When your project has included tight curves, difficult angles, and utmost precision, 5-axis CNC machines are an "option" no longer but the "sole solution."

But with quotes for 5-axis CNC machines price ranging between hundreds of thousands to million dollars, most engineers and purchasing managers are puzzled: Where is the huge price disparity coming from? Where is the investment bottom line?

As a core technology for manufacturing complex parts, the cost of 5-axis CNC machining is not a static number, but rather variable. Most companies make irrational choices by ignoring these variables.

In this article, the veil will be lifted, and the seven important determinants that govern 5-axis CNC machining cost will be explored in depth, and how, by choosing a reputable online 5-axis CNC machining provider, you will be able to shy away from large capital outlays and thus reap the benefits of cutting-edge manufacturing technology directly.

Key Answer Summary

| Cost Drivers | Impact on Price and Value |

| Machine Tool Rigidity and Structure | Determine the stability in machining, precision life, and material compatibility. The price differential between a moving column machine structure and a C-bridge structure is considerable. |

| Core Component Brand and Performance | The CNC system (e.g., Heidenhain, Siemens), spindle (torque, speed, cooling system), and linear motor/ball screw are the primary cost drivers. |

| Compensation Level and Positioning Accuracy | Volumetric compensation availability, positioning accuracy, and repeatability have a direct influence on quality and price of parts. |

| Automation | Inclusion of a tool magazine, robot loading and unloading system, and in-process measurement significantly influences initial capital and labor cost in the long term. |

| Brand Premium and Origin | Taiwanese brands, original German/Japanese machines, and mainland Chinese 5-axis CNC machines form a clear price level. |

| Technical Support and Warranty | After-sales response time, spare parts availability, and technical training, all included within the quote, are value guarantees implied. |

| Configuration and Options | From base model to fully equipped model, high-pressure internal coolant, oil mist filtration, and specialist software modules all add to the cost. |

Why Is It Reliable? JS Precision Breaks Down The Cost Structure

JS Precision has long been committed to 5 axis CNC machining for the past 15 years, serving over 500 corporate customers in challenging fields such as medical devices, aerospace, auto parts, and precision molds.

We used to complete machining over 10,000 intricate titanium alloy components for an aerospace company at a mean qualification rate of over 99.5% per component. We've also optimized aluminum alloy component processes for several civilian product manufacturers and increased machining efficiency by 40%.

In these practical exercises, we gained an effective insight into the cost differences between different brands and models of 5-axis machine tools.

For example, we have an effective insight into the price difference between Heidenhain CNC systems and normal systems and the operating cost comparison over time between 40,000 rpm and 24,000 rpm electric spindles based on real data.

This book condenses from this front line experience. Each observation is specifically attached to one specific project example, and each piece of data is based on actual live business records. You can trust its professionalism.

If you're confused by 5-axis CNC machine prices, JS Precision can leverage its ample experience to provide a correct price quotation. Choose our service and you don't need to go searching for complicated parameters. Just submit your specification and receive a direct answer.

Breaking The Barriers To Manufacturing: How 5-Axis CNC Exceeds The Definition Of "Machinability"

After our hands-on experience, let's learn why 5-Axis CNC Machining is a powerful tool for processing complex parts. Its core value is its revolutionary motion principle, which is also the foundation of understanding custom 5 axis CNC machining manufacturing.

Core Concept:

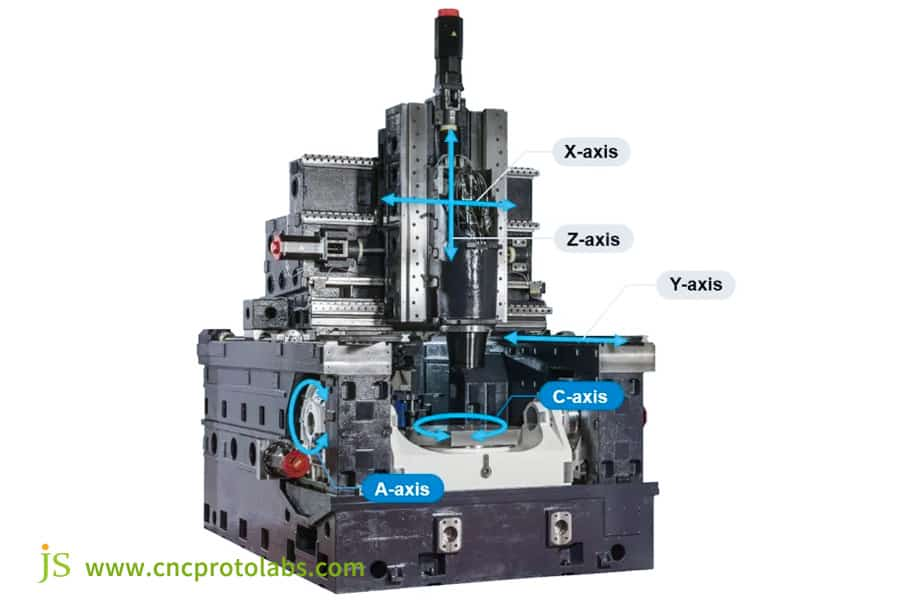

5-axis linkage refers to the combined motion of X, Y, and Z linear axes and A and C rotary axes such that the tool can approach the workpiece at various angles and machine complex surfaces.

In 3+2 position machining, angles cannot be changed in real-time since A and C axis angles need to be pre-defined to machine along the X, Y, and Z axes. It is the basis of 5-axis machine tools to machine complex parts and the main distinction between 5-Axis CNC Machining and 3-axis machining.

Value Transformation:

The first advantage is "single-clamping" and the avoidance of re-clamping mistakes (accuracy of up to ±0.005mm), correct tool angles (surface roughness Ra0.8, preventing polishing steps), and minimizing machining cycles (cutting, for example, machining time of some auto component by half from 48 hours to 24 hours).

These are precisely the reasons why custom 5-axis CNC machining manufacturing meets diverse needs and is irreplaceable in high-end manufacturing.

To produce intricate parts, you require 5-axis technology, JS Precision's custom 5 axis CNC machining manufacturing service has your need covered. We exercise total control from process design through to production delivery. Our service lets you achieve high-quality 5-axis CNC machine parts within a matter of time.

Cost And Reward: 5-Axis Machine Price Range

When the significance of 5-axis CNC machine is understood, the 5-axis CNC machine price is the most vital factor to consider. According to market data and service experience, we categorized various machine tools of different market categories into three types for arranging a budget plan:

| Machine Tool Type | Price Range (US$) | Applicable Materials | Applications |

| Economy (Domestic/Taiwanese Entry-Level) | 120,000-220,000 | Aluminum alloys, engineering plastics | Simple parts processing, consumer products. |

| Mainstream High-Performance (Leading Taiwan Brands/Mainland Chinese High-End) | 220,000-520,000 | Steel, stainless steel, titanium alloys | All precision parts and 5-axis machining work online. |

| Top-of-the-line Flagship (Authentic German/Japanese) | 520,000-1,500,000+ | High-temperature alloys, titanium alloys | Aerospace, high-end medical, precision molds. |

For the majority of firms, a 5-axis machine tool in mid- to high-end is a significant capital investment with recurring operational expenses. Through a professional service provider, capital expenditure can be translated into sustainable operating costs, allowing responding to needs in a more elastic way.

