Every time I have an innovative design idea and am ready to roll up my sleeves and work hard, one of the most troublesome links for me is to get those necessary custom parts. Especially in our fast-paced product development, any link will lag behind and the progress of the entire project will suffer. To be honest, gettingcustom CNC machiningmanufacturing parts often becomes the most anxious problem.

Why do you say that?

The traditional approach is too tiring.Want to know a rough CNC machining price first?Send the drawing, and then wait, waiting for a few days is a common thing. After finally receiving the quotation, you may have to make many calls and send many emails to the supplier for a certain detail on the drawing to explain it clearly, which is particularly laborious. More importantly,when can the parts be really obtained in the end?There is often no accurate time for this time.

I guess you have also encountered this kind of trouble? Waiting for a quote for a part for several days is very anxious. Communicate with the factory over and over again, for fear that they have misunderstood the drawing.

As a result, when the parts were tested, the accuracy was not up to standard and could not be installed. The entire project was immediately suspended and the original plan was disrupted. These seemingly "small" troubles are actually eating up our precious time andproject budgetbit by bit, which really makes people angry and helpless.

1. Key Information Extraction:

| Module | Core points | Detailed Explanation |

| Parts display and technical strength | Precision drawing restoration capability. |

• High definition physical display.

• Complex structure CNC overall machining.

• High precision hole positions ensure assembly accuracy.

|

| Core Process Deconstruction |

1. Overall structural advantage.

2. Strengthen surface performance.

|

• Integrated cutting of convex platform (non splicing).

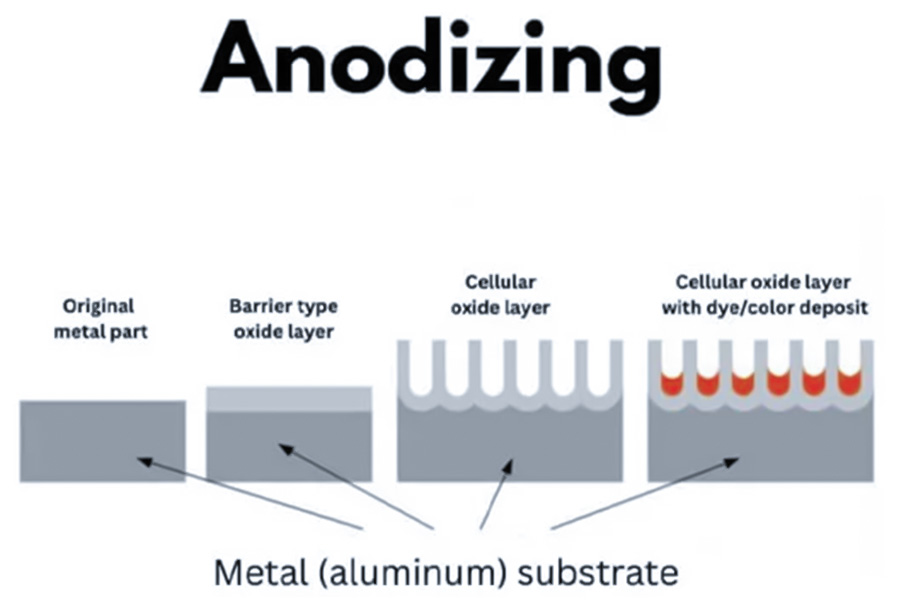

• Black anodizing treatment (wear-resistant/corrosion-resistant).

|

| Core advantages of online services |

Advantage 1: Instant and transparent quotation.

Advantage 2: Flexible customization capability.

Advantage 3: Minimalist process.

|

• Upload drawings → Minute level quotation.

• Online material selection/quantity/process → Real time price changes.

• Support production of 1-1000+pieces.

• The entire process is operated online (saving time and effort).

|

| Empirical evidence of successful cases | Medical equipment customer: Fast delivery. |

• Pain points: 3-week lead time+old supplier delay.

• Solution: 10 minute quotation+free DFM optimization.

• Result: 5-day delivery → Successfully participated in the exhibition ahead of schedule.

|

| Quality assurance system | Dual protection both online and offline. |

• ISO9001 certification.

• Three coordinate precision detection.

