You're buying cheerful tableware for your new home and the pack includes "18/10 stainless steel." Or maybe you're designing a sheet metal fabrication parts that comes into contact with food and the bill of materials calls for "Type 304 (18/8)." What do the phrases "18/8," "18/10," and "18/0" even represent? Are they just marketing hype, or do they matter a great deal?

We at JS work with these materials on a daily basis and can tell you that these numbers aren't random,they're the key to knowing stainless steel's performance, longevity, and cost. Essentially, 18/8 is 18% chromium and 8% nickel. The proportion of chromium to nickel basically refers to the strength of the material, specifically its rust and corrosion resistivity, and the difference can be significant.

Knowing this information will give you an edge when buying kitchen goods or making a selection for a project. Below, this guide will provide you with a brief overview of the main differences, typical uses, and advantages and disadvantages of thesethree most common stainless steel grades--18/8, 18/10, and 18/0--so you can make a more conscious decision.

Core answer summary:

|

Stainless steel type

|

Chromium proportion |

Proportion of nickel

|

Key features |

Is it magnetic?

|

Common uses |

| 18/8 | ~18% | ~8% |

Rust prevention is good, suitable for the most common and versatile scenarios.

|

No magnetism (unable to attract magnets) | Food processing machines, insulated cups, and most everyday stainless steel items. |

| 18/10 | ~18% | ~10% | The strongest rust prevention ability, super bright surface, super sturdy and durable. |

No magnetism (not attracting magnets at all)

|

High end kitchen pots, pans, cutlery sets, and medical small tools. |

| 18/0 | ~18% | 0 | Rust prevention is okay, the price is cheaper, but it comes with magnetism. |

Magnetic (able to attract magnets)

|

Affordable tableware, cookware that can be used on induction cookers, and small car accessories. |

Why Can You Trust This Guide? JS Experts Break Down The Keys To Material Selection

In JS, 18/8, 18/10, and 18/0 stainless steel are not just terms in a textbook, they are, in fact, processed and tested in our workshops every day, processing thousands of tons of material, from sheet metal fabrication pieces to complete equipment. We have seen for ourselves that even a 0.1% change in the chromium and nickel content can make or break a material in terms of its strength, workability, and, more crucially, corrosion resistance.

"As Harry Brearley, the inventor of stainless steel, observed, stainless steel's rust resistance stems from its invisible 'armor' (the chromium oxide layer) on its surface."

The foundation ofthis guide is our engineering team's decades of hands-on experience, rigorous test data (e.g., salt spray testdata), andclose knowledge of many application environments.We share this information, if for no other reason than to provide you with reliable and practical material selection guidelines.

Password Cracking: What Do The Numbers "18" And "10" Represent?

Let's quickly define what these two significant numbers in stainless steel names are:

The initial "18" in, for example, 304 stainless steel is the percentage of chromium (Cr) content.The chromium is what gives stainless steel rust resistance. Chromium readily creates a tight protective layer of chromium oxide on the steel's surface, like a natural shield, which keeps the iron matrix underneath isolated from water and air, the causes of rust. That is the origin of stainless.

The final digit, usually"10," "8," or "0," specifies the nickel (Ni) content. Nickel has a significant beneficial effect on the overall resistance to corrosion of the material, particularly against acid environments. Furthermore, the addition of nickel gives stainless steel a whiter, more lustrous appearance, enhances ductility in fabrication, and reduces cracking.

Essentially, the major factor for rust resistance is chromium (Cr), and the factor responsible for increasing acid corrosion resistance, material gloss, and toughness is nickel (Ni).

