used for skull reconstruction,and PLA may be used for temporary scaffolds.Biomaterials(alginate,collagen)used as bioinks must conform to the ISO 10993 standard.

4.Printing manufacturing:precise operation of xyz 3D printer

5.Clinical application:laboratory to operating room

We provide total support to the entire process,with ISO 9001:2015 technology-certified technology ensuring accuracy and controllability.We have thoroughly experienced staff in data modeling,material choice,and print output,ready to respond quickly to demands and create efficient and dependable data-to-entity translation in 3D printing.We provide you with error-free tailor-made services.

Pros And Cons:A Balanced Perspective

Advantage:Enhance medical models

- Customized treatment:

- Production of complex structure:

Just produce complex human tissue,such as porous titanium alloy scaffolds for better efficiency in bone integration.

- Save cycle time and cost:

It only takes 24-48 hours for the xyz 3D printer to complete the production of 3D printing parts,and it is 30%-50% cheaper to personalize in small quantities than with traditional methods.

- Improve surgical safety and efficacy:

Preoperative models and guides reduce blind procedure,and accuracy of screw placement in complex spinal surgery has been increased from 85% to 98%.

Limitations:Technical and application limitations

- Material limitations:

Dozens of sole accepted materials exist,and the biomechanical properties of bio ink are insufficient.There is an elastic modulus mismatch of some metal materials with bones.

- Excessive cost and threshold:

High-precision xyz 3D printers are expensive,and the maintenance fees are very high with no professional staff.

- Lack of regulation:

It is difficult to authenticate customized products according to traditional standards,and the application process must be investigated.

- Bioprinting Challenge:

Bioprinted tissue has a short lifespan and it is difficult to generate elaborate vascular structures.

We have specific solutions for these challenges:advanced equipment lowrs the cost threshold,there are rich sets of approved materials to satisfy demand,technical problems are solved by a highly qualified team,and actively participates in regulatory procedures.Choose us to enjoy the advantages of 3D printing to the fullest and avoid technology bottlenecks.

Materials Used In Medical 3D Printing

Metal material

- Titanium alloy(Ti-6Al-4V):

Extensive application,low density,and similar elastic modulus to bones.SLS technology for XYZ 3D printer printing,and porous architecture stimulates bone cell growth,used in joint prostheses,etc.

- Cobalt chromium alloy:

Excellent wear and fatigue behavior,highly suitable for dental implants,etc.

- Magnesium alloy:

Biodegradable,suitable for temporary fracture fixation brackets,requires controlled rate of degradation.

Polymer material

- PEEK:

High performance,elastic modulus of 3.8GPa,printed by FDM technology on xyz 3D printer,used for repairing skull and spine.

- PLA:

Biodegradable,from renewable resource materials,suitable for short-term use of 3D printing parts such as surgery guides.

- Resin material:

UV cured resin is of high accuracy and suitable for high-accuracy tools,with minimal biocompatibility.

Biomaterial

- Natural materials:

Alginate is suitable for skin and cartilage printing.Collagen facilitates cell adhesion and is used in tissue engineering scaffolds.

- Synthetic material:

PEG is water-soluble and can be functionalized with biological activity.PCL is highly mechanical in strength and mixing it with hydroxyapatite enhances bone inductivity.

- Cell material composite ink:

Cells are mixed with biological materials and printed using xyz 3D printer,cells are able to form functional tissues.

We have the most sophisticated medical grade 3D printing material system that satisfies stringent high standard requirements.Our state-of-the-art technology ensures accurate material deposition and high-quality guarantees for your project.

The Future Of 3D Printing In Medicine

Material Innovation:Multi functionality and Intelligence

Developing intelligent responsive materials,such as temperature sensitive bioinks and pH sensitive drug scaffolds.Integrating natural and synthetic materials,such as collagen PCL composite scaffolds,to balance biocompatibility and mechanical properties.

Equipment Upgradation:Accurate and Efficient

Parallel XYZ 3D printers are becoming intelligent,implementing AI in a way that enables full process automation.Design composite machines to print multiple materials simultaneously to enable 'integrated organ' printing.