• Full process traceability+providing quality inspection reports.

|

2. Solution Core: From A Drawing To A Precision Entity

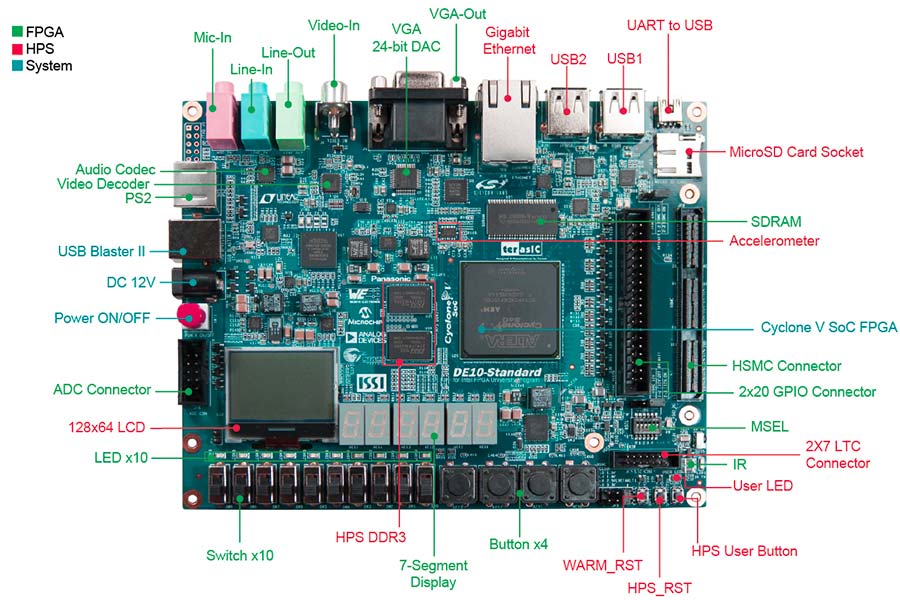

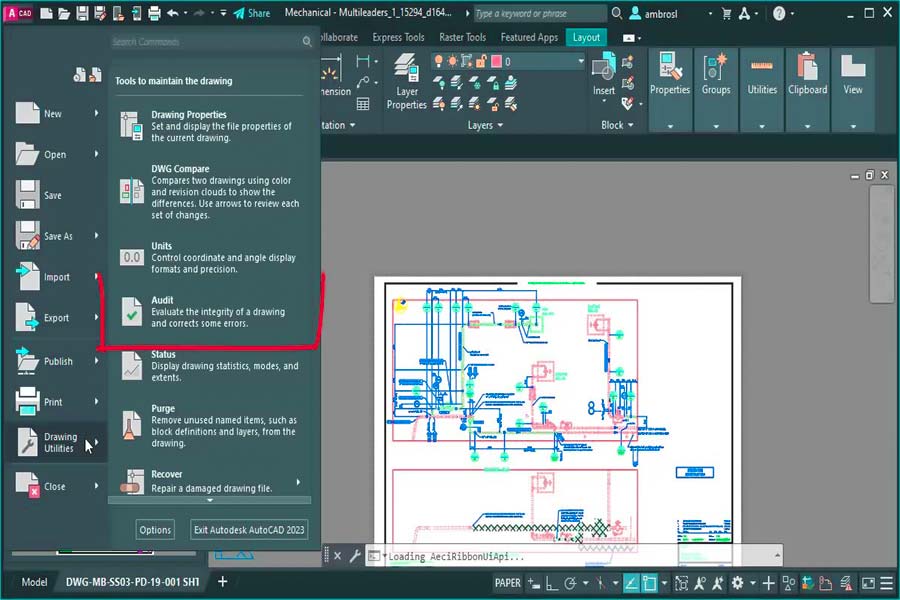

This is a chassismounting plate for an automation devicethat we just made, a typical custom CNC machining manufacturing project. Although its structure is a bit complicated, we just followed the drawing strictly and used CNC to gnaw it out bit by bit.

This picture is quite clear. Let me tell you how we handle this kind of CNC machining parts, andlet you see our JS processing technology:

(1) Look at this contour and hole position:

- This board has an irregular shape, with steps on the edge and a bunch of mounting holes on it.

- The difficulty lies in ensuring that the position of these holes must be extremely accurate, otherwise they will not match when the equipment is installed. We directly use thefive-axis CNCin the workshop, clamp it once, and process these complex contours, steps and all holes in one go. The position accuracy of the things producedin this way is absolutely guaranteed, and you will be much less worried when you take it back for assembly.

(2) Focus on the boss on the left:

- This raised small platform is critical. It is not welded or assembled later, but milled directly from a thick piece of 6061 aluminum alloy!

- The advantage of doing this is that the whole part is integrated, high in strength, and particularly strong and durable.This is also a particularly big advantage of CNC machiningcompared to other methods, which can make complex one-piece structures.