18/10 Stainless Steel: The Pinnacle Of Quality And Performance

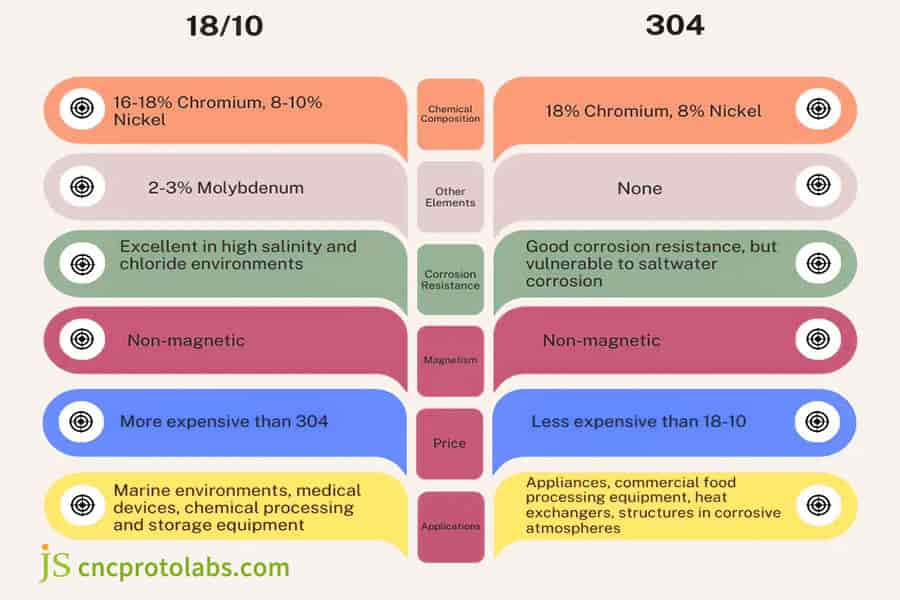

Let medetail why 18/10 stainless steel isthe embodiment ofquality.It sessence issimple: Roughly18% chromium (Cr) and 10% nickel (Ni).

Why is it so highly regarded?

The 18% chromium content is crucial. The chromium oxide (Cr₂O₃) passive film it spontaneously forms on thesurface of thesteel is typically 2-3 nanometers thick. This filmis a solid first line of defense against corrosion and acids found in foods like ketchup and lemon juice.In addition, it possesses the best surface gloss and, when held in the hand, is noticeably heavier and more solid.

It's all due to these remarkable features that 18/10 stainless steel is the firstchoice in thehigher-endmarket. You can find it used in high-end table ware, surgical instruments, and even seaside hardware. Of course, in the kitchen, 18/10 stainless steel pans, whichaspire towards longevityandelegance, are its signature.

But as they always say, good things do not come cheap. A 10% content typically results in a 20-30% higher material cost for 18/10 stainless steel compared to 18/8 stainless steel.This is mainly becausethe nickel added inside is relatively expensive.