Comparison of First-Year Transaction Costs for Buying and Outsourcing 5-Axis CNC Machine Tools

| Transaction Method | First-Time Purchase/Partnership Charge (USD) | First-Year Latent Costs (USD) | First-Year Total Transaction Charge (USD) | Transaction Risks |

| Purchasing a Low-Cost Machine Tool | 120,000 - 220,000 | 45,000 - 75,000 | 165,000 - 295,000 | Accuracy not meeting standards, talent shortage, downtime losses. |

| Purchasing a Mainstream High-Power Machine Tool | 220,000 - 520,000 | 60,000 - 100,000 | 280,000 - 620,000 | High capital occupation and high maintenance costs. |

| JS Precision Outsourcing Services | 0 (No equipment cost) | 0 (No equipment cost) | Billed per order (e.g., 50 titanium parts for 80,000) | No risk, controllable quality and lead time. |

If you do not want to shoulder the big expense of purchasing machine tools, JS Precision's online 5 axis CNC machining services can be employed. No equipment investment required; simply provide your machining specification and receive a reasonable 5 axis CNC machine price quote.

Cost Effect: How Core Components Influence The Final Price

Core components are a major contributor to the ultimate price of a 5-axis CNC machine tool. The quality of these "brain," "heart," and "sensory" components directly impacts cost and performance:

1. "Brain"—the CNC system: Top-range systems like Heidenhain and Siemens 840D are 3-5 times costlier than traditional systems but come equipped with ±0.001mm path error control, facilitating precise surface complexness, failure minimization, and long-term stability.

2. "Heart" of the electric spindle: Efficiency and material adaptability depend on speed and torque. The price difference between an electric spindle of 24,000 rpm and 40,000 rpm is nearly double. Liquid-cooled, high-torque spindles are necessary when cutting hard-to-machine materials like titanium alloys, which means even higher cost.

3. "Senses" - Feedback System: Closed-loop control with a grating scale offers real-time error correction. While costing 20%-30% more than an ordinary encoder, it ensures that machine tool accuracy is preserved after long-term use and thus is strictly required for mass production of high-precision 5 axis CNC machine parts.

JS Precision has a heavy investment in machine tools with quality core components. Quality core components are needed to produce 5 axis CNC machine parts that meet the requirements of customers, and it is the key to winning our trust.

Machine Tool Configuration: Why Do Different Options Result In Price Variations?

Apart from basic elements, other arrangements have a significant impact on the 5-axis CNC machine price. The configurations mentioned above directly impact machining capacity and efficiency, and hence they require special attention:

1.Precision Compensation Package: This is the most significant difference between a raw machine and an optimally fine-tuned machine. Spatial error compensation and pre-production laser calibration may improve accuracy by 30%-50% but at the cost of 10%-15%. It is needed for high-precision machining of parts.

2.Automation Accessories: A 24-tool tool magazine will cost about $10,000-15,000, while a 120-tool tool magazine will cost $50,000-80,000. Robotic loading and unloading systems integrated into the machine allow unmanned production but add more than 30% to the overall cost, and thus are best used for mass production.

3.Process Support Systems: Oil mist collectors and internal coolant pressures (>70 bar) fall in this class. Internal coolant pressure increases the tool life by 30% and improves the surface quality too but increases cost by 5%-8%. It is suitable for turning hard-to-machine material.

Different configuration combinations can result in price differences of over 50% for a given machine type. Choose according to your actual requirements to avoid wasteful over-configuration or production-constrained under-configuration.

The Wave Of Localization: A Rational Trade-Off Between Chinese And Imported 5-Axis CNC Machines

When one makes a decision to choose a 5-axis CNC machine tool, between Chinese and foreign brands, businesses are always in a dilemma. Both have their advantages and disadvantages when it comes to cost, performance, and aftersales. Based on our experience, the major differences are listed below:

| Comparison Size | Foreign Brands (Germany/Japan) | Chinese Brands (High-End Mainland China) |

| Technical Maturity | High, years of technical accumulation. | High, with rapid progress in recent years. |

| Precision and Stability | High precision, excellent long-term stability. | Meet most precision requirements, with better stability. |

| Price | High, 50%-100% higher than local brands. | High cost-effectiveness, low prices. |

| After-sales Service | Delayed response speed (7-15 days), high spare part expenses. | Quick response speed (2-3 days), low spare part expenses. |

| Operating Habits | The interface is not compatible with Chinese habits. | The interface is compatible with Chinese habits. |

| Residual Value | High, 40%-50% after 5 years. | Medium, 20%-30% after 5 years. |

JS Precision adopts the "imported flagship + Our "domestic high-end" hybrid equipment approach utilizes imported machine tools for precision work of high accuracy and domestic high-end machine tools for routine precision parts, matching the most cost-effective 5 axis CNC machine China solution according to demand.

