When you need a material as transparent as glass, as resilient as steel, fireproof, insulating, lightweight, and molding-friendly,your choice seems to have only one: polycarbonate sheets.

But after you've gotten an estimate, a question comes to mind: Why so much more expensive than acrylic (PMMA) and even at metal prices? Is this premium earned through greater performance, or are there manufacturing secrets?

This book will explore why polycarbonate sheets are costly, like their nature, production process, and cost structure. Furthermore, drawing on JS's wealth of experience in injection molding, we provide technical and practical information to help you better understand polycarbonate sheets and make smart buying decisions.

Core Answer Summary

| Core Topics | Key Information | JS Support |

| Reasons for the Premium Pricing | Raw material dependence on petroleum (price fluctuations), complex processes (high equipment costs), and brand premium. | High cost-effective supply of polycarbonate sheets. |

| Key Issues of Injection Molding | Strict drying (moisture content<0.02%), high-temperature processing (260-320 ℃), and high mold temperature control are required. | Injection molding process optimization service. |

| Key Applications | Transparent monitoring (sensor housing), corrosion-resistant and impact resistant (equipment protective panel). | Customized high-precision flow sensor housing and protective panel. |

| Price Volatility | Regional production capacity (low prices in the Asia Pacific region), tariffs and logistics (high import prices), quality standards. | Global market procurement consulting and cost control services. |

Why Are Polycarbonate Sheets So Expensive? JS's Experience Sharing

JS has rich experience in injection molding,e.g., injection molding of polycarbonate sheets and bespoke injection molding parts, and accumulated rich case studies.

We have delivered solutions to customers in various industries ranging from electronics, automotive, and medical.For example, we created high-precision polycarbonate sensor housings for a maker of automotive components. Improving the injection molding process, we raised the qualification rate of the product from a baseline of 85% to 99.5%.

In addition, we have a completely designed online injection molding service system, facilitating rapid response to orders. From design discussion to sample production, our average cycle is 30% shorter than the industry average.

This guide is composed of our portfolio of project experiences in the thousands. Each of the points and their accompanying analysis is based on real-life examples and facts. Its reliability and professionalism can be trusted.

JS deals with injection molding and processing of polycarbonate sheets, and can provide you with good quality custom injection molding manufacturing services. If you need any help, feel free to contact us and our experts will put you through to start an effective collaboration.

Getting To Know The King: What Is Polycarbonate?

Before finding out why polycarbonate sheets cost so much, let's find out about the "king" material, polycarbonate, used also in injection molding. Many people may wonder, 'Is PC plastic?' The answer is yes, polycarbonate (PC) is a high-performance engineering plastic that surpasses ordinary plastics with respect to strength and transparency.

Chemical Nature

Polycarbonate is a high-performance engineering plastic made by the polycondensation reaction of bisphenol A (BPA) and phosgene (or diphenyl carbonate). Its chemical makeup provides it with unique properties that form the foundation for high-performance injection molding parts manufacture.

Performance Labels

Polycarbonate has wide impact resistance, with an impact strength 250 times higher than ordinary glass and approximately 10 times higher than acrylic sheet. It is also perfect in terms of transparency (transmittance above 90%) and great temperature resistance (stable across -40°C to 120°C), which is why it is the material of choice for polycarbonate sheets and injection molding parts.

The Birth Process: How Is The Polycarbonate Sheet Transformed From Chemical Raw Materials To Perfect Sheet?

Having developed some understanding of the basics of polycarbonate, now let's see how the molding process is carried out from raw materials chemically to sheet, also related to injection molding.

Raw Material Preparation

Raw material processing for polycarbonate is complex. Phenol is refined from petroleum and purified via chemical reaction to produce bisphenol A (BPA). It requires extremely tight temperature and pressure control, and BPA has to be more than 99.9% pure, which forms the basis of high-grade polycarbonate sheets and injection molding parts.

Polymerization Process

There are two basic polycarbonate polymerization processes:

Melt Transesterification: Diphenyl carbonate and Bisphenol A are mixed and treated under low pressure and high temperature to give polycarbonate. It does not require solvents but has high equipment requirements.