(3) Finally, look at the surface:

What we hand over is not a blank. Look at this surface, it is black and shiny, it isblack anodized. Not only does it look good, but more importantly, it is scratch-resistant and corrosion-resistant, allowing the parts to be used in the equipment for a longer time.

JS's hard power: not only can it be made, but also can be done well and quickly

If you want to get the parts quickly and well, processing parameters are the key. We have accumulated a lot of practical experience and optimizedthe process for different materials and structures:

| Key process parameters | Typical capabilities of JS company | Differences from the public |

| Multi axis machining capability | 5 axis linkage precision machining. | Complete complex parts in one clamping to reduce error accumulation. |

| Experience in special materials | Titanium alloy, Inconel, PEEK, etc. | Master the cutting parameters of special materials to ensure the yield of finished products. |

| Quick sampling cycle | Provide the first sample within 48 hours at the fastest. | Dedicated rapid response production line, non extrusion regular orders. |

| Tolerance control capability | Conventional ± 0.025mm, precision machining can reach ± 0.01mm. | Strict process control, not relying solely on final testing. |

"So you see, from understanding the drawings to making high-precision parts, what we JS pursue is accurate restoration, reliable structure, and good surface. In addition, the core process parameters we have accumulated can allow you to get reliable parts faster while controlling the CNC machining price. Don't let the parts get in the way of your good ideas. Send a drawing and let's talk about how to help you speed up your project!"

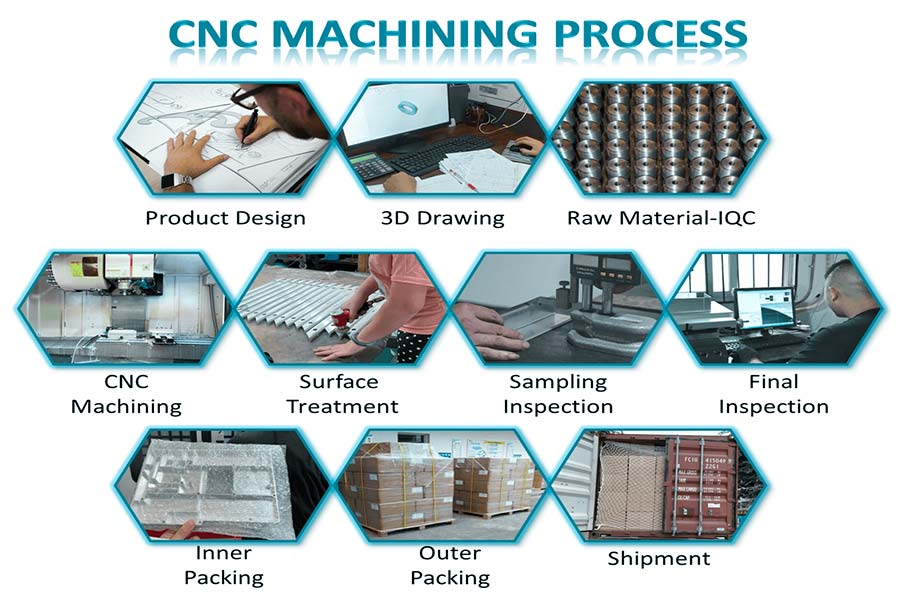

3. Why Choose Our Online CNC Machining Service?

When looking for aCNC machining partner, efficiency, reliability and transparency are crucial. We JS do online CNC machining services, aiming at the real challenges faced in product development, and solve them with real skills and good processes.The following are our core advantages that distinguish us from other suppliers:

Advantage 1: Fast quotation and clear price

This is our most hardcore advantage! Send your 3D drawings, and within 10 minutes, you will get a clear quotation. You can adjust the material, quantity and surface treatment options online in real time, and the price will change clearly, so that budget planning is under control. Say goodbye to the days of waiting for quotations!

Advantage 2: Hard power as a foundation, can customize complex parts

No matter how complex your design is, JS can do it. We have advanced equipment (such as 5 axis CNC) and rich experience, and provide dozens of engineering materials and surface treatment processes. Fromsingle prototypesto small batch production of thousands of pieces, the processing quality of our factory is very stable. The core ofcustom CNC machining manufacturing- accurate restoration of complex designs, this is our confidence.

Advantage 3: Worry-free process, one platform to get it all

From posting sketches, quotes, orders, payments, to tracking production updates, the whole thing is transparent on our site. adieu to slow manner of back-and-forth coordination and communication with multiple contacts. use saved time to focus on core design work.