If you are struggling between imported and domestic machine tools, JS Precision's hybrid equipment strategy can provide a flexible 5 axis CNC machine China solution. Whether you need the ultimate in precision or maximum cost-performance, we're here to help. Choose us for customized service.

Underneath The Iceberg: Be Aware Of "Hidden Costs" When Purchasing

When many companies calculate the 5-axis CNC machine price, only refer to the initial estimate and do not account for "hidden costs." Such "hidden costs" may accumulate later and even exceed the initial cost of purchase:

1. Installation Costs: The 380V special power high voltage, heavy-duty bearing foundations (≥1000kg/m2), and compressed air models of the 5-axis machines cost $10,000-30,000 and would require professional installation that would last 1-2 months.

2. Operating and Consumable Costs: The cost of electricity will be $5,000-8,000 yearly, and consumables such as cutting fluid, tools, and filters will be $8,000-15,000. Machining hard-to-machine materials wears tools out quickly, contributing to consumable costs.

3. Training and Skill Cost: 5-axis machine programmers and operators are in short supply and earn 50%-80% more than typical technicians (approximately $60,000-100,000/yr). New hires will require 3-6 months of training ($5,000-10,000), interrupting productive work while training.

4. Maintenance Time and Cost: Once the warranty is over, replacing heavy-duty parts such as the electric spindle and CNC unit could cost up to $20,000-50,000. Production line time lost is worth $10,000-20,000 per day, a loss difficult to make up.

They might incur 20%-30% of the original purchase price in year one. Care should be taken initially to prevent cost pressure subsequently.

The Value Of Time: The Fact Of Lead Time And Expedited Fees

In addition to price, lead time is a significant factor in purchasing 5-axis machine tools. Manufacturer-to-manufacturer lead times can greatly differ, and expedited fees that are too high can decelerate project momentum:

- Normal Lead Time: Foreign machine tools have a normal lead time of 6-12 months and domestic high-end machine tools have a normal lead time of 3-6 months, so urgent projects are not available.

- Rush Fees: Some producers offer rush services but at an extra charge of 10%-20% of the contract. Timely delivery is not assured and also relies primarily on supply chain status.

JS Precision Online 5 Axis Machining Service Packages and Transaction Data Comparison Table

| Service Package Type | Applicable Part Type | Single-Piece Machining Price Range (USD) | Standard Delivery | Expedited Delivery (Additional Fee) | Additional Transaction Services |

| Prototype Rapid Processing Package | Small Prototype Batch (1-50) | 800-3,000 | 3-5 weeks | 1-2 weeks (+15%) | Free design optimization and accuracy testing. |

| Volume Production Package | Medium Batch (51-500) | 500-2,000 | 5-8 weeks | 3-4 weeks (+10%) | Free warehousing and partial delivery. |

| High-End Customization Package | High-Precision Complex Parts (Any Batch) | 1,500-5,000 | 8-12 weeks | 5-6 weeks (+20%) | Dedicated project manager and full process monitoring. |

JS Precision understands your time requirements. Choosing our online 5 axis CNC machining services eliminates the need for waiting, as equipment capacity is ready and drawings can be uploaded to queue for production. The process from review to delivery can be completed in as fast as 3 weeks, eliminating the long cycle of equipment procurement and debugging.

Case Study: How JS Precision Saves A Client 35% On Overall Costs Through Intelligent Process Planning

Having already examined the bulk of the cost drivers, we shall look at a live case study to show how JS Precision facilitates customers to control 5 axis CNC machining price and overcome live challenges.

Customer Pain Point

A medical device company needed a small batch of 50 complex titanium alloy orthopedic implant prototype production. The company first planned to purchase a low-cost 5-axis machine at around $120,000. They had not considered the hidden costs and the technical entry barriers, however.