Interfacial Phosgene Method: The Bisphenol A is dissolved in an alkaline solution of water and reacted with phosgene in an organic solvent. It is under mild conditions but requires very strict precautions.

Both must be properly controlled and of high quality, which increases the cost of production and therefore the polycarbonate sheets price.

Molding Techniques

Extrusion is utilized as the primary process to mold polycarbonate sheets. Polycarbonate pellets are molten and preheated and then conveyed through a screw and then extruded in sheet format by a die. Speed and temperature need to be controlled so that there is quality.

Co-extrusion technology is also available with the application of UV protective coating for further weather resistance, but it involves the coordination of several machines, so more cost and complexity to make and then push the polycarbonate sheets price upwards.

JS is experienced in the entire process of polycarbonate manufacturing and provides one-stop custom injection molding manufacturing services from raw material procurement to molding. Do you want polycarbonate sheets or injection molding parts? Please feel free to contact us and we will provide professional service.

Cost Analysis: Why Are Raw Materials So Expensive?

The reason why polycarbonate sheets are so costly is primarily due to regularly high raw materials prices, reflecting directly on injection molding parts costs and the injection molding prices.

Oil Price Volatility

Upstream polycarbonate industry chain is highly related to crude oil. The raw material phenol is an oil product, and the fluctuation of crude oil prices would lead to volatility of bisphenol A, polycarbonate, and phenol prices.

In 2022, global tensions boosted the price of crude oil and raised the price of phenol to $1,800 from $1,200 per ton while that of bisphenol A rose to $2,800 from $2,000 per ton.

The Shackles: Bisphenol A

Bisphenol A (BPA) is a critical raw material whose world production capacity rests in the hands of a limited chosen firms, and supply may thus be disrupted.

The complex manufacturing process, high capital requiring requirement, and long construction time to build capacity leave its cost open to increase when demand rises, making polycarbonate to be costly and leading to a rise in polycarbonate sheets price.

Environmental Protection and Regulatory Costs

The environmental requirements of various countries have been raised, and the production of bisphenol A and polycarbonate requires a huge investment in building environmental protection facilities to treat the "three wastes", as well as bearing monitoring and evaluation costs.

Furthermore, bisphenol A applications are highly controlled with high-tech processes and testing equipment employed to regulate migration, which adds extra expenses that are ultimately passed on to the prices of polycarbonate sheet and injection molding parts.

JS has a solid history of cost control of raw materials and can provide you with affordable custom injection molding manufacturing services and high-quality polycarbonate sheets. If you need any of these, you can purchase them using our user-friendly online injection molding services platform.

Process Cost: Why Molds And Equipment Are More Expensive

In addition to the expense of raw materials, the high expense of molds and equipment also adds to the price of polycarbonate sheets.

Equipment that is corrosion-resistant and high-pressure

Polycarbonate production (polymerization and extrusion) is high-temperature, high-pressure, or corrosive environment based and thus requires equipment which can tolerate these conditions. For example, corrosion-resistant interior wall stainless steel of high strength, which costs millions of dollars, is required in polymerization reactors.

The extruder screw barrel requires wear-resistant and high-temperature resistant alloys, and the high equipment cost directly increases the production cost of polycarbonate sheets.

The Hard Cost of Drying

Polycarbonate is highly hygroscopic and requires vigorous drying before processing, with dehumidifiers having a water content of less than 0.02%. Dehumidification equipment is expensive to purchase and operate (hundreds of thousands of dollars per equipment set) and consumes significant energy (thousands of dollars per day), which raises the price of polycarbonate sheets.

Mold Precision Requirements

Polycarbonate sheet requires high dimensional tolerances and surface finish. Molds require high-precision machining (with CNC machining centers, etc.) and high-strength, wear-resistant steel as raw material. A single extrusion mold costs hundreds of thousands of dollars and requires professional maintenance.

Companies must manufacture a series of molds to meet orders, further driving costs, leading to expensive polycarbonate sheet prices and affecting the injection molding parts prices.