JS vs. other platforms:

| Comparison items | JS Company | Euro Metal Solutions | Xometry |

| Price transparency | Real time changes, materials/processes can be selected and seen immediately. | Manual communication is required, and changes are not real-time. | Lock after submission, modifications require a new inquiry. |

| Quotation speed | <10 minutes (automatic system). | Usually takes 1-2 working days (email/phone communication). | Hours to days (requiring manual review). |

| Local delivery in Asia | Serving global customers, with our own factory and flexible express delivery. | Mainly based on European factories, with long delivery cycles in Asia. | Global network, Asia region relies on partners for timeliness. |

| Complex component response | Quick evaluation by a 5-axis expert team. | Focusing on traditional fields may result in slower response times for complex and miscellaneous items. | Dependent on network factories, with uneven response levels. |

"In the end, choosing JS's online service is fast, accurate and worry-free. Don't waste time waiting for quotes and urging progress. Upload the drawing and try it. You will get the answer in a few minutes. The price is transparent and the process is simple. We speak with strength and help you push the project faster!"

4. Success Case: Helping A Medical Device Startup Accelerate Product Launch

Customer background and challenges:

They are a small business that manufactures portablediagnostic devices. They need to have the mounting base core motherboard prototype manufactured and tested as soon as possible within three weeks in order to catch up with a big exhibition. The previous supplier took too long to give their quotations and could not offer guaranteed timely delivery, and so they were worried.

JS's solution:

The customer placed the drawing on our website on Monday morning.We quoted within 10 minutesand they placed an order immediately. Our engineers helped them to redesign the drawing at no cost and suggested a sharp corner be substituted with a rounded corner so that it will be smoother in production. And then we only used 5 working days to complete the CNC machining parts and anodizing, and made express expedited delivery arrangements.

Final result:

The customer received high-quality parts a week in advance, assembled and tested the equipment smoothly, and successfully debuted it at the exhibition. They praisedour service as "amazingly fast, professional and reliable", which saved them precious time.

"This case proves that we can help customers sprint deadlines with efficient collaboration. If you are also rushing a project, contact us at JS! The engineering team is on call at any time to ensure that you get the perfect parts quickly!"

5. Our Quality Assurance System: Online Service, Equally Rigorous Offline

Let me tell you how we ensure the quality of parts - onlinecnc machining servicesis convenient and fast, and we are even more serious about offline quality control:

(1) We have passed authoritative certification:

We hold theinternationally recognized ISO9001:2015quality management system certification. This is not a decoration, it means that our entire process, from order acceptance to delivery, has strict standards for each step to ensure that each step is reliable and controllable.

(2) Precision testing, data speaks:

Whether the parts are well made, experience alone is not enough, it depends on accurate equipment measurement. We are equipped with professional testing equipment to ensure that eachkey dimension strictly meets your drawing requirements:

| Test equipment | Main purpose | Advantage |

| Coordinate measuring machine (CMM) | Precise measurement of complex shapes and spatial dimensions (length, width, and height positions). | The highest accuracy and wide coverage. |

| Micrometer/caliper, etc | Daily sampling inspection of key dimensions, thickness, diameter, etc. | Convenient and solid foundation. |

| Anime imager | Quick measurement of planar dimensions, hole positions, and contour shapes. | Efficient and intuitive. |

(3) The whole production process is traceable, transparent and assured:

Quality is not checked at the last step. From the storage of raw materials to the final packaging and shipment ofCNC machining parts, every step of operation and every inspection is recorded. If you have any questions about a part, we can provide its complete quality inspection report (FQC Report) at any time, so that you can use it with confidence.

"Online, we pursue efficiency and convenience, and offline, we rely on authoritative certification, advanced equipment and rigorous processes to ensure quality. Choosing JS, you get not only parts, but also a commitment to quality and peace of mind. Need reliable high-precision parts? Feel free to contact us at any time!"

6. Call To Action: Turn The Design Plan Into A Finished Product Now

Don't wait any longer, try it now!

Want to turn your design into a physical object quickly? The service process we have created is specifically designed to help engineers like you save time and effort.Upload the drawingand you can see the effect immediately.

Zero risk, look at the price before deciding:

Upload your CAD drawing now! Get an accurateCNC machining priceand delivery date for free and immediately. No need to guess, no need to wait, make a decision with a clear mind, no risk at all.

Your creativity is kept confidential:

Worried about design security? No need!We attach great importance to intellectual property protection. As long as you need, we can sign a non-disclosure agreement (NDA) at any time to ensure that your design details only serve your project.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com