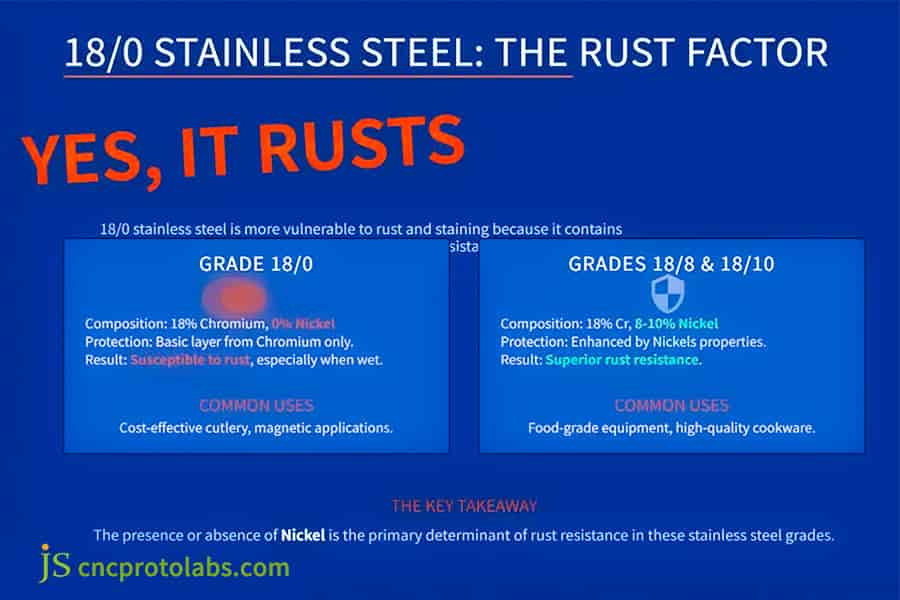

Figure 1: An infographic comparing three stainless steel grades (18/0, 18/8, 18/10) with their rust resistance properties. The title reads “18/0 STAINLESS STEEL: THE RUST FACTOR” with “YES, IT RUSTS” highlighted. The key takeaway is that nickel presence determines rust resistance.

Figure 1: An infographic comparing three stainless steel grades (18/0, 18/8, 18/10) with their rust resistance properties. The title reads “18/0 STAINLESS STEEL: THE RUST FACTOR” with “YES, IT RUSTS” highlighted. The key takeaway is that nickel presence determines rust resistance.

18/8 Stainless Steel: A Workhorse In Our Industry

In everyday engineering design work, 18/8 stainless steel is an unsung hero we can't live without.It's phenomenally widespread, but precisely because of that, we need to understand it intimately.

In plain language, the overall composition of 18/8 stainless steel is approximately 18% chromium and 8% nickel. This combination has proven resilient over the years, providing an excellent balance between performance, cost, and processing intricacy. It is commonly referred to as AISI 304 or SAE 304 in engineering blueprints and diagrams to indicate the same tested-and-proven material by "18/8."

To be honest, compared to the higher priced 18/10 stainless steel (containing 10% nickel), 18/8 stainless steel has slightly inferior corrosion resistance when facing corrosive substances such as concentrated lemon juice or vinegar and other strong acids.

That "weaker" is relative, though. For the most environments we encounter on a daily basis, like water, weak acids and bases, and atmospheric conditions,18/8 stainless steel is quite good and very reliable. Its affordability is also a central feature of its widespread application as a common material in the trade.

Why is it a norm? To what degree is it applied?The fact is its better general performance, medium price, and ease of processing:

- Many home items like cups, thermoses, sinks, and tableware are made from 18/8 stainless steel.

- The food and pharmaceutical industries necessitate high levels of hygiene, and 18/8 stainless steel is used extensively in food processing equipment, storage tanks, and pipelines.

- Applied to exterior building wall ornamentation and interior handrails, in pipes, storage tanks, and equipment casings in a wide range of industries—basically every industrial use you can imagine.

Lastly, 18/8 stainless steel is the "expendable and dependable" choice we hold most dear when designing. It's used all over, from kitchen sinks to chemical plant piping.

In particular, its excellent formability makes it ideal for custom sheet metal fabrication manufacturing. From bending, stamping, and welding, 18/8 stainless steel is extremely conformable, making designing and creating elaborate components cost-effective and reliable. It is the foundation for most of the chassis, housings, and structural components we design and make to order for private clients.

"18/8 stainless steel is a reliable, economical, and process-friendly industry cornerstone. If your project requires a balance between performance and cost, feel free to contact our JS Precision engineers anytime!!"

Figure 2: This infographic compares 18/10 and 304 stainless steels, detailing their chemical composition, corrosion resistance, magnetism, price, and applications. 18/10 contains molybdenum for better salinity resistance.

Figure 2: This infographic compares 18/10 and 304 stainless steels, detailing their chemical composition, corrosion resistance, magnetism, price, and applications. 18/10 contains molybdenum for better salinity resistance.

18/0 Stainless Steel: An Affordable Option With "Magnetic" Options

When we at JS Company routinely select materials, 18/0 stainless steel often attracts attention for two key features:its affordability and its magnetic properties.