Reasons Behind Price: Many Factors Affecting Price

Besides raw material and process fees, a number of other variables affect the price of polycarbonate sheet, and thus the injection molding price.

Brand Premium

Price differences are quite high between brands of polycarbonate. International companies like Covestro, SABIC, and Mitsubishi, due to their technological advancement, strict quality checks, and good brand name, charge 10%-30% more than normal brands for their products.

They invest a lot in R&D and testing and supply quality products and services. End-users are willing to pay extra, so the prices of their polycarbonate sheets and injection molding parts are high.

Specifications

Polycarbonate sheet specifications have a direct impact on cost:

Thickness and Size: Thicker and larger sheets require more material, are more difficult to produce and deliver, and are therefore more costly. For example, 10mm sheet costs roughly twice as much as 5mm sheet.

UV Coating: UV-coated sheets provide superior weather resistance and are priced 15%-25% higher than uncoated sheets.

Special Properties: Special boards such as fireproof and anti-static boards are priced 2-3 times higher than ordinary boards due to the addition of additives or the use of special processes, corresponding to the various requirements for injection molding parts.

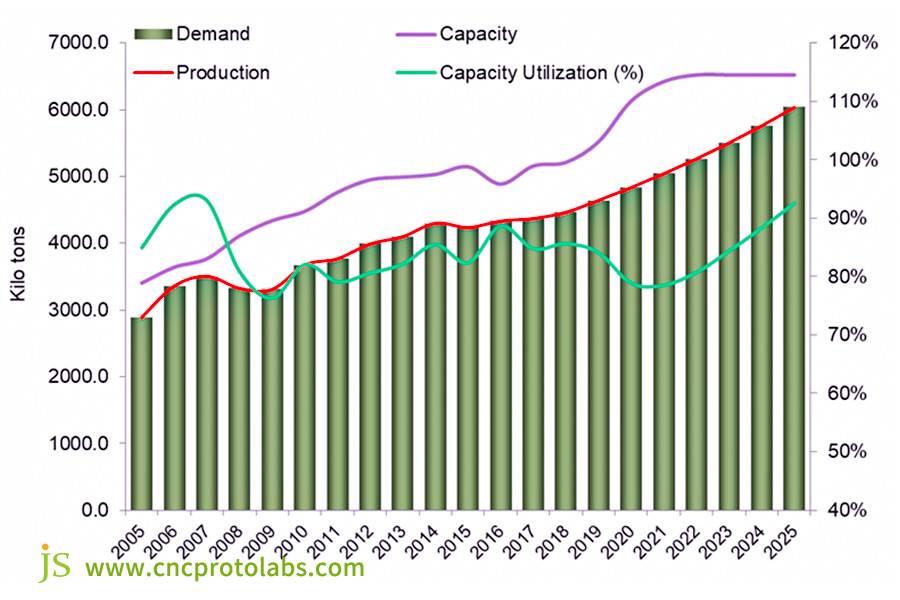

Market Supply and Demand

Prices are set based on global polycarbonate production capacity versus demand: prices rise when demand exceeds production capacity, and fall when demand is lower than production capacity. In the early stage of the 2020 pandemic, demand dropped and prices were kept low.The surge in demand in 2021-2022 coupled with lagged capacity pushed the prices up.

Also, global trade policies (such as high tariffs and trade barriers) impact polycarbonate trade, thus impacting supply, demand, and prices, which indirectly impact injection molding prices.

In our effort to more accurately define the effect of different factors on polycarbonate-related product transaction prices, the following is a comparison of typical polycarbonate product transaction prices:

| Product Type | Brand/Origin | Specifications | Transaction Price (USD/Unit) | Price Determining Factors |

| Polycarbonate Sheet (Translucent, No UV Coating) | Chinese Domestic Brand | 5mm Thick, 1220×2440mm | 25-30/sheet | Domestic availability in large quantity, no brand premium, no special coating. |

| Polycarbonate Sheet (Translucent with UV Coating) | Chinese Domestic Brand | 5mm Thick, 1220×2440mm | 32-38/sheet | 15%-25% less without UV coating as there is additional cost of UV co-extrusion process. |

