Gear manufacturing constitutes the basic element of the transmission core of renewable energy equipment. The gear systems of renewable energy equipment are designed to endure severe loads such as extreme gusts and salt spray corrosion over their 25-year design life.

The accuracy of gear cutting is the main factor that leads to gear durability. One small gear fault may lead to the complete stoppage of the machine which means daily losses of more than tens of thousands of US dollars for a single megawatt-class wind turbine.

It is very risky to rely on using "standard parts". The main topic of this article is the essence of excellent gear manufacturing and how to establish a dependable transmission core through custom gears as well as CNC gear manufacturing.

Quick Overview of Core Answers

| Core Questions | Key Answers | Value for You |

| Why is it necessary for renewable energy gears to be customized? | Extreme conditions of use dictate that gears should be customized in terms of materials, design, and heat treatment. Off-the-shelf parts are simply not capable of meeting the required lifespan and reliability standards. | Realize that customization is a value investment that provides a long-term return on investment for projects. |

| What is the key to ensuring the long-term reliability of gearboxes? | Taking advantage of the accuracy of CNC gear manufacturing, together with the use of special materials and advanced heat treatment, perfect the gear machining. | Set the technology of a high-reliability product and create partner evaluation criteria. |

| How to select the right manufacturing partner? | Evaluate their experience in large gear manufacturing, technology integration, and engineering support capabilities without considering the location. | Get a supplier selection framework, focusing on partners who are capable of delivering full lifecycle value. |

Key Takeaways:

- Customization is Standard:

The custom gears aspect to the different parts of the wind turbines and hydro turbines is due to varied load and space constraints.

- Power Generation Depends on Precision:

Increasing gear transmission efficiency by only 0.5% results in a big raise of the expected annual power production from megawatt, class units that depend on ultra-precision CNC gear manufacturing.

- Large-Scale Production Reveals the Level of Skills Test:

The execution of large gear manufacturing with heavy-duty clamping and deformation control at a high level is what sets apart an ordinary factory from an industry leader.

- Drawings are the Cornerstone of Successful Manufacturing Cooperation:

Without a doubt, accurate gear manufacturing drawing is the basis for great gear-making partnerships, and are to comprise all major features.

Why Trust This Guide? JS Precision Wind Turbine Gear Manufacturing Achievements

The professionalism and authority of this guide are rooted in JS Precision's 15 years of deep cultivation and accumulation in the fields of gear manufacturing and gear machining. It also relies on the practical experience of over 500 global renewable energy projects, covering multiple scenarios such as onshore/offshore wind power and hydropower.

JS Precision has full-process capabilities in large gear manufacturing. We company can machine large gears with diameters up to 8 meters and a module of 40.

The CNC gear manufacturing process of JS Precision is capable of achieving ISO 6 high-precision machining, which is far superior to the industry-standard ISO 8. Every step of the gear machining process is equipped with a digital inspection system, allowing full-dimensional traceability.

JS Precision wholesale collaborates with top global specialty steel suppliers, who are able to provide material formulas for custom gears. In the salt spray environment of offshore wind power, its super carburizing process can produce a gear surface hardness of HRC 62 while still keeping a core toughness of above 120J.

Unlike the service life, the failure rate of JS Precision's custom gearboxes and gear components for wind farms in North America, Europe, and Asia has been less than 0.8% since 2025, whereas the industry average is 3%.

All conclusions and methods in this guide are based on real-world project verification and strictly adhere to the ISO 1328:2013 gear precision design standard, ensuring the scientific rigor and practicality of the content.

Want to verify JS Precision's professional gear manufacturing capabilities? Contact JS Precision's engineering team, submit your renewable energy project's basic information, and receive a free customized gear machining process plan to proactively mitigate potential risks in gear design and manufacturing.

Why Do Wind And Hydraulic Systems Rely On Custom Gears?

Wind and hydropower machinery work in very different environments and thus, gears manufacturing for these industries is highly customized. Along with the custom design, the precision of the gear machining should also be very precise, off-the-shelf gears dont comply with the AGMA 2001-D04 standard.

Problems of Using Standard Gears

- Poor Material Compatibility: Standard gears are made of a general, purpose alloy steel, which is not capable of withstanding extreme temperature fluctuations and exposure to such harsh environments as salt spray and moisture under the water.

- Heat Treatment Mismatch: Standard gears come with a hardened layer of fixed thickness, which is unable to match the varying bending stresses of wind power.

- No Optimized Tooth Profile Design: The standard tooth profile is not suitable for the variable load spectrum, which leads to uneven load distribution.