It contains approximately 18% chromium (Cr) but virtually no nickel (Ni). It forms a thin chromium oxide protective layer on the surface, rendering it resistant to typical rust.

However, precisely because it lacks this nickel, its overall corrosion resistance, especially when exposed to corrosive substances like vinegar, lemon juice, or salt, is inferior to that of stainless steels with higher nickel content (such as 304). Over time or in harsh environments, rust easily forms on the surface.

But its magnetic properties are a major advantage for us!Magnets attract it, meaning pots and pans made from it can be used directly on popular induction cooktops. Many pots and pans used on induction cooktops, as well as frequently used dishes in cafeterias, are often made of18/0 stainless steel, offering excellent cost control.

In terms of specific applications:

Other than tableware and kitchenware, it's also commonly employed in auto exhaust pipe components and exterior trim appearance. In some of the projects we've worked on, e.g., cost-conscious sheet metal fabrication parts with less corrosion resistance requirements, such as equipment casing inner linings, specialty brackets, or protective covers, 18/0 stainless steel is an acceptable substitute. It is relatively simple to stamp and bend, has better processability, and because it is magnetic, sometimes allows it to meet certain assembly or functional requirements (e.g., those which require suction and fixation).

The choice goes hand in hand with the application. Following is a comparison ofhow it performs in an acidic environmentwhen compared to a range of widely used stainless steel materials:

Performance of different stainless steels in acidic environment (room temperature, 24 hours immersion)

|

Material type

|

Tomato sauce (with salt)

|

Lemon Juice (Natural)

|

Acetic acid (5% concentration)

|

Data sources |

|

18/0 (430)

|

Moderate pitting risk

|

Obvious pitting risk

|

Slight loss of gloss/pitting corrosion

|

Intl. Molybdenum Assoc. (IMOA) |

|

304 (18/8)

|

Slight loss of light

|

Slight loss of light

|

Almost unchanged

|

Euro Inox (Stainless Steel Assoc.) |

|

316 (including Mo)

|

Almost unchanged

|

Almost unchanged

|

No visible changes

|

Nickel Institute |

"18/0 stainless steel is the low-cost, low-price magnetic alternative, particularly well-suited for induction cooking tops and other money-saving applications. Want to cut costs on magnetic stainless steel parts? Feel free to browse our online sheet metal fabrication services on the JS website or give me a call!"

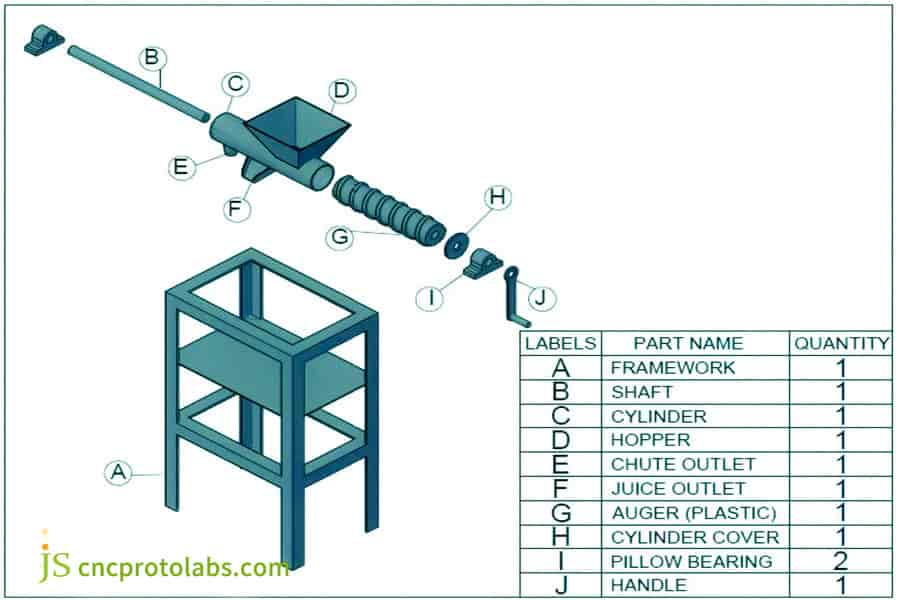

Case Study: Designing A Hopper For A High-End Juice Brand

Let me share a real-life experience of designing a juice mixing hopper for a high-end organic juice firm. This case studyintroduces the importance of selecting the right material, especially when working under stringent conditions.