| Polycarbonate Sheet (Translucent with UV Coating) | Covestro (Germany) | 5mm Thick, 1220×2440mm | 45-55/sheet | Foreign businesses are 10%-30% less than the above-mentioned price with import tax and logistic fees. |

| Polycarbonate Sensor Housing | JS Company Customization | Regular size, ordinary PC material. | 1.2-1.5/piece | Quotation includes cost-sharing of the mold and no additional performance specification. |

| Polycarbonate Sensor Housing | JS Company Customization | Conventional size, chemically modified PC material. | 1.7-2.1 per piece | Prices are around 40% greater compared to standard PC due to process optimization and material alteration. |

JS provides polycarbonate sheets and injection molding parts of various brands and specifications to meet your various needs. Product details and injection molding prices quotations are available at any time on our online injection molding services website. Feel free to enquire and order.

Global Chessboard: Where Do Price Differences Come From?

Polycarbonate sheet prices vary significantly around the world based on the region, which influences the home price and injection molding price.

Regional Capacity Distribution

Asia-Pacific (mainly China) is the world's largest production and consumption market of polycarbonate with over 40% of world-wide capacity. Economies of scale in corporations reduce costs, and domestic sheet prices are consequently lower. Lower production capacities put countries like

Africa and South America in a weak position where they are forced to import. Sheets' prices are 20%-50% more expensive than in the Asia-Pacific due to shipping and taxes, causing price imbalances worldwide.

Tariffs and Logistics

Importation of foreign polycarbonate sheet involves levies (US: 5%-10%, EU: 6%-12%) and high overseas freight (sea freight from Europe and the US to China: $200-500/ton), as well as incurring storage insurance fees. These are transferred to the final consumer and add to the cost of imported sheet as well as the import value of related injection molding parts.

Quality Standards

Europe and America have strict quality requirements for polycarbonate sheets, with clear indicators such as impact resistance and light transmittance. They also require a 10-15 year weather resistance commitment, and companies invest heavily to meet the standards, resulting in high product prices.

Third World countries with lower standards translate to variable quality and cheap price. Injection molding quality parts require sheets that are strictly compliant at a higher cost.

The following is a comparison of polycarbonate sheet price variations between regions:

| Region | Proportion of Main Production Capacity | Price Features | Principal Influencing Factors |

| Asia Pacific (China predominantly) | More than 40% | Lower | Scale factors and sufficient local production capacity. |

| Europe | Approximately 25% | Higher | Strict quality requirements and import tariffs (on non-local articles). |

| US | Approximately 20% | Higher | Strict quality requirements and import tariffs (on non-local articles). |

| Africa and South America | Less than 15% | Highest | Based primarily on imports, with high tariffs and shipping costs. |

Exploring The Injection Molding Process: Challenges And Solutions

Major Challenges

Hard Drying: Polycarbonate has strong hygroscopicity. If the polycarbonate is not dried adequately before injection molding, bubbles in the product can easily occur. The amount of moisture must be controlled at below 0.02%.

High-Temperature Processing: Melt temperature is 260°C to 320°C, requiring equipment resistance to high temperatures and potentially compromising the material.

High Mold Temperature: It requires the mold temperature of 80°C to 120°C to reduce internal stress and prevent cracking. It requires specific heating apparatus, which is energy-hungry.

Annealing: The material will experience internal stress and must be processed under controlled temperature during annealing. Deformation can readily occur due to improper annealing, thus increasing complexity and cost of manufacturing.

Solution

Drying Solution: Dry under 120°C-140°C with dehumidifier for 4-6 hours. Dry the material again by using an insulated hopper to maintain temperature and resist moisture pick-up.

Temperature Control Solution: Select a precision temperature-control injection molding machine, use zoned heating to control barrel temperature, and add a check valve to reduce material residence time and prevent degradation.

Mold Temperature Control Solution: Use a stand-alone mold temperature controller with closed-loop control to maintain constant mold temperature. Internal stress in complex molds can be reduced by using zoned heating.

