5 axis CNC machining services are the central solution that solves the problem of processing complex impellers, precision cavities, and irregular structures that occur when machining complex impellers of aerospace, precision cavities of robotic joints, and irregular structures of biomedical products. It is a technology with flexibility and precision that go beyond what can be done with machining.

However, 5-axis CNCmachining is more than just an improvement in machinery, it is an overall process optimization system from design to delivery.

This paper not only involves technical analysis, it also functions as a value map to illustrate the manner in which the benefits of 5-axis CNC machining are fulfilled in improved component function, lower total cost of ownership, and accelerated time-to-market.

Core Answers Table

| Core Dimension | Typical Limitations of 3-axis CNC Machining | Transformation Achieved by 5-axis CNC Machining |

| Geometric Capability and Precision | Because five-sided machining is performed by several setups, there are accumulated errors. It is also difficult to cut complex surfaces. | Single clamping completes five sided machining, with better 5-axis CNC machining tolerance control, especially improving spatial geometric accuracy and surface continuity. |

| Efficiency and Cost | There is low overall efficiency because of the increase in auxiliary time, fixture costs, and the chance of human error with multiple setups. | The major benefits of the 5-axis CNC machining technique is the reduction in the number of setups, the time taken for working, number of fixtures, and the first pass yield, thus decreasing the 5-axis CNC machining cost. |

| Application & Design Freedom | Primarily limited to simple box-type parts, design must then be accommodated by process. | Unleash the potential of complex parts 5-axis machining, empowering integrated molding of impellers, turbines, medical implants, 5-axis CNC machining for robotic arms, and more. |

Key Conclusion:

1. Precision because of less human intervention: Single set-up ensures that high precision 5-axis CNC machining tolerance levels remain free from repetitive positioning errors.

2. True Cost is based on Total Cost of Ownership (TCO):While the hourly cost of a 5-axis machine is certainly more, eliminating processes, fixtures, and scrap often outweighs the additional cost of 3-axis machining.

3.Success Requires Design for Additive Manufacturing (DFAM) :Optimization of part positioning, approaches towards cutting-tool accessibility, and cutting techniques in design phase ensures optimal utilization of 5-axis machining capabilities.

4.Expert suppliers are required: Sensitive components require engineer expertise and process know-how. JS Precision can eliminate risks of trial and error.

Choose JS Precision's 5-Axis CNC Machining Services: To Meet Complex Manufacturing Needs

In the area of 5 axis CNC machining, experience is the most precious thing. JS Precision has been engaged in this area for 12 years and has solved more than 6,000 complex parts machining solutions for four high-precision industries including aerospace, medical devices, industrial robots, and optical instruments.

We have finished machining blades for turbines with an accuracy of ± 0.008mm for airplane manufacturers, done complex surface molding of orthopedic devices for hospitals, and manufactured wrist units with integrated wrists for robot makers.

These examples encompass machining work involving titanium alloys, high-temperature alloys, and engineering plastics, thus building up our in-house expertise in machining thin-walled components, deep-cavity components, and components with unusual shapes.

According to the requirements for machining consistency in the international standard ISO 13041-4:2004 "Accuracy assessment of CNC machine tools - Part 4: Five axis linkage machine tools", our process stability has been certified by this standard.

Each point and each data set within this guide has practical experience behind it, and there is no empty theory here, just experience.

Interested in evaluating whether our technology is suitable for your complex components? Share your components requirements today, and JS Precision will give you a free analysis of feasibility in adherence to ISO standards so that you can confidently choose 5 axis CNC machining services.

Unlocking Potential: How Does 5 Axis CNC Machining Services Work?

A background in 5 axis CNC machining services is not complex and involves the following understandings:

3 axis machining is akin to painting a wall in fixed angles and is limited to flat surfaces only, while 5 axis cnc machining is akin to the human arm and also able to move up, down, left, and right (XYZ linear movement) and also able to rotate the wrist and elbow (AC or BC rotary movement) and is thus able to position the "brush" to touch any angle of the "wall" - which is the essence of dealing with complex components.

Core Motion Analysis: The combined magic of XYZ linear + AC/B rotary axes

In 5-axis machine tools, the fundamental benefit is realized through the combination of rotational and linear motion, which is preferably offered in two configurations:

- Rotary table configuration: In this configuration, the workpiece is mounted on a rotary table (A-axis rotation, C-axis rotation), and the cutting tool is fixed. This is suitable for machining multi-sided small and medium-scale workpieces.

- Swiveling Head Configuration: In swiveling head configuration, the cutting tool is mounted on a swiveling spindle head (B-axis swiveling, C-axis rotation), and the workpiece is fixed. This is suitable for working complex curved surfaces of large workpieces.

Both of these allow the tool easy access to the workpiece from the side, undercuts, and even from behind, and thus are ideal for machining bevels and other hard to reach areas that are typical with 3-axis machining.

From CAD to Cutting: The Key Role of Digital Twins and Tool Path Planning

The specific processing of 5-axis CNC machining requires high-level CAD/CAM software support. The 3D CAD model imported to achieve digital twin creation involves planning collision-free continuous paths with factors like tool length and cutting angles taken into account. The virtual simulation stage determines possible collision avoidance problems and problems of overcutting.

The CAM programming team of JS Precision boasts an average experience of more than 8 years and the capability to optimize the path of complex components.

Beyond The Plane: Precision Advantage Duel Between 5-Axis Vs 3-Axis CNC Machining

When machining the same complicated part, the accuracy gap between 5-axis vs 3-axis CNC machining is considerable.

3-axis machining involves setups and changes in orientation, including positioning errors in each orientation, the 5-axis CNC machining process accomplishes all machining within a single orientation in the shortest tolerance chain, including the use of greater than ±0.01mm positional accuracy and more than 30% improved contour accuracy.

According to the standard ASME B5.54-2020 "Performance Evaluation Standard for CNC Machine Tools and Machining Centers," the spatial positioning accuracy for 5-axis machine centers needs to meet the ±0.015mm/m standard, and all of our machines have passed this standard.

The Terminator of Cumulative Errors: Why is "Doing it Right the First Time" More Precise?

The major cause for the inaccuracy in 3-axis machining is multiple setup processes. Assuming the positioning error to be ±0.005mm for each time the setup is done, accumulation of error from four setups could reach as much as ±0.02mm, for 5-axis machining, only one setup is needed, hence, the positioning error becomes irrelevant.

It is observed from our experiments that when machining a cubic part with 3 intersecting holes, the value of coaxiality for 3-axis machining is 0.035mm, but for 5-axis machining, it is 0.008mm, an improvement of 77% in accuracy.

A Leap in Surface Quality - Continuous Tool Marks and Optimal Cutting Conditions

5-axis simultaneous machining allows the side edge of the tool to contact the curved surface at the optimal angle at all times, so there are constant tool marks on the workpiece. The Ra value of surface roughness is only 0.8μm or lower, so there is little polishing work required, and even finished products in some parts are possible.

| Machining Method | Number of Operations Needed for Clamping | Error in Positioning Accuracy | Surface Roughness Value for Ra | Workload for Processing Operations |

| 3-axis machining | 3-5 times | ±0.02-±0.05mm | 1.6-3.2μm | A large amount of polishing is required |

| 5-axis machining | 1 time | ±0.005 ± 0.015 mm | 0.4-0.8μm | Basically no need to handle |

Interested in learning the depth of the accuracy difference between 5-axis vs 3-axis CNC machining? Contact us to obtain our test comparison manual, which has the accuracy information and pictures of the surface finishes of the various parts to aid in decision-making.

Figure 1 Three axis machining may result in tool marks and burrs on the surface of the workpiece, while five axis machining can achieve a smoother surface.

Investing In Complexity: Key Factors Determining The 5-Axis CNC Machining Cost

Some of the concerns of the customers are associated with the 5-axis CNC machining cost, but the cost is mainly depending upon the plan and processing requirement. Cost transparency assists in making rational designs and preventing additional expenses. Also, the cost of complex parts 5-axis machining is depending upon geometric complexity, material, and tolerance.

Main Cost Drivers: Programming Time, Machining Cycle, and Materials

The core components of 5-axis CNC machining cost:

- Programming time cost: Planning routes for complex components takes several hours to a few days for senior engineers. Deep cavities and undercut components require simulation of collisions repeatedly, and this labor impact affects quotes.

- Machining cycle cost: The cutting speed for 5-axis NC machines is not lower than that for 3-axis machines, but non-stop machining of complex curved surfaces takes longer, and the price per machine hour is 1.5-2 times higher than that for 3-axis machines.

- Material Costs: Special materials like titanium alloys are 3-5 times more expensive than regular steels, and their poor machining ability further prolongs machining time.

Optimization of Design and Expenditure: Working Together and its Importance

Design optimization can result in considerable costs being cut.

For instance, the customer’s part had the inner corner radius of 0.5mm, and this required specific micro-tools and an 8-hour processing cycle.We proposed improving it to 1.5mm with conventional tools, with shorter cycles of 3 hours and with costs decreased by 40%.

Improvement of aspect ratio with proper dimensions (not exceeding 5:1 ratio) would be useful to reduce costs apart from proper blank choice.

Want to lower your costs while still achieving accurate modeling for complicated components? Then share your design plan with JS Precision, and we will offer you free suggestions from our engineers on how to lower the 5-axis CNC machining cost.

How Can 5-Axis CNC Machining Cost Achieve Better Overall Economy?

Many people only see the higher hourly rate of 5-axis machine tools, but ignore their full process cost advantages.The benefits of 5-axis CNC machining are not only reflected in accuracy and efficiency, but also in reducing total cost of ownership (TCO). The overall economy of complex parts far exceeds that of 3-axis machining.

Direct Cost Reduction: Fixtures, Labor Hours, and Floor Space

5-axis machining systems directly decrease cost in the following ways:

- Lower equipment cost: 3-axis machining needs several complex fixtures whose cost of design and manufacture is in thousands of dollars. 5-axis machining needs general-purpose fixures, with costs reduced by over 70%.

- Lower labor costs: While integrating various processes, if some parts need 3 processes on a 3-axis machine, all those processes can be done at one time on a 5-axis machine, thus increasing efficiency by 40%-60%.

- Reduce footprint: One 5-axis unit can replace 2-3 3-axis units, reducing workshop space and equipment investment.

Indirect Value Enhancement: Simplification of Design, Acceleration, and Risk

The 5-axis machining also offers major indirect benefits:

- Design simplification: Combining several parts assembled into one single structure reduces the cost of assembly and the cost of connectors and increases rigidity.

- Smaller Delivery Times: The production time cycle is reduced by 30%-50%, allowing forrapid exploitation of market opportunities by the customer.

- Less Risk: With single clamping, errors on the part of human operators are eliminated, resulting in a first-article success rate of over 98%.

Challenging The Micron Scale: Achieving System Engineering With Strict 5-Axis CNC Machining Tolerance

Achieving strict 5-axis CNC machining tolerance (such as ± 0.01mm) requires more than just high-precision machine tools. This is a system engineering involving multiple stages, and JS Precision has put in place an all-encompassing guaranteeing system that assures the required tolerances are maintained for the complex parts 5-axis machining.

Machine Tools are Just the Foundation: Thermal Stability, Calibration, and Tool Management

The key for high-precision machining lies in a stable operating and equipment condition.

- Constant Temperature Workshop. Temperature maintained at 20±0.5℃ to inhibit expansion and contraction caused by temperature.

- Periodic Calibrations: Calibration with a laser interferometer on a quarterly basis and quick verification on a monthly basis to ensure machine tool accuracy.

- Tool Management: Utilizing hydraulic or shrink-fit tool holders with clamping accuracy below 0.002mm, provision of a tool wear indicator that enables constant monitoring.

The Nature of Process and Programming: Specialized Approaches to Counter Particular Obstacles

Various complex components need specialized processing strategies:

- Machining of Thin-walled Parts: Low-cutting force factors, several small cuts of material removal, and deformation-reducing support devices.

- Deep cavity machining: The use of long holders plus dynamic milling to dampen vibrations and optimize the machining path to prevent errors.

- Cutting order: Roughing before finishing, exterior before interior, primary features before secondary ones, and stress relief after rough machining.

Require micron-level accuracy for 5-axis CNC machining tolerance? Then call on the process diagnostic experts at JS Precision for a process diagnostic service, and our team will provide you with a tailored precision guarantee plan for your complex parts 5-axis machining.

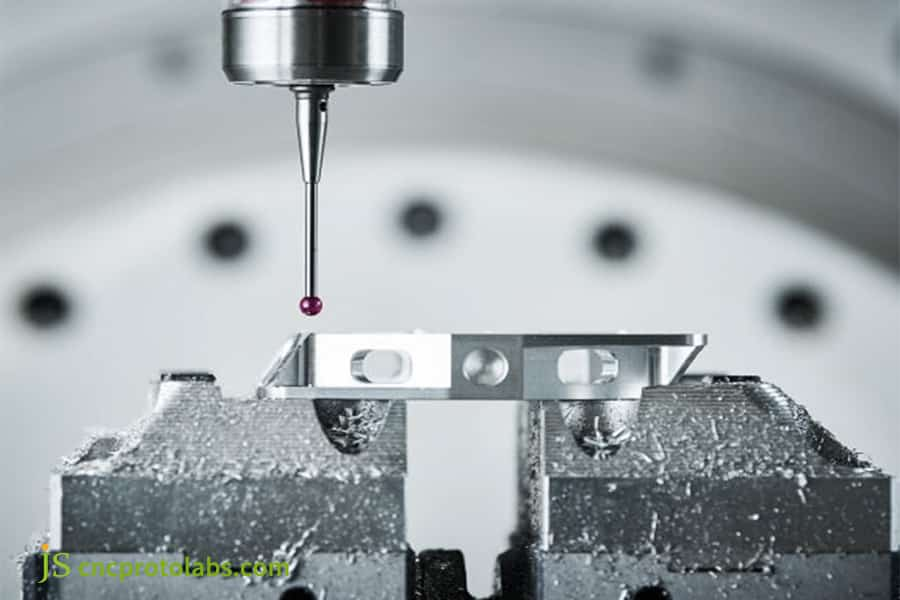

Figure 2 The CMM probe is measuring the metal workpiece clamped in the machining vise.

Conquering Complexity: Unique Challenges And Countermeasures In Complex Parts 5-Axis Machining

Complex parts 5-axis machining often faces extreme challenges such as narrow spaces in impellers, complex flow channels in vortex shells, and deformation of thin-walled components. These sections require high machining accuracy, machining speed, and stability, and 5 axis machining services can solve the problem.

The "Dance" of Tool and Workpiece: Intelligent Toolpaths to Avoid Collision

Collisions are one of the major risks in machining complex parts. During CAM programming, we provide a full 3D model (workpiece, fixture, tool, spindle) with "layered cutting + path optimization" and use short-bladed tools or customized tool holders in tight areas to completely remove risks of collision.

Ensuring Strength and Precision: Machining Deformation and Vibration

Complex components are likely to deform and vibrate. We offer:

- Deformation control: Incremental rough cutting and finishing, stress relief after rough cutting, and small cutting amounts and high spindle speed when finishing.

- Vibration Control: High rigidity machine tools and cutters, optimization of cut parameters, and vibration dampers in tool holders for deep cavities or slender structures.

Figure 3: 5-axis is suitable for processing complex geometric parts, such as impellers, orthopedic implants, injection molds, and aerospace brackets.

Key Features Of 5-Axis CNC Machining For Robotic Arms

The requirements of the robotics industry regarding basic components have risen to be lightweight, strong, precise, and designed on a single platform. 5-axis CNC machining for robotic arms satisfies all these requirements impeccably and has become the most adopted solution, with benefits of 5-axis CNC machining being particularly evident in this field.

A Paradigm of Integrated Machining: From Multiple Assemblies to a Single Complex Component

Traditional robot parts are mostly assembled structures, with high weight, insufficient rigidity, and significant cumulative errors.

5-axis machining achieves integrated molding. For example, a robotic wrist component, which traditionally consists of nine separate pieces weighing 2.5 kg—can be produced with an equivalent component manufactured from a single part and an overall machine weighting just 2.1 kg with an improved rigidity of 40%.

Precision Matters: Accuracy of the Critical Bearing Seats and Transmission Interfaces

The accuracy levels required for critical components such as the bearing seats of the robot joint and gear fixing surfaces are much higher, namely the coaxiality of the bearing hole to within ±0.01mm, while the end face perpendicularity is 0.005mm/m. The use of 5-axis single-clamping ensures the positioning accuracy regarding geometric errors of the mentioned components.

Integration Increased By 300%, Cost Reduced By 28%: Integrated Intelligent Manufacturing Of Wrist Modules For Collaborative Robots

In terms of 5-axis CNC machining for robotic arms, it is a highly illustrative field in which the value of 5 axis CNC machining services is comprehensively brought out.

The Customer’s Problem

A customer was thus developing a new generation of compact wrist modules for collaborative robots. In the original solution, there were 9 assembled aluminum components, and there were three issues with these components:

The coaxiality of the bearing hole was just 0.03mm, making it hard to achieve accurate motion, there were disorganized wires inside, causing difficulties and frequent failures, and the connecting components were adding weight and moments of inertia, thus slowing down dynamic response speed.

JS Precision Solution

Our engineering team worked closely with a customer to offer the following comprehensive solution:

Topology Optimization Design: By performing finite element analysis, the functionalities of the 9 components were merged into one. Mounting cavities of high accuracy for sensors, low-weight cavities, and integrated cable channels were machined directly into the single component, allowing it to be strong enough while having low weight.

5-Axis Precision Forming: Through the use of a five-axis machining center, the machining of all mounting surfaces, curved surfaces, and even the internal parts was completed in one clamping operation, thereby eliminating the possibility of assembly errors.

Process Optimization: Appropriate cutting tools and processing parameters were selected in terms of the processing qualities of the aluminum sheets, and high-speed cutting processing technology was used.

Final Success Results

Fully integrated intelligent manufacturing implements overall upgrades, with a decreased component count from 9 to 1, thereby enhancing integration by 300%, weight reduced by 18%, and flexibility improved by 40%, with a value for bearing hole coaxibility of 0.008mm, reduced overall manufacturing cost by 28%, and shortened assembly cycle by 80%.

Interested in learning more about successful examples of 5-axis CNC machining for robotic arms? Please enter your industry and part type, and JS Precision will share the details of similar examples.

Figure 4 Hollow wrist compact robot

FAQs

Q1: Can 5-axis machining substitute 3-axis machining?

Not completely. 5-axis machining has been developed for difficult parts and can accommodate complex shapes like multi-surface, deep-cavity parts, which would be difficult to produce with 3-axis machining. But when it involves simple plane and hole shapes, 3-axis machining would be considered to be more economical and appropriate.

Q2: Can 5-axis machining be relied on in obtaining a tolerance of ±0.025mm?

Extremely reliable. With JS Precision's constant temperature workshop, precision machine tools, and professional process warranty, an accuracy of +/-0.025mm is standard for 5-axis CNC machine tolerance, and even more precise requirements can be easily fulfilled.

Q3: Is the programming time expected to be quite long?

5 axis programming is indeed longer than 3 axis programming, but we do have experienced engineers and a mature process library at our end when it comes to doing the programming work efficiently. In fact, doing the programming work will be justified by the fact that it actually hastens turnaround time for processing and assembly.

Q4: Do you offer machining solutions consulting for my parts?

Definitely. This is one of our fundamental services. All you need is your 3D model and machining requirements, and we shall provide you with your free manufacturing feasibility analysis and optimization. This is done by our team of experts in 5-axis machining.

Q5: Is the technology of 5-axis machining able to be employed during small-batch production (from

Very suitable. there is no complex machining required in Five-axis machining, components are easily replaced with the use of program switch-off, which does not involve the use of other machining tools. It is the most effective machining technique when it comes to producing small batches of components with complex designs.

Q6: Have you worked on similar projects in our industry (e.g., medical/optics)?

Our experience and background lie in several high-precision industries like the aerospace industry, medical industry, robotics industry, and optics industry for different parts. Kindly share the industry in which you operate, and we will provide you with non-confidential case studies for reference.

Q7: Is logistics and communication convenient in completing the 5-axis machining process in China?

It is highly convenient. Being an organization, we have a professional project management team that ensures constant updates of progress through instant messaging. Furthermore, we have coordinated with reputable logistics companies to guarantee the safe and timely delivery of the components.

Q8: How do I begin my 5-axis machining project?

Just send us the 3D model for your part, material needs, tolerance level, and quantity. Our team of experts will quickly provide the process analysis report, quotation, and delivery time for you. Then the project may begin.

Summary

5 axis CNC machining services are not an unattainable high-end technology, but a practical tool for solving complex machining problems, reducing total costs, and enhancing product competitiveness.

It offers greater precision with less interference, overcomes difficult structures with intelligent processes, and builds more economic efficiency through comprehensive collaboration. Whatever industry you belong to, whether it is aerospace, medical devices, or robots, or any other high-precision industry, JS Precision can offer you expert services of 5-axis machining.

Examine the possibilities in your design today:

Please send us the 3D files of your complex parts to get a free report on the manufacturability of the parts based on their 3D file, and a transparent quote prepared by our 5-axis machining expert. Join hands together to turn your innovative designs into highly competitive products.

Disclaimer

The contents of this page are for informational purposes only.JS Precision Services,there are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the JS Precision Network. It's the buyer's responsibility Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

JS Precision Team

JS Precision is an industry-leading company, focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. Choose JS Precision this means selection efficiency, quality and professionalism.

To learn more, visit our website:www.cncprotolabs.com