The client's challenge:

They also produce organic juice of very high quality from massive amounts of highly acidic fruits like pineapples and lemons. The focal product in their production process is the hopper, the large vessel in which the fruit that has been blended.

Their customer had two broad requirements:

- First, complete assurance of cleanliness and purity of juice, with absolutely no possibility of metal contamination, was of absolute interest to their brand.

- Second, the hardware must withstand repeated, prolonged contact with extremely acidic juice and remain for many years.

Which material worked best?

Ordinary stainless steel behaved radically differently under these extreme conditions of severe acid and prolonged contact.Internally, we tested three options:

Option 1: 18/0 stainless steel

This was the cheapest and most attractive option, as it turned out. But our engineers were immediately suspicious. 18/0 stainless steel has the worst acid resistance.

Think about it:It will likely rust quickly when exposed to acidic beverages like lemon juice and pineapple juice. Once it has rusted,metal ionscan leach into the juice, blatently violating food safety regulations and instantly ruining the brand's reputation. This was just too much of a risk and absolutely unacceptable, so we didn't even entertain this option initially.

Option 2: 18/8 stainless steel (or otherwise referred to as the more well-known 304 stainless steel)

This is a stalwart of the food industry, offering excellent value and safe for repeated contact with food.But this particular situation was long-term, high-acid concentration exposure!

Although 304 stainless steel is much stronger than 18/0, experience and conservatism by our engineers indicate that in the long term, there is still a risk of localized corrosion (e.g., pinprick rust spots).

While the risk is less with 18/0, if the equipment does develop a problem after a short period of time and manufacturing has to stop to have it repaired or even replaced, subsequent loss and erosion of brand trust can easily end up being much more than the initial cost savings in the material. We don't want to have thecustomer nor ourselves pay this "what if" cost.

Option 3: 18/10 Stainless Steel (Specifically Grade 316)

The most expensive choice, yet an actual "corrosion warrior." Its foundation chemistry is 18% chromium and 10% nickel, creating a hard protective coating. Worth noting is that Grade 316 also has 2-3% molybdenum, which is specifically charged with repelling chlorides and hostile acids. This provides an excellent first-class barrier, ensuring absolutely pure juice while prolonging equipment life and lowering maintenance costs.

JS's professional recommendation is clear:

Due to the client's high standards and long-term value focus,we strongly recommend using 18/10 (Grade 316) stainless steelfor these hoppers. While the initial material cost is clearly higher than the other two options, in our view, the value derived from this investment greatly outweighs the cost:

- Clean Food Safety:Completely eliminates the risk of metal contamination, safeguarding the client'sbrand values—purity and safety.

- Very long service life:Reduces downtime, repair, and replacement costs to a significant degree due to corrosion damage.

- Lowest lifecycle cost:We help our customers calculate the total cost. Although the initial cost is greater, in the long run, it is usually more cost-effective compared to the use of less expensive materials and recurring replacement.