JS Precision Analysis and Solution

We first compared costs to the customer: $120,000 for the machine tool + approximately $22,000 for maintenance/ consumables in the first year + $80,000 for a professional engineer's yearly salary + $15,000 for infrastructure = an initial cost of over $237,000. And the customer had no background in 5-axis machining, so technical risks of low accuracy and poor efficiency existed.

From this, we proposed an alternative: we suggested that the first three batches (50 pieces) of prototypes be outsourced to JS Precision. We would then have our engineers optimize the manufacturability of the part and streamline some of the complicated structures first before using in-house, locally sourced, high-grade 5-axis machine tools for machining to get precision as well as cost-effectiveness.

Comparison of Results

The final result was significant: customer-purchased solution of the customer cost a first-year fixed investment of over $237,000, with indefinite delivery time and high risk.

JS Precision solution gave an overall machining cost of only $80,000, zero fixed asset investment, and shipped qualified prototypes in just three weeks, with an overall cost savings of over 35%. The customer could also focus their capital on core R&D, leaving their resources for production.

Customer feedback: "JS Precision not only provided us with a 5 axis CNC machining price list but also provided us with valued business analysis. They explained to us that capacity in machining isn't always gain for manufacturing, and dealing with them was a key component of winning product release."

If you are in the same cost position, JS Precision will save you money with intelligent process planning. Competitive custom 5 axis CNC machining manufacturing service is provided on small-run prototypes as well as production runs. Tapping into our services reduces your cost exposure.

FAQs

Q1: Necessarily more expensive than 3-axis is 5-axis machining?

On simple parts, 5-axis machining is actually more expensive with more equipment and operating cost. But on complex parts, it's the reverse. 5-axis machining will reduce setups, eliminate special fixtures, reduce secondary operations, and reduce the cost per part by a significant amount. If you are unsure, please send us your drawings and we will evaluate the 5 axis CNC machining price for you free of charge.

Q2: Is an online purchase of a 5-axis machining quote trustworthy?

Completely reliable, provided you're on a professional platform like JS Precision. With smart algorithms and 15 years' process database, we can calculate a quote in seconds that includes all costs, no surprise. Besides, the uploaded 3D model will be reviewed by our experienced engineers for accuracy and reasonableness of a quote, offering you an open view of the cost structure of a 5-axis CNC machine.

Q3: What type of material do you work on to design 5-axis CNC machine parts?

We machine 5 axis CNC machine parts in all material types, ranging from metals like aluminum, stainless steel, and titanium to engineering plastic materials like PEEK and ULTEM to general materials like copper and steel. It will depend on the material to be machined. In your request, specify the material of your choice, and we will allocate the equipment and process required for quality inspection.

Q4: How will the web service alter my drawing if that is required?

JS Precision has a good change management engineering. Simply post an updated version of your drawing via the site, and the software will immediately produce a change order, splitting the effect of the change on 5 axis CNC machining price and delivery date. Moreover, your own project manager will direct the process of change from start to finish, reporting problems right away to avoid process interruption, ensuring that the changed parts are finished timely and of top quality.

Summary

Purchasing a 5 axis CNC machine or contracting out 5-axis machining service is a high-technology investment with total technical, financial, and strategic studies. Identifying these seven cost drivers will lead you through the marketing fog and spot the intrinsic value.

To most firms, having one 5-axis CNC machining partner that boasts newer technology, more process knowledge, and open book pricing is the fastest and most efficient route to success and innovation. At JS Precision, challenges no longer have to be your headache.

Try JS Precision's intelligent quoting engine today!

Upload your 3D model and receive an instant 5-axis Machining Feasibility and Cost Estimate in 30 seconds. Not only will you be receiving a real 5 axis CNC machining price, but our engineers will even provide you with some initial optimization suggestions for your model. Become part of JS Precision's top and most efficient 5-axis production facility and let you speed up the fulfillment of your vision.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com