Annealing Solution: Parameters vary with product thickness and structure. Maintain at 100°C-120°C for 2-4 hours, followed by slow cooling to reduce internal stress and prevent deformation.

JS has deep experience in polycarbonate injection molding and can effectively address a wide range of problems to produce high-quality injection molding parts. If you have the same requirements, choose our custom injection molding manufacturing service for professional process support. Feel free to contact us and place an order.

JS Case Study: Winning The Battle For Sensor Housing Upgrades

Company Background

A manufacturer of automated filling lines for the food, beverage, and chemical industries needed transparency (for visual inspection), chemical resistance (to detergents and industrial liquids), and impact resistance (to protect against accidental impact) for the high-precision flow sensor housings in its manufacturing line.

Initial Choice and Dilemma

The firm had been using polyoxymethylene (POM) injection molding material for sensor housings for several years. Nevertheless, the POM did not provide the required level of transparency and lacked corrosion and impact resistance. Housings were commonly broken during use, causing production line downtime as well as impacting the productivity.

JS Solution

After our intervention, we first had in-depth communication with the client about their requirements.After our engineering department analyzed the situation, we upgraded the material to chemically modified polycarbonate (PC). After the material upgrade, JS fixed several injection molding problems:

- Using special dehumidification equipment to dry the PC material completely to eliminate air bubbles.

- Simplifying the mold design to improve housing dimensional tolerancing and surface finish.

- Modifying injection parameters (temperature, pressure, and speed) to promote consistent product performance.

Final Results

Whereas the price of a single housing increased by around 40% in material, the upgrade yielded phenomenal results:

Real-time visual inspection without risking the housing was achieved, sensor downtime due to housing damage decreased by 90%, the efficiency of the production line was significantly improved, and overall costs of production were kept low, creating greater value for customers.

FAQs

Q1: Can PC be processed on a normal plastic injection molding machine?

It is not recommended. PC melts at 260°C-320°C. The barrel and screw of standard machines are difficult to resist high heat and tend to wear and get damaged. Besides, their low temperature control accuracy can easily lead to material degradation. Therefore, one needs to replace high-temperature components or select a specialized PC injection molding machine.

Q2: How do you identify by appearance PC sheets from acrylic sheets?

There are two simple methods to distinguish between them:

- Watch the light transmittance. PC sheets are about 90% transmittance, whereas acrylic sheets are 92%-93% transmittance. Under the same lighting environment, acrylic sheets are more transparent.

- Watch the edge hardness. PC sheets have soft edges and will bend but not crack and will not turn white. The edge of acrylic is hard and easy to crack and will leave a clear white track when broken.

Q3: How to proceed if the UV coating on a PC sheet is worn. Will it yellow quickly?

Minor wear on the UV coating can be repaired by applying a special UV repair agent and then curing it using UV light. For heavy, more severe wear, the sheet should be replaced in order to maintain the weather resistance. Once the UV coating is worn off, the PC sheet no longer enjoys the benefit of UV protection. Within 3-6 months of constant exposure to sunlight, it starts to become significantly yellow.

Q4: Are PC sheets cold-workable or bendable?

PC boards can be bent and cold processed, but there are conditional limitations:the bend radius must not be less than 10 times the sheet thickness to prevent cracking. Cold cutting and drilling require special cutting equipment and tools, and force and speed must be controlled to prevent cracking and burrs. Annealing following processing is recommended to reduce internal stress at edges and improve stability.

Summary

The cost of polycarbonate sheets is not merely a cost shift, it is the result of advanced chemical synthesis, stringent process requirements, and replaceable performance. It's a smart investment in quality, safety, and long-term benefits.

If you need top-notch injection molding parts, JS is a reliable choice. Supported by experienced technical personnel, abundant practical experience, and comprehensive online injection molding services, we can offer one-stop custom injection molding manufacturing services, ranging from material selection and process improvement to delivery of production.

No matter whether you're struggling with production problems or cost control, we can provide professional services. Get in touch with us to start a cooperation.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com