Key Performance Data Comparison (simulating a juice production environment with 5% citric acid, 60°C, and trace Cl- (50 ppm))

| Material type |

Metal ion precipitation after 3000 hours of immersion

|

Critical pitting temperature (℃)

|

Critical chloride ion concentration induced by pitting corrosion (ppm) |

Annual corrosion rate (mm/yr)

|

Risk assessment of long-term exposure to high acid fruit juice

|

| 18/0 (430) | >500 (severely exceeding the standard) | < 15 | < 10 |

>0.5 (catastrophic)

|

Extremely high risk (pollution/failure)

|

|

18/8 (304)

|

50-150 (approaching/exceeding risk) |

15-25

|

~ 100 |

0.05 - 0.15

|

Medium to high risk (potential pitting/shortened lifespan)

|

|

18/10 (316)

|

<5 (far below the limit) |

> 35

|

> 1000 |

< 0.001

|

Extremely low risk (safety/longevity)

|

Data source: NACE Corrosion Engineer's Reference Book (4th Ed.)

Materials Performance Magazine (MP, Aug 2023)

JS's value goes beyond manufacturing:

Our case study encompasses more than producing a hopper. We thoroughly understand the corrosive characteristics of juice and apply our material science knowledge to help customers make the best long-term value decision between "penny-pinching" and "peace of mind/safety." From design consultation to precise manufacturing, we provide solutions.

"When choosing a hopper for a high-end juice production line, 18/10 (316) stainless steel is the best for safety and longitivity. JS is material aware and aware of your company's pain points. Don't let material failure ruin quality. Reach out to us today or visit our online sheet metal fabrication services to allow our engineers shield your mission-critical equipment!"

Figure 3: This image shows a detailed decomposition diagram of a juice-making device, with all parts like the hopper, cylinder, auger, and framework clearly labeled with names and quantities.

Figure 3: This image shows a detailed decomposition diagram of a juice-making device, with all parts like the hopper, cylinder, auger, and framework clearly labeled with names and quantities.

How To Care For Different Stainless Steels?

As a JS engineer who deals with various types of stainless steel daily, I'd like to share some useful maintenance tips. To get your sheet metal fabrication parts or cookware to look brand new for decades,remember the following:

(1) Universal rules apply to all types

- Gentle cleaning is best:For routine cleaning, warm water with a little mild dish soap is sufficient. Never use steel wool or strong acid or alkaline cleaners (like toilet cleaners or bleach), as these will damage the stainless steel's protective coating.

- Wipe with the grain:When cleaning and drying, it's best to follow the "grain" (if any) of the stainless steel surface. This will minimize unsightly scratches and maintain a polished finish.

- Dry promptly to prevent marks:After washing or contact with water,always dry immediately with a soft cloth!Tap water, in particular, can easily leave watermarks, which can be difficult to remove over time.

(2) 18/8 and 18/10 (Type 304): Relatively tough

These types have a high nickel content, offer excellent corrosion resistance, and are easy to use for daily use. Use the general cleaning and maintenance methods described above for general safety and generally shouldn't cause any problems. Many of the 18 10 stainless steel pans, pots, sinks, and complex sheet metal fabrication parts we use at home are made of this type.They are durable.

(3) 18/0 (430): Need to be more careful

- Afraid of acid! This is the key.Because it does not contain nickel, its acid resistance is much worse. Acidic foods such as ketchup, salad dressing (mayonnaise), lemon juice, and vinegar should not be left in 18/0 stainless steel pans, plates, or bowls for a long time. Wash them as soon as possible after eating or using them.

- Dry them immediately after washing!This is especially important for 18/0. It is not only to prevent ordinary water stains, but more importantly to prevent residual moisture from causing rust and spots on the surface. Wiping it dry can greatly reduce the risk of rust.

- For stubborn stains, try baking soda:If there are burnt food or stubborn stains, don't scrape them hard. Try using a damp cloth to dip some baking soda into a paste and gently rub it, or use a special stainless steel cleaning cream (choose a mild one), which usually works.

"Mastering these simple tips will help you maintain any stainless steel in the best possible condition and extend its lifespan. If you require specific care instructions for your sheet metal fabrication parts, feel free to get in touch with JS!"