Extension of Application:From 'Repair' to 'Regeneration'

Completely shatter organ transplantation and construct full organs with vascular structures.Popularize personalized medicine and achieve 'on-demand printing' with mini xyz 3D printers.Popularization and price decline

Bring desktop-level xyz 3D printer price down,simple to use.Construct cloud platform,organize resources,and reduce institutional investment.3D printing is transforming the medical model.We are monitoring the trends,innovating continuously,and can provide future-driven personalized solutions to share the future with you.

Case Study:A Life Changing Custom Skull Implant

Patient situation:

A young patient who has a tremendous skull deficiency resulting from a car accident.The traditional repair methods are difficult to fit properly and possess poor aesthetics.

Technical challenges:

- Inaccuracy in the anatomical fit:

Skull deficit up to 12cm×8cm,serrated edges and intricate curvature at the back of the frontal and temporal bones,where conservative vascular channels and nerve grooves have to be provided.Standard CT modeling has an error up to 2mm.

- Synchronizing morphology and function:

Implants need to achieve biocompatibility,mechanical compatibility(comparable elastic modulus with 10-30GPa of skull),and postoperative aesthetics simultaneously,and one procedure is difficult to balance.

- Limits of intraoperative adaptability:

Traditional restorations are of high stiffness and can't accommodate tiny anatomical variations during surgery,which can readily lead to poor fit or secondary damage.

JS’s Solution:

- SLA Preoperative Planning:

Leverage the high-resolution(0.02mm layer thickness)quality of SLA to print a 1:1 defect model of the skull from CT data and reproduce anatomical data.The surgeons can rehearse the surgery,identify the fitting border,and control the error to 0.3mm.

- SLS function and form unification:

Employ SLS technology to sinter the titanium alloy powder to create one-piece implant body.The contact surface is designed to have a porosity structure of 500-800μm(cancellous bone simulation)to realize bone integration.The surface is laser polished with roughness Ra≤1.2μm to provide enhanced aesthetic properties.A thin-walled structure of 0.5mm for intraoperative adjustment at the edge.

Achieve results:

The adhesion between implant and the edge of defect reached 99.5%,reducing the operation time by 40 minutes.CT scan at 3 months postoperation showed new callus formation in porous structure,and there was no rejection response in 6-month follow-up.The rate of bone integration was up to 92%,and the appearance of symmetry in skull was up to 96%.It solved the issue of fit and cosmetic in traditional methods,and the clinical effect was excellent.As a professional custom processing factory, JS relies on advanced additive manufacturing technology and ISO 9001:2015 certified processes to accurately restore complex structures. Our professional team customizes products with fast turnover and reasonable pricing to ensure efficient project completion.

FAQs

Q1:Are 3D printed medical components safe?

Yes,they are safe when printed with certified biocompatible materials and made and sterilized under strict quality control.The implantable parts to be placed in the body need to be cleared by strict government regulatory agencies.Q2:Can 3D printing fabricate functional organs?

Today,intricate organs such as the heart and liver are not possible to print.Yet,researchers have already printed skin,cartilage,and vascular structures,which is a great achievement towards the ultimate goal.Q3:How do I obtain a quotation for a medical device prototype?

It's simple.Here's how you can post your 3D CAD file on our secure online platform.Select your material and our system will give you an instant clear 3D printing quotation.Q4:Why has 3D printing been so commonly embraced in dentistry?

Due to the low quantity,high personalization,and high demand of dental products(crowns,braces,and guides),which are most suited to the capabilities of 3D printing technology,they can tremendously increase efficiency and precision.

Summary

3D printing is shifting from the development of intelligent materials and equipment intelligence upgrades to 'regenerative' medicine and becoming more a cornerstone of precision medicine.Despite the difficulties it faces,such as materials,expenses,and regulation,its potential is limitless with developments in technology.

Being a niche custom 3D printing manufacturing firm,JS emphasizes providing quality services.With online 3D printing services,you are able to have personalized services in your pocket,and low-cost 3D printing prices allow projects to be done quickly within budget.Choose us and indulge in a journey of effective and precise 3D printing.Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com