Why You Need Custom Gears

The main benefit of custom gears is in converting the initial expenditure into a long, term reduction of costs through end-to-end gear manufacturing customization.

JS Precision gear manufacturing offers the customization of tooth profile modification and heat treatment for custom gears that be capable of extending gear life by 30% and also improving the transmission efficiency by a further 0.5%.

How To Select Gear Manufacturing Companies With Strong Capabilities In The Field Of Renewable Energy?

High quality gear manufacturing companies, including gear manufacturing companies in USA, are the key to implementing custom gear performance. Many companies focus too much on "gear manufacturing near me", neglecting core technical capabilities, and screening should focus on technology and experience rather than geographical location.

Key Evaluation Criteria

- Experience in large gear manufacturing: Independent processing of the main shaft wind turbine gears with a diameter of more than 3 meters and heavy, duty gears weighing more than 50 tons.

- Materials and heat treatment expertise: Heat treatment capabilities on-site as well as the ability to adjust the heat treatment process for custom gears.

- Testing and certification facilities: Having a large gear measurement center and possessing industry certifications like GL, DNV, capability to supply full-process testing data.

- Engineering support capabilities: Offering load analysis and gear profile modification services, the ability to optimize the designs based on the gear manufacturing drawings.

Reconsidering the Priority for "Gear Manufacturing Near Me"

"Gear Manufacturing Near Me" does offer the convenience of communication, but if the local companies lack industry experience, the risks are increased.

Experienced custom gear manufacturer, whether they are gear manufacturing companies in USA or international professional manufacturers, can provide more reliable custom gears with lower overall costs.

Commonly Used Materials and Performance Table for Wind Turbine Gears

| Material Grade | Surface Hardness (HRC) | Core Toughness (J) | Effective Hardened Layer (mm) | Applicable Scenarios | Salt Spray Corrosion Resistance |

| 18CrNiMo7-6 | 58-62 | 110-130 | 1.4-1.8 | Offshore Wind Turbine Main Shaft Gear | ★★★★ |

| 20MnCr5 | 56-60 | 90-110 | 1.0-1.4 | Onshore Wind Turbine Yaw Gear | ★★★ |

| SAE 8620 | 57-61 | 100-120 | 1.2-1.6 | Hydropower Speed Control Mechanism Gear | ★★★★☆ |

| 316L Stainless Steel | 45-50 | 150-180 | — | Offshore Wind Turbine Pitch Gear | ★★★★★ |

| 20CrNi2Mo | 55-59 | 100-120 | 1.1-1.5 | Onshore Wind Turbine Speed Increaser Gear | ★★★ |

How Can CNC Gear Manufacturing Become The Guardian Of Renewable Energy Gear Accuracy?

At the heart of the whole precision gear manufacturing is CNC gear manufacturing technology. This technology is very significant in producing custom gears that are efficient and have a long lifespan and also it resolves the problems of poor precision and inconsistent results that are typically experienced in the conventional gear machining.

The Three Core Advantages of CNC Technology

- Submicron-level Repeatability: CNC gear manufacturing is capable of achieving a repeatability of 0.001mm, therefore the dimensions of the teeth of custom gears are always consistent.

- Complex Geometric Machining Capability: This is product of the ability of the machine to create complex profiles accurately. For example, it can carry out tooth tip trimming that reduces vibration and noise.

- Batch Consistency Guarantee: Utilization of digital means is what allows each batch of custom gears to have a consistent precision, thus the replacement requirement of wind farm spare parts is satisfied.

CNC Gear Manufacturing Precision Parameter Table

| Machining Process | Machining Equipment | Precision Tolerance (mm) | Applicable Gear Type | Machining Efficiency (pieces/day) | Precision Grade |

| CNC Hobbing | Large CNC Hobbing Machine | 0.005 | Wind Turbine Yaw Gear | 2-3 | ISO 7 |

| CNC Gear Grinding | Precision Forming Gear Grinding Machine | 0.001 | Wind Turbine Spindle Gear | 1-2 | ISO 6 |

| CNC Turning | Heavy Duty CNC Lathe | 0.002 | Large Gear Blank | 3-5 | ISO 8 |

| CNC Milling | CNC Floor-type Milling and Boring Machine | 0.003 | Gearbox Housing | 2-4 | ISO 7 |

| CNC Gear Shaping | High Precision CNC Gear Shaping Machine | 0.004 | Hydroelectric Speed Regulating Gear | 4-6 | ISO 7 |

Want higher transmission precision for your custom gears? Submit your gear manufacturing drawing. JS Precision, leveraging CNC gear manufacturing technology, will provide you with micron-level tooth profile control, improving gear transmission efficiency.

What Unique Challenges Does Large Gear Manufacturing Bring To Wind And Hydropower Projects?

The ever-increasing size of renewable energy equipment is making large gear manufacturing a core challenge even in the field of gear manufacturing. Large gears are much more difficult to manufacture than ordinary gears, and they are the key factor that distinguishes the capabilities of gear manufacturing companies.

Engineering Challenges Beyond Machine Tool Specifications

- Heavy Workpiece Clamping: Gears larger than 50 tons require special tooling designed to fit them to prevent clamping deformation from affecting the accuracy of the operation.

- Heat Treatment Deformation Control: Large gears are very likely to get distorted during heat treatment. Hence, they require process optimization by simulation and special tooling to effectively control the deformation.

- Segmented Machining and Assembly: In order to make ultra-large gears, segmented machining and precision assembly are used to ensure that after assembly the tooth profile accuracy complies with the standards.

Quality Assurance: Full-Process Data Monitoring

Quality control when manufacturing large gears begins with the steel ingot and ultrasonic testing to ensure that no defects are present. It also involves online measurement during the machining operation, recording the entire heat treatment curve, and finally, 3D scanning inspection to validate the performance of the custom gears.

Want to solve the technical challenges of large gear manufacturing? Contact JS Precision's large gear manufacturing engineers to receive a free customized machining solution, overcoming the challenges of manufacturing and precision control in heavy-duty gears.

Figure 1: A top-down view of a factory scene where a worker in safety gear is manually inspecting a massive, complexly designed circular metal gear on the workshop floor.

Figure 1: A top-down view of a factory scene where a worker in safety gear is manually inspecting a massive, complexly designed circular metal gear on the workshop floor.

What Are The Key Engineering Factors To Consider When Designing An Efficient Custom Gearbox?

The efficiency of custom gearbox determines the transmission efficiency and energy consumption of the equipment. The design needs to be combined with the equipment operating conditions, achieve compatibility with the system.

Design Inputs: Identify Your Unique Operating Conditions

In order to manufacture an efficient custom gearbox, it is necessary to completely understand the core parameters of operation that are typically the starting point for gear manufacturing:

- Peak Torque: It must be able to handle the maximum torque under extreme operation conditions, e.g., torque variations during emergency braking of wind power or starting of hydropower.

- Speed Range: Equipment's high and low-speed ranges, achieving accurate speed regulation via the custom gearbox.

- Installation Space Limits: When it comes to compact equipment, the volume of custom gearbox must be strictly controlled, and there must be adequate installation space.

- Environmental Conditions: Find out the temperature differences, humidity, and corrosion conditions that influence the custom gearbox materials and sealing design.

Completely integrate the Gearbox with the System

A custom gearbox is deeply integrated with the equipment, aligned with the generator, and its rigidity is enhanced. In addition, vibration and noise can be controlled through gear profile optimization, and service life can be extended.

How To Achieve High-Precision Tooth Profile Of Wind Turbine Yaw Gear In CNC Gear Manufacturing?

The accuracy of the yaw gear influences how precisely the wind turbine can be aligned, and how efficiently it can generate power. CNC gear manufacturing is the key to very high precision.

Challenges: Requirements for Large Diameters and High Tooth Surface Load Capacity

Yaw gear manufacturing poses two main challenges:

- The diameters can be larger than 5 meters, which makes machining very difficult.

- The gear must be able to handle the overturning moment of the whole turbine, thus the tooth surface hardness has to be HRC 58 or even higher, and the cumulative pitch accuracy must be 0.02mm.

Solutions: Segmented Machining and Online Measurement

JS Precision has solved these problems by CNC gear manufacturing: segmented machining and docking with the help of large CNC equipment, on-machine measurement to adjust for errors, and precision grinding to achieve a total circumference tooth profile error of <0.02mm.

Want to achieve high-precision machining of yaw gears? Submit your yaw gear specifications, and JS Precision will leverage its advanced CNC gear manufacturing technology to provide you with a customized machining solution, ensuring wind alignment accuracy and power generation efficiency.

How To Design a Compact Custom Gearbox For Vertical Axis Wind Turbines?

Vertical axis wind turbines (VAWTs) possess a sleek design, hence their custom gearboxes must comply with the features of being compact and having a high power density. The fulfillment of these demands calls for customization and optimization facilitated by gear manufacturing.

Space Constraints and High Torque Density Requirements

The custom gearboxes of vertical axis wind turbines have very little room for the installation of new pieces. This causes the volume to be reduced by more than 30% while they also transmit low-speed, high-torque power falling thus under the attribute of extremely high power density.

Innovative Design: Planetary Gear System and Integration

JS Precision designs a compact custom gearbox, a multi-stage planetary gear system not only lowers the volume by 40% but also raises the power density by 25%, plus, the design is integrated with the generator housing, thus the high-strength steel is used to satisfy the requirements of custom gears.

Figure 2: A white custom gearbox unit, designed for a vertical axis wind turbine, mounted on a tall pole against a clear blue sky.

Figure 2: A white custom gearbox unit, designed for a vertical axis wind turbine, mounted on a tall pole against a clear blue sky.

What Technical Parameters Do I Need To Prepare To Collaborate With Custom Gear Manufacturer?

Regarding custom gear manufacturers, precise technical parameters are of great importance. Manufacturing gear drawings are the main communicative tool, so they directly decide the manufacturing accuracy of custom gears and gearboxes.

Technical Dialogue Checklist for Initiating Collaboration

Effective collaboration requires complete technical parameters, such as:

- Application Scenarios: Provide accurate and detailed information for the equipment type, power, etc. to help the gear manufacturing team decide the best route.

- Basic Parameters: The main characteristics such as gear module and number of teeth are the basics of gear machining.

- Performance Requirements: Specify torque, speed, life cycle, and special requirements (e.g. noise reduction, corrosion prevention).

- Operating Conditions: Give the type of lubrication and environment parameters, which impact the choice of materials and processes.

- Installation Dimensions: Convey interface dimensions and tolerances to facilitate perfect matching with the equipment.

Gear Manufacturing Drawing: The Most Authoritative Way of Conveying Your Ideas

Correct gear manufacturing drawing should specify: gear geometry and tolerances, material specifications, heat treatment requirements, and testing standards thus ensuring gear manufacturing quality is controllable.

Case Study: Reduce Wind Power Operation And Maintenance Costs By 35%! JS Precision Helps North American Wind Farms Solve Early Pitting Corrosion Of Gearboxes

Challenge

During a 2.0MW unit's gearbox planetary-grade custom gears (material 18CrNiMo7, 6) in a 200MW wind farm in North America, the gear tooth surfaces showed signs of early pitting corrosion after a short period of only 18 months and resulted in a failure rate of 8%.

The original European supplier's repair chain was over 6 months, and the replacement cost per unit was more than $20, 000, thus the wind farm's power generation losses and O&M costs were heavily hit.

JS Precision's Solution

1.Root Cause Analysis and DFM Optimization:

Upon receiving the request we immediately ran a metallographic analysis of the failed gears and we saw that the original gear manufacturing had an unreasonable carburized layer gradient and coarse carbide morphology, which was the main reason for pitting corrosion.

Heat treatment process was redesigned by engineers, the effective hardened layer depth was optimized from 1.4mm to 1.6mm through controlled atmosphere carburizing, and carbide morphology was also optimized.

2.Precision Manufacturing Process Upgrade:

In the CNC gear manufacturing process, the process of "pre grinding rolling teeth → controlled atmosphere carburizing quenching → precision forming grinding teeth" is adopted, and the tooth surface is modified according to the wind field load spectrum to optimize the load distribution

3. Supply Chain and Quality Assurance Enhancement:

The team used vacuum degassing special steel ingots as the raw material, thus ensuring complete traceability from blank to finished product. A residual stress test report on the tooth surface of each gear is also provided.

Results

Following the change of JS Precision's specially made gears, the wind farm gearbox has been functioning well for over 3 years without the occurrence of any new pitting failures on the tooth surface. Failure rate for similar gearboxes has been lowered to less than 1%.

Taking into account the total gear procurement cost and the downtime losses avoided, the maintenance cost of this part has been cut by 35%, resulting in an annual saving of over $500, 000 for the wind farm.

Want to replicate this successful case of cost reduction in wind turbine gears? Upload your gear manufacturing drawing to JS Precision to receive free DFM optimization suggestions and professional solutions for early pitting and other failure issues in custom gears.

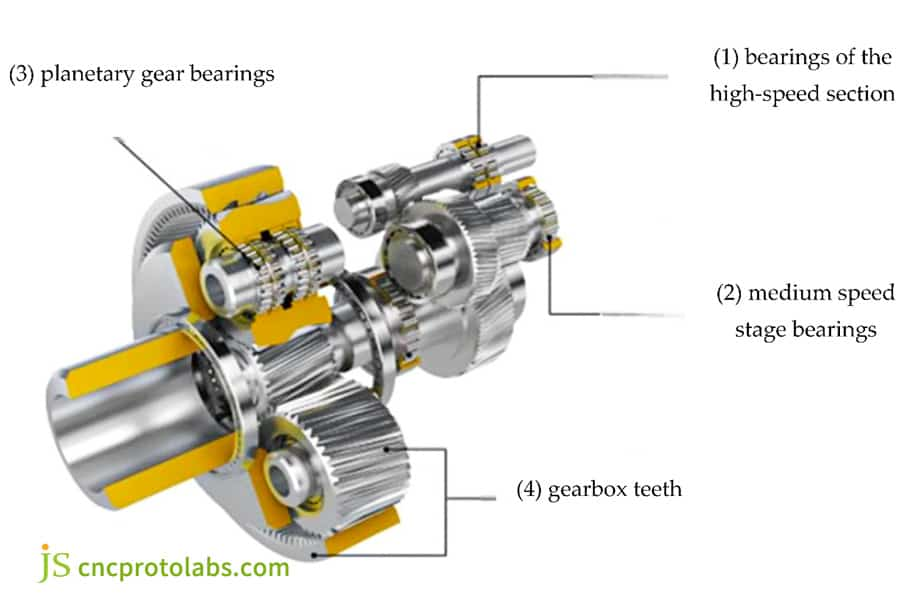

Figure 3: A technical diagram detailing the internal components of a wind turbine gearbox, including labeled parts like bearings and gearbox teeth, illustrating the complex system targeted by maintenance solutions.

Figure 3: A technical diagram detailing the internal components of a wind turbine gearbox, including labeled parts like bearings and gearbox teeth, illustrating the complex system targeted by maintenance solutions.

FAQs

Q1: What materials are most frequently used in wind turbine gears?

The main material used in the manufacture of wind turbine gears is alloy steels with high hardenability, such as 18CrNiMo7-6 and 20MnCr5. After carburizing and quenching, the surface hardness reaches HRC 58-62. The core has a good toughness, thus the material is suitable for the complex load of wind power.

Q2: What level of precision can be expected from large hydroelectric gears?

Large hydroelectric gears usually have to comply with AGMA Grade 12 or ISO Grade 7 or higher standards. The emphasis is on controlling the cumulative pitch error to achieve smooth transmission, low noise, and quiet operation.

Q3: What is the typical timespan for designing and delivering a large custom gear?

The lead time for large custom gear blanks varies from 6 to 12 months, depending on the size and the heat treatment process. Precision machining takes about one-third of the total lead time.

Q4: How can the quality of large gears be guaranteed during their transportation and installation?

Specialised tooling and packaging are necessary. Major surfaces will be covered with anti-rust oil and protected with covers. Detailed suspension and installation instructions will be provided to ensure that the quality of transportation and installation is maintained.

Q5: What is the maximum size and module of gears that can be machined?

JS Precision large gear manufacturing is capable of producing gear with a diameter of 8 meters and a module of 40. The specific case for the solution will be checked based on gear manufacturing drawings.

Q6: Can you provide a fatigue test or finite element analysis for your gears?

JS Precision is able to offer FEA finite element analysis based on load spectrum, and can also make arrangements for bench tests to complete a comprehensive assessment of gear performance.

Q7: What kind of special treatments are applied to offshore wind turbine gears with super-high corrosion protection?

Besides using corrosion-resistant materials, offshore wind turbine gears can also be treated by super carburizing and epoxy coating to greatly enhance their resistance to salt spray corrosion.

Q8: What is the minimum order quantity (MOQ) for custom gears?

JS Precision is capable of supporting the whole process of custom gears, from single-piece prototype to mass production. Single, piece prototypes are mainly used for R&D verification, and mass production can enable more cost-effective gear manufacturing quotes.

Summary

Renewable energy requires the precision gears for stable power generation, and gear manufacturing is the cornerstone. Selecting a custom gear manufacturer with professional skills and experience assures the operation of your gears for at least 25 years. JS Precision uses its expert gear manufacturing to build dependable transmission cores for your projects.

Don't wait any longer, equip your renewable energy projects with the power that won't fail.

Please send us your gear manufacturing drawing or project requirements, and JS Precision engineering experts will respond with professional technical analysis and internationally competitive tailor-made solutions within 24 hours. Harnessing the power of precision gears, let's create a greener tomorrow together.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com