Figure 4: This image shows five 18/10 stainless-steel pans, each paired with a cleaning product like Easy-Off, steel wool, Brillo Cameo, baking soda with lemon, and Bar Keepers Friend. The title reads “The Best Way to Clean a Discolored Stainless Steel Pan”.

Figure 4: This image shows five 18/10 stainless-steel pans, each paired with a cleaning product like Easy-Off, steel wool, Brillo Cameo, baking soda with lemon, and Bar Keepers Friend. The title reads “The Best Way to Clean a Discolored Stainless Steel Pan”.

Common Misconception Clarified: Is 18/10 Stainless Steel Toxic?

Regarding the frequently asked question, "Is 18/10 stainless steel toxic?" As an engineer at JS, I can clearly answer:Don't worry, it's completely safe.

Why do I say that?

High-quality stainless steels like 18/10 and 18/8 are structurally stable. In everyday use, whether cooking, serving, or washing, the chromium and nickel in them rarely leach into food. This is why we prefer this type of stainless steel for pots, pans, cutlery, and even hospital equipment.

Some may have heard about the risks of heavy metal poisoning, but based on my product testing and industry standards, 18/10 stainless steel products that meet the requirements are completely harmless under normal use. Feel free to use them.

FAQs

Q1: How can I distinguish them visually?

It's almost but not quite impossible to consistently distinguish them visually.

18/10 sometimes will appear lighter, but this is entirely unreliable. The simplest and best thing to do is test it with a magnet: if it sticks to the magnet, then it is 18/0, if it doesn't, then it's 18/8 or 18/10. We are only specifying one test as a means of verification.

Q2: Is 18/10 "healthier" than 18/8?

I can only say: 18/10 isn't healthier than 18/8.

Both are totally safe for food contact and have undergone millions of tests in our plants. The one difference is how long-lasting they are. 18/10 has a small percentage of added nickel, which resists corrosion from daily cleaning and bumps more, but there is no health benefit. You can choose either one with certainty.

Q3: Why is my "non-magnetic" 18/8 stainless steel knife slightly magnetic?

Knives are stamped and polished during production. These processes can create a slight magnetic effect within the material, much like kneading dough changes its texture. However, rest assured, this does not affect its rust resistance at all, and it will not chip or rust with daily use.We rigorously test this during production.

Q4: Which frying pan is best for my needs?

I would recommend the following:

- If you have an induction cooker, you must choose an 18/0 magnetic stainless steel pot, or a high-end pot with a magnetic bottom plate, or else the cooker will not recognize it.

- If you're on a gas or electric stovetop, 18/10 is the better option. It's less prone to being scratched and corroded, and the bottom of the pot will not adhere to the stovetop. Themost important consideration is which type of stovetop you have.

Summary

The stamps 18/8, 18/10, and 18/0 are important differences in the rust-proofing, lifespan, luster, and cost of stainless steel. 18/10 has the best performance but comes at the highest cost. 18/8 is a middle-of-the-road and most common option. 18/0 is low cost and magnetic, and therefore is best applied in situations where magnetism is needed or in situations where cost is the issue.There's no single right answer, it all depends on your intended use and your budget.

So, how do you choose? JS recommends considering the following:

- Seeking ultimate durability and corrosion resistance? For high-end cookware and core components used daily, choose 18/10. It contains more nickel, making it more resistant to wear and chemicals over time.

- Need reliable performance without the extra cost? 18/8 is a safe bet in most applications. From kitchenware toequipment covers,it's our first-line standard.

- Need magnetic properties or cost is essential? For induction cooktop bases and some structural components, 18/0 is a cost-effective choice. It's cheap and magnetically attractive,but less rust-resistant.

Unsure? Don't guess!

Submit your design to our online platform (https://www.cncprotolabs.com/contact-us). Our JS team will carefully review your specific requirements. Then, based on these requirements, we'll recommend the most suitable stainless steel grade and provide you with a clear, realistic sheet metal fabrication price. Choosing the right material ensures your product's longevity. Leave it to our professionals to review!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com