Life-saving pacemakers are contained in completely waterproof plastic shells, whereas the enormous fuel tanks of speeding cars are a single continuous plastic shape. They aren't injection molded all at once, nor assembled with glue.

Its durability, sealing, and strength are derived from a covert technique called "plastic welding." It is tough enough to withstand years' duration of corrosion that fuel causes but thin enough not to crimp or cut hair-thin wires.

You can ask: Is it tougher than screws or glue? This guide will provide a complete explanation of the plastic welding strength from the perspectives of welding fundamentals, processes, strength, and cost. Based on JS's experience, it will make you clearly understand how to use plastic welding correctly to solve various plastic joining problems.

Key Answer Summary

| Core Theme | Key Conclusions | Key Basis |

| Plastic Welding Effectiveness | Effective, meeting strength and sealing standards. | Strength reaches 80%-95% of the parent material and can pass IP68 testing. |

| Material Requirements | Same material required, select matching welding material. | Melting temperature difference ≤ 10 ℃, refer to compatibility chart. |

| Cost Advantage | Lower total cost for medium and large-volume production. | Unit cost of 0.1-0.5 USD for an annual production of 50,000 units. |

| Mainstream Process Efficiency | Ultrasonic welding offers high efficiency. | Ultrasonic welding speeds of 0.5-2 seconds per unit are suitable for mass production. |

| Applicable Processes for Thick-Walled Parts | Deep penetration welding is suitable for thick-walled parts. | Realize deep material fusion and enhance structural stability. |

Why believe JS's Guide? Analysis Of Plastic Weld Strength

JS has over 10 years of expertise in plastic welding for a variety of core markets, including automotive, medical, and consumer electronics.

To illustrate, we had previously worked on 500,000 plastic bumper weld repairs annually for a top automotive client with a 99.8% pass rate implemented consistently. We also performed welding of micro-sensor casings for customers in the medical device industry to IP68 sealing specifications.

They ranged from millimeter-sized micro-parts to meter-sized large-sized structural parts, with thousands of process parameters and solutions to problems. We compiled this handbook based on these real project experiences. All recommendations have been proven in use, so you can be confident of its professionalism and applicability.

Choose JS Precision Manufacturing's plastic welding services. Simply provide us with your product specifications and material requirements, and we will quickly review and customize a solution that will easily solve your plastic joining problems without worrying about the risk of quality.

What Is Plastic Welding? Why Is It The "Ultimate Solution" For Joining Plastics?

Plastic welding uses heat, vibration, or laser to join the contacting faces of two plastic parts together, creating an invisible and robust joint upon cooling. Why is it called the "ultimate solution" for joining plastics?

A comparison with traditional means reveals its superiority:

| Connection Method | Strength | Sealing | Appearance | Durability |

| Plastic Welding | High (Near parent material strength) | Excellent (Leak-tight and seamless) | Good (No visible marks) | Strong (Aging and vibration resistance) |

| Gluing | Medium (Dependent on adhesive viscosity) | Bad (Dependent on weather conditions and leakage) | Fair (May have glue residue) | Weak (Glue deteriorates and fails quickly) |

| Screw Connection | Medium (Relying on screw fixation) | Bad (Gap exists) | Bad (With traces of screw holes) | Fair (Affected by loosening due to extended use) |

As the table shows, plastic welding surpasses traditional methods in both the most important parameters of strength and seal and thus in being particularly well-suited to being used where high-reliability is required. It also has extensive use complemented by sheet metal fabrication parts to provide greater overall product stability.

JS provides custom plastic welding services based on your product specifications and accepts custom sheet metal fabrication manufacturing orders to meet your integrated processing needs and increase production efficiency.

How Is Plastic Welding Manufactured? Six Mainstream Processes Revealed

Different plastic parts and applications require different plastic welding processes. Below is an in-depth analysis of six mainstream processes:

| Process Type | Principle | Applicable Materials | Advantages | Disadvantages |

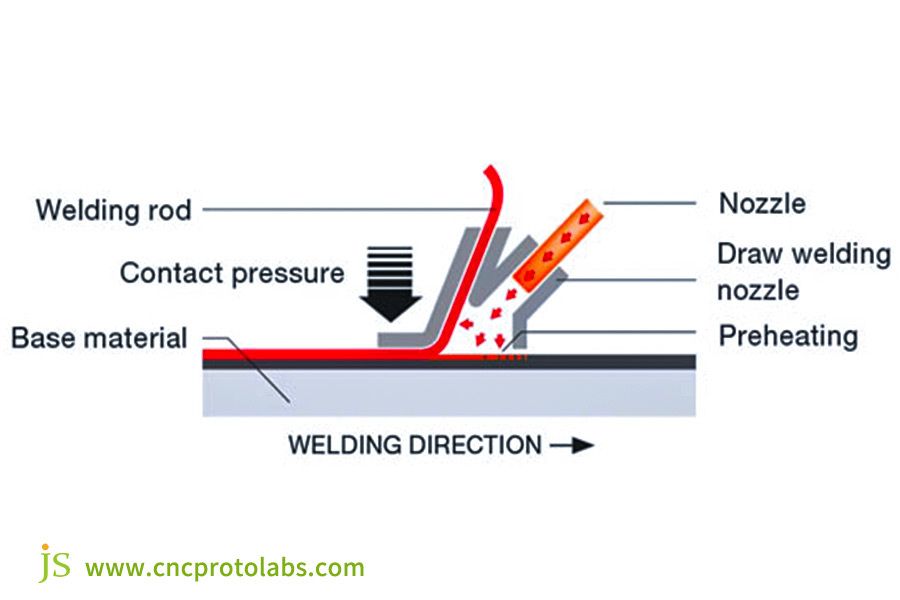

| Hot Air Welding | The hot air is used to melt the plastic surface and then weld and pressurize it. | PP, PE, and PVC. | Low cost of equipment ($1,000-3,000 USD), simple operation. | Low speed, low accuracy, and compatible with simple parts. |

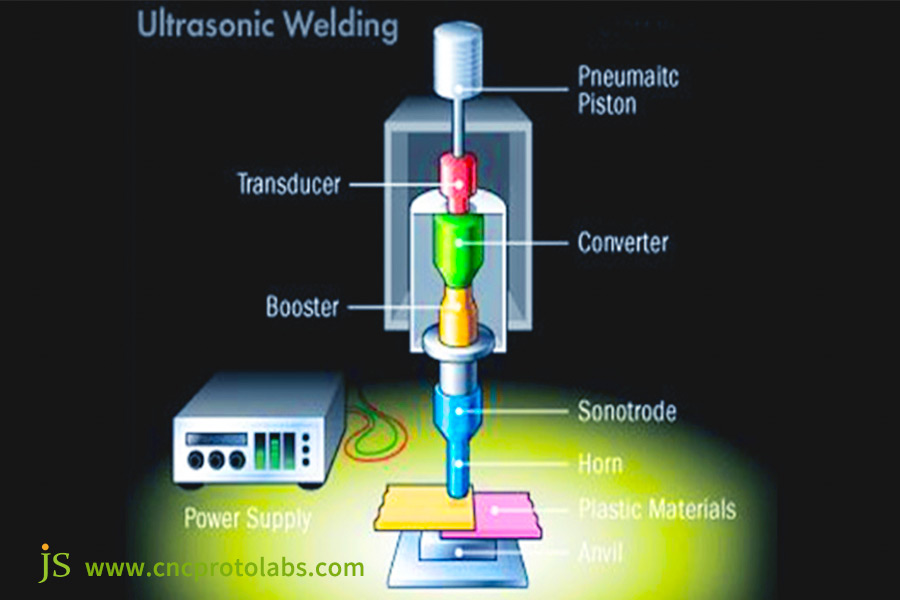

| Ultrasonic Welding | Heat and melting of surfaces to be contacted is made by high frequency vibration. | ABS, PS, and PC. | High speed (0.5-2 seconds per part), high accuracy, and no residue. | High cost of equipment ($5,000-20,000 USD), depending on the size of the part. |

| Vibration Friction Welding | Components vibrate relatively to each other, generate heat and sinters the components. | PP,PE,and PC. | High strength, suitable for big plastic components. | Large equipment size and complex setup, not suitable for micro components. |

| Laser Welding | Focused laser heating creates highly localized melting of the mating surfaces. | PET, PMMA, and PC. | Extremely high precision (≤0.01mm error), no mechanical stress. | Expensive equipment cost, needs transparency of material. |

| Rotary Friction Welding | Rotating a part warms and deforms it to a fixed one. | ABS, PP, and PE. | Seal well and are used for symmetrical buildings. | Only in the case of round/symmetrical parts, their use is limited. |

| Implant Welding | Metal is melted and inserted into the plastic to form a joint. | ABS, PA, and PC. | Forms safe joints and suitable for composite materials. | Pre-planned insert location involved and involves much pre-preparation. |

Once you are aware of the properties of these processes, you can select the most appropriate plastic welding method for your product requirements.

Other methods such as deep penetration welding may be applied to weld thick-walled plastic parts with deeper material penetration and greater overall joint strength, meeting requirements for increased structural stability.

Does Plastic Welding Really Work? Scientific Verification Of Strength And Sealing

Plastic welding success can be proven directly through scientific testing data. As far as strength is concerned, successful plastic welding can achieve 80%-95% of the parent material strength. The exact figures are given in the table below:

| Welding Process | Test Material | Weld Tensile Strength (MPa) | Relative to Parent Material Strength (%) |

| Ultrasonic Welding | ABS | 25 | 89 |

| Hot Air Welding | PP | 18 | 85 |

| Laser Welding | PC | 60 | 92 |

In terms of sealing performance, plastic welding parts also perform well.

Water-tightness and air pressure sealing tests have validated that ultrasonically welded medical devices meet IP68 sealing standards, being leak-free after immersion in water for 24 hours at a depth of 1.5 meters. Auto-components welded are leak-free and void-free after they are subjected to 0.5 MPa pressure for 30 minutes.

These points validate that plastic welding fully meets the stringent strength and sealing requirements of various industries.

JS Precision Manufacturing performs strength and sealing testing on every batch of welded parts to guarantee product quality. We also have transparent sheet metal fabrication price, allowing you to easily view your cost structure and avoid unnecessary expense.

Is Welding Expensive? Anatomizing The Investment And Return Equation

Plastic welding is prohibitively costly for a lot of people, but in a long-term ROI perspective, it actually has a lot of benefits. The cost is as follows:

Initial Investment

The cost of automated welding equipment varies based on the process: hot air welding equipment is approximately $1,000-3,000 USD, ultrasonic welding equipment costs $5,000-20,000 USD, and laser welding equipment costs $20,000-50,000 USD. The equipment can be used for 5-8 years, which suits large-scale production.

Unit Cost

As production increases to a given volume, the unit cost of welding plastic decreases significantly.

For example, with an annual demand of 50,000 units, ultrasonic welding brings the cost per unit down to just $0.1-0.5 USD, significantly lower than gluing ($0.3-1.0 USD/unit) and screwing ($0.5-1.5 USD/unit). This is due to the high degree of automation efficiency, reducing labor as well as consumables cost.

Overall Profitability

For medium to high production quantities (annual demand ≥ 50,000 units), plastic welding yields significant total profitability.

As an example for the scenario of a car bumper, where an investment of $15,000 in ultrasonic equipment is made, cost per unit at the 100,000 units per year production quantity is $0.30, with $70,000 per year saved, 6-12 months payback, and continued cost savings.

Conclusion: In medium- and high-volume production, the total cost of plastic welding is typically much lower than that of other forms of joining, and it is key to gaining automatic manufacturing and reducing per-unit cost.

How To Test Whether Plastics Are Weldable? Material Compatibility Testing

Material compatibility testing is the first step in welding plastics successfully. The specific requirements are given below:

1.The First Rule: The Materials Must Be Identical

Different plastics cannot be welded effectively since they exhibit an immense difference in their molecular structure and melting property. The selection of proper welding material is indispensable for effective welding.

For example, PP has to be welded to PP, and ABS to ABS. These materials if mixed will result in cracked joints and extremely poor weld strength.

2.Key Parameter: Melting Temperature

Each plastic has a different melting point. While welding, try to make the temperatures of both parts nearly the same.

For example, PP melts between 160-170°C, ABS between 220-250°C, and PC between 220-230°C. There should be a temperature difference of not more than 10°C for full melting. A higher temperature difference will halt melting or even burn the plastics.

3.Chemical Compatibility

Two plastics cannot undergo chemical reactions during welding.For example, welding PVC to some plastics can release hydrogen chloride gas, which is harmful and can soften the weld. Welding fluoropolymers to most common plastics can produce toxic products and reduce weld strength.

4.Useful Tool: Use the Plastic Welding Compatibility Chart

The Plastic Welding Compatibility Chart shows plastic compatibility (e.g., "weldable," "limited weld," and "unweldable") and allows easy checking for compatibility, reducing trial and error costs and maximizing welding success ratios.

JS provides plastic welding compatibility testing services, determining your material's weldability and recommending support processes. We also accept custom sheet metal fabrication manufacturing orders to meet your diverse processing needs.

Beyond Strength: The Wide Range Of Applications For Plastic Welded Parts

Plastic welding with its sealing and strength advantages has widespread application in many industries. Common uses:

Medical Industry: Used for sealing equipment such as hearing aids, syringes, and sensors.For example, JS welds very small microphone components utilized in high-end hearing aids, offering IP68-rated protection from moisture and dust to protect internal components.

Motor Vehicle Industry: Complementing plastic parts such as bumpers, dashboards, and radiators. Vibration friction welding of motor vehicle bumpers enhances their strength by 30% to absorb minor impacts without cracking.

Electronics Industry: Sealing sensor housing and connectors. Electronic sensor laser welding makes them stable at elevated temperatures and humidity, and the failure rate is below 0.5%.

Packaging Industry: Joining food containers and plastic bottle caps. Rotary friction welding of plastic bottle caps yields better sealing properties, extending food shelf life by 3-6 months.

Home Appliance Industry: Joining washing machine inner drums and air conditioner outer parts. Hot air welding of plastic appliance parts makes them more durable and extends their lifespan by 5-8 years.

Plastic welding in such uses is typically utilized in conjunction with sheet metal fabrication parts. Plastic components in auto dashboards, for example, are welded onto metal brackets so that it becomes sealed and reinforces the structure overall.

Beyond Equipment: Four Key Factors To Consider When Welding Plastics

Other than selecting the right equipment and materials, four of the most important factors within the welding process have a direct impact on the quality of plastic welding:

1. Surface Cleaning

Clean the plastic surface of oil, dust, and impurities before welding. Impurities can cause gaps in the weld seam, reduce strength by 30% -50%, and break the seal. Cleaning the surface with alcohol and letting it dry first is recommended before welding.

2. Pressure Control

Proper pressure is to be used for welding. Insufficient pressure will lead to improper bonding of the melted materials and weld cracking, while excessive pressure will lead to component deformation, impacting appearance and accuracy. For instance, for ultrasonic welding of ABS, use 0.1-0.5 MPa pressure, which is varied based on thickness.

3. Temperature Control

Different plastics melt at different temperatures, and temperature adjustment is required. The plastic won't melt completely with too low a temperature and will result in poor weld strength, while too high a temperature will burn the plastic, create smoke, and reduce the structure's strength. For example, when welding PP, 160-170°C should be used and when welding ABS, 220-250°C should be used.

4. Cooling Time

Sufficient cooling time should be left after welding in order to allow molten plastic to harden fully. Insufficient cooling results in an undefined weld, prone to crack under stress, excessive cooling reduces efficiency. Cooling time is usually 2-3 times welding time. Ultrasonic welding, for example, lasts for 0.8 seconds, while cooling lasts for 1.6-2.4 seconds.

JS closely controls these four most crucial factors in the process of plastic welding so that every weld is standard quality through standardized practices. We even offer online sheet metal fabrication services. Just order online and we'll contact you in no time, saving both your time and money.

On The Road To Success: Five Practical Tips For Plastic Welding

Mastery of these five handy tips will significantly enhance your plastic welding success rate:

1. Choosing the Right Welding Tool

Choose tools based on part size and material:

- For micro parts (such as medical sensors), choose an ultrasonic welder for extreme precision and trace-free welds.

- For large parts (such as car radiators), choose a vibration friction welder for large-area welding.

- For simple repairs (such as cracks in plastic basins), choose hot air equipment for low expense and versatility.

2. Test Samples Ahead

Before mass welding, test samples have to be produced. Test weld strength (tensile strength, flexure) and sealing (air pressure resistance, water resistance). Only when proper parameters can mass production proceed. It can prevent batch scrapping and loss due to improper parameters.

3. Control Welding Speed

Speed welding must be equivalent to the heat efficiency. Too fast will result in the plastic not being heated sufficiently, and a substandard weld will be produced, too slow will result in overheating, burning, and warping.

As an example, when welding PP using hot-air welding, control the speed to 5-10 mm/s in order to prevent burning.

4. Provide a uniform Welding Environment

The welding environment must be constant in temperature and humidity, and dust-free. Humidity will cause moisture deposits on the plastic surface, affecting bonding, excessive dust will introduce impurities, reducing strength, and temperature fluctuation will affect the melting state.

Welding must ideally be carried out in a clean room with 20-25°C temperature and 40%-60% humidity.

5. Regularly Keep Equipment in Order

Welding equipment must be inspected and maintained on a routine basis.

- Hot air welder heating elements need to be cleaned monthly to prevent dust interference with efficiency.

- Ultrasonic welder vibrators need to be calibrated quarterly to ensure correct frequency.

- Pressure sensors need to be tested every half year to ensure accurate pressure measurement, to maximize equipment life and reduce failures.

Case Study: How Ultrasonic Welding Ensures Clear Sound Quality In Smart Hearing Aids

Customer Pain Points

One high-performance hearing aid producer required hermetic sealing of a miniature microphone piece (3mm x 5mm) in a minute depression. They had four demands:

Full sealing to prevent dust and moisture from interfering with sound quality, extremely high accuracy (≤0.01mm deviation) to eliminate sensitivity loss, no engraving on the outside surface, and no adhesive.

JS's Solution

1.Process selection

Precision ultrasonic welding was selected because it is extremely accurate, involves short welding duration (0.5-2 seconds per unit), and welds tracelessly and fulfills all the accuracy and appearance needs of the customer.

2.Materials and Design

We used medical-grade ABS material for the bottom cap and outer case after consultation with the customer in order to enhance material compatibility and prevent cracking during welding. We also created a 0.2mm weld rib to offer weld strength and seal performance.

3.Parameter Control

After a set of trial welds had been performed, the optimal parameters were determined:

Ultrasonic frequency 35kHz, welding pressure 0.3MPa, welding time 0.8 seconds, and cooling time 2 seconds. Parameters such as these ensure sufficient plastic melting, prevent parts deformation, and meet the conditions for sealing.

Final Results

The project reached 100% in yield rate and welds cleared the IP68 sealing test (no leak after 24 hours immersion in 1.5 meters of water), fully encasing the microphone components.

Customer testimonies validated 40% improvement in mass production efficiency, 99.5% long-term reliability in demanding environments, and ≤0.1% sound quality distortion rate. Sheet metal fabrication parts included with the project were supplied by JS, supporting in-house production and cost-efficient endeavor.

FAQs

Q1: Is the plastic weld strong?

Yes, welds of plastic, if well executed, can be 80%-95% as strong as the parent material. This has to be done using material matching, correct process parameters, and sufficient cooling time. For example, tensile weld strength in ultrasonically welded ABS is 25 MPa, which is almost as close to parent material at 28 MPa, and can withstand the lifetime of long service.

Q2: Is plastic welding difficult?

The difficulty of plastic welding operation is moderate, but professional training is required, including equipment operation, plastic behavior, and control of process parameters. Temperature and speed control directly impact weld quality. Fundamental welding processes can be taught to trainees in 1-2 weeks of formal training and practice. Additional project experience is required for advanced processes.

Q3: Is plastic welding unsafe when it comes to producing hazardous fumes?

Any thermoplastic process will generate fumes. What fumes are generated depends on the plastic. For example, heating PVC may release hydrogen chloride gas, All processes should therefore be carried out under good ventilation with an exhaust filtration system to minimize inhalation of fumes. Special material when welded, operators will also need to use protective masks for them to be protected.

Q4: What do you need to provide in order to quote on welding services?

Kindly provide three key pieces of information: a 3D CAD product drawing with the weld area circled, the precise plastic material (e.g., PP, ABS), and yearly product demand (e.g., 10,000 units, 100,000 units). Such information allows us to properly estimate the feasibility of welding operations, make best recommendations, and calculate costs, ultimately providing an exact quote.

Summary

Plastic welding is not a "similar" process, but a scientifically proven, highly controllable, and precise technology. Its superior strength, sealing, and reliability made a door for its integration into high-end manufacturing.

JS as a reliable manufacturing and processing company, provides quality sheet metal fabrication parts as well as transparent sheet metal fabrication prices. Choosing us not only ensures quality welding products, but skilled and prompt service as well, so plastic joining problems are easy peasy.

Our online sheet metal fabrication services offer rapid ordering, and we provide full project support from beginning to end to help you finish manufacturing effectively and enhance product competitiveness.

Disclaimer

The contents of this page are for informational purposes